When maintaining a lawn mower, grasping the various elements that contribute to its functionality is essential. This knowledge allows users to perform repairs and replacements effectively, ensuring that the machine operates at its best. Familiarity with the layout and specific components can make a significant difference in achieving optimal performance.

In this section, we delve into the key features that make up this type of equipment. By exploring the essential components, readers will gain insights into how each part interacts within the machine. Recognizing these elements will aid in troubleshooting issues and planning maintenance tasks effectively.

Furthermore, understanding these components helps users identify compatible replacements, ensuring that any repairs or upgrades are executed seamlessly. A well-informed approach to maintaining the machinery not only prolongs its lifespan but also enhances its efficiency, providing a well-manicured lawn for all to enjoy.

tags: Overview”>

tags: Overview”>

This section aims to provide a comprehensive understanding of the specific mower model’s components, helping users identify essential elements for maintenance and repairs. By exploring the various segments of the machine, one can enhance its longevity and performance.

General Features

- Engine specifications

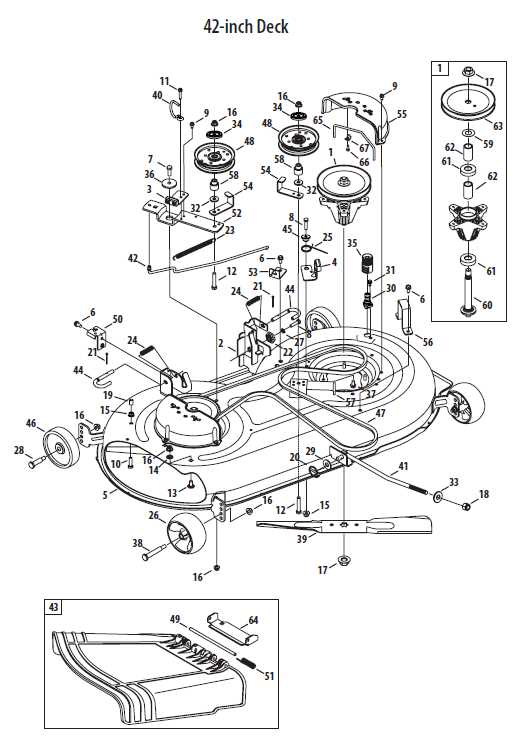

- Cutting width and deck design

- Transmission type

Key Components

- Powertrain

- Cutting mechanism

- Steering assembly

Maintenance Essentials

- Routine checks

- Replacement parts

- Recommended lubricants

Common Issues

- Engine performance problems

- Cutting efficiency declines

- Hydraulic system failures

Upgrade Options

- Enhanced blades

- Accessory attachments

- Performance tuning kits

Safety Considerations

- Protective gear

- Operational guidelines

- Emergency shut-off mechanisms

Resources for Owners

- User manuals

- Online forums and communities

- Parts suppliers

