In the world of machinery, comprehending the intricacies of mechanical systems is essential for optimal performance. Each machine consists of numerous elements that work together harmoniously to achieve specific functions. A clear understanding of these components can greatly enhance maintenance and repair efficiency.

Exploring the layout of these elements provides valuable insights into their interconnections and roles. By examining a structured representation, operators and technicians can easily identify critical parts, facilitating timely interventions and minimizing downtime. This knowledge not only aids in troubleshooting but also promotes informed decision-making regarding upgrades and replacements.

Furthermore, grasping the specifics of equipment configurations enables users to maximize the lifespan of their machinery. Familiarity with individual pieces and their functionalities empowers professionals to conduct routine inspections and preventative maintenance effectively. Ultimately, a comprehensive overview of the system’s architecture is a key factor in ensuring operational excellence.

Understanding Case 1835b Components

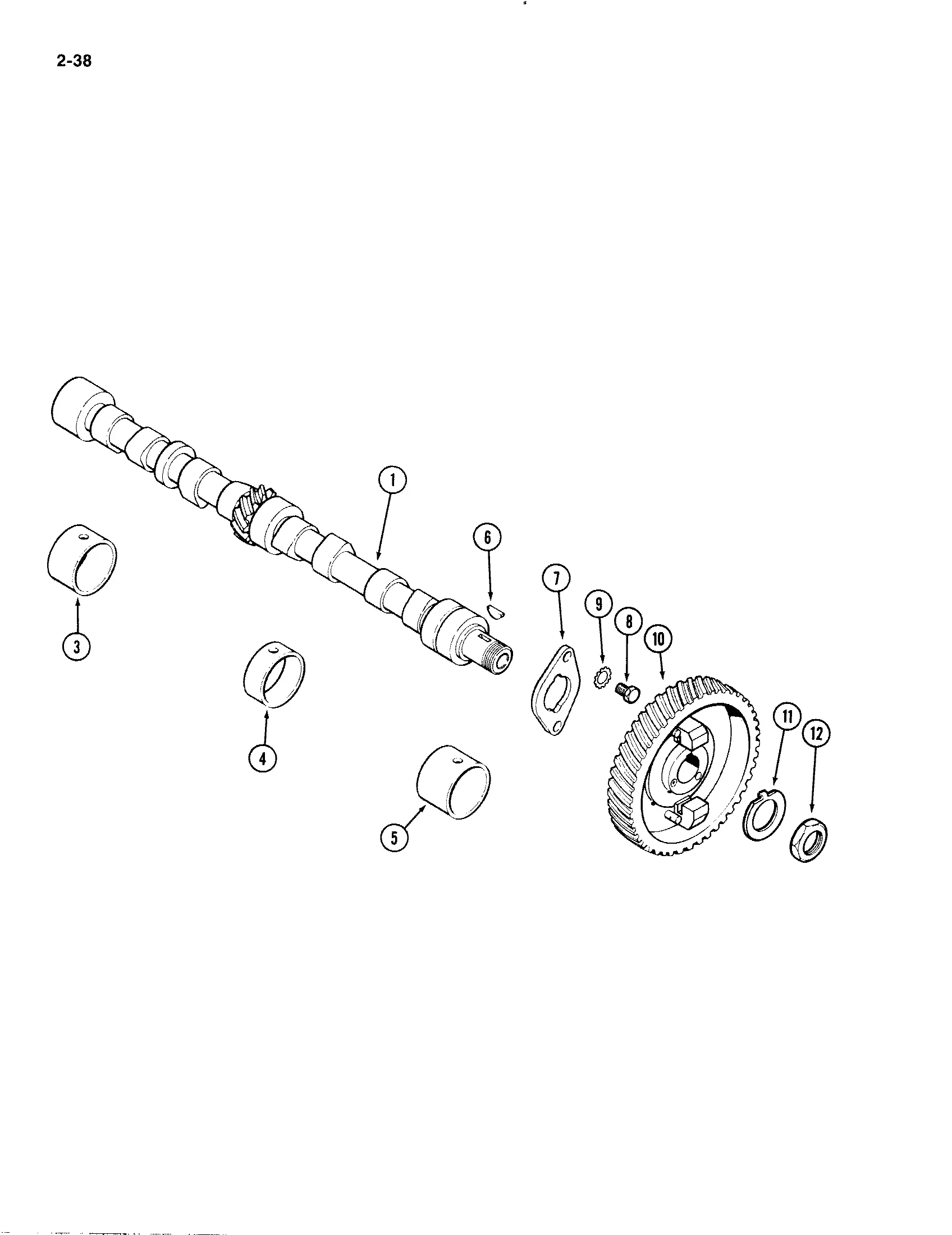

In any mechanical system, the intricate interplay of various elements is crucial for optimal performance. A thorough grasp of these components not only enhances maintenance practices but also improves overall functionality. This section delves into the essential elements that contribute to the efficiency and reliability of a particular model.

