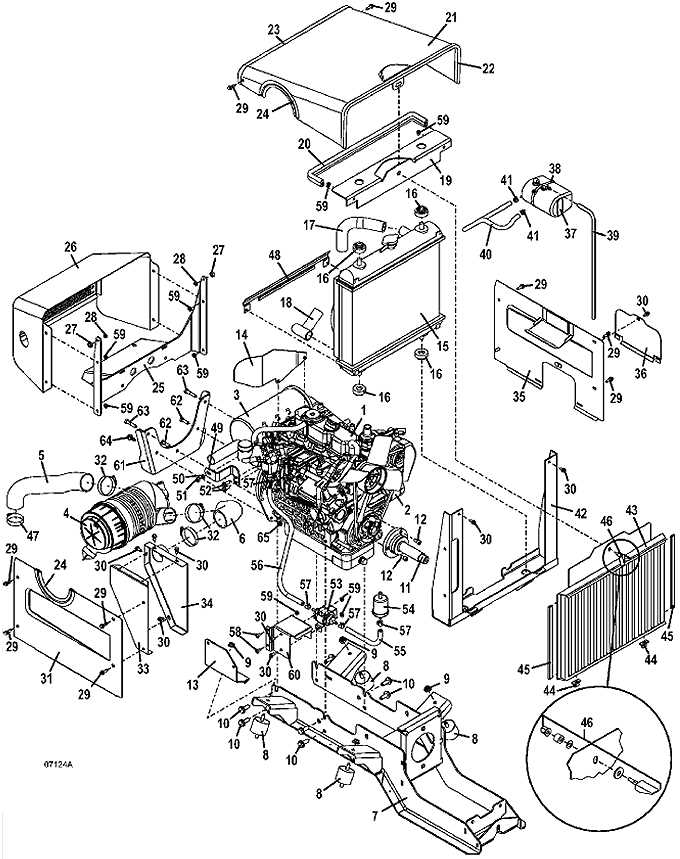

The efficiency of small engines relies heavily on the intricate systems that manage fuel delivery. A well-functioning mechanism ensures optimal performance, enabling these machines to operate smoothly and reliably. Understanding the various components that contribute to this system is essential for maintenance and troubleshooting.

In this section, we will explore the essential elements involved in the fuel management process. Each component plays a critical role, from regulating the air-fuel mixture to facilitating combustion. Familiarizing yourself with these features not only enhances your knowledge but also empowers you to address potential issues effectively.

