In the realm of automotive enhancement, comprehending the intricate elements that contribute to an engine’s efficiency is essential. The various components that play a crucial role in optimizing fuel and air mixture can significantly impact performance. This section delves into the essential features that drive these systems and the relationships between their different elements.

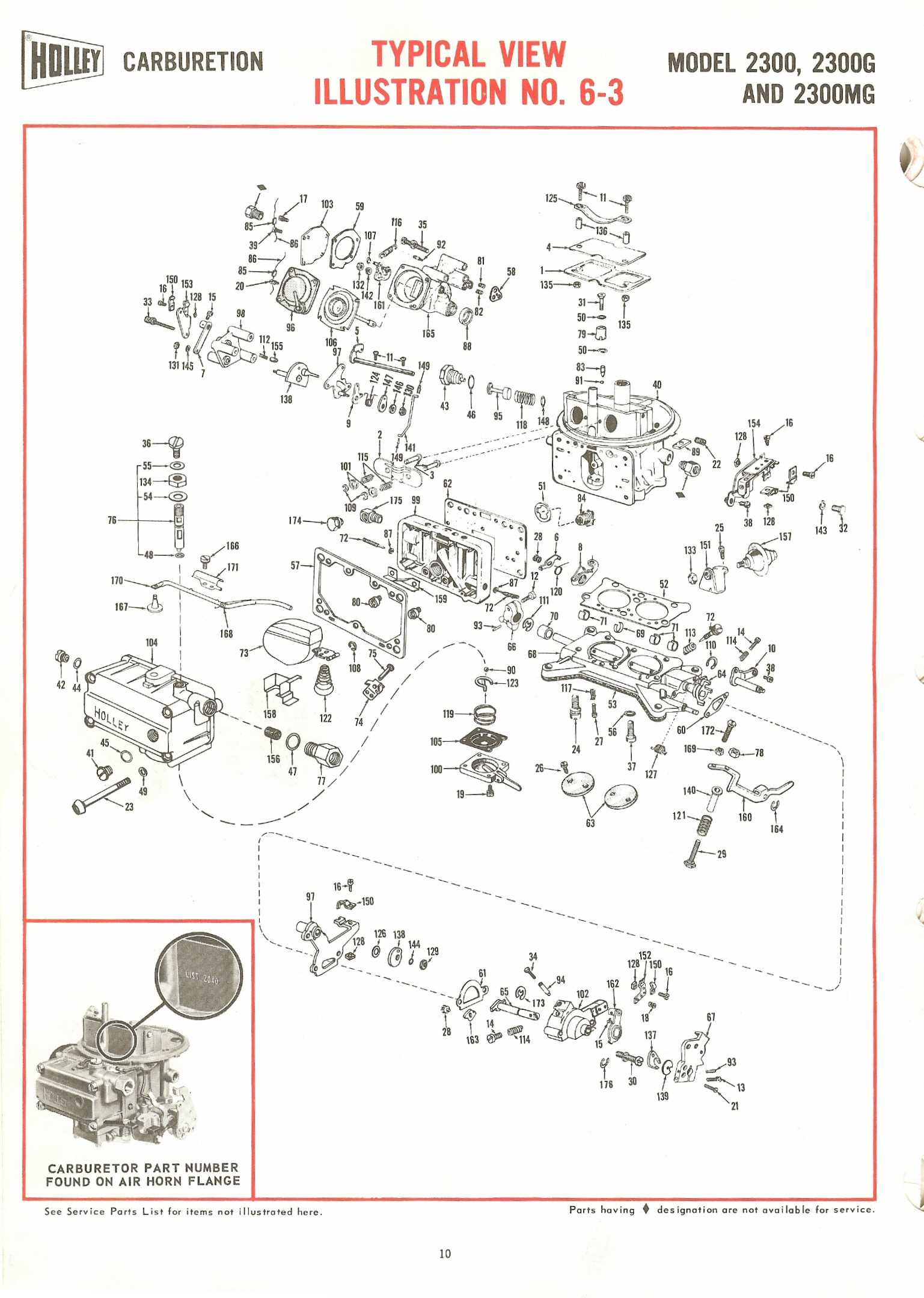

