The intricate mechanisms that facilitate the precise blending of air and fuel are essential for optimal engine performance. This section delves into the various elements that contribute to this process, illuminating their roles and interactions. A comprehensive grasp of these components not only enhances one’s understanding of engine functionality but also aids in diagnosing potential issues that may arise over time.

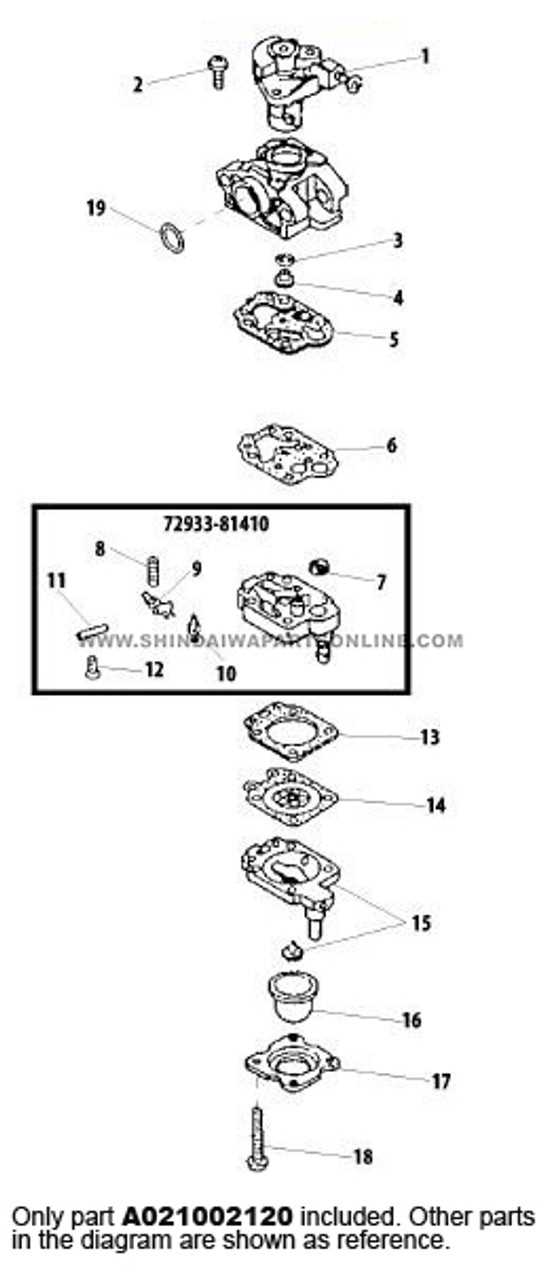

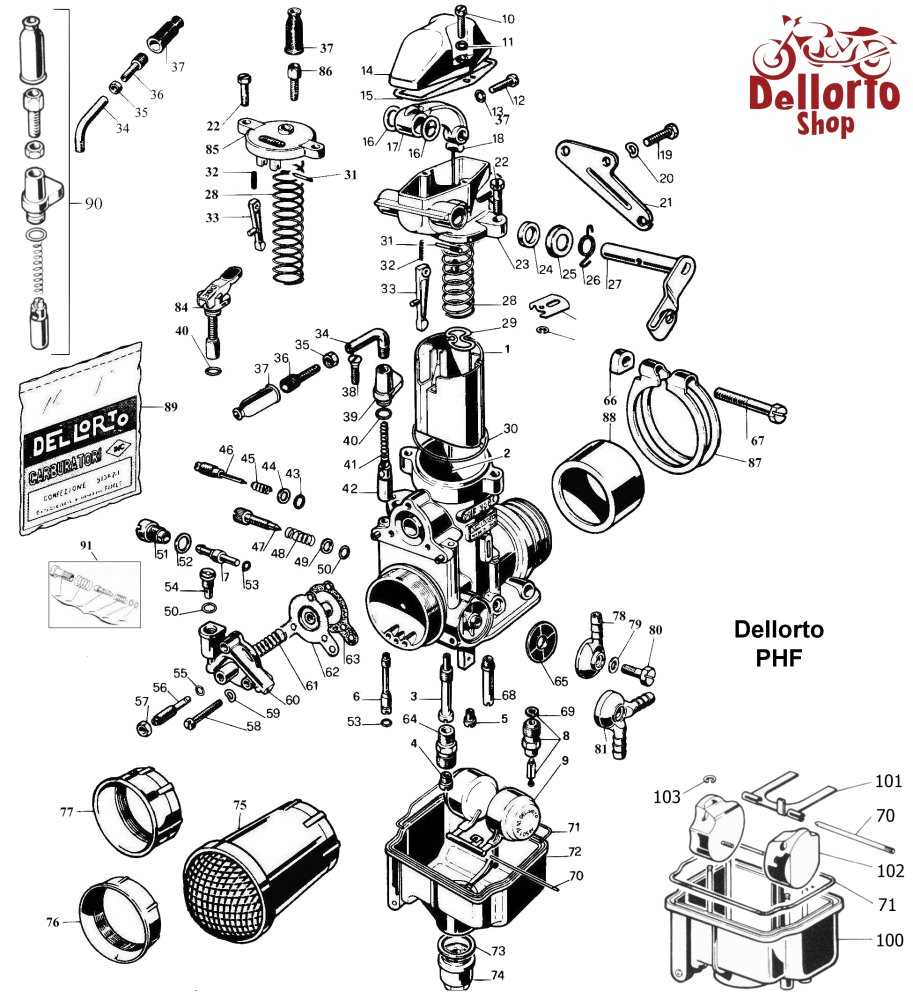

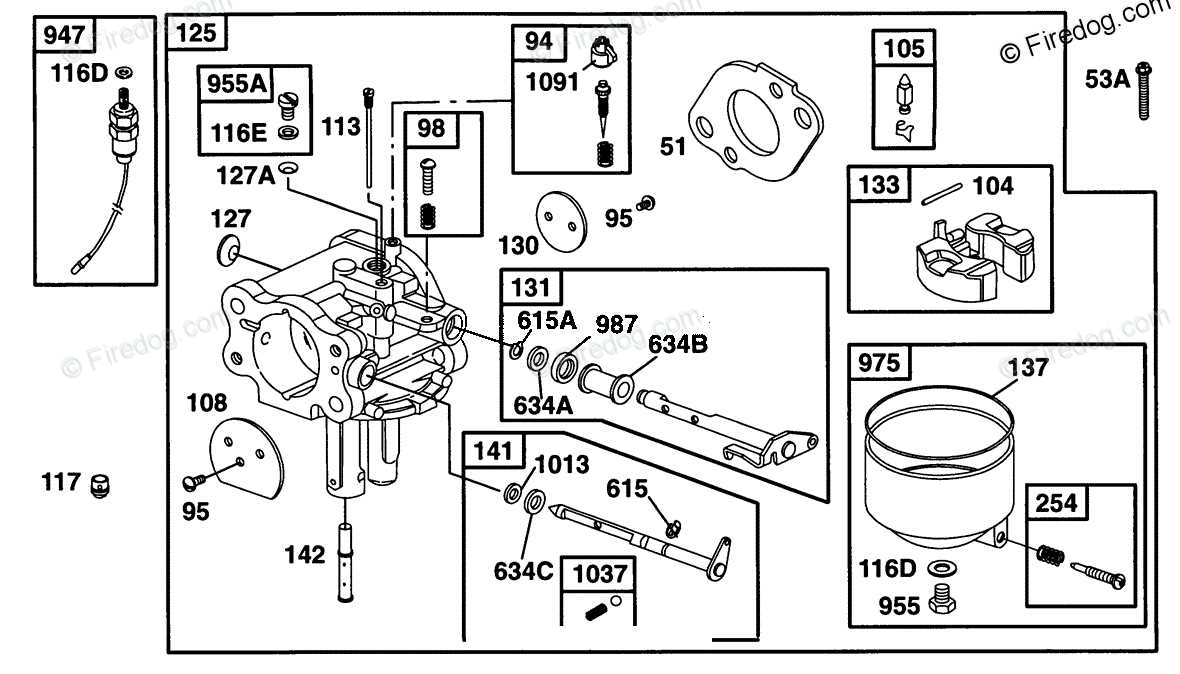

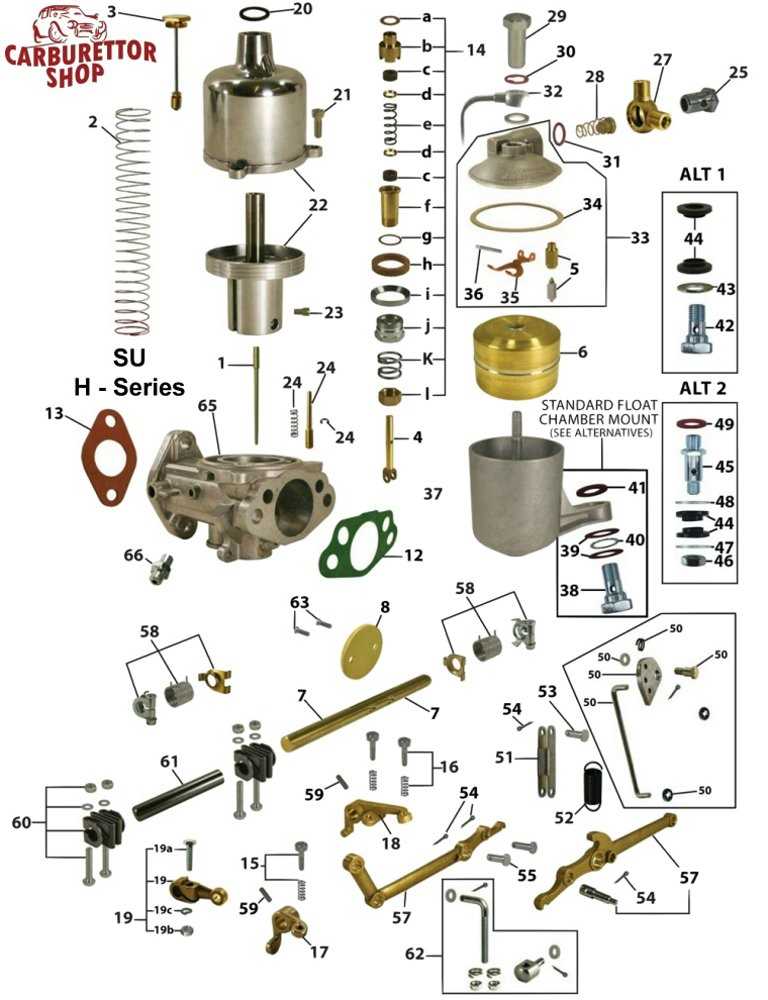

Visual representation of these essential elements serves as a valuable tool for enthusiasts and professionals alike. By dissecting the assembly into its individual constituents, one can appreciate how each piece works in harmony with others to create the necessary conditions for combustion. This knowledge empowers individuals to make informed decisions regarding maintenance and upgrades.

In this exploration, we will outline the specific roles and characteristics of each segment within the assembly. From the regulating units that manage airflow to the mechanisms responsible for delivering fuel, each component plays a vital part in ensuring that the engine operates efficiently. Understanding these relationships is key to mastering the art of automotive maintenance and repair.

Understanding Carburetor Components

The intricate assembly responsible for mixing air and fuel in an engine plays a crucial role in its performance and efficiency. A comprehensive grasp of its various elements is essential for effective maintenance and troubleshooting. Each component serves a distinct purpose, contributing to the overall functionality of the system.