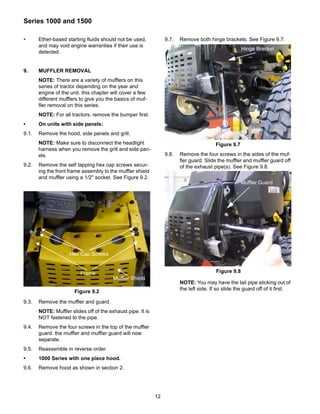

Assembly and Disassembly

- Step-by-step guides

- Tools required

- Best practices for reassembly

Cost Analysis

- Initial investment

- Maintenance costs

- Potential resale value

Comparison with Other Models

- Similar mower specifications

- Pros and cons

- Market positioning

Final Thoughts

- Long-term benefits of maintenance

- Investment in quality parts

- Commitment to safe operations

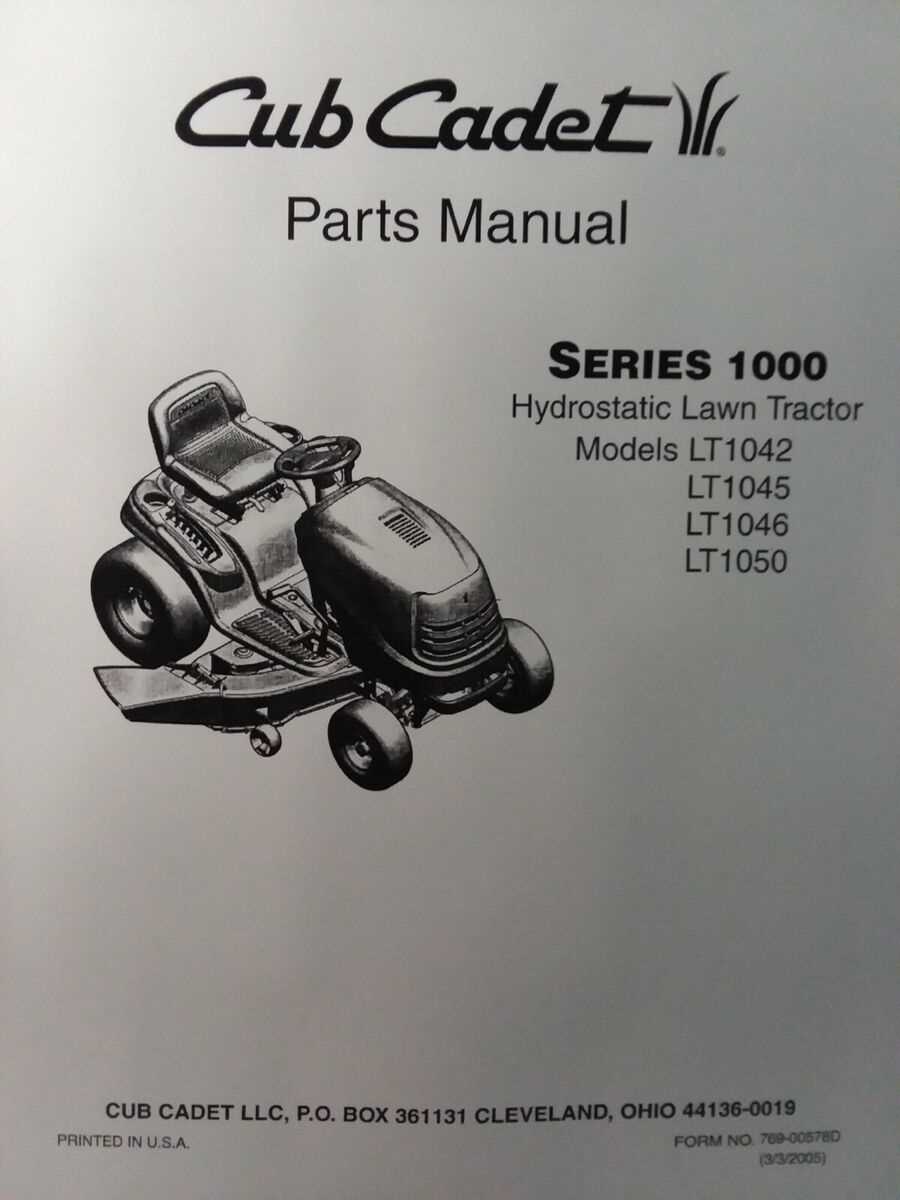

Key Features of LTX1045 Model

This model stands out due to its innovative design and practical functionalities. Users appreciate its robust construction, which ensures durability and reliability in various outdoor tasks. The incorporation of advanced technology enhances efficiency, making it an ideal choice for those seeking a dependable solution for lawn care and maintenance.

Performance and Efficiency

- Powerful engine for superior cutting performance.

- Efficient fuel consumption, providing longer operational time.

- High-speed operation, reducing time spent on large areas.

User-Friendly Features

- Ergonomic seat design for enhanced comfort during extended use.

- Easy-to-use controls, simplifying operation for all users.

- Adjustable cutting heights to suit various grass types and conditions.

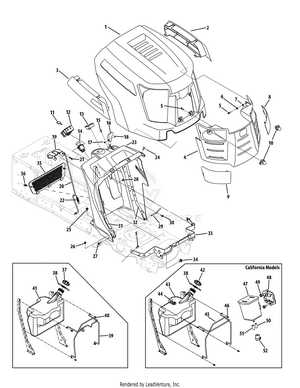

Importance of Parts Diagram

Understanding the arrangement and components of machinery is crucial for maintenance and repairs. A well-structured visual representation assists users in identifying various elements efficiently, ensuring smooth operation and longevity of the equipment. This resource serves as a vital guide for technicians and owners alike.

Enhancing Maintenance Procedures

A clear visual representation can significantly streamline maintenance tasks. Here are a few benefits:

- Facilitates quick identification of components.

- Helps in locating replacement elements without confusion.

- Reduces time spent on troubleshooting issues.