Key Elements to Consider

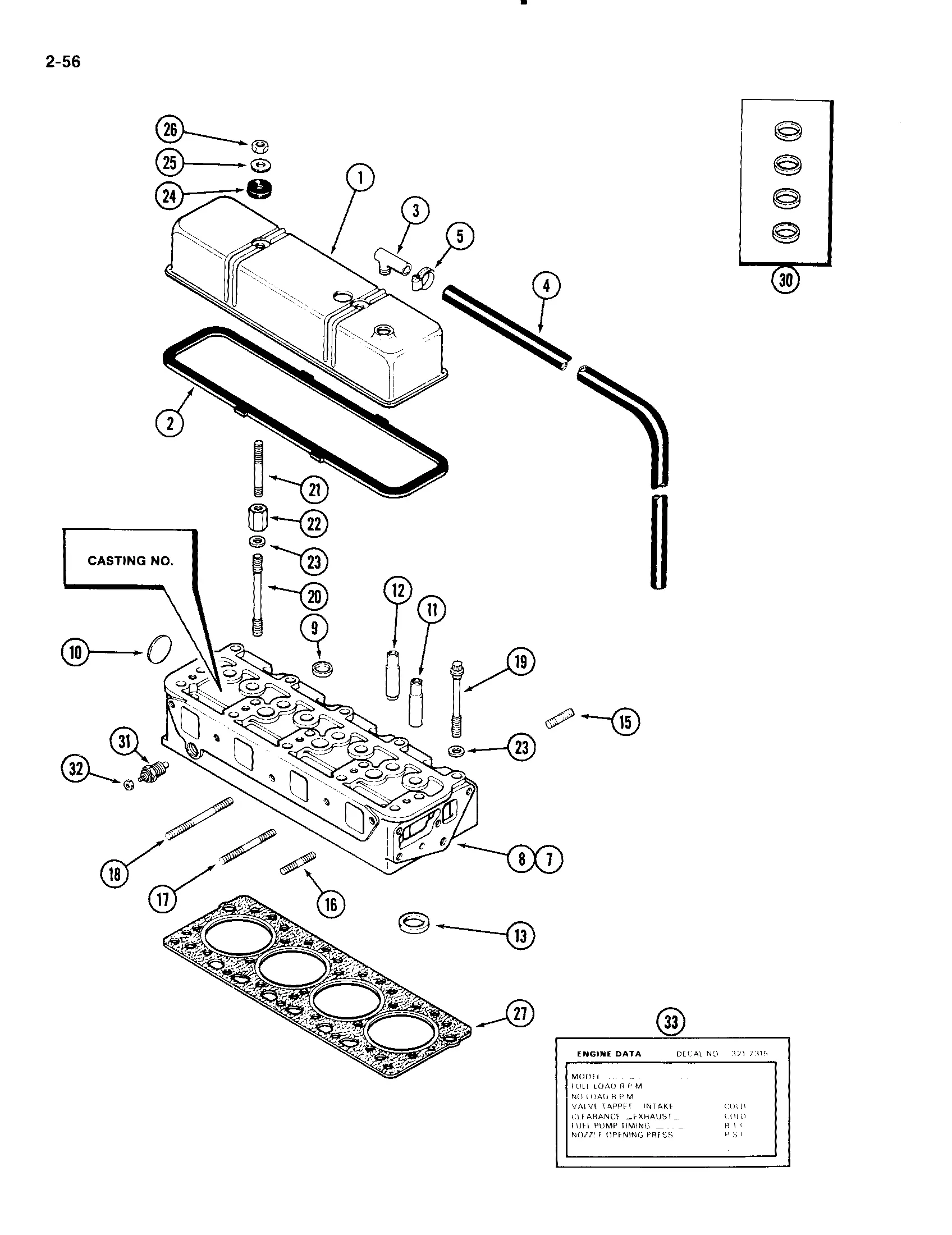

- Engine Assembly

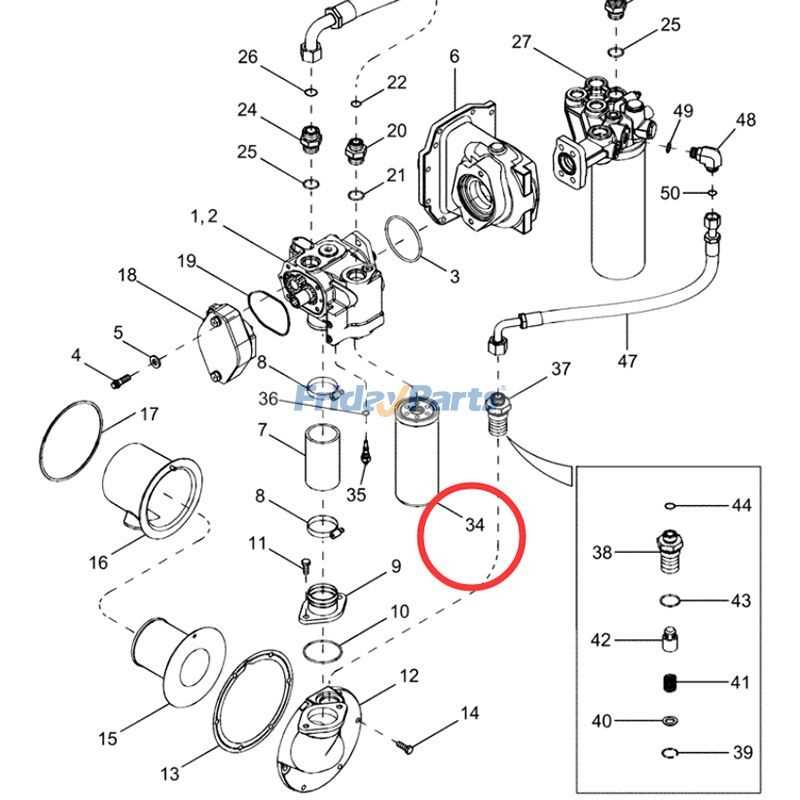

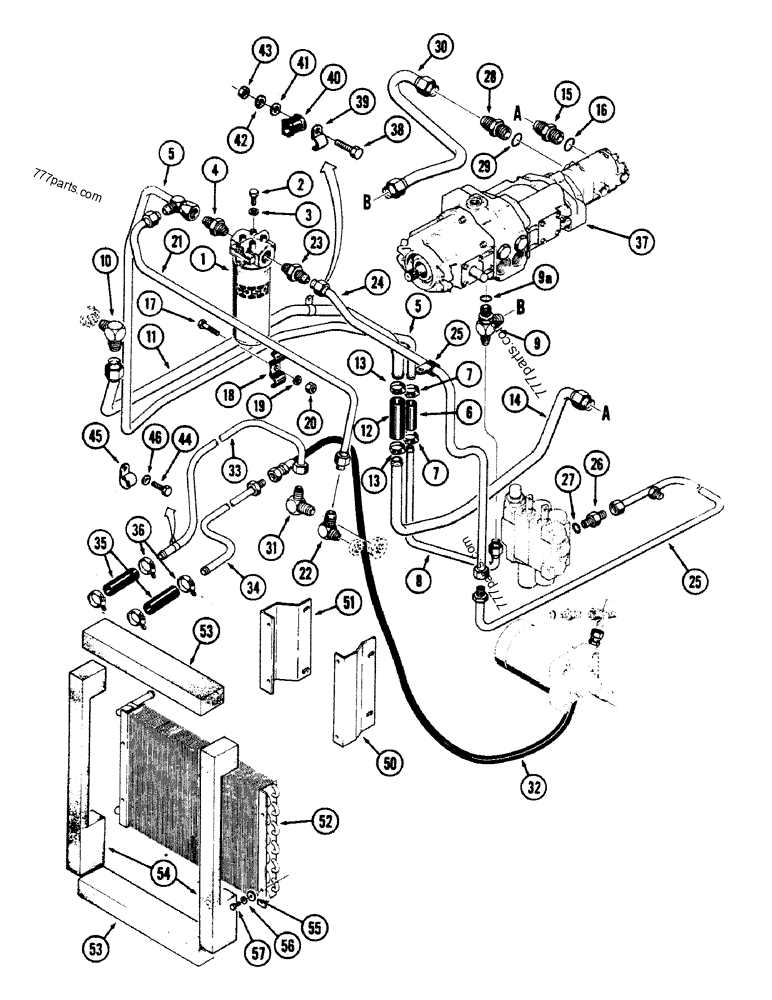

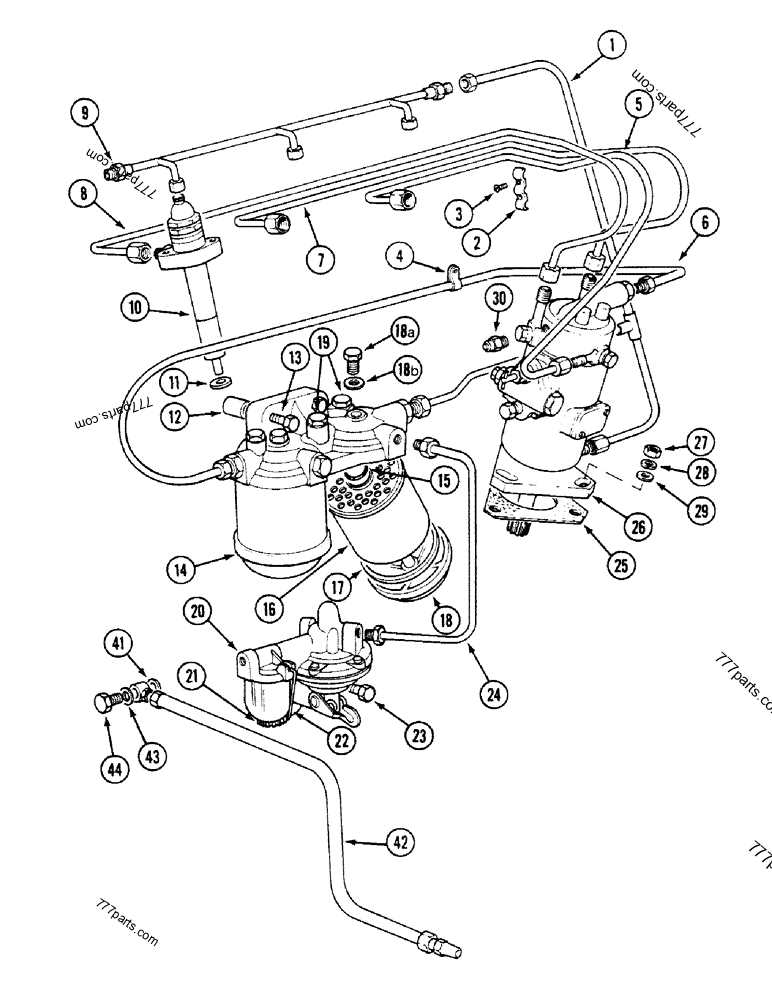

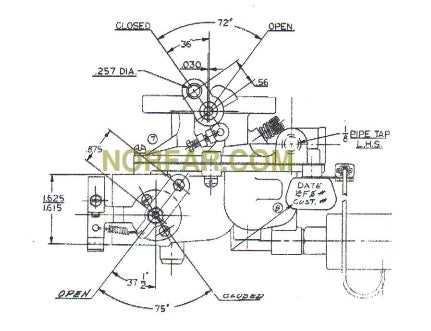

- Hydraulic System

- Transmission Mechanism

- Electrical Components

- Chassis Structure

Each of these components plays a pivotal role in ensuring that the machine operates smoothly. Understanding how they interact is vital for troubleshooting and repairs.

Maintaining Efficiency

- Regular Inspections

- Lubrication of Moving Parts

- Replacement of Worn Components

- Monitoring Fluid Levels

- Electrical System Checks

Implementing a consistent maintenance routine helps in identifying potential issues before they escalate, ensuring longevity and optimal operation of the equipment.