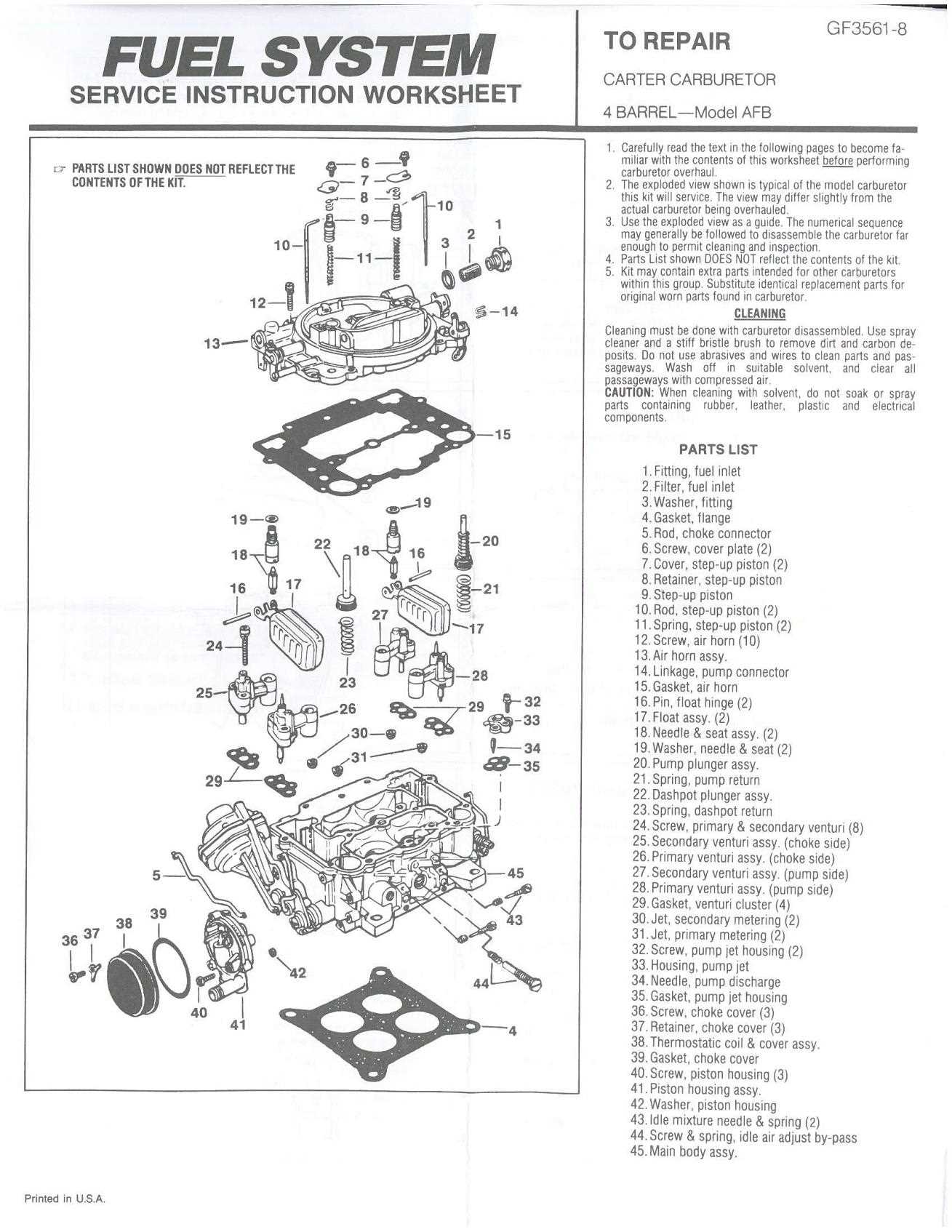

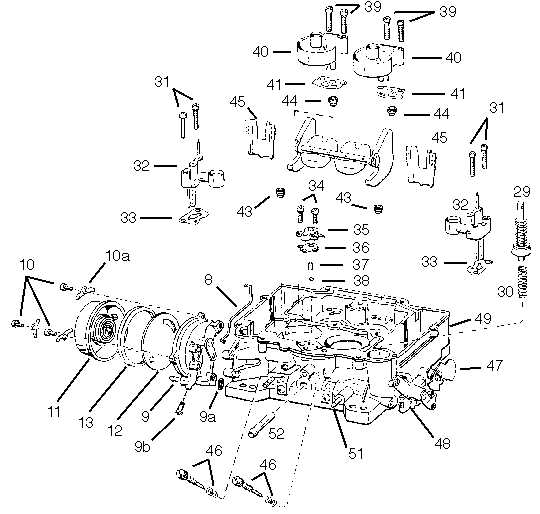

Visual aids are invaluable for grasping the complexity of these mechanisms. By examining a detailed representation of the structure, one can better appreciate how each segment interacts within the larger framework. Such illustrations serve not only as educational tools but also as guides for enthusiasts looking to enhance their knowledge or tackle repairs and modifications.