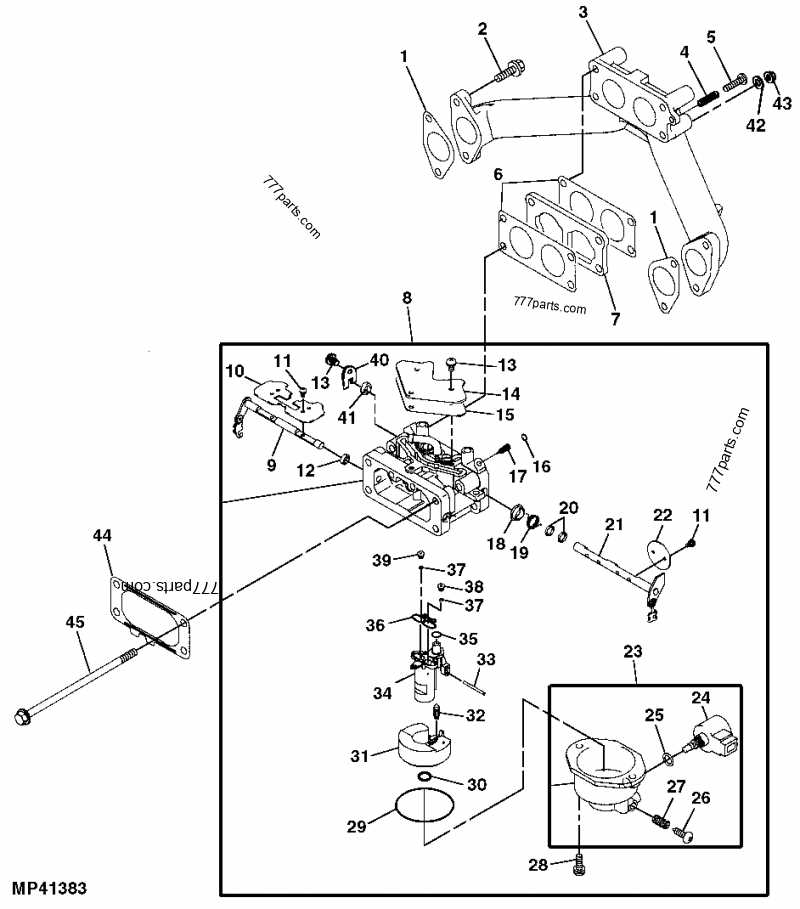

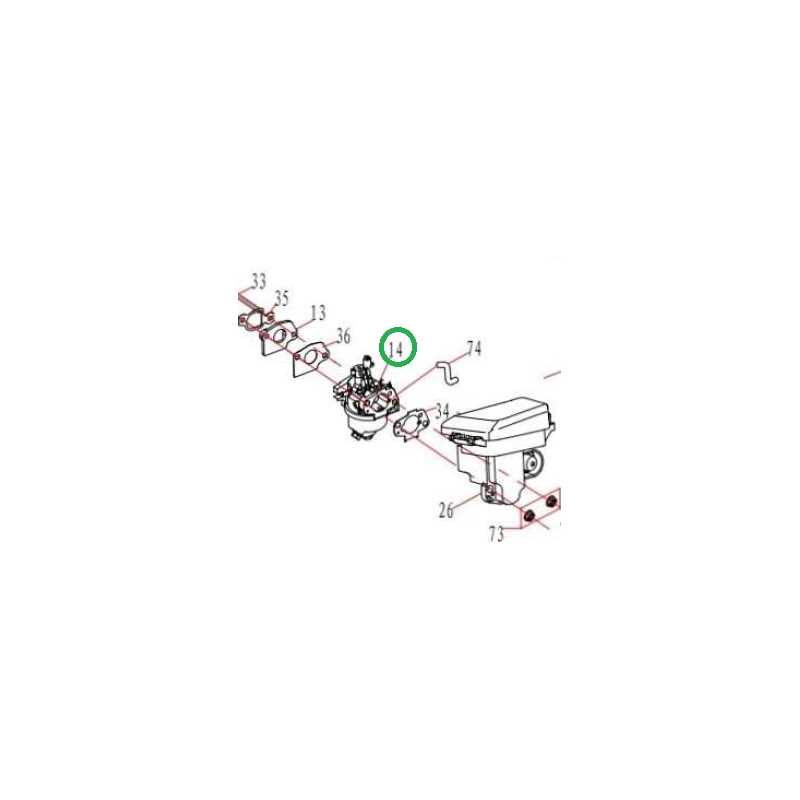

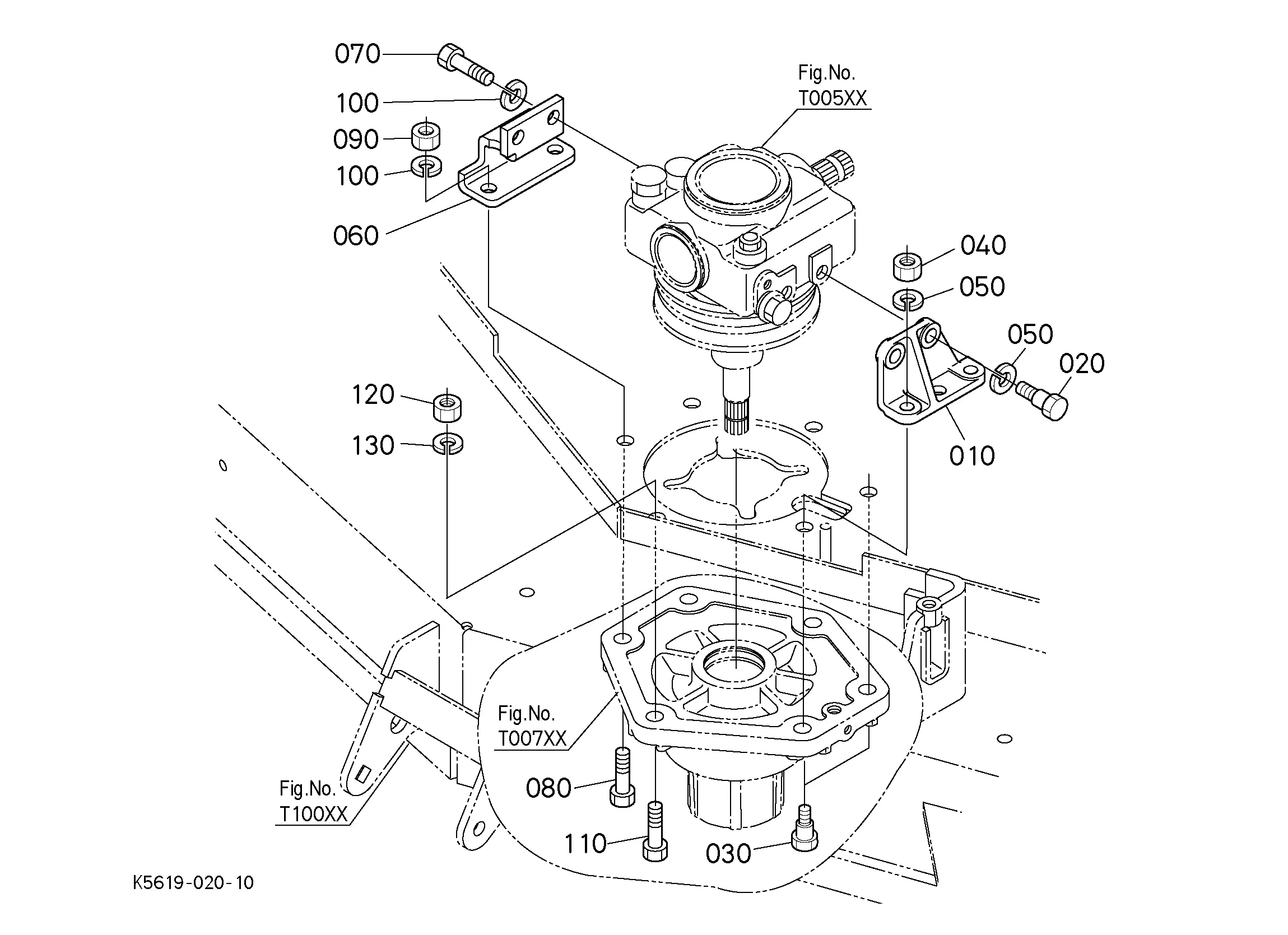

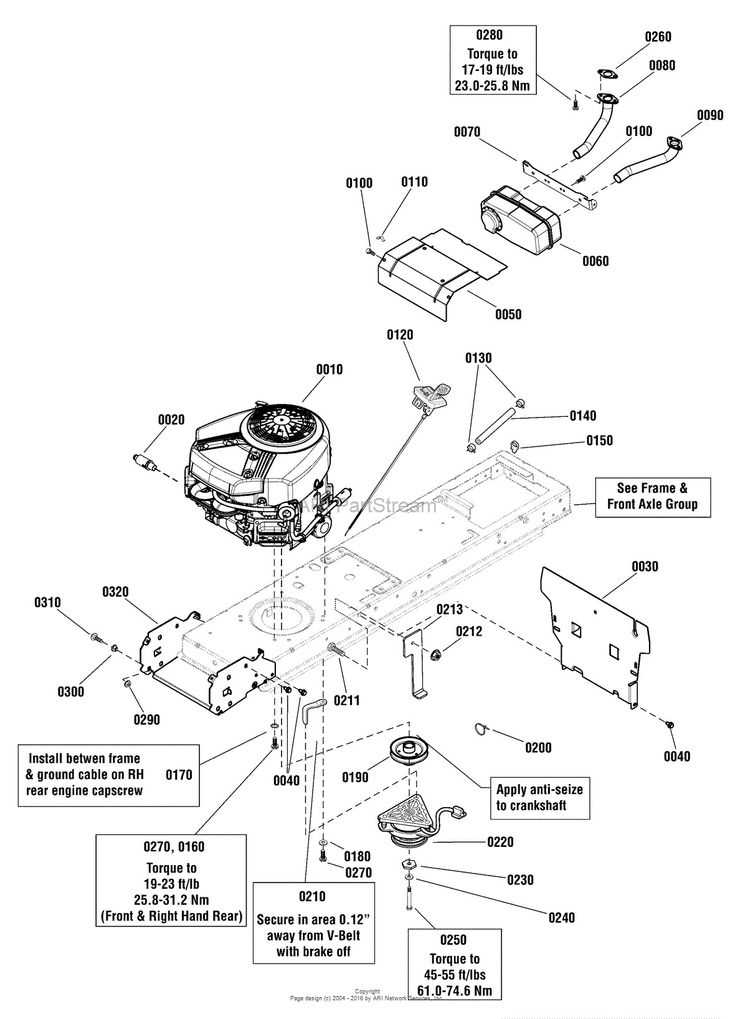

By examining a detailed visual representation of these components, you can gain insight into their interactions and functionality. This understanding is invaluable for both enthusiasts and professionals alike, as it lays the groundwork for more effective repairs and optimizations.

