For those who take pride in their outdoor spaces, maintaining a high-performing machine is essential. Knowing the intricate details of your mower’s construction not only enhances performance but also extends its lifespan. A comprehensive exploration of the individual elements will empower users to troubleshoot and replace components effectively.

Every mower has its unique assembly, consisting of various parts that work in harmony. Familiarity with these pieces allows operators to recognize potential issues early and address them before they escalate. Delving into the specifics of each element can provide valuable insights for both novice and experienced users alike.

Ultimately, mastering the intricacies of your machine’s layout can lead to a more efficient and enjoyable mowing experience. Whether it’s for routine maintenance or repairs, understanding the anatomy of your lawn care equipment is key to achieving optimal results.

Understanding Cub Cadet LT1046

This section explores the intricacies of a popular model within the realm of lawn care machinery. Recognized for its reliability and efficiency, this equipment has gained a reputation among enthusiasts and professionals alike. Its design combines innovative engineering with user-friendly features, making it a go-to choice for maintaining lawns of various sizes.

One of the standout characteristics of this model is its powerful engine, which offers robust performance while ensuring fuel efficiency. Additionally, the cutting system is engineered to provide a clean and precise finish, adapting seamlessly to different grass types and conditions.

To better understand the components involved, the following table outlines key features and specifications:

| Feature | Description |

|---|---|

| Engine Type | Single-cylinder, air-cooled |

| Cutting Width | 46 inches |

| Transmission | Automatic |

| Deck Material | Steel |

| Turning Radius | 16 inches |

Understanding these elements is crucial for optimizing performance and ensuring longevity, thereby enhancing the overall mowing experience. Regular maintenance and familiarity with the machinery’s components further contribute to its efficacy and durability.

Key Features of the LT1046 Model

This particular lawn tractor is designed to provide both efficiency and comfort for users tackling various outdoor tasks. Its innovative engineering and robust build ensure reliable performance, making it an excellent choice for homeowners and landscapers alike.

- Powerful Engine: Equipped with a high-performance engine, this model offers exceptional torque and speed, allowing for smooth operation across different terrains.

- Comfortable Seating: The ergonomic seat provides ample support and cushioning, enhancing user comfort during extended mowing sessions.

- Durable Deck: The reinforced cutting deck is designed to withstand wear and tear, ensuring longevity and effectiveness in grass cutting.

- Easy Maneuverability: With a tight turning radius, this tractor allows for easy navigation around obstacles, making it ideal for residential yards.

- Adjustable Cutting Heights: Users can easily customize the height of the cut, providing flexibility for different grass types and conditions.

- Advanced Safety Features: Safety mechanisms are integrated to protect users, including automatic blade shut-off when the operator leaves the seat.

Overall, this lawn tractor combines functionality with user-friendly features, making it a reliable tool for maintaining a well-manicured lawn.

Essential Maintenance Tips for Longevity

Proper upkeep is crucial for extending the life of your outdoor equipment. Regular attention ensures optimal performance and can prevent costly repairs down the line. By implementing a few key practices, you can enhance reliability and efficiency.

Regular Cleaning: Keeping your machinery free of dirt and debris prevents wear and tear. Ensure all surfaces are clean, especially around moving parts, to promote smooth operation.

Fluid Checks: Consistently monitor and change fluids as needed. This includes oil, fuel, and coolant. Fresh fluids reduce friction and keep the engine running smoothly.

Inspection of Components: Regularly inspect belts, filters, and blades for signs of damage. Early detection of issues can save you from more significant problems in the future.

Sharpening Blades: Keeping cutting edges sharp enhances performance and reduces strain on the engine. Dull blades can lead to uneven cuts and increased fuel consumption.

Storage Practices: When not in use, store your equipment in a dry, sheltered place. This protects it from the elements and helps maintain its condition over time.

By adhering to these maintenance tips, you will ensure that your machinery remains efficient and reliable for years to come.

Common Issues and Troubleshooting Steps

Every machine may encounter certain challenges during its operation, leading to potential disruptions. Understanding these common problems and their solutions can significantly enhance the user experience and prolong the life of the equipment.

1. Engine Won’t Start: This is a frequent issue that can stem from various causes such as a dead battery or clogged fuel lines. Check the battery voltage and connections, and ensure that the fuel supply is clean and adequate.

2. Poor Cutting Performance: If the cutting quality is lacking, it could be due to dull blades or incorrect cutting height settings. Inspect the blades for sharpness and adjust the height according to the desired grass length.

3. Overheating: Machines can overheat for reasons such as low oil levels or obstructed air filters. Regularly check oil levels and clean or replace air filters to maintain optimal performance.

4. Unusual Noises: Strange sounds during operation may indicate loose or worn components. Conduct a thorough inspection of belts, pulleys, and other moving parts to identify and address any issues.