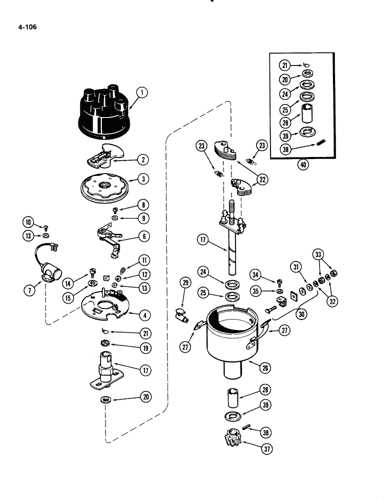

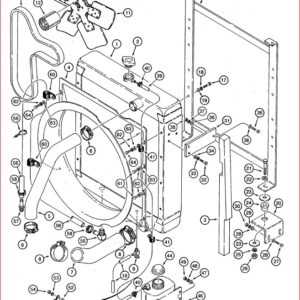

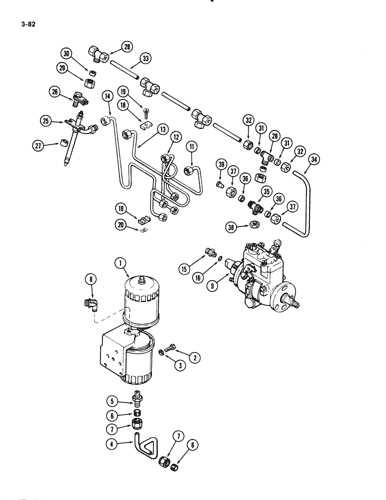

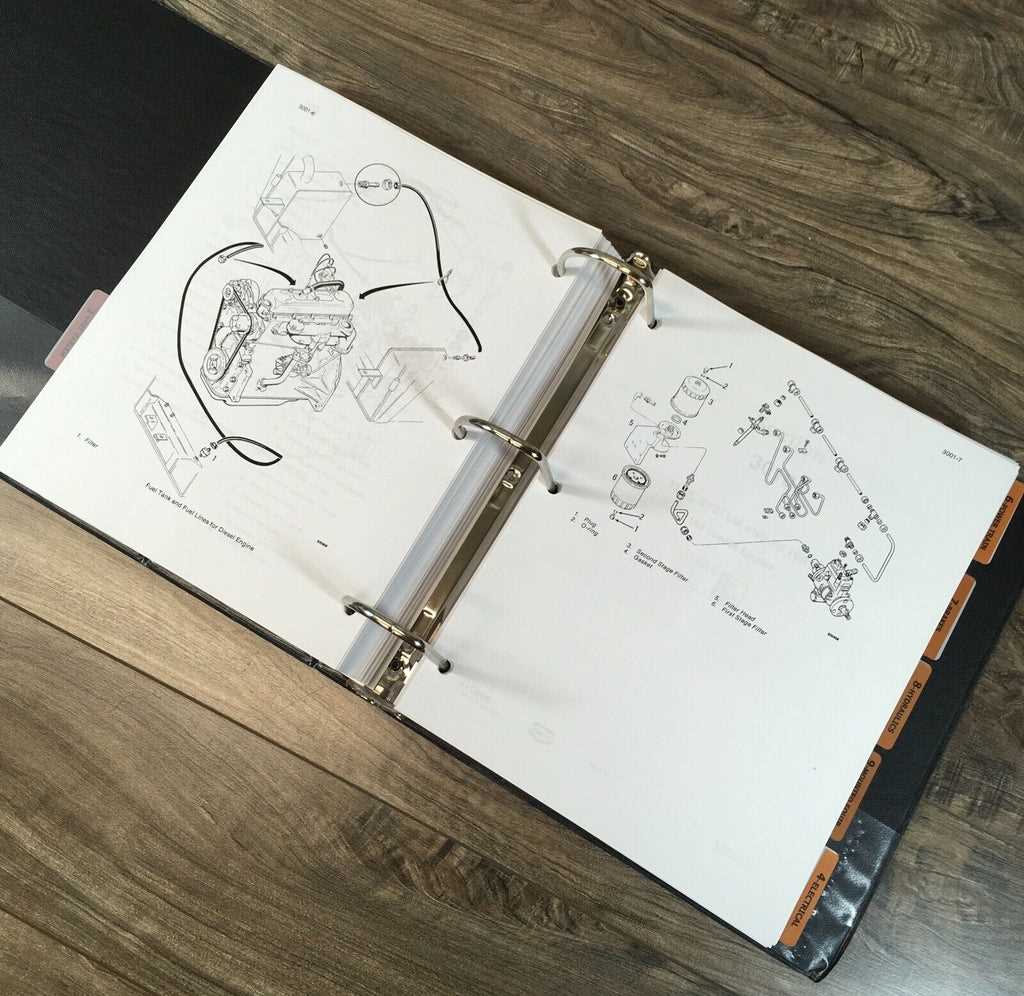

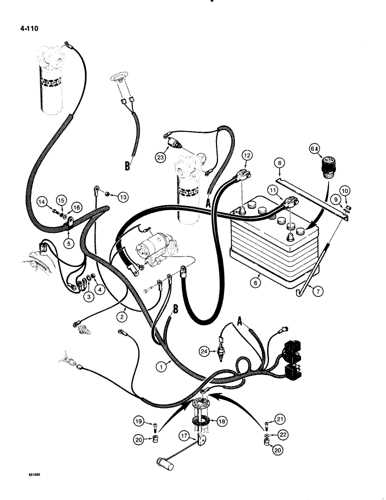

Importance of Parts Diagrams

Understanding the composition and assembly of machinery is crucial for effective maintenance and repair. Visual representations of components provide valuable insights, ensuring technicians can easily identify and locate each element within a system.

These illustrations serve multiple purposes:

- Facilitate quick identification of components, reducing downtime during repairs.

- Enhance communication among team members by providing a common reference point.

- Assist in training new personnel, making it easier to grasp complex systems.

Moreover, having access to detailed layouts aids in:

- Streamlining the ordering process for replacements, minimizing errors.

- Improving overall efficiency in troubleshooting by offering a clear overview.

- Extending the lifespan of equipment through proper maintenance guided by accurate references.

In summary, detailed illustrations of machinery components are essential tools that contribute significantly to operational efficiency and the longevity of equipment.

Common Issues with Case 1835b

When operating heavy machinery, encountering various challenges is common. Understanding these issues can significantly enhance performance and longevity. Here are some frequently observed problems that operators might face.

- Hydraulic Failures:

Leaks or loss of pressure can lead to inefficient operation. Regular maintenance of seals and hoses is crucial to prevent this issue.

- Electrical Malfunctions:

Electrical systems can be prone to failures, affecting ignition and overall functionality. Inspecting wiring and connections frequently can help mitigate these problems.

- Engine Performance:

Poor engine performance may arise from fuel issues or air intake problems. Regular checks on filters and fuel quality are essential.

- Transmission Difficulties:

Issues with gear shifting or slipping can occur. Ensuring proper fluid levels and addressing leaks promptly can resolve these concerns.

- Wear and Tear:

Components may wear out over time, leading to decreased efficiency. Routine inspections and timely replacements are key to maintaining optimal performance.

Addressing these common issues proactively can enhance the operational efficiency and lifespan of the equipment. Regular maintenance and attentive care are vital for ensuring smooth and effective functionality.

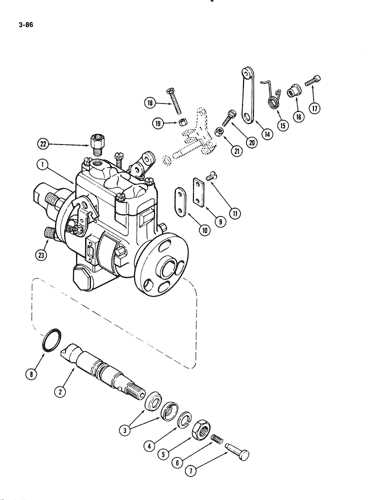

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. Such visual aids provide clarity by illustrating the relationship between various elements, enabling users to identify and locate specific parts quickly.

Identifying Components

Begin by familiarizing yourself with the symbols and labels used in the representation. Each element typically has a unique identifier, which helps in distinguishing between different items. Pay attention to any legends or keys that explain these symbols, as they are crucial for accurate interpretation.

Interpreting Connections

Next, observe how the components are interconnected. Lines or arrows often indicate relationships or flow, guiding you in understanding the assembly and function of the entire system. Analyzing these connections is vital for troubleshooting and ensuring proper reassembly after repairs.