Assisting in Repair Processes

During repair activities, a visual guide plays an essential role:

- Provides step-by-step guidance for disassembly and reassembly.

- Minimizes the risk of errors by illustrating proper placements.

- Enhances the understanding of how different parts interact with each other.

In conclusion, utilizing a visual reference is indispensable for anyone involved in the upkeep of machinery, promoting efficiency and accuracy throughout the entire process.

Identifying Major Components

Understanding the key elements of a machine is essential for effective maintenance and repair. By recognizing these vital parts, users can ensure proper functionality and longevity of their equipment. This section will outline the significant components commonly found in such machinery, facilitating better comprehension and care.

Essential Mechanisms

The primary mechanisms play a crucial role in the overall operation of the equipment. Identifying these components can help in troubleshooting issues and performing necessary adjustments.

| Component | Description |

|---|---|

| Engine | Provides the power needed for operation. |

| Transmission | Transfers power from the engine to the wheels. |

| Deck | Houses the cutting blade and aids in cutting grass effectively. |

| Wheels | Support mobility and maneuverability of the unit. |

Additional Features

Besides the main mechanisms, there are various auxiliary parts that enhance functionality and user experience. Familiarizing oneself with these can lead to better operational efficiency.

| Component | Description |

|---|---|

| Steering System | Allows for precise navigation and control. |

| Fuel System | Stores and supplies fuel to the engine for operation. |

| Battery | Provides electrical power for starting and accessory operations. |

| Controls | Enable the user to operate various functions of the machine. |

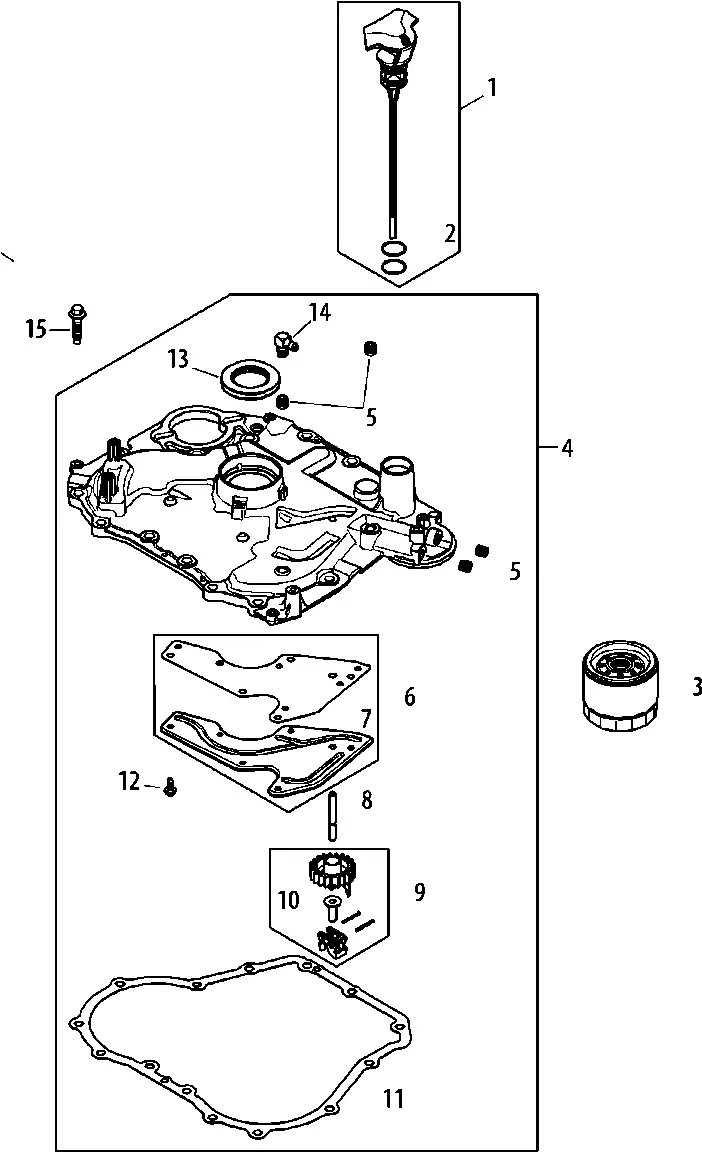

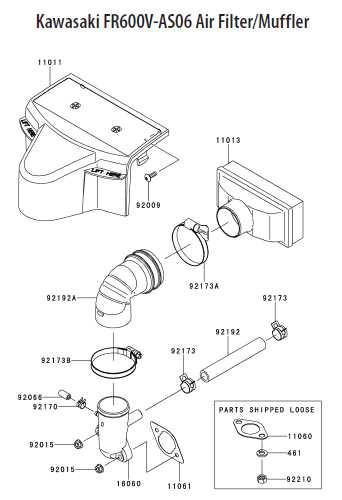

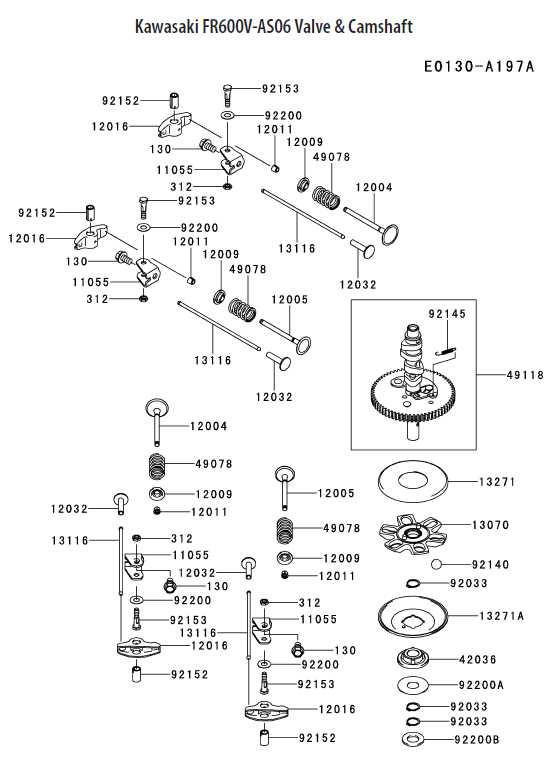

Understanding the Engine Assembly

The engine assembly serves as the heart of a lawn mower, playing a critical role in its overall functionality. This section delves into the various components that make up the engine, highlighting their individual purposes and how they interact to ensure optimal performance. Understanding this assembly is essential for maintenance, troubleshooting, and repairs.

Key Components of the Engine

Within the engine assembly, several key parts work in unison to convert fuel into mechanical energy. Each component, from the fuel system to the ignition, contributes to the effective operation of the machine.

| Component | Function |

|---|---|

| Fuel System | Delivers the fuel to the engine for combustion. |

| Ignition System | Ignites the fuel-air mixture to start the engine. |

| Cooling System | Prevents overheating by dissipating heat away from the engine. |

| Crankshaft | Converts linear motion from the pistons into rotational motion. |

| Valves | Control the intake of air and fuel, and the exhaust of gases. |

Maintenance Tips

Regular maintenance of the engine assembly ensures longevity and reliable performance. Keeping the fuel system clean, checking the ignition components, and ensuring proper cooling are vital steps. A well-maintained engine not only performs better but also enhances the lifespan of the entire lawn mower.

Transmission System Breakdown

The transmission system is a crucial component in the functioning of various machinery, enabling the effective transfer of power from the engine to the wheels. Understanding its structure and functionality can significantly enhance maintenance and troubleshooting efforts.

Key elements of the transmission system include:

- Gearbox: This unit manages gear changes to optimize power delivery.

- Driveshaft: Responsible for transmitting power from the gearbox to the wheels.

- Clutch: Engages and disengages the engine from the transmission, allowing smooth transitions.

- Belts and Chains: These components link various parts of the system, ensuring synchronized movement.

Regular inspection and maintenance of these elements can prevent mechanical failures and prolong the lifespan of the equipment. Awareness of common issues and appropriate replacement practices is essential for optimal performance.

In summary, a well-maintained transmission system is vital for efficient operation, contributing to the overall effectiveness of the machinery.

Electrical System Overview

The electrical system in lawn maintenance equipment plays a vital role in ensuring efficient operation and performance. This system encompasses various components that work in harmony to manage power distribution, control mechanisms, and lighting functions. A comprehensive understanding of the electrical configuration aids in effective troubleshooting and maintenance.

Key Components

Each element within the electrical system serves a specific purpose, contributing to the overall functionality. Below are some of the essential parts:

| Component | Description |

|---|---|

| Battery | Stores electrical energy for starting and operating the engine. |

| Starter Motor | Engages the engine during ignition, facilitating smooth starting. |

| Wiring Harness | Connects various electrical parts, ensuring proper power flow. |

| Ignition Switch | Controls power to the starter and electrical accessories. |

Maintenance Tips

Regular checks and maintenance of the electrical components are crucial for optimal performance. Ensure connections are tight, inspect wiring for wear, and replace any faulty elements promptly to prevent larger issues.