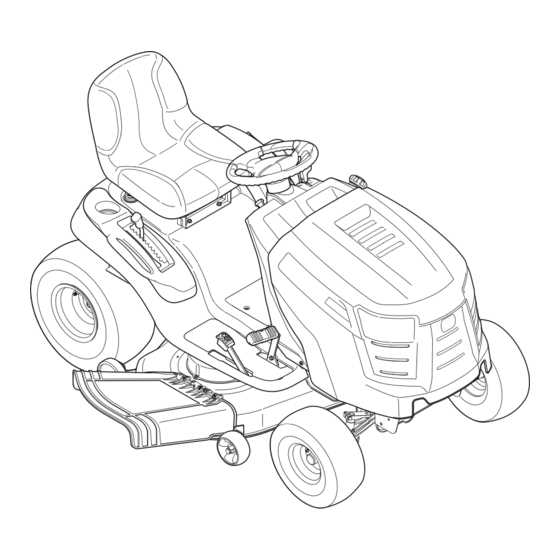

Parts Diagram Overview Explained

Understanding the components and their relationships within a mechanical system is crucial for effective maintenance and repairs. An illustrative representation provides valuable insights into how different elements interact, ensuring users can identify and locate specific items with ease.

Importance of Visual Representation

A visual guide serves as a reference point, making it easier for users to comprehend the layout and arrangement of various components. This clarity simplifies troubleshooting, allowing for quicker identification of issues and necessary replacements. Moreover, it aids in assembly and disassembly processes, enhancing overall efficiency.

Key Components Overview

| Component Name | Description | Function |

|---|---|---|

| Engine | Power unit | Drives the entire system |

| Chassis | Frame structure | Supports all components |

| Transmission | Gear mechanism | Transfers power from the engine |

| Deck | Cutting surface | Manages grass cutting |

| Wheels | Mobility components | Provides movement and stability |

By familiarizing oneself with these critical elements, users can enhance their understanding and confidence when working with the machine. Proper knowledge of each part leads to more informed decisions during maintenance and repair activities.

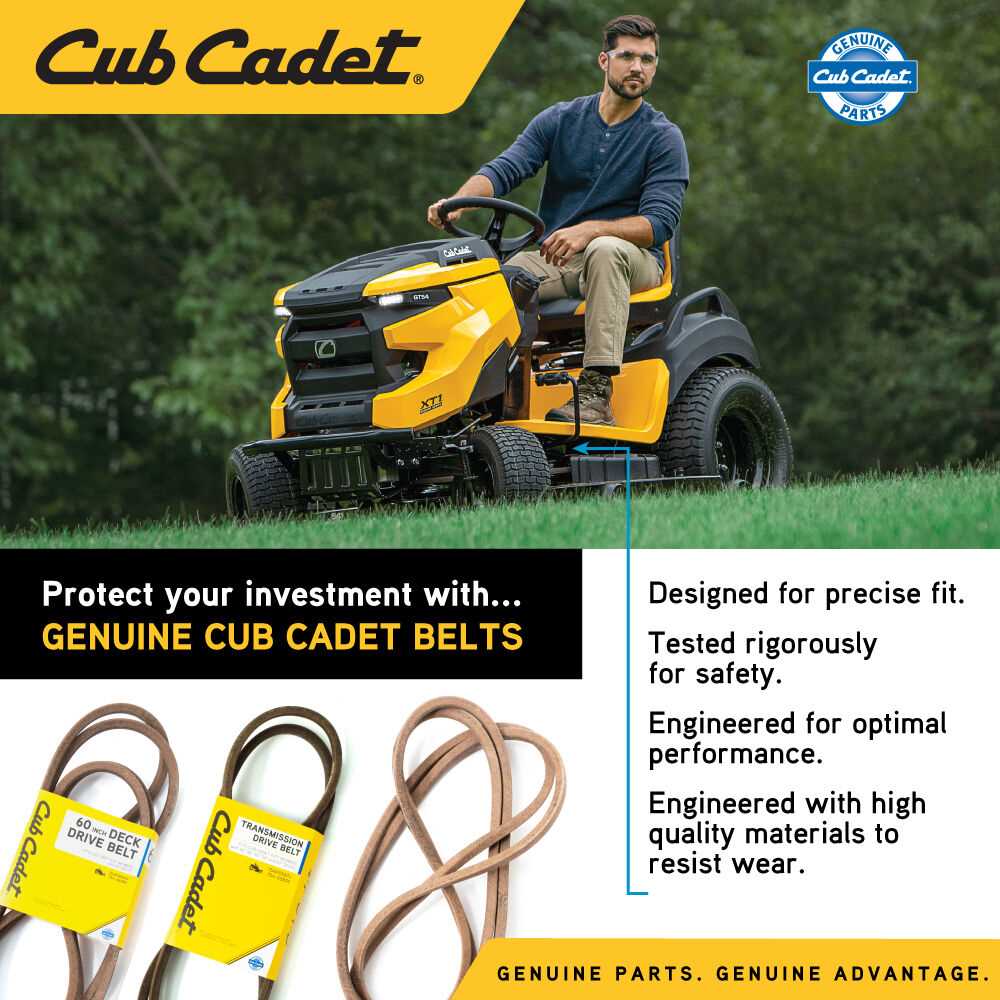

Importance of Using Genuine Parts

Utilizing authentic components for machinery maintenance is crucial for ensuring optimal performance and longevity. Original elements are designed specifically for the equipment, ensuring compatibility and reliability that aftermarket alternatives often cannot match.