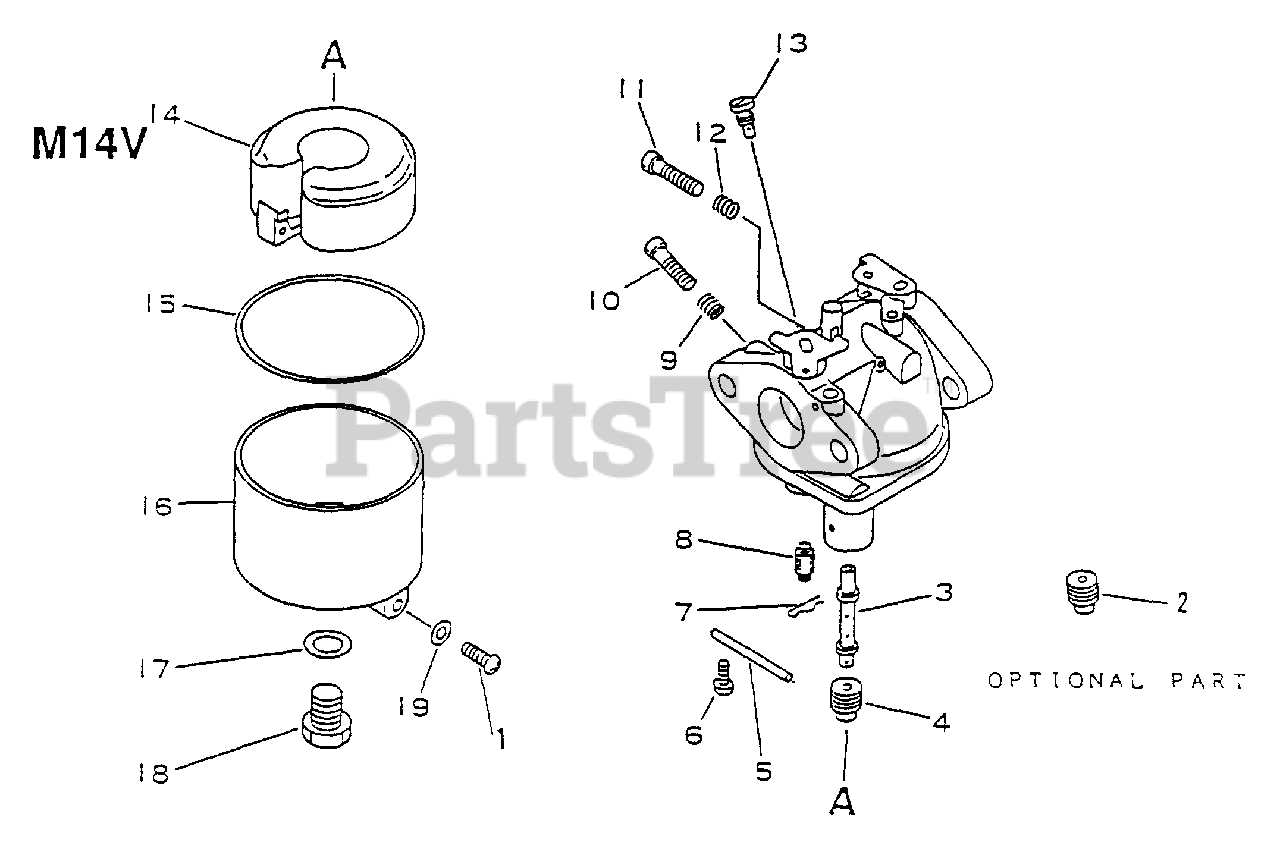

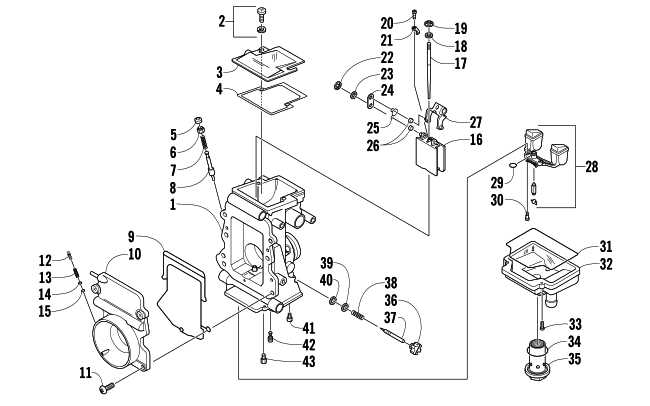

Lawn Mower Carburetor Overview

This section provides a comprehensive understanding of the essential component responsible for mixing air and fuel to facilitate combustion in various outdoor equipment. Its design plays a crucial role in engine performance, efficiency, and overall functionality.

Key Functions

The primary role of this mechanism is to ensure the correct ratio of air to fuel. By accurately mixing these elements, it enables optimal combustion, which leads to improved power output and reduced emissions. A well-functioning assembly contributes significantly to the longevity of the equipment.

Common Components

| Component | Function |

|---|---|

| Choke | Regulates airflow for easier starting |

| Float | Maintains fuel level within the chamber |

| Jet | Controls the flow of fuel into the airflow |

| Throttle | Adjusts the engine speed and power |

Essential Components of Carburetors

The effective operation of fuel delivery systems relies on a series of critical elements that work harmoniously to optimize performance. Understanding these components is vital for maintaining efficiency and ensuring proper functionality in any engine.

One key element is the chamber, which facilitates the mixing of air and fuel in precise proportions. This mixture is crucial for combustion, affecting the engine’s power output and efficiency. Another important feature is the throttle valve, which regulates the airflow and, consequently, the engine’s speed and power levels.

Additionally, the float assembly plays a significant role in maintaining the correct fuel level within the system, preventing overflow and ensuring a consistent supply to the mixing chamber. Moreover, the adjustment screws allow for fine-tuning of the air-fuel mixture, enabling optimal performance across various conditions.