One key element in this assembly is the chamber where the mixing occurs. It allows for the optimal combination of air and liquid fuel, ensuring that the engine receives the correct mixture for combustion. Additionally, various valves regulate airflow and fuel delivery, enabling smooth operation across different engine speeds.

Another important feature is the float mechanism, which maintains the appropriate level of fuel in the chamber. This component ensures that the engine has a consistent supply of fuel, preventing stalls and performance issues. Furthermore, jets play a vital role in determining the fuel flow rate, impacting both power output and efficiency.

Understanding these elements and their functions not only aids in identifying problems but also enhances the ability to fine-tune the system for optimal performance. A well-maintained assembly can lead to improved fuel efficiency and engine responsiveness.

Basic Functionality of a Carburetor

The device responsible for mixing air and fuel plays a crucial role in the operation of internal combustion engines. Its primary task is to create an optimal mixture that allows for efficient combustion, ultimately affecting performance, fuel efficiency, and emissions. Understanding how this mechanism works is essential for troubleshooting and maintenance.

The basic functionality can be broken down into several key processes:

- Air Intake: The mechanism draws in air from the atmosphere, which is essential for the combustion process.

- Fuel Delivery: A controlled amount of fuel is introduced into the incoming air, ensuring the right mixture for optimal combustion.

- Mixing: The air and fuel are thoroughly combined to form a homogeneous mixture, critical for proper engine function.

- Atomization: The fuel is broken into tiny droplets, allowing for better vaporization and more efficient combustion.

- Throttle Control: This mechanism regulates the amount of air-fuel mixture entering the engine, impacting speed and power output.

Each of these functions is vital for ensuring that the engine runs smoothly and efficiently. Understanding these processes can help diagnose performance issues and enhance the overall functioning of the engine.

Key Parts of a Carburetor Explained

This section delves into the essential components that facilitate the mixing of air and fuel in an internal combustion engine. Understanding these elements is crucial for grasping how engines operate efficiently, affecting both performance and fuel consumption.

1. Fuel Bowl

The fuel bowl serves as a reservoir, maintaining a steady supply of liquid for combustion. It regulates the fuel level and ensures that the engine receives the right amount during operation. A proper balance in this chamber is vital to prevent flooding or starving the engine of fuel.

2. Venturi Effect

The principle of the Venturi effect is fundamental in the process of air intake. As air passes through a narrowed section, its velocity increases, resulting in a drop in pressure. This phenomenon draws fuel into the airstream, creating a fine mist that mixes with air, optimizing combustion. Understanding this concept is key for diagnosing performance issues related to air-fuel mixing.

Recognizing the significance of these components allows for better maintenance and tuning, ensuring the overall health and efficiency of the engine system.

How to Read Carburetor Diagrams

Understanding technical illustrations related to fuel mixing mechanisms is crucial for efficient maintenance and repair. These visuals provide essential information about the components and their interconnections, allowing for effective troubleshooting and enhancements. Grasping how to interpret these schematics can significantly streamline the process of restoration and adjustment.

To effectively navigate these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Different elements are represented by unique icons. Learning what each symbol signifies is the first step to comprehension.

- Identify Key Components: Focus on primary elements such as valves, jets, and floats. Knowing their functions aids in understanding their arrangement.

- Analyze Connections: Observe how different components are linked. Understanding the flow of fuel and air through these connections is vital for diagnosing issues.

Additionally, paying attention to the layout can provide insights into the operational principles:

- Orientation: Most illustrations are designed with a specific viewing angle. Recognizing this can prevent confusion.

- Color Coding: Some diagrams use colors to distinguish between different fluids or functions. This can be helpful in identifying the purpose of each section quickly.

- Annotations: Look for notes or labels that offer additional context or instructions, which can enhance your understanding.

By applying these strategies, anyone can become adept at interpreting these technical representations, facilitating smoother repairs and modifications.

Common Carburetor Types and Their Features

Understanding the various configurations of fuel delivery mechanisms is essential for optimizing engine performance. Each type offers unique characteristics that cater to different engine designs and operational needs. This section explores several prevalent types, highlighting their distinguishing features and applications.