Maintenance Parts and Their Functions

Proper upkeep of machinery is essential for ensuring optimal performance and longevity. Each component plays a significant role in maintaining the overall functionality of the equipment. Understanding the purpose of various elements can aid in effective maintenance and enhance the user experience.

The following table outlines some of the key components involved in maintenance, along with their specific functions:

| Component | Function |

|---|---|

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean air supply for efficient combustion. |

| Oil Filter | Removes contaminants from the engine oil, maintaining proper lubrication and reducing wear on engine parts. |

| Fuel Filter | Filters impurities from the fuel system, promoting smooth operation and preventing damage to the engine. |

| Blades | Provides cutting efficiency, ensuring a clean and even cut of grass or other materials. |

| Belt | Transfers power from the engine to the cutting deck or other accessories, allowing for effective operation. |

Common Replacement Parts List

Maintaining equipment in optimal condition often requires the replacement of specific components. Understanding which elements are commonly substituted can enhance the performance and longevity of your machine. Below is a curated list of frequently replaced items that ensure your equipment runs smoothly.

- Blades

- Batteries

- Belts

- Filters

- Wheels

- Spindles

Each of these components plays a crucial role in the overall functionality and efficiency of your equipment. Regular inspections and timely replacements can prevent costly repairs and downtime.

When selecting replacement items, consider the following:

- Ensure compatibility with your specific model.

- Choose high-quality options for better durability.

- Consult the manufacturer’s recommendations for optimal performance.

By staying informed about the necessary components, you can maintain your equipment effectively and prolong its lifespan.

Utilizing the Parts Diagram Effectively

Understanding the layout of components is essential for anyone looking to maintain or repair machinery. A visual representation not only aids in identifying various elements but also simplifies the process of reassembly. By referencing this representation, users can streamline their workflow and enhance their efficiency when working on their equipment.

Identifying Essential Components

Utilizing a visual layout allows users to quickly locate necessary items. Each element is marked clearly, making it easier to distinguish between similar parts. This clarity minimizes the chance of confusion and helps ensure that the right components are selected for repairs.

Streamlining Maintenance Processes

When maintenance is required, having a visual guide simplifies the entire procedure. Users can refer to the layout to understand how each piece fits together, facilitating quicker disassembly and reassembly. This efficiency not only saves time but also reduces the risk of errors, leading to a smoother maintenance experience.

Troubleshooting Using the Diagram

Identifying issues with machinery can often be simplified by utilizing a visual representation of components. This section focuses on how to effectively use such illustrations to diagnose and resolve problems. A clear understanding of the layout and function of each part can lead to quicker solutions and improved maintenance practices.

Common Issues and Solutions

- Engine Won’t Start:

- Check the fuel level and quality.

- Inspect the battery connections for corrosion or looseness.

- Examine the ignition system for faults.

- Poor Performance:

- Ensure air filters are clean and free from debris.

- Review fuel lines for clogs or leaks.

- Inspect belts for wear and tension.

- Unusual Noises:

- Identify any loose components that may need tightening.

- Check for debris in moving parts.

- Assess lubrication levels in bearings and gears.

Steps for Effective Diagnosis

- Start by referencing the visual aid to identify the parts in question.

- Follow the flow of operation to pinpoint where the malfunction may originate.

- Consult additional resources if necessary to verify the issue.

- Implement corrective actions based on your findings.

Where to Find Replacement Parts

Locating suitable components for your machinery can be a straightforward process if you know where to look. Numerous resources are available that provide quality alternatives, ensuring your equipment remains in top condition. This section will guide you through various avenues to source the necessary replacements efficiently.

Online Retailers

Many online platforms offer a wide selection of components. Here are some reliable sources:

- Dedicated gardening equipment websites

- Large e-commerce sites with extensive inventories

- Specialized dealers focused on outdoor machinery

Local Stores

Visiting local shops can also yield beneficial results. Consider checking out:

- Hardware stores that stock a variety of tools and equipment

- Garden centers with sections dedicated to maintenance supplies

- Authorized service centers that provide genuine replacements

By exploring both online and local options, you can find the best alternatives to keep your machinery running smoothly.