Maintaining a lawn mower requires a thorough understanding of its essential components. Each element plays a crucial role in ensuring optimal performance and longevity. Familiarity with the various segments of the equipment can enhance repair efficiency and support effective upkeep.

In this section, we will explore the different assembly components of a popular riding mower model. This guide will provide a comprehensive overview of each part’s function, helping users identify potential issues and streamline the maintenance process. By understanding the arrangement and significance of these components, operators can better manage their equipment and ensure a well-maintained lawn.

Cub Cadet RZT 50 Deck Parts Overview

This section provides an insight into the essential components of the mower’s cutting system. Understanding these elements is crucial for effective maintenance and performance optimization. Each component plays a vital role in ensuring a smooth operation and quality cutting results.

The primary components include:

- Cutting Blades: Sharp edges designed for efficient grass trimming.

- Spindles: Support and drive the blades for rotation.

- Belts: Transfer power from the engine to the spindles.

- Washers: Provide stability and secure blade assembly.

- Deck Shell: The main body housing the cutting mechanism.

Regular inspection and maintenance of these components can enhance the longevity and effectiveness of the mowing machine. Make sure to follow the manufacturer’s recommendations for replacement and service intervals.

Key Components of the Deck Assembly

The assembly that houses the cutting blades plays a crucial role in the functionality of lawn maintenance equipment. Understanding its key elements helps in maintenance and repair, ensuring optimal performance and longevity.

1. Cutting Blades: These sharp implements are essential for effectively trimming grass. Their design and sharpness directly influence the quality of the cut.

2. Spindle Assembly: This component serves as the rotating hub for the blades, allowing them to spin at high speeds. A well-functioning spindle is vital for efficient operation.

3. Belt System: The belt connects the engine to the spindle assembly, transferring power for blade rotation. Regular checks on the belt’s condition can prevent unexpected failures.

4. Mounting Brackets: These fixtures secure the assembly to the frame of the mower. Ensuring they are tight and free from corrosion is essential for stability during operation.

5. Anti-Scalp Wheels: Positioned around the periphery, these wheels prevent the blades from scalping the lawn, maintaining an even cut across varied terrains.

Regular inspection and maintenance of these crucial elements can enhance performance and prolong the life of the equipment.

Identifying Different Deck Parts

This section focuses on recognizing the various components associated with lawn mowing equipment. Understanding these elements is essential for effective maintenance and repair, ensuring the longevity and efficiency of your machine. Each component plays a vital role in the overall functionality, contributing to a well-manicured lawn.

Key Components Overview

The main segments consist of several critical elements that enhance the operational capabilities. Here’s a brief description of these essential components:

| Component | Description |

|---|---|

| Blade | Responsible for cutting grass efficiently, it is a crucial part of the machinery. |

| Spindle | This component holds the blade in place and enables rotation for cutting. |

| Idler Pulley | Helps maintain the tension on the drive belt, ensuring smooth operation. |

| Drive Belt | Transfers power from the engine to the cutting mechanism. |

Visual Identification Tips

To facilitate identification, familiarizing oneself with the layout and function of each segment is beneficial. Regular inspections can help in spotting wear and tear, allowing for timely interventions to keep the equipment running optimally.

Maintenance Tips for Deck Components

Regular upkeep of essential components ensures optimal performance and longevity. Proper care not only enhances functionality but also prevents premature wear and tear. Here are some key recommendations for maintaining these critical elements.

- Clean Regularly: Remove grass clippings and debris after each use to prevent buildup.

- Check for Damage: Inspect all components for signs of wear, rust, or cracks before each season.

- Lubricate Moving Parts: Apply appropriate lubricant to bearings and hinges to ensure smooth operation.

- Sharpen Blades: Keep blades sharp for an even cut and to reduce strain on the engine.

- Adjust Tension: Regularly check and adjust the tension of belts to prevent slippage.

- Store Properly: During off-season, store components in a dry location to prevent rust and damage.

By following these tips, users can maximize efficiency and extend the lifespan of these vital elements.

Common Issues with Deck Components

When operating a lawn mower, various challenges can arise related to the cutting assembly. Understanding these common concerns can help ensure optimal performance and prolong the lifespan of your equipment.

- Uneven Cutting: A frequent problem is inconsistent grass height after mowing, which can be attributed to misalignment or wear of the cutting blades.