Lastly, the gaskets and seals ensure that all components remain airtight, preventing leaks that could disrupt the delicate balance necessary for efficient operation. Each of these components is essential, and their proper functioning is critical for the overall success of the engine’s performance.

How Carburetors Function in Mowers

In small engines, the process of mixing fuel with air is crucial for efficient operation. This blending creates a combustible mixture that powers the engine, enabling it to perform various tasks. Understanding this mechanism reveals the essential role played by specific components within the system.

The primary function of this assembly is to draw in air and combine it with liquid fuel. As air flows through, it creates a vacuum that pulls fuel from a reservoir. This mixture then enters the combustion chamber, where ignition occurs. The ratio of air to fuel is vital, as it directly affects the engine’s performance and efficiency.

Moreover, the system is equipped with various elements that regulate the flow of air and fuel, ensuring optimal performance under different conditions. Adjustments to these components allow for modifications in the mixture, catering to factors such as temperature and load. This adaptability is key to maintaining smooth operation and longevity.

Ultimately, the effectiveness of this mechanism hinges on its ability to maintain a precise balance, ensuring that the engine runs smoothly and efficiently, delivering reliable power when needed.

Identifying Common Carburetor Issues

Understanding the common problems associated with fuel mixing systems is crucial for efficient engine performance. These mechanisms play a vital role in delivering the right fuel-air mixture, and any malfunction can lead to a host of operational issues. By recognizing the signs of trouble, users can take proactive measures to restore functionality.

Signs of Malfunction

- Difficulty starting the engine

- Unstable idle or fluctuating RPMs

- Excessive fuel consumption

- Black smoke from the exhaust

- Unusual sounds during operation

Troubleshooting Steps

- Check the fuel supply for contamination or low levels.

- Inspect for clogged passages or jets within the system.

- Examine seals and gaskets for wear or damage.

- Test for proper float level and adjustments.

- Ensure all connections are secure and free from leaks.

By staying vigilant and conducting regular checks, users can mitigate many of these issues and maintain optimal performance.

Tools for Carburetor Maintenance

Proper upkeep of the fuel system components is essential for optimal performance and longevity. A variety of tools are necessary to ensure thorough cleaning and adjustments, allowing for smooth operation and efficiency. Understanding which instruments to utilize can greatly simplify the maintenance process.

Essential Tools

To effectively maintain the fuel system, certain tools are indispensable. Here’s a list of the primary instruments you’ll need:

| Tool | Purpose |

|---|---|

| Socket Set | To remove and tighten fasteners securely. |

| Cleaning Brush | To remove debris and buildup from components. |

| Screwdriver Set | For adjusting screws and securing parts. |

| Fuel System Cleaner | To dissolve gunk and improve flow. |

| Multimeter | To check electrical components and ensure proper functioning. |

Additional Tools

In addition to the essentials, several supplementary tools can enhance your maintenance efforts:

| Tool | Purpose |

|---|---|

| Torque Wrench | To ensure fasteners are tightened to manufacturer specifications. |

| Vacuum Gauge | To assess the performance of the fuel system. |

| Shop Towels | For cleaning and wiping down components. |

| Safety Goggles | To protect eyes during cleaning and repairs. |

| Gloves | To keep hands clean and safe from chemicals. |

Step-by-Step Carburetor Cleaning Guide

Maintaining optimal performance in your engine requires periodic attention to its fuel delivery system. A thorough cleaning can restore efficiency and prevent future issues. This guide will walk you through a straightforward process to ensure your mechanism operates smoothly.

Gather Necessary Supplies

Before starting, collect the following tools and materials: cleaning solution, brushes, compressed air, and protective gloves. Having everything ready will make the process more efficient.

Step-by-Step Cleaning Process

1. Disassembly: Carefully remove the assembly from the engine. Take note of how each component fits together for easier reassembly.

2. Soak Components: Place the disassembled parts in a suitable cleaning solution to dissolve built-up grime.

3. Scrubbing: Use brushes to clean any stubborn residue. Ensure all surfaces are thoroughly scrubbed for a complete clean.

4. Rinsing: Rinse the components with clean water to remove any remaining cleaning solution.

5. Drying: Use compressed air to dry all parts thoroughly, ensuring no moisture remains that could lead to rust.

6. Reassembly: Once everything is dry, carefully put the components back together, following the notes you made earlier.

7. Testing: Reinstall the assembly into the engine and perform a test run to ensure everything functions correctly.

Regular maintenance of your fuel delivery system will enhance performance and extend the lifespan of your engine. Follow these steps to keep everything running smoothly.

Understanding Carburetor Adjustments

Fine-tuning the fuel-air mixture is crucial for optimal engine performance. Adjustments can enhance efficiency, reduce emissions, and improve overall functionality. Familiarity with these modifications allows users to achieve smoother operation and longevity of their machinery.

Importance of Proper Settings

Achieving the right balance between fuel and air is essential for preventing issues such as stalling or rough idling. Incorrect configurations can lead to excessive consumption or engine damage. Regular checks and adjustments help maintain peak performance, ensuring that equipment runs reliably.

Common Adjustment Procedures

Typically, adjustments involve altering screws or valves that control the mixture and idle speed. Understanding the specific mechanisms and their impacts allows for precise tuning. Each adjustment can result in significant changes, making it essential to follow guidelines carefully for the best outcomes.

Fuel Types and Carburetor Performance

The selection of fuel significantly impacts the efficiency and functionality of engine systems. Various fuel compositions can lead to different operational characteristics, affecting everything from combustion efficiency to overall power output. Understanding these differences is crucial for optimizing performance and ensuring longevity.

Types of Fuels

- Regular Gasoline: A common choice for many engines, it provides a balance between cost and performance.

- Premium Gasoline: Often contains a higher octane rating, which can enhance power in high-performance engines.

- Ethanol-blended Fuels: Typically mixed with gasoline, these can reduce emissions but may also cause issues with moisture absorption.

- Diesel Fuel: Used in compression ignition engines, it offers excellent fuel economy and torque.

- Alternative Fuels: Options like propane and natural gas are gaining popularity for their environmental benefits.

Impact on Performance

The choice of fuel not only influences the efficiency of combustion but also affects the maintenance and tuning requirements of the system. Here are some key considerations:

- Combustion Efficiency: Fuels with higher octane ratings can resist knocking, allowing for more aggressive tuning.

- Fuel System Compatibility: Some blends can cause deterioration of rubber components, requiring more frequent replacements.

- Energy Density: Fuels with higher energy content provide better power output, crucial for demanding applications.

- Emissions: Certain fuels produce fewer pollutants, aligning with environmental regulations.

In conclusion, understanding the relationship between fuel types and engine performance is essential for achieving optimal functionality and reliability. Making informed choices regarding fuel can lead to enhanced performance and reduced wear on engine components.

Signs of a Failing Carburetor

Recognizing the early indicators of a malfunctioning fuel delivery system is crucial for maintaining optimal engine performance. Various symptoms can signal that the mechanism is struggling, potentially leading to further complications if not addressed promptly.

| Symptom | Description |

|---|---|

| Hard Starting | The engine may require multiple attempts to start or may not start at all, indicating issues with fuel flow. |

| Irregular Idling | The engine might idle roughly or fluctuate, suggesting inconsistent fuel delivery. |

| Power Loss | Reduced acceleration or difficulty maintaining speed can point to inadequate fuel mixture. |

| Excessive Smoke | Unusual amounts of smoke from the exhaust may indicate a rich fuel mixture or improper combustion. |

| Fuel Leaks | Visible leaks around the system may signal damage or wear, leading to potential safety hazards. |

Replacing Carburetor Parts: What to Know

Maintaining the functionality of essential engine components is crucial for optimal performance. When the time comes to replace certain elements, understanding the process can greatly enhance efficiency and longevity. This guide outlines key considerations to ensure a smooth replacement experience.

Understanding the Components

Before diving into replacements, it’s important to familiarize yourself with the individual elements involved. Recognizing how each piece contributes to overall operation will aid in effective troubleshooting and installation. Here are common components that may require attention:

- Gaskets

- Needles

- Floats

- Jets

- Choke mechanisms

Steps for Replacement

To ensure successful replacement, follow these essential steps:

- Gather necessary tools and new components.

- Disconnect the power source to ensure safety.

- Carefully remove the existing element, noting its orientation and connection points.

- Install the new component, ensuring a secure fit.

- Reconnect everything and test for proper operation.

By adhering to these guidelines, you’ll not only enhance performance but also prolong the life of your equipment. Proper care and timely replacements are key to maintaining efficiency and functionality.

Differences Between Carburetor Models

Understanding the variations among different fuel delivery systems is crucial for effective maintenance and repair. Each design serves a specific purpose, resulting in unique characteristics that influence performance, efficiency, and compatibility with various engines.

Construction Materials: One of the primary distinctions lies in the materials used. Some systems are crafted from lightweight plastic, while others utilize durable metal components. This choice affects durability, heat resistance, and overall weight.

Adjustment Mechanisms: Different models also feature varying adjustment methods. Some systems allow for manual tuning, enabling users to optimize fuel-air mixtures based on specific conditions. Others may incorporate automatic adjustments, which provide convenience but can limit customization.

Design Complexity: The complexity of internal structures can significantly vary. Simpler designs may have fewer components, making them easier to service, while more intricate systems can enhance performance but require specialized knowledge for repairs.

Fuel Efficiency: Variations in design often lead to differences in fuel consumption. Some configurations are engineered for higher efficiency, reducing waste and promoting longer operation times, which is essential for users aiming to minimize costs.

Compatibility: Lastly, not all systems are universally compatible with every engine type. Understanding these distinctions is vital for selecting the right model, ensuring optimal performance and reliability across various applications.

Safety Precautions for Carburetor Work

When engaging in maintenance activities involving engine components, it is essential to prioritize safety to prevent accidents and ensure proper functionality. Familiarity with the tools and materials used, as well as adherence to safety guidelines, can significantly mitigate risks associated with this type of work.

Personal Protective Equipment

Before starting any task, equip yourself with appropriate personal protective equipment (PPE). This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges and chemicals, and a mask if working with hazardous substances. Ensuring that you have the right gear is crucial for your safety.

Work Environment Considerations

Always perform maintenance in a well-ventilated area to avoid inhaling harmful fumes. Keep your workspace organized and free from clutter to minimize the risk of slips and falls. Additionally, ensure that all tools are in good condition and stored properly after use. Being mindful of your environment can prevent accidents and promote efficiency.

Finding Replacement Parts Online

When it comes to maintaining outdoor equipment, sourcing the right components can often be a daunting task. Fortunately, the internet provides a wealth of resources to help enthusiasts locate the necessary items to ensure their machines run smoothly. With just a few clicks, you can explore various platforms that specialize in providing access to a wide array of essential elements for your equipment.

One effective strategy is to utilize specific search terms related to your needs. By including the make and model of your device, along with descriptions of the components you require, you increase the likelihood of finding exactly what you need. Additionally, visiting forums and community groups dedicated to similar equipment can offer valuable insights and recommendations for reputable online vendors.

Moreover, consider checking out reviews of online retailers to gauge the quality of their offerings and customer service. This can save you time and money, ensuring you receive durable and reliable replacements. Many sites also provide detailed specifications and compatibility information, helping you make informed decisions before completing your purchase.

Finally, don’t overlook the benefits of comparing prices across multiple platforms. This can help you find competitive deals and avoid overspending. By taking the time to research and evaluate your options, you can confidently secure the components necessary to keep your equipment performing at its best.