Whether you are a seasoned mechanic or a curious hobbyist, understanding these fundamental assemblies can lead to improved performance and efficiency. By familiarizing yourself with the layout and function of each piece, you can make informed decisions that will ultimately elevate your vehicle’s capabilities.

Edelbrock Carburetor Basics

This section explores the fundamental aspects of a key component in fuel delivery systems, focusing on its operation and significance. Understanding its design and functionality is essential for achieving optimal performance in various engine configurations.

At its core, this mechanism is responsible for mixing air and fuel in the correct proportions, ensuring efficient combustion. Key elements include the float assembly, throttle linkage, and metering system, each contributing to the overall efficiency and responsiveness of the engine.

Proper tuning and maintenance are crucial for maximizing performance. Adjustments to fuel mixture and airflow can greatly influence engine behavior, making knowledge of this assembly vital for enthusiasts and professionals alike.

Understanding Carburetor Functionality

At its core, the mechanism that blends air and fuel plays a crucial role in engine performance. By controlling the mixture, it ensures optimal combustion, which directly impacts efficiency and power output. The intricate design allows for precise adjustments, catering to various conditions and demands.

Key components work in harmony to achieve the desired mixture. The throttle body regulates airflow, while the fuel delivery system ensures the correct amount of liquid enters the combustion chamber. Understanding these interactions provides insight into the overall performance and tuning potential of the engine.

Moreover, maintenance and adjustments are essential for longevity and reliability. Regular checks and calibration can significantly enhance functionality, leading to smoother operation and better fuel economy. Delving into these aspects empowers enthusiasts and professionals alike to optimize their setups for ultimate performance.

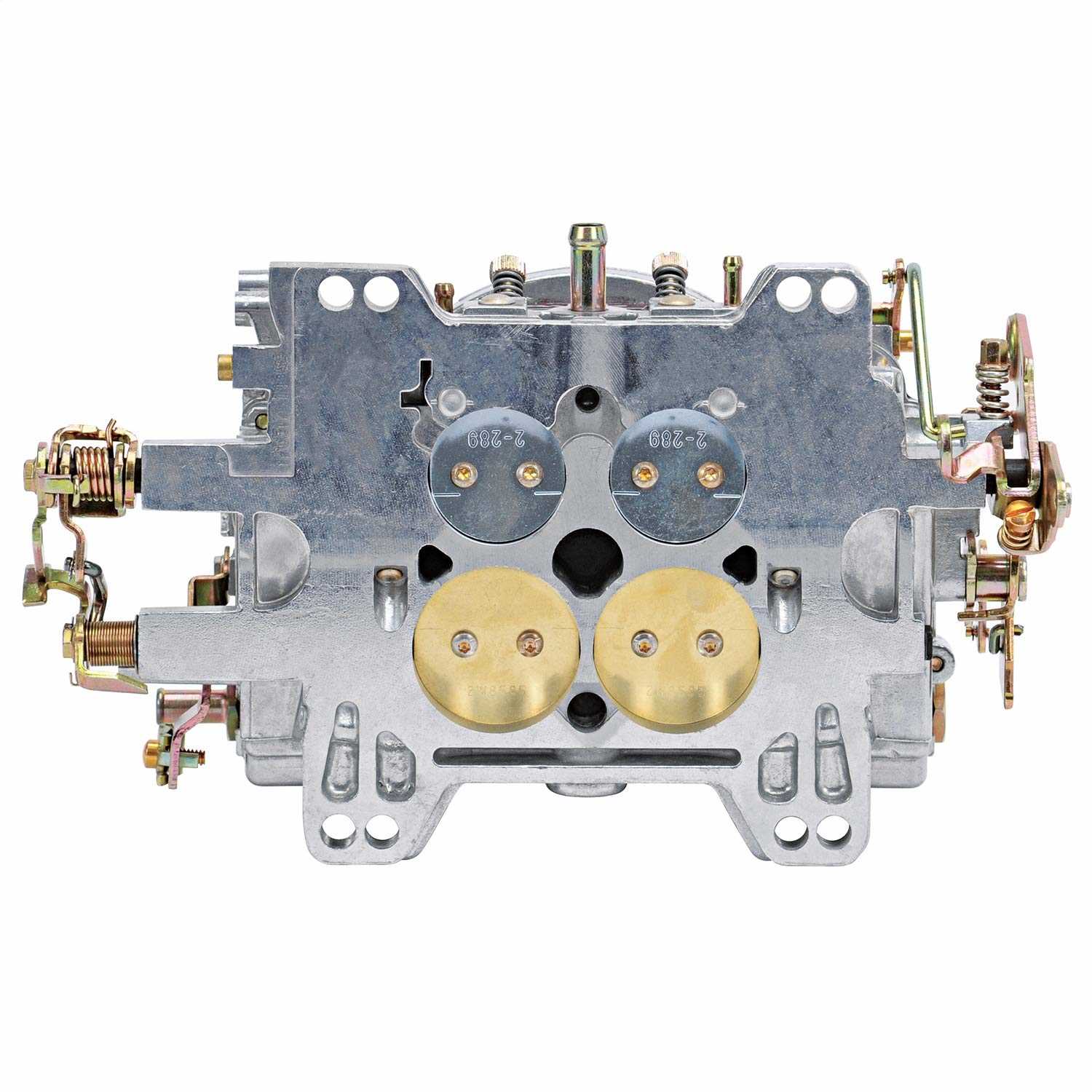

Key Components of Edelbrock Models

Understanding the essential elements of various performance induction systems can significantly enhance engine functionality and efficiency. Each model incorporates specific features that contribute to optimal air-fuel mixture delivery, ensuring reliable performance and adaptability to diverse driving conditions.

- Throttle Body: This critical component controls the airflow entering the engine, affecting acceleration and responsiveness.

- Venturi: The design of this section plays a vital role in creating a vacuum that draws in fuel, essential for maintaining the correct mixture.

- Float Chamber: This element regulates the fuel supply, ensuring consistent delivery regardless of engine demand.

- Fuel Inlet: This entry point connects to the fuel line, delivering necessary fuel to the system efficiently.

- Mixture Screws: These adjustable screws allow fine-tuning of the air-fuel mixture, optimizing performance based on driving conditions.

Familiarity with these components aids in proper maintenance and modification, contributing to enhanced vehicle performance. Each element works in harmony, creating a system that meets the demands of enthusiasts and everyday drivers alike.

Importance of Proper Tuning

Achieving optimal performance from an engine relies heavily on precise adjustments to its fuel delivery system. These adjustments play a critical role in ensuring that the air-fuel mixture is balanced, enabling the engine to operate efficiently and responsively. Neglecting this aspect can lead to a host of issues, including reduced power output, increased emissions, and decreased fuel efficiency.

Effective tuning not only enhances performance but also prolongs the lifespan of engine components. When the mixture is calibrated correctly, it minimizes wear and tear on vital parts, ultimately saving on costly repairs. Additionally, a well-tuned system can significantly improve throttle response, providing a more enjoyable driving experience.

Moreover, regular adjustments and fine-tuning can help identify underlying problems before they escalate. This proactive approach allows for timely interventions, ensuring that the engine runs smoothly and efficiently. In essence, proper calibration is not just a maintenance task; it is a vital investment in the overall health and performance of the vehicle.

Common Issues with Carburetors

Many enthusiasts encounter various challenges when dealing with fuel mixing systems. Understanding these common pitfalls can lead to improved performance and longevity of the engine.

Fuel Leaks: One of the most frequent problems is the presence of fuel leaks, which can occur due to worn seals or improper fittings. Addressing these leaks promptly is crucial for safety and efficiency.

Inefficient Fuel Mixture: An incorrect air-fuel ratio can lead to poor combustion, resulting in reduced power and increased emissions. Regular adjustments and checks can help maintain the ideal mix.

Clogged Jets: Over time, deposits can accumulate in the jets, restricting fuel flow. Cleaning or replacing these components is essential for optimal performance.

Starting Difficulties: Many users report issues with starting, often due to a faulty choke or incorrect adjustments. Ensuring that these mechanisms function properly can alleviate this frustration.

Erratic Idle: A rough or unstable idle can indicate several underlying issues, including vacuum leaks or improperly set adjustments. Diagnosing these problems can significantly enhance engine stability.

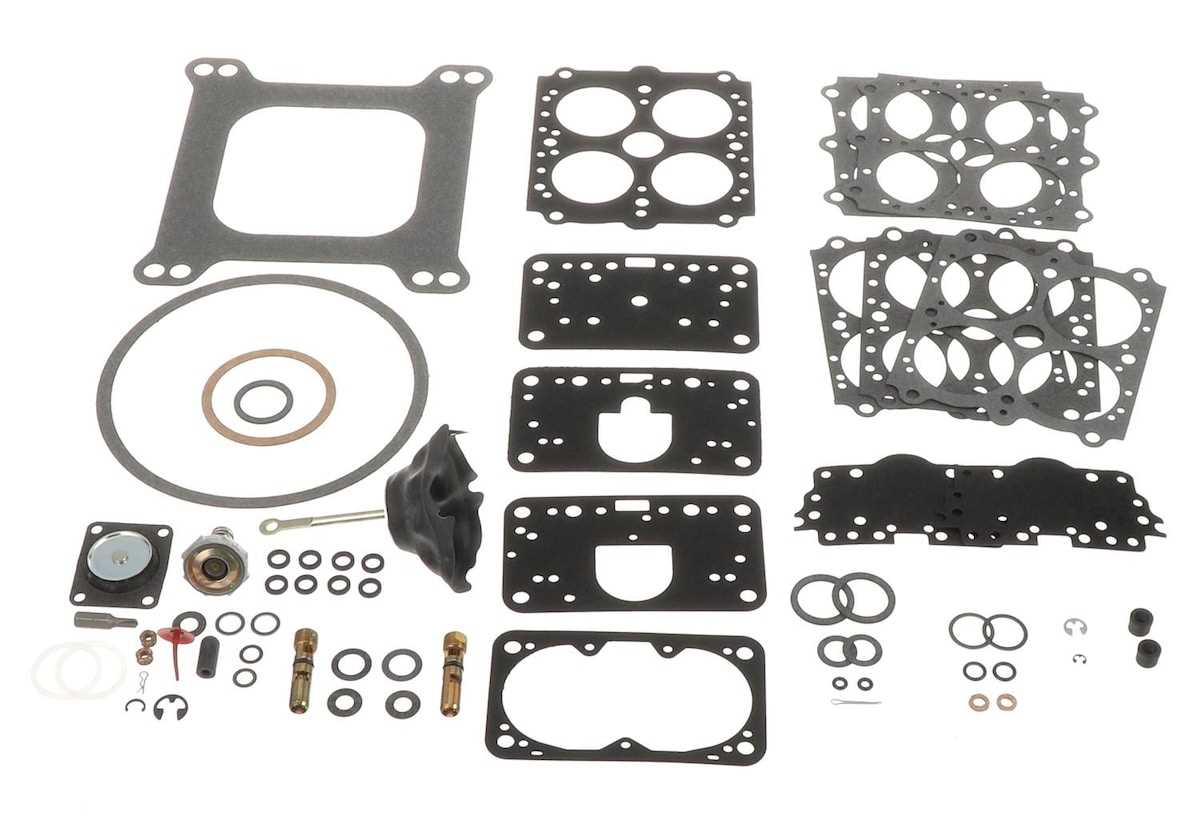

Maintenance Tips for Longevity

Ensuring the durability of your engine components requires regular upkeep and attention to detail. Following a structured maintenance routine can prevent issues and extend the life of vital systems.

Regular Cleaning

- Inspect and clean surfaces to remove dirt and debris.

- Use appropriate solvents to avoid damaging sensitive areas.

- Pay special attention to fuel pathways and air intakes.

Periodic Checks

- Examine seals and gaskets for wear and tear.

- Monitor performance and listen for unusual sounds.

- Replace any worn components promptly to avoid further damage.

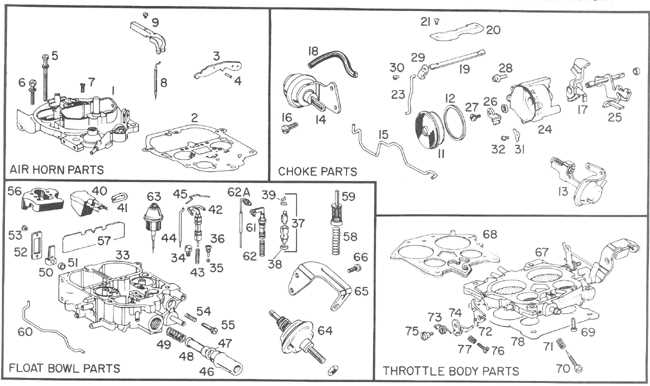

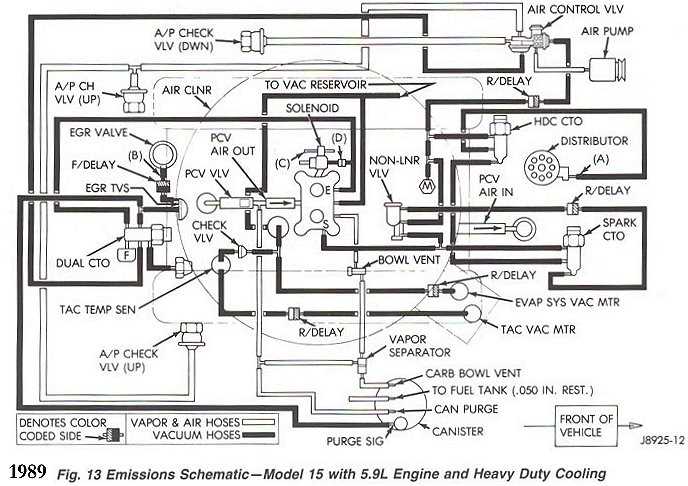

Visual Guide to Parts Diagram

This section aims to provide a comprehensive overview of the components that make up a specific mechanism. Understanding these elements is crucial for anyone looking to enhance their knowledge and skills in assembly or maintenance. Visual aids can greatly assist in identifying each piece and its function within the overall system.

Key Components Overview

Familiarity with the various elements is essential for effective management and repair. Below is a brief explanation of the primary components, along with their roles.

| Component Name | Description |

|---|---|

| Float Chamber | Maintains the fuel level and regulates the flow into the mixing area. |

| Venturi | Creates a pressure drop that draws fuel into the airstream for mixing. |

| Throttle Body | Controls the air and fuel mixture entering the combustion chamber. |

Importance of Each Element

Each part plays a vital role in ensuring optimal performance and efficiency. Recognizing their functions can help in troubleshooting and making informed adjustments.

Upgrading Your Carburetor System

Enhancing your fuel delivery system can significantly improve engine performance and efficiency. By focusing on key components and their interactions, you can unlock greater power and responsiveness from your vehicle. This process often involves selecting high-quality alternatives and making precise adjustments for optimal functionality.

Choosing the Right Components: Start by evaluating the current setup. Consider upgrading to a more efficient model that better matches your engine’s requirements. This can lead to improved airflow and fuel atomization, essential for maximizing output.

Tuning for Performance: After selecting new elements, precise tuning is vital. Adjustments to the air-fuel mixture and idle speed can make a significant difference. Utilizing specialized tools or professional assistance can help achieve the ultimate balance.

Maintaining Your System: Regular maintenance is crucial for longevity and performance. Periodically inspect and clean your setup to prevent build-up and ensure smooth operation. A well-maintained system not only performs better but also enhances reliability on the road.

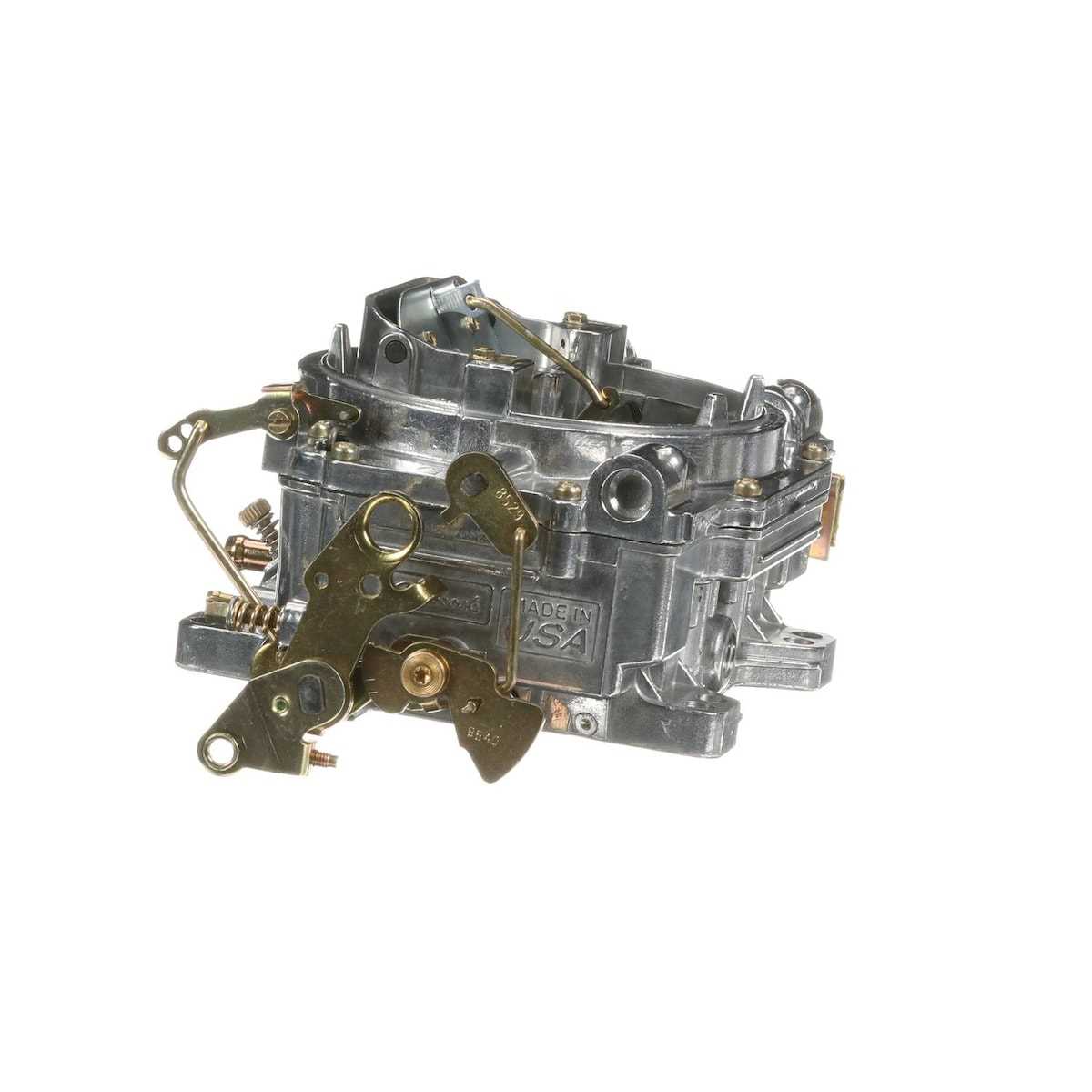

Comparing Different Edelbrock Models

When exploring the various models available from a renowned manufacturer, it becomes essential to understand the unique features and specifications each version offers. These variations cater to distinct performance needs and engine configurations, making it crucial for enthusiasts and professionals alike to choose the right one for their applications.

Performance and Features

Each model showcases a range of capabilities, from fuel efficiency to power output. Some are designed for optimal street performance, delivering smooth acceleration and responsiveness, while others focus on high-performance applications, maximizing horsepower and torque. Understanding the differences in airflow design, tuning options, and adaptability to engine types can significantly impact the overall driving experience.

Application Suitability

Choosing the right model also involves considering the specific use case. Whether for classic cars, racing applications, or daily drivers, each variant presents its own advantages. Factors such as installation ease, maintenance requirements, and compatibility with existing engine setups play pivotal roles in the decision-making process. By assessing these criteria, one can make a more informed choice that aligns with their performance goals.