Maintenance Tips for Optimal Performance

Ensuring peak efficiency requires regular upkeep and attention to detail. Implementing a systematic approach to maintenance can significantly enhance longevity and functionality.

- Conduct routine inspections to identify wear and tear.

- Keep all moving parts clean and lubricated to reduce friction.

- Check fluid levels regularly to prevent overheating.

- Replace any worn components promptly to avoid further damage.

- Follow manufacturer guidelines for maintenance schedules.

By adhering to these practices, you can delve into the ultimate care for your machinery, ensuring it operates smoothly and efficiently for years to come.

Where to Find Replacement Parts

Finding suitable components for machinery can be a challenge, but numerous resources can assist in this quest. Whether you’re a seasoned technician or a novice, knowing where to look is essential for ensuring optimal performance and longevity of your equipment.

Online Marketplaces

Websites like eBay and Amazon offer a wide selection of components, often at competitive prices. These platforms allow users to compare options and read reviews, making it easier to choose the right item for your needs.

Specialty Suppliers

For more specific requirements, consider reaching out to specialty suppliers. Many of these businesses focus exclusively on machinery, providing expert advice and high-quality components. It’s beneficial to establish a relationship with a trusted supplier for ongoing support.

Comparing Case 1835b with Other Models

This section explores the similarities and differences between a specific machinery model and its counterparts in the industry. By analyzing performance metrics, design features, and user experiences, we can uncover the unique strengths and weaknesses of each option, providing valuable insights for potential users.

| Feature | Model A | Model B | Subject Model |

|---|---|---|---|

| Engine Power | 75 HP | 80 HP | 85 HP |

| Operating Weight | 6500 lbs | 7000 lbs | 7200 lbs |

| Hydraulic Flow | 15 GPM | 20 GPM | 18 GPM |

| Lift Capacity | 2500 lbs | 3000 lbs | 2800 lbs |

Through this comparative analysis, users can make informed decisions based on their specific needs and operational requirements, ultimately enhancing productivity and efficiency in their tasks.

Tools Required for Repairs

When it comes to performing maintenance or fixing machinery, having the right set of tools is essential for achieving optimal results. Each task may require specific instruments that ensure precision and efficiency. A well-equipped workspace can significantly reduce the time and effort involved in repairs, leading to more successful outcomes.

Essential Hand Tools

Hand tools are fundamental for any repair job. Screwdrivers, wrenches, and pliers are indispensable for assembling or disassembling components. Additionally, a good set of hex keys can help access tight spaces. Investing in high-quality tools can improve durability and performance, making your tasks easier and more effective.

Power Tools and Accessories

For more extensive repairs, power tools become invaluable. Drills and impact drivers can speed up processes that would otherwise be time-consuming with manual tools. Moreover, having a variety of attachments can enhance functionality, allowing for versatility in tackling different projects. Ensure that you also have appropriate safety gear to protect yourself while using these powerful instruments.

Safety Precautions During Maintenance

Ensuring safety while performing upkeep tasks is essential to prevent accidents and promote a secure working environment. Proper precautions not only protect personnel but also enhance the efficiency of maintenance operations.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and helmets.

- Ensure that the work area is well-ventilated to avoid inhaling harmful fumes.

- Keep all tools and equipment in good condition to prevent malfunctions.

Emergency Protocols

- Familiarize yourself with emergency exits and first aid stations.

- Have a fire extinguisher accessible in case of emergencies.

- Report any unsafe conditions immediately to a supervisor.

Tips for Efficient Troubleshooting

Effective problem-solving requires a systematic approach to identify and resolve issues promptly. Utilizing the right strategies can significantly enhance your efficiency and accuracy in diagnosing faults.

- Gather Information: Collect relevant details about the issue. This may include user reports, error messages, and operational history.

- Consult Resources: Refer to manuals, online forums, and technical support documents to gain insights into common problems and solutions.

- Prioritize Tasks: Focus on the most critical issues first. Determine which problems impact functionality the most.

- Utilize Checklists: Create checklists to ensure no steps are overlooked during the troubleshooting process.

By implementing these strategies, you can delve deeper into the underlying causes of malfunctions and achieve more effective resolutions.

Ultimate Guide to Parts Ordering

When it comes to acquiring components for machinery, understanding the process can save time and money. This guide provides a comprehensive overview of how to efficiently source the necessary items for optimal performