When delving into the intricacies of a car’s mechanical framework, it becomes essential to familiarize oneself with the various elements that contribute to its performance. A comprehensive overview of these elements provides valuable insights into how they interact to ensure optimal functionality. This exploration serves as a foundation for appreciating the engineering behind modern automobiles.

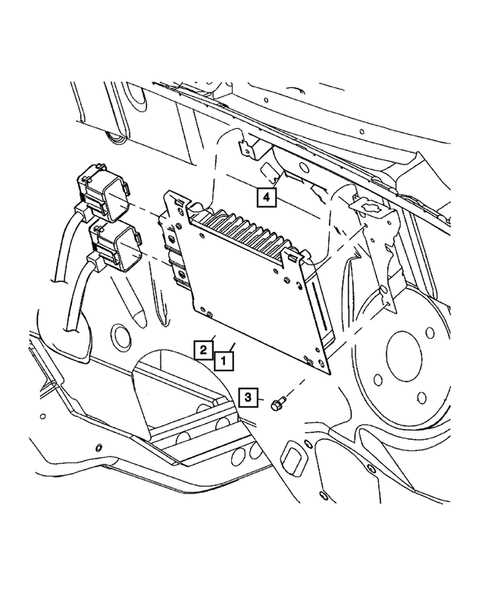

Visual representations of the intricate arrangements within the vehicle serve as crucial tools for enthusiasts and professionals alike. By analyzing these representations, one can gain a clearer understanding of the roles played by each segment. This knowledge not only aids in maintenance but also enhances the overall appreciation of automotive engineering.

Furthermore, recognizing the significance of each component facilitates informed decision-making during repairs and upgrades. Whether one is a seasoned mechanic or a curious car owner, grasping the layout of these essential mechanisms can lead to a more rewarding experience in managing vehicle upkeep.

Understanding the PT Cruiser Engine

This section delves into the intricate components of a specific vehicle model, emphasizing its mechanical systems. The aim is to provide a comprehensive overview that enhances the reader’s knowledge of how various elements work in harmony to ensure optimal performance.

Key Components Overview

The following list outlines the essential elements that contribute to the overall functionality of this vehicle:

- Power Source: The main unit responsible for converting fuel into energy.

- Cooling Mechanism: A system designed to regulate temperature, preventing overheating.

- Fuel Delivery System: Ensures the appropriate mixture of fuel and air for efficient combustion.

- Exhaust Management: Handles the expulsion of gases generated during operation.

- Control Unit: Monitors and adjusts various functions for optimal efficiency.

Importance of Maintenance

Regular upkeep of these critical systems is vital for longevity and performance. Key practices include:

- Routine inspections of fluid levels and filters.

- Scheduled replacement of worn components to prevent failure.

- Periodic assessments of the overall system to ensure all parts are functioning harmoniously.

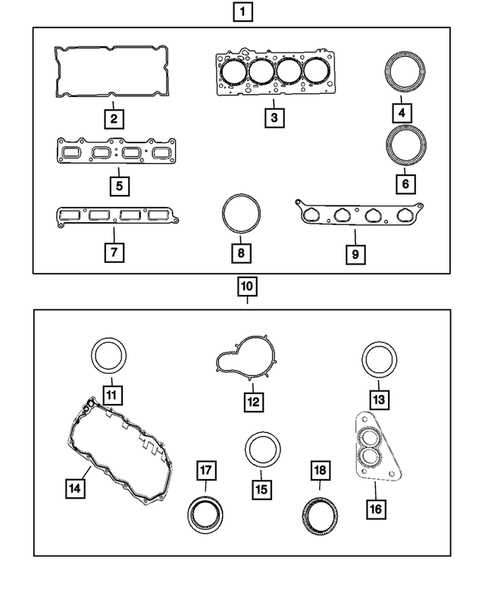

Overview of Engine Components

This section provides a comprehensive look at the vital elements that contribute to the functionality of an automotive power unit. Each component plays a crucial role in ensuring optimal performance, efficiency, and reliability. Understanding these elements is essential for both enthusiasts and professionals working in the field.

| Component Name | Function |

|---|---|

| Cylinder Block | Serves as the main structure, housing cylinders and supporting various components. |

| Pistons | Convert fuel combustion into mechanical motion. |

| Crankshaft | Transforms the up-and-down motion of the pistons into rotational motion. |

| Camshaft | Controls the opening and closing of intake and exhaust valves. |

| Valves | Regulate the flow of air and fuel into the combustion chamber. |

| Intake Manifold | Distributes the air-fuel mixture to the cylinders. |

| Exhaust Manifold | Channels exhaust gases away from the cylinders. |

| Fuel Injector | Delivers fuel into the combustion chamber in a fine spray. |

Common Issues with PT Cruiser Engines

The vehicle is known for its unique design and functionality; however, it is not without its share of challenges. Owners often encounter various complications that can affect performance and reliability. Understanding these frequent problems can help in timely maintenance and prevention.

- Cooling System Failures:

Overheating can occur due to issues within the cooling system, such as radiator leaks or thermostat malfunctions.

- Fuel System Problems:

Blockages or leaks in the fuel lines can lead to inadequate fuel delivery, resulting in poor performance or stalling.

- Ignition Difficulties:

Malfunctions in the ignition system, including worn spark plugs or faulty coils, may cause starting issues or misfires.

- Transmission Concerns:

Shifting difficulties can arise from transmission fluid leaks or internal component wear, leading to a decrease in drivability.

- Electrical System Glitches:

Electrical components can fail, causing erratic behavior of lights, windows, or dashboard indicators.

Identifying these common complications early on can significantly enhance the longevity and efficiency of the vehicle, ensuring a smoother driving experience.

Importance of Regular Maintenance

Consistent upkeep of your vehicle is crucial for ensuring its longevity and optimal performance. Routine checks and services help identify potential issues before they escalate, safeguarding against costly repairs and enhancing overall reliability.

Regular maintenance not only improves functionality but also contributes to safety on the road. By ensuring that all components are in good working condition, you reduce the risk of unexpected breakdowns and accidents. Moreover, adhering to a maintenance schedule can lead to better fuel efficiency, allowing you to save money over time.

Additionally, a well-maintained vehicle retains its value more effectively. Prospective buyers often seek out cars that have been properly cared for, making it easier to achieve a favorable resale price. Investing time and resources in maintenance is not merely an obligation; it is a strategy that pays dividends in the long run.

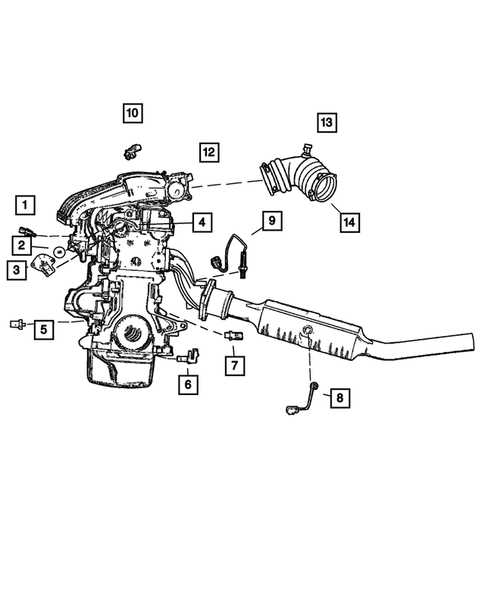

Identifying Engine Part Functions

Understanding the roles of various components within a vehicle’s propulsion system is essential for both maintenance and repair. Each element contributes to the overall efficiency and performance of the system, and recognizing their specific functions can aid in troubleshooting and optimizing operation.

Key functions of these crucial components include:

- Power Generation: This refers to the process by which the vehicle produces energy required for movement.

- Fuel Management: Involves the regulation and distribution of fuel to ensure optimal combustion.

- Air Intake Control: Essential for regulating airflow, which is vital for the combustion process.

- Exhaust Management: Responsible for directing and filtering exhaust gases to minimize environmental impact.

In order to enhance understanding, it is beneficial to examine each component’s role:

- Power Generation: This is primarily handled by converting fuel into mechanical energy through a series of controlled explosions.

- Fuel Management: This system ensures that the right amount of fuel is available for combustion, which is crucial for performance.

- Air Intake Control: Proper airflow is critical; this system adjusts the volume of air entering the combustion chamber.

- Exhaust Management: This helps in reducing harmful emissions, ensuring compliance with environmental regulations.

By familiarizing oneself with the functionalities of these components, one can significantly enhance the overall performance and longevity of the vehicle.

How to Replace Engine Parts

Changing various components of a vehicle can seem daunting, but with the right approach, it becomes a manageable task. Understanding the basics of the process can help streamline the work and ensure optimal performance after the replacements. Follow these steps to facilitate a smooth transition during the procedure.

Before diving into the replacement, it’s essential to gather the necessary tools and components. This preparation minimizes downtime and ensures you have everything at hand.

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent any electrical hazards. |

| 2 | Remove any covering or components that obstruct access to the area requiring attention. |

| 3 | Carefully detach the component by unscrewing bolts or unclipping connectors. |

| 4 | Install the new item, ensuring proper alignment with existing fixtures. |

| 5 | Reassemble any coverings and reconnect the power source. |

| 6 | Start the vehicle and monitor for any unusual noises or performance issues. |

By following these steps, you can effectively replace various elements within the system, enhancing your vehicle’s functionality and longevity. Remember to consult your manual for specific instructions related to your model for the best results.

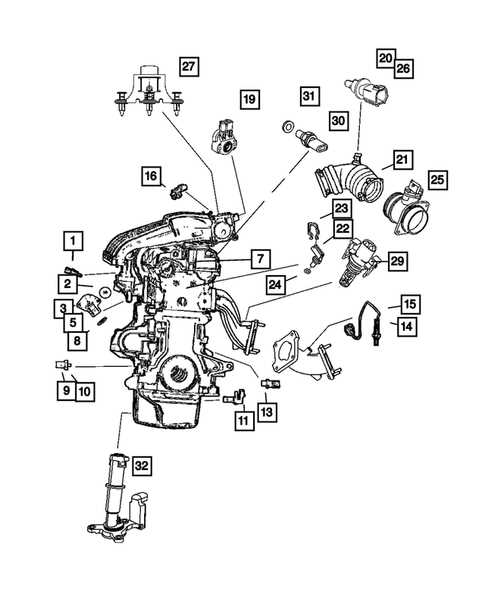

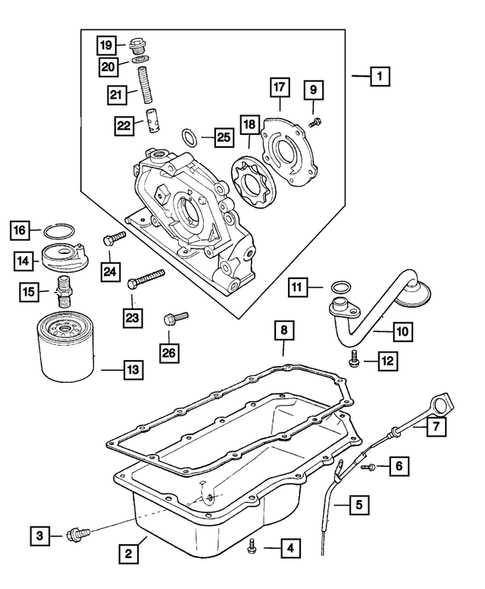

Diagram of Engine Assembly

This section provides a comprehensive overview of the components that work together to facilitate the functionality of a motorized vehicle. Understanding the arrangement and interaction of these elements is crucial for anyone involved in maintenance or repair tasks.

Key Components Overview

Each element plays a vital role in ensuring optimal performance. Below is a summary of the significant components typically found in the assembly:

| Component | Description |

|---|---|

| Block | The main structure housing various internal mechanisms. |

| Head | Seals the top of the block and contains valves and spark plugs. |

| Cylinder | Holds the pistons, allowing them to move up and down. |

| Crankshaft | Converts the linear motion of the pistons into rotational motion. |

| Camshaft | Controls the timing of the valve openings and closings. |

| Timing Belt | Synchronizes the rotation of the crankshaft and camshaft. |

Importance of Each Element

Recognizing the significance of each component aids in troubleshooting and repairs. A well-coordinated assembly maximizes efficiency and minimizes wear, ensuring longevity and reliability.

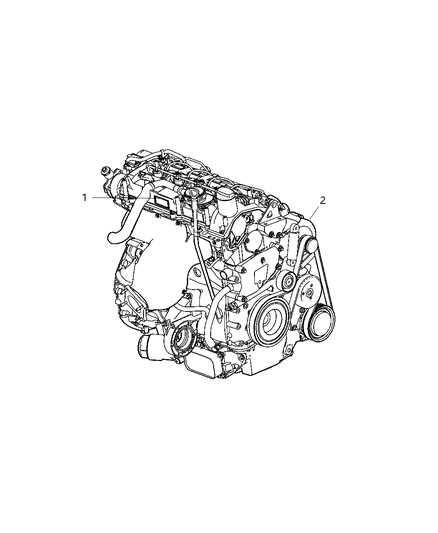

Comparing Engine Models and Variants

This section explores the various configurations and variations of powertrains available for a specific vehicle model. Understanding these distinctions is essential for enthusiasts, mechanics, and potential buyers to appreciate the advancements and options provided throughout the production years.

Different configurations may offer unique features that affect performance, fuel efficiency, and overall driving experience. Here, we will examine some of the notable variants, highlighting their specifications and characteristics to provide a comprehensive overview.

| Model Year | Type | Displacement | Horsepower | Torque |

|---|---|---|---|---|

| 2001 | 4-Cylinder | 2.4L | 150 hp | 165 lb-ft |

| 2003 | Turbocharged 4-Cylinder | 2.4L | 180 hp | 210 lb-ft |

| 2005 | High-Performance 4-Cylinder | 2.4L | 220 hp | 245 lb-ft |

Each variant offers a distinct blend of power and efficiency, appealing to different preferences and driving styles. By analyzing these variations, one can gain insights into the evolution of the vehicle and the engineering advancements that have taken place.

Diagnosing Engine Performance Problems

Understanding the underlying issues affecting a vehicle’s operation is crucial for maintaining optimal performance. Various factors can contribute to diminished functionality, leading to inefficient operation and potential breakdowns. Identifying these problems early can save time and resources, ensuring smooth driving experiences.

Common Symptoms of Malfunction

Drivers may notice several indications that suggest a need for further investigation. For instance, irregular acceleration, unusual noises, or fluctuating fuel efficiency can point to deeper issues. Observing these signs closely can help pinpoint specific areas requiring attention.

Steps to Troubleshoot

Begin the diagnostic process by performing a visual inspection. Look for signs of wear or damage in critical components. Next, utilize diagnostic tools to retrieve error codes that can reveal system malfunctions. Conducting a thorough assessment can lead to identifying the root cause and implementing the necessary repairs.

Upgrading Engine Components Effectively

Enhancing the performance of your vehicle involves strategically improving various elements that contribute to its overall functionality. These upgrades can lead to increased efficiency, better power delivery, and enhanced driving experience. By focusing on specific areas, enthusiasts can achieve significant improvements without overhauling the entire system.

Identifying Key Areas for Improvement: Prioritize components that have the most impact on performance. Factors such as airflow, fuel delivery, and ignition timing are critical for optimizing operation. Researching and understanding which areas are bottlenecks will guide you in selecting the right upgrades.

Choosing Quality Components: When selecting new elements, prioritize quality over cost. High-grade materials and reputable brands ensure durability and reliability. Investing in well-engineered components can yield better long-term results compared to cheaper alternatives that may fail or underperform.

Installation Considerations: Proper installation is crucial for the effectiveness of any upgrade. Following manufacturer guidelines and employing professional assistance when necessary will help ensure that modifications are done correctly. Misalignment or improper fitting can negate the benefits of any enhancements made.

Regular Maintenance: After upgrading, it’s essential to keep up with routine maintenance. Monitoring the performance and making adjustments as needed can help sustain improvements over time. Regular checks also help identify any emerging issues that could affect overall performance.

Resources for Engine Repair Guides

When tackling automotive repairs, having access to comprehensive materials can significantly enhance the efficiency of the process. Numerous sources offer valuable insights, troubleshooting tips, and detailed instructions that cater to both novice and experienced mechanics. Utilizing these resources can lead to a smoother repair experience and a better understanding of the underlying mechanisms involved.

Online platforms, such as forums and dedicated automotive websites, serve as excellent starting points. Forums often feature discussions where enthusiasts share their personal experiences, solutions, and advice regarding specific issues. Additionally, many websites provide step-by-step tutorials, diagrams, and videos that visually guide users through various repair procedures, making it easier to follow along.

Another effective resource is the availability of repair manuals. These publications typically cover a range of vehicles and provide detailed information about maintenance, common issues, and repair techniques. Many manuals are available in both digital and print formats, allowing users to choose the most convenient option for their needs.

Finally, don’t overlook the value of local workshops and community colleges that may offer classes or seminars focused on automotive repair. Engaging in hands-on learning can supplement the theoretical knowledge gained from online resources, providing a well-rounded understanding of mechanical systems.