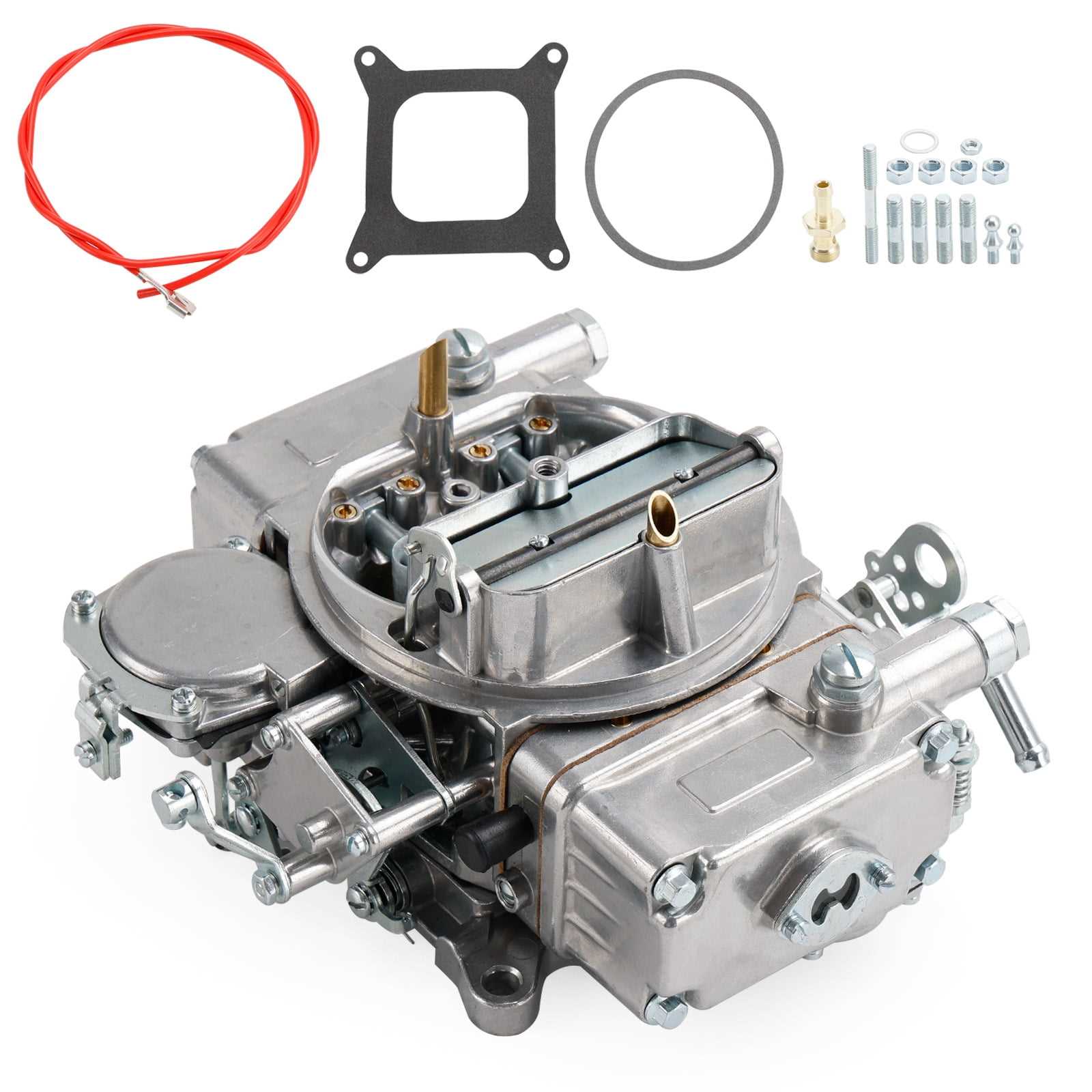

Installation Process Explained

Understanding the steps involved in setting up your new fuel delivery system is crucial for achieving optimal performance. Each stage plays a vital role in ensuring that everything functions smoothly and efficiently. Proper installation not only enhances performance but also extends the longevity of your components.

Preparation Steps

Before you begin, gather all necessary tools and materials. Ensure the workspace is clean and well-lit. Read through the manufacturer’s instructions thoroughly to familiarize yourself with the components. Taking time to prepare will lead to a more seamless installation experience.

Step-by-Step Installation

Start by securely mounting the unit, ensuring all connections are tight. Follow the outlined sequence for attaching fuel lines and adjusting settings. Double-check every connection to avoid leaks. After installation, take a moment to inspect everything carefully and conduct a test run to confirm that the setup is functioning as intended. Attention to detail during this process will yield the best results.

Performance Enhancements and Modifications

Improving the efficiency and power of your engine can be an exciting journey for enthusiasts. By exploring various upgrades, you can unlock greater performance potential, leading to a more thrilling driving experience. This section will discuss several strategies and components that can contribute to enhanced performance.

- Intake Modifications:

- Upgrading the air intake system allows for improved airflow, enhancing combustion efficiency.

- Installing high-performance filters can increase airflow and reduce restrictions.

- Fuel Delivery Improvements:

- Utilizing larger fuel injectors ensures the engine receives an adequate fuel supply, especially under high load.

- Adjusting the fuel pressure regulator can optimize fuel delivery based on the engine’s requirements.

- Jetting Adjustments:

- Fine-tuning the jets can significantly impact the air-fuel mixture, allowing for better performance and responsiveness.

- Experimenting with different jet sizes can help achieve optimal tuning for various driving conditions.

- Throttle Response Enhancements:

- Upgrading the throttle linkage can improve response times and overall drivability.

- Consider a high-performance throttle body for increased airflow and quicker acceleration.

- Exhaust System Upgrades:

- Replacing the exhaust manifold with a performance variant can reduce backpressure and enhance exhaust flow.

- Installing a high-flow muffler can improve sound while also boosting performance.

Each of these enhancements can contribute to a more powerful and efficient engine. Careful consideration and tuning will ensure that these modifications work harmoniously together, resulting in a remarkable improvement in performance.