Single Barrel Systems are often utilized in smaller engines, providing simplicity and efficiency. They feature a single throat that regulates air and fuel mixture, making them ideal for low-power applications where basic performance is sufficient.

Dual Barrel Designs enhance performance by using two throats, allowing for better air and fuel flow. These systems offer improved acceleration and responsiveness, making them popular in performance-oriented vehicles. Their design enables a smoother transition between different power demands.

Downdraft Models are characterized by their vertical airflow, directing the mixture downward into the engine. This configuration promotes better atomization of the fuel, leading to more efficient combustion. They are commonly found in high-performance engines due to their ability to handle larger volumes of air and fuel.

Side Draft Systems, on the other hand, draw air horizontally into the intake manifold. This design is often used in racing applications where space is limited, and it offers a unique advantage in reducing the overall height of the engine compartment. These mechanisms can provide significant power gains when tuned correctly.

Each type of fuel delivery mechanism plays a crucial role in the overall performance and efficiency of an engine. Understanding their specific attributes allows for better customization and tuning, ensuring that vehicles operate at their best under various conditions.

Importance of Proper Air-Fuel Mixture

The right balance between air and fuel is crucial for optimal engine performance. This mixture influences not only efficiency but also the longevity of the engine components. Understanding how to achieve and maintain this balance can lead to significant improvements in vehicle operation.

An improper ratio can lead to various issues, including:

- Reduced Efficiency: An incorrect blend can cause excessive fuel consumption, reducing overall efficiency.

- Engine Damage: A too-rich or too-lean mixture can lead to overheating and wear on internal components.

- Emissions Issues: Poorly balanced mixtures contribute to higher emissions, affecting environmental compliance.

- Performance Problems: Vehicles may experience misfiring, stalling, or sluggish acceleration due to mixture imbalances.

To ensure the ideal mixture, consider the following:

- Regular Maintenance: Routine inspections can help identify issues before they escalate.

- Use Quality Fuels: Opt for fuels that meet the required specifications for optimal performance.

- Monitor Engine Conditions: Keep an eye on temperature and pressure to detect any anomalies in the mixture.

- Adjust as Needed: Be prepared to make necessary adjustments based on environmental changes or wear over time.

In summary, achieving the proper air-fuel mixture is essential for maximizing engine efficiency, minimizing emissions, and prolonging the life of engine components. Careful attention to this aspect can yield significant benefits for both performance and environmental impact.

Identifying Wear and Tear in Parts

Recognizing degradation in components is essential for maintaining optimal functionality and performance. Over time, regular usage can lead to various forms of deterioration, which can significantly impact efficiency and overall operation. This section focuses on the signs that indicate when critical elements require attention, ensuring that users can identify issues before they lead to more serious complications.

Common Signs of Deterioration

Several indicators can help users detect wear in essential elements. Observing these symptoms early can prevent further damage and extend the lifespan of the equipment.

| Indicator | Description |

|---|---|

| Cracks | Visible fractures that compromise structural integrity. |

| Corrosion | Rust or oxidation that leads to material breakdown. |

| Excessive Play | Looseness in connections that can lead to inefficiencies. |

| Wear Marks | Surface abrasions that indicate frequent friction. |

| Discoloration | Changes in color that may signify overheating or chemical exposure. |

Importance of Regular Inspections

Conducting routine evaluations can help users spot potential issues before they escalate. By incorporating a maintenance schedule, one can ensure that all vital components are functioning as intended, leading to increased longevity and performance efficiency.

Step-by-Step Carburetor Disassembly Guide

Disassembling a fuel mixing device requires careful attention and systematic approach to ensure all components are handled properly. This guide will walk you through the process of taking apart this essential machinery for cleaning, repair, or replacement of worn elements. Following these steps will help you maintain efficiency and performance in your engine.

-

Gather necessary tools and safety equipment:

- Flathead and Phillips screwdrivers

- Wrenches and pliers

- Clean cloths

- Container for small components

- Safety goggles and gloves

-

Ensure the device is cool and disconnected:

- Turn off the engine and allow it to cool completely.

- Disconnect the fuel supply to prevent leaks.

-

Remove the outer casing:

- Unscrew any screws or bolts securing the casing.

- Carefully lift off the casing to expose the inner mechanisms.

-

Take out the float assembly:

- Locate the float and gently detach it from its housing.

- Pay attention to the orientation and placement of any attached components.

-

Extract the needle valve:

- Carefully remove the retaining clip if present.

- Pull out the needle valve and inspect it for wear or damage.

-

Remove the jets and other adjustable elements:

- Unscrew and take out the main jet and idle jet.

- Keep track of their locations and orientations for reassembly.

-

Disassemble additional internal components:

- Remove any remaining screws or fasteners holding the body together.

- Carefully separate any other internal elements, noting their arrangement.

Once disassembled, take time to clean each element thoroughly and inspect for any damage. Proper reassembly will ensure the effective functioning of the system.

Reassembly Tips for Carburetor Parts

When it comes to putting together the various components of a fuel delivery system, careful attention to detail is crucial. Ensuring that each element is reconnected correctly can enhance performance and longevity. This section provides essential guidelines to streamline the reassembly process, making it efficient and straightforward.

Begin by organizing all components systematically. Group similar items together and ensure that any small pieces are kept secure. A clean workspace can prevent mix-ups and damage during reassembly. Using labeled containers can further aid in tracking each component’s location.

Next, refer to a reference guide or schematic to ensure accuracy. This visual aid can serve as a roadmap, highlighting the correct positioning and orientation of each component. Pay special attention to seals and gaskets; replacing these parts when worn can prevent leaks and maintain optimal function.

During reassembly, apply a moderate amount of torque when fastening components. Over-tightening can lead to damage or misalignment, while under-tightening may result in leaks or operational issues. Use a torque wrench if available, to achieve precise specifications.

After reassembly, conduct a thorough inspection to confirm that all components are properly seated and secured. Testing the system for any leaks or irregularities before final installation can save time and ensure reliability. With these tips in mind, the task of reassembling the fuel delivery mechanism can be executed with confidence and precision.

Tools Required for Carburetor Maintenance

Proper upkeep of fuel delivery systems is essential for optimal engine performance. To effectively maintain these mechanisms, certain tools are indispensable. Having the right equipment ensures that the maintenance process is efficient and thorough, leading to improved functionality and longevity of the engine.

Wrenches and Sockets: A variety of wrenches and socket sets are crucial for loosening and tightening various components. Different sizes are often necessary to accommodate the range of fasteners used in these assemblies.

Cleaners and Solvents: Specialized cleaning agents are vital for removing deposits and grime that can accumulate over time. These solutions help restore the performance of the components by ensuring that they operate free from obstructions.

Brushes: A set of brushes, particularly those with fine bristles, is essential for scrubbing intricate areas. This helps to dislodge stubborn debris and ensures thorough cleaning.

Gasket Scraper: A gasket scraper is important for removing old gaskets without damaging surfaces. This tool helps in preparing the area for new seals, which is critical for preventing leaks.

Measuring Tools: Accurate measuring tools, such as calipers and rulers, are necessary for assessing the dimensions of various components. Proper measurements are vital for ensuring that replacements fit correctly and function as intended.

Vacuum Gauge: This tool is useful for diagnosing performance issues. It helps in determining the efficiency of air and fuel flow, indicating whether adjustments or repairs are necessary.

Equipping yourself with these essential tools will facilitate effective maintenance, ensuring that the fuel delivery system operates smoothly and reliably.

Common Carburetor Problems and Solutions

Issues with fuel-air mixing components can lead to performance problems in various engines. Identifying these common malfunctions is essential for maintaining optimal functionality. This section outlines frequent challenges encountered and offers practical solutions for resolution.

Frequent Issues

- Fuel Leakage: This occurs when seals and gaskets deteriorate, causing gasoline to escape.

- Stalling Engine: Insufficient fuel delivery or incorrect air-to-fuel ratio can cause the engine to stop unexpectedly.

- Hard Starting: Problems with the flow of fuel can make ignition difficult, leading to frustration during startup.

- Uneven Idling: Fluctuations in idle speed may indicate blockages or malfunctions in the mixing chamber.

- Excessive Smoke: This can result from an overly rich mixture, leading to poor combustion and increased emissions.

Solutions

- Repairing Fuel Leakage: Replace damaged seals and gaskets. Regular inspections can prevent leaks before they occur.

- Fixing Stalling Issues: Check fuel lines for blockages and adjust the mixture settings for better performance.

- Improving Startup: Clean the fuel delivery system and ensure proper pump function to facilitate easier ignition.

- Stabilizing Idle: Clean or replace the jets and passages to ensure a smooth flow of fuel and air.

- Reducing Smoke Production: Adjust the air-fuel mixture to achieve the correct balance for combustion, and clean any carbon deposits.

Upgrading Carburetor Components for Performance

Enhancing the efficiency of fuel delivery systems can significantly boost engine output and responsiveness. By focusing on specific elements within these mechanisms, enthusiasts can achieve a more powerful and efficient operation. Improvements may involve modifying or replacing certain components to ensure optimal air-fuel mixtures, allowing for better combustion and increased horsepower.

One common approach is upgrading the flow capacity of the air intake. Utilizing high-performance filters and larger throttle bodies can lead to improved airflow, which is essential for maximizing power. Additionally, adjusting the jetting system allows for finer control over fuel delivery, ensuring that the engine receives the appropriate amount of fuel for varying conditions.

Another area for enhancement is the use of advanced materials in the construction of critical elements. Lightweight and durable materials can reduce weight and improve thermal management, leading to increased efficiency. Incorporating precision-engineered components can also result in better fit and function, minimizing potential leaks and losses in performance.

Lastly, tuning is a vital step in optimizing overall performance. Regular adjustments based on real-time data can ensure that the system operates at peak efficiency, adapting to changes in environment or driving conditions. This ongoing attention to detail can provide significant gains in performance and reliability over time.

Resources for Carburetor Repair and Maintenance

Maintaining the performance of an engine requires access to reliable information and tools. For those looking to enhance their skills in servicing fuel delivery systems, a variety of resources are available. These can guide enthusiasts and professionals alike through the intricacies of repair and upkeep, ensuring optimal functionality.

Online Forums and Communities: Engaging with fellow enthusiasts can provide valuable insights. Websites dedicated to automotive discussions often feature sections where individuals share their experiences, troubleshooting tips, and repair stories. Joining such platforms fosters a sense of community and enhances knowledge.

Instructional Videos: Visual learners benefit significantly from tutorial videos. Platforms like YouTube host countless channels focused on engine maintenance, offering step-by-step guides that demystify complex procedures. These resources can help users grasp techniques effectively and apply them confidently.

Repair Manuals: Comprehensive guides are essential for anyone involved in maintenance tasks. Reputable manuals provide detailed instructions, specifications, and troubleshooting information. These documents serve as invaluable references during the repair process, ensuring that all actions align with manufacturer recommendations.

Specialty Retailers: Stores that focus on automotive supplies often have knowledgeable staff who can assist with inquiries. Many also offer workshops or demonstrations on various servicing techniques. Utilizing these resources can enhance understanding and provide hands-on experience with different tools and methods.

Online Courses: For those seeking structured learning, numerous online platforms offer courses on automotive repair. These courses cover a wide range of topics, from basic maintenance to advanced troubleshooting, equipping participants with the skills necessary for effective servicing.

Leveraging these diverse resources will empower individuals to improve their technical expertise, ensuring efficient operation and longevity of their fuel systems.