- Excessive Vibration: If you notice unusual shaking during operation, this may indicate a loose or damaged component within the cutting assembly.

- Clogging: Debris buildup is another common issue, often caused by wet grass or an accumulation of dirt, impacting the mower’s efficiency.

- Noise Levels: Increased noise can signal that components are worn out or require lubrication, leading to further damage if not addressed promptly.

- Blade Wear: Over time, cutting blades can dull or chip, leading to poor cutting performance and necessitating regular inspections and replacements.

Addressing these issues promptly can enhance the efficiency of your mower and prevent more serious problems down the line.

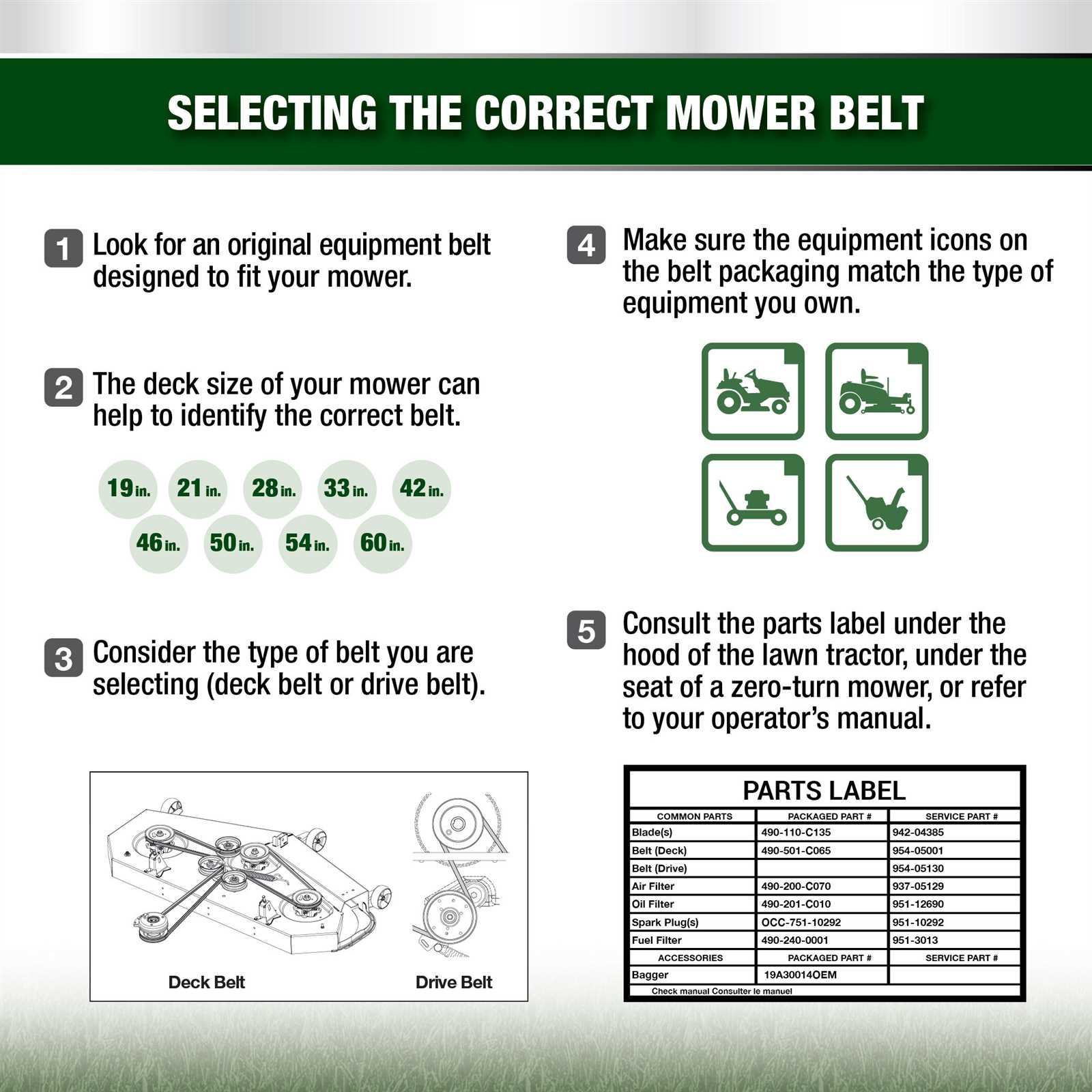

Replacement Parts for Cub Cadet Deck

Maintaining the efficiency and performance of your mower requires regular attention to its components. Understanding the various replacement options available can help ensure a smooth operation and prolong the life of your equipment.