One significant advantage of using original replacements is enhanced durability. Genuine items are crafted to meet strict quality standards, which minimizes the risk of premature wear and tear. This means that investing in these components can lead to fewer breakdowns and lower overall maintenance costs.

Moreover, performance is another critical factor. Authentic pieces are engineered to function seamlessly with the machine, delivering the expected efficiency and power. When non-genuine parts are used, there can be discrepancies in functionality, which may lead to decreased output and unsatisfactory results.

Finally, warranty protection is an essential consideration. Many manufacturers stipulate that using original components is necessary to maintain the warranty on the equipment. Utilizing unauthorized alternatives may void this coverage, exposing the owner to potentially significant repair costs.

Identifying Key Components of the Diagram

Understanding the essential elements depicted in a schematic can significantly enhance your ability to maintain and repair machinery. This section will explore the various sections and symbols, enabling users to recognize and interpret the crucial components that contribute to the overall functionality of the equipment.

Major Sections

Each section of the schematic is designed to represent specific functionalities, such as the power system and steering mechanisms. By breaking down these sections, users can pinpoint areas requiring attention or replacement, ensuring smooth operation.

Symbolic Representations

The use of standardized symbols is vital for quick identification of components. Familiarizing yourself with these representations will facilitate efficient troubleshooting and enhance your understanding of the equipment’s layout and design.

Step-by-Step Assembly Instructions

In this section, we will explore a systematic approach to assembling your lawn equipment efficiently and effectively. Following these guidelines will ensure that each component is properly integrated, resulting in optimal performance and longevity.

Begin by gathering all necessary components and tools in a well-lit workspace. Carefully review the assembly manual to familiarize yourself with each part’s function and placement. Start with the base frame, securing it firmly to provide a stable foundation for the subsequent assemblies.

Next, attach the power unit, ensuring that all connections are tight and aligned according to the manual. Once the power unit is in place, proceed to install the steering mechanism, followed by the seat and control systems, checking that each element operates smoothly.

After the main structure is complete, focus on the finishing touches. Install any protective covers and ensure all fasteners are tightened securely. Finally, conduct a thorough inspection to confirm that everything is assembled correctly before powering on the machine.

Where to Find Replacement Parts

Finding the right components for your equipment can enhance its performance and extend its lifespan. Various sources offer access to these essential items, catering to different needs and preferences. Whether you are seeking original or aftermarket solutions, there are several avenues to explore.

| Source | Description |

|---|---|

| Authorized Dealers | These vendors provide genuine components that ensure compatibility and reliability. |

| Online Retailers | Websites dedicated to lawn and garden equipment often stock a wide selection of components at competitive prices. |

| Local Repair Shops | Many repair facilities maintain inventory and can assist with finding the necessary items quickly. |

| Manufacturers’ Websites | Direct access to the manufacturer’s online store can lead to exclusive options and updates. |

| Auctions and Classifieds | Check platforms that offer second-hand items for potentially lower-priced options. |

By exploring these various options, you can ensure that your machine continues to operate at its best. Always compare prices and availability to make an informed choice.

Comparing Aftermarket vs. OEM Options

When it comes to replacement components for outdoor equipment, the choice often lies between original manufacturer offerings and third-party alternatives. Each category presents distinct advantages and drawbacks that can significantly affect performance, durability, and cost-effectiveness.

Original manufacturer products are designed specifically for particular models, ensuring a precise fit and compatibility. These components often come with warranties and assurances of quality, making them a reliable choice for users seeking longevity and performance.

On the other hand, third-party alternatives frequently offer a more budget-friendly option, appealing to those looking to save money without sacrificing functionality. While these may not always match the same standards as their original counterparts, many can deliver comparable performance and can be easier to find in various locations.

Ultimately, the decision between these two options hinges on individual needs, preferences, and budget considerations. Careful evaluation of both categories can help users make informed choices that align with their specific requirements.

Cost Analysis of Repairing LT1046

This section explores the financial implications of restoring a specific lawn care machine. Understanding the various expenses involved can help owners make informed decisions about maintenance versus replacement.

Key factors influencing repair costs include:

- Labor Expenses: Professional services can vary significantly depending on location and complexity of the repair.

- Replacement Components: The price of necessary parts can fluctuate based on brand and availability.

- Diagnostic Fees: Initial assessments may incur costs, which can add to the total expense.

- Time Investment: The duration of repairs may impact overall labor costs.

To provide a clearer picture, consider a breakdown of typical costs:

- Labor: $50 – $100 per hour

- Parts: $20 – $200 depending on the item

- Diagnostic: $30 – $60 for assessment

In summary, a comprehensive evaluation of these elements will aid in determining the ultimate cost-effectiveness of repairs versus acquiring a new unit.