Understanding the various elements of a riding mower is essential for both maintenance and repair. This guide delves into the intricate layout of a specific model, offering a clear overview of its essential features and mechanisms. By familiarizing oneself with the arrangement of components, users can better appreciate the functionality and design of the machine.

In this section, we will provide a detailed representation of the mower’s structure, emphasizing the interconnected parts that contribute to its performance. Gaining insight into these components not only aids in troubleshooting but also enhances the overall user experience.

Whether you are a seasoned operator or a new owner, having a thorough understanding of the mower’s configuration is invaluable. This resource aims to equip you with the knowledge necessary to navigate the complexities of your equipment effectively.

This section provides a comprehensive overview of a specific lawn maintenance machine designed for efficiency and ease of use. The goal is to familiarize users with its essential components and their functions, enabling better understanding and maintenance.

- Introduction to the Model

An overview of the machine’s purpose and features.

- Key Specifications

A detailed look at the technical specifications, including dimensions and engine type.

- Components Overview

A summary of the main parts and their roles in the machine’s operation.

- Maintenance Tips

Advice on regular upkeep to prolong the life of the equipment.

- Common Issues and Solutions

A guide to troubleshooting frequent problems encountered during use.

- Safety Precautions

Important safety measures to consider while operating the machine.

- Accessories and Upgrades

An exploration of optional attachments and enhancements available for improved functionality.

- Assembly Instructions

A step-by-step guide to assembling the machine upon purchase.

- Usage Guidelines

Best practices for operating the machine effectively.

- Resources for Further Information

Links and references to manuals, online communities, and support.

Key Features of ZT1 42 Model

The ZT1 42 model stands out in its category due to a combination of innovative design and practical functionalities. This model is engineered to enhance efficiency and comfort, catering to the needs of users who seek reliability and performance in their outdoor equipment.

Performance and Efficiency

Equipped with a powerful engine, this model delivers robust performance while ensuring fuel efficiency. Its advanced transmission system provides smooth operation, allowing for easy maneuverability and control during use.

Comfort and Usability

The design of this model prioritizes user comfort with features such as an adjustable seat and ergonomic controls. These aspects contribute to a pleasant mowing experience, minimizing fatigue during extended use.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine that maximizes efficiency |

| Transmission | Advanced system for smooth acceleration |

| Comfort Seat | Adjustable seating for enhanced user comfort |

| Maneuverability | Compact design for easy navigation |

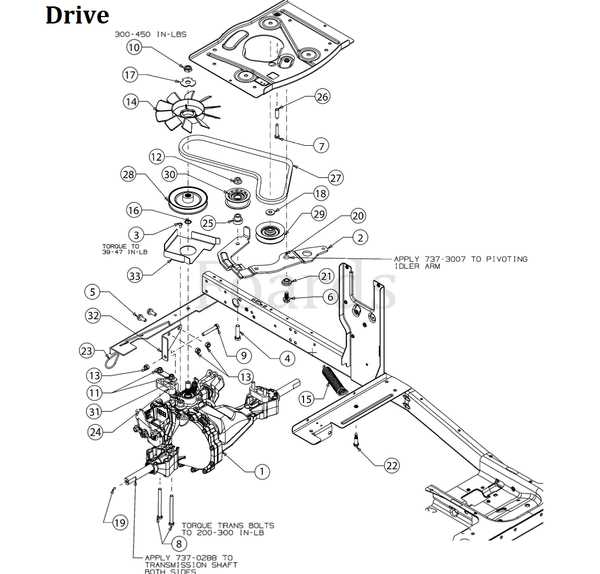

Importance of Parts Diagrams

Understanding the structure and components of machinery is essential for effective maintenance and repair. Visual representations serve as valuable tools, enabling users to identify various elements, comprehend their functions, and ensure accurate assembly or disassembly. These illustrations not only facilitate troubleshooting but also enhance the efficiency of repair processes, leading to better operational performance.

Enhancing Maintenance Efficiency

Visual guides play a crucial role in simplifying maintenance tasks. By providing clear images and annotations, users can quickly locate specific components and understand their relationships within the system. This clarity reduces the likelihood of errors during repairs, ultimately saving time and resources. Furthermore, having a reliable reference helps in planning maintenance schedules and ensuring that all necessary tools and materials are available.

Facilitating Troubleshooting

In the event of a malfunction, having access to accurate illustrations can significantly streamline the diagnostic process. Users can compare the actual state of the equipment with the visual guide, making it easier to pinpoint issues and implement effective solutions. This methodical approach not only minimizes downtime but also promotes a deeper understanding of the machinery, empowering users to handle similar challenges in the future.

| Benefit | Description |

|---|---|

| Time-saving | Quick identification of components reduces repair duration. |

| Accuracy | Visual references help prevent assembly errors. |

| Efficiency | Streamlined processes lead to better overall performance. |

Understanding Component Layouts

Effective organization of mechanical elements is crucial for ensuring optimal functionality and ease of maintenance in any machinery. Grasping the arrangement of individual components enables users to comprehend how different parts interact and contribute to the overall performance of the system. This knowledge can enhance troubleshooting skills and aid in timely repairs, thus prolonging the lifespan of the equipment.

Importance of Layout Clarity

A clear depiction of component positioning assists operators in quickly identifying specific sections during inspections or repairs. When each part is distinctly outlined, it reduces the risk of errors during maintenance tasks, ensuring that replacements or adjustments are made accurately. Understanding the layout fosters confidence in handling the equipment effectively.

Benefits of Familiarization

Becoming acquainted with the arrangement of elements not only streamlines maintenance processes but also empowers users to perform minor repairs independently. By knowing where each component resides, operators can address common issues without relying heavily on professional service, ultimately saving time and resources.

Identifying Replacement Parts

Finding the right components for your machinery can be essential for maintaining its performance and longevity. Understanding the various elements involved allows for informed decisions when it comes to repairs and upgrades.

To effectively identify necessary components, consider the following steps:

- Refer to the user manual to locate specifications and descriptions of each component.

- Inspect the existing elements for any identifiable numbers or markings that indicate the manufacturer or model.

- Utilize online resources and forums where fellow users share their experiences and recommendations.

In addition, the following tools may assist you in the identification process:

- Visual Aids: Diagrams or illustrations that show the layout of various elements.

- Measurement Tools: Use calipers or rulers to determine the size and dimensions of components.

- Part Retailers: Websites or catalogs that offer parts along with images and descriptions for easier comparison.

By following these guidelines, you can ensure that you select the correct components to keep your machinery operating smoothly.

Common Maintenance Issues

Regular upkeep is essential to ensure optimal performance and longevity of any machinery. Users often encounter several frequent challenges that can affect the efficiency and reliability of their equipment. Identifying these issues early can prevent more significant problems down the line, saving both time and resources.

One common concern is the wear and tear of the cutting blades, which can lead to uneven cuts and increased strain on the engine. Regular inspection and sharpening of these components are necessary to maintain their effectiveness. Additionally, debris accumulation around the deck can hinder airflow and cooling, making it crucial to clean this area frequently.

Another aspect to monitor is the fuel system. Stale fuel can cause starting difficulties and affect engine performance. It is advisable to replace fuel regularly and check for leaks in the lines to avoid operational interruptions. Moreover, the battery requires attention; ensuring it is charged and the terminals are clean helps prevent electrical issues.

Lastly, inspecting the tire pressure and condition is vital for safe operation and maneuverability. Improperly inflated or worn tires can lead to reduced traction and handling difficulties. Addressing these common maintenance challenges can significantly enhance the overall functionality and lifespan of the equipment.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for anyone working with machinery. These visual representations serve as a guide, detailing various components and their interrelationships. By interpreting these illustrations correctly, users can ensure proper assembly, maintenance, and repair of their equipment.

Familiarize Yourself with Symbols

Technical illustrations often employ specific symbols and notations to represent different elements. Familiarizing yourself with these can significantly enhance your comprehension.

- Shapes: Different shapes indicate distinct components, such as circles for connectors and rectangles for bodies.

- Lines: Solid lines typically represent physical connections, while dashed lines may indicate optional or hidden features.

- Labels: Components are usually labeled with numbers or letters, which correlate with a corresponding list.

Follow the Legend

Most illustrations come with a legend that explains the symbols used. Referring to this legend is essential for accurate interpretation.

- Locate the legend on the page, usually situated in a corner.

- Match the symbols in the illustration with those in the legend to understand each component’s purpose.

- Use this information to identify parts you may need to replace or repair.

Parts Ordering Process Explained

Understanding the procedure for acquiring components is essential for maintaining and repairing your equipment effectively. This section will provide a clear overview of how to navigate the ordering system to ensure you receive the necessary items promptly.

Steps to Follow

- Identify the required components for your equipment.

- Gather information, such as model numbers and descriptions, to assist in locating the correct items.

- Visit an authorized retailer or an online platform that specializes in equipment components.

- Search for the needed items using the gathered information.

- Add the desired components to your cart and proceed to checkout.

- Provide your shipping and payment details to finalize the order.

- Confirm the order and wait for a confirmation email with tracking information.

Tips for Efficient Ordering

- Double-check the model and part specifications to avoid errors.

- Consider purchasing multiple items at once to save on shipping costs.

- Keep track of past orders to streamline future purchases.

- Sign up for notifications or newsletters from suppliers for updates on new arrivals and discounts.

Tools Needed for Repairs

When undertaking maintenance or fixing issues with your equipment, having the right tools is essential for efficiency and effectiveness. Proper tools not only make the job easier but also ensure that repairs are done correctly and safely.

- Wrenches: Different sizes are necessary to tackle various nuts and bolts.

- Screwdrivers: A set of flathead and Phillips screwdrivers will be helpful for various screws.

- Socket Set: This will provide versatility for different fastening requirements.

- Pliers: Useful for gripping and twisting wires or removing stubborn parts.

- Safety Gear: Gloves and goggles are important for personal protection during repairs.

Additionally, it may be beneficial to have specialized tools based on the specific tasks at hand. Regular maintenance can also be simplified by using equipment designed for specific functions, enhancing your overall repair experience.

Safety Tips for Maintenance

Ensuring a secure environment during upkeep is crucial for both personal safety and the longevity of the equipment. Proper precautions help prevent accidents and enhance the efficiency of the maintenance process. Adopting best practices can significantly reduce the risk of injuries while working with machinery.

Preparation and Personal Protective Equipment

Before starting any maintenance tasks, it is essential to equip yourself with appropriate personal protective equipment (PPE). This may include gloves, safety glasses, and sturdy footwear. Always assess the work area for potential hazards, ensuring it is clean and well-lit to facilitate safe operations.

Following Manufacturer Guidelines

Adhering to the manufacturer’s instructions is vital when performing maintenance. These guidelines provide important information on the proper procedures and precautions specific to the equipment. Regularly reviewing the operational manual ensures that you remain informed about safety protocols and maintenance schedules, minimizing risks associated with equipment handling.

Frequently Asked Questions

This section aims to address common inquiries related to lawn care equipment and its maintenance. Understanding the essential components and their functions can help users enhance their knowledge and effectively troubleshoot any issues that may arise.

What should I do if I experience issues with my mower?

If you encounter problems with your lawn maintenance machine, it’s advisable to first consult the user manual for troubleshooting tips. Common issues may include difficulties in starting, unusual noises, or poor cutting performance. Checking the fuel level, battery condition, and blade sharpness can often resolve these concerns.

How often should I perform maintenance on my equipment?

Regular maintenance is crucial for optimal performance and longevity. It is recommended to inspect and service the machinery at the beginning and end of each season. Tasks may include oil changes, air filter replacements, and blade sharpening. Following a consistent maintenance schedule ensures your device operates efficiently.