Essential Components for Maintenance

Regular upkeep may necessitate the replacement of several crucial elements. Here are the key components to consider:

- Blades: Ensuring sharpness for effective cutting.

- Belts: Vital for transferring power smoothly.

- Spindles: Important for blade rotation and stability.

- Washers: Essential for securing parts in place.

Finding Quality Replacements

When looking for replacements, it’s important to choose high-quality components. Here are some tips:

- Check manufacturer specifications to ensure compatibility.

- Read reviews to gauge reliability and performance.

- Purchase from reputable dealers to avoid counterfeit items.

Tools Needed for Deck Repairs

To effectively conduct maintenance and repairs on your lawn mowing equipment, it’s essential to have the right instruments at your disposal. Utilizing proper tools not only enhances efficiency but also ensures that the job is completed safely and correctly. Below is a list of must-have equipment that will assist you in various repair tasks.

Essential tools include wrenches, screwdrivers, and pliers. These basic hand tools are crucial for loosening or tightening bolts and screws. Additionally, a socket set can provide the versatility needed for different sizes of fasteners.

For more intricate work, consider acquiring a torque wrench to ensure components are secured to the manufacturer’s specifications. A multimeter may also be necessary for diagnosing electrical issues that could arise during repairs.

Lastly, safety equipment such as gloves and goggles is vital to protect yourself while working on machinery. Keeping your workspace organized and well-equipped will facilitate smoother repairs and prolong the life of your equipment.

How to Access the Deck Assembly

To reach the assembly beneath the cutting unit, it is essential to follow a series of systematic steps. Understanding the layout and structure of the equipment will facilitate the process, ensuring efficient access for maintenance or repairs.

Begin by parking the equipment on a flat, stable surface. Turn off the engine and engage the parking brake to prevent any accidental movement. Next, remove any obstacles or attachments that may hinder your access to the undercarriage.

Locate and detach the fasteners securing the protective cover, if applicable. Carefully lift the cover away to expose the components below. Ensure to keep track of all fasteners and parts during this process to simplify reassembly.

Once the cover is removed, inspect the assembly for any visible signs of wear or damage. If further disassembly is required, identify additional components that need to be detached to gain complete access to the inner workings.

Always consult the user manual for specific instructions related to your model. This will provide detailed guidance on safely accessing and handling the assembly without causing harm to the equipment or yourself.

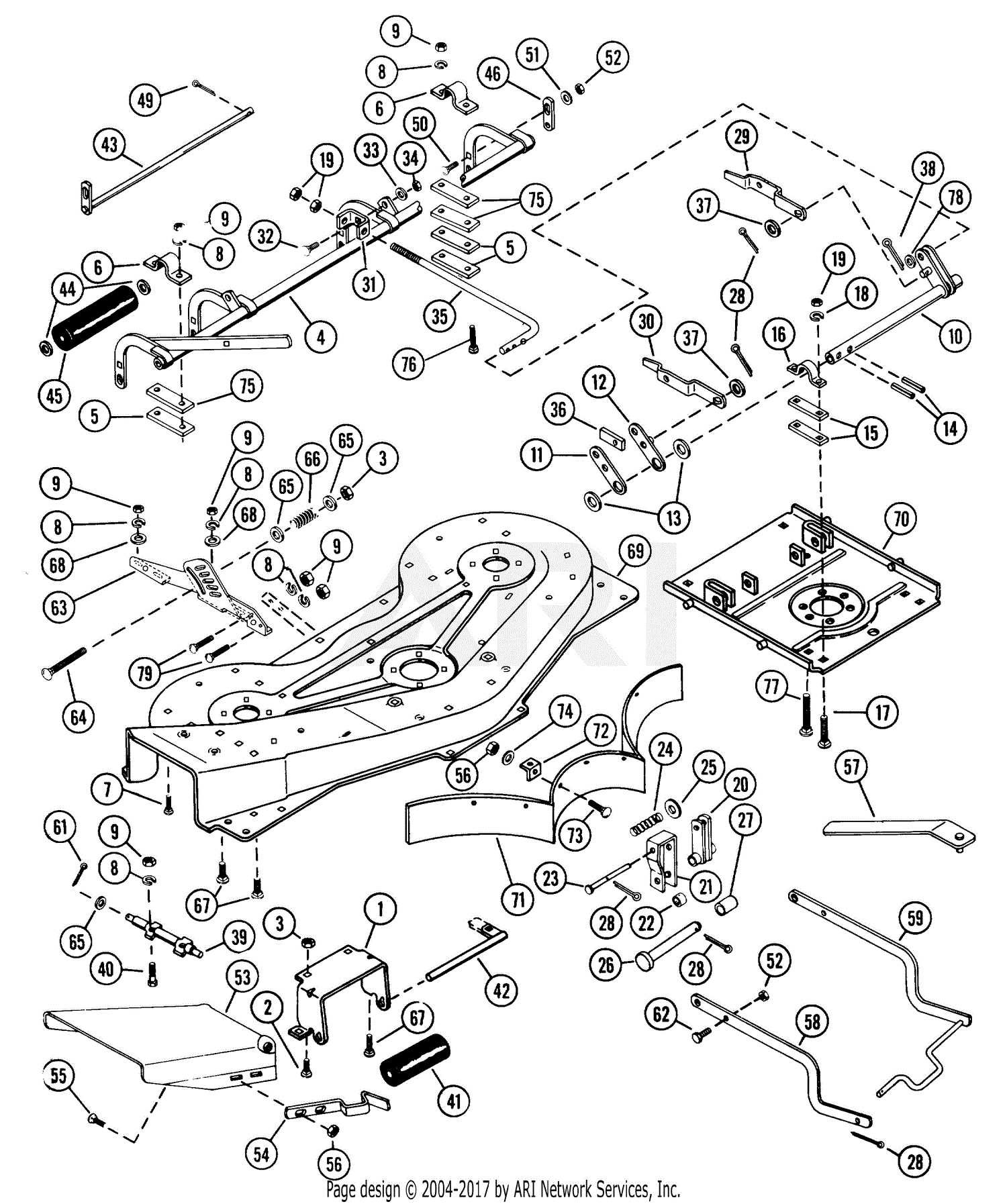

Diagram Explanation for Easy Reference

This section aims to provide a clear understanding of the layout and components essential for maintenance and repair tasks. It is designed to facilitate easy identification and comprehension of various elements involved in the machinery’s operation.

By utilizing a visual representation, users can quickly locate specific items, enhancing the efficiency of repairs and replacements. Familiarity with this layout can significantly reduce downtime and improve the overall experience when handling the equipment.

| Component | Description |

|---|---|

| Housing | The outer structure that encases the internal mechanisms. |

| Blades | The sharp elements responsible for cutting grass or other materials. |

| Spindle | A rotating shaft that drives the blades, ensuring smooth operation. |

| Mounting Brackets | Support structures that secure components in place. |

| Belt | A flexible loop that transmits power from the engine to the blades. |

Safety Precautions During Repairs

When performing maintenance on machinery, it is essential to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines ensures that individuals remain secure while working with equipment components.

Here are key safety measures to consider:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Disconnect the power source before starting any repair work to eliminate the risk of accidental activation.

- Use tools that are well-maintained and designed for the specific task to reduce the likelihood of injury.

- Ensure the workspace is clean and organized to minimize tripping hazards and improve efficiency.

- Read the user manual for safety instructions and guidelines relevant to the specific machinery being serviced.

By following these precautions, individuals can ensure a safer working environment and effectively complete their maintenance tasks.

Finding Authentic Replacement Parts

When it comes to maintaining your outdoor equipment, sourcing genuine components is crucial for ensuring optimal performance and longevity. High-quality replacements not only enhance the functionality of your machinery but also safeguard it against potential damage caused by inferior alternatives.

To locate reliable replacements, consider exploring authorized dealers and certified retailers. These sources typically offer a wide selection of authentic items that meet the manufacturer’s specifications. Additionally, online platforms dedicated to outdoor equipment can provide valuable resources for comparing prices and reading reviews from other users.

Verification of Authenticity is essential when selecting components. Always look for clear markings or part numbers that indicate the item’s legitimacy. Cross-referencing these details with official documentation can help prevent the use of counterfeit goods.

Furthermore, joining online communities or forums related to your equipment can offer insights and recommendations from fellow enthusiasts. Engaging with these groups can help you stay informed about the latest product releases and trends, making your search for replacements much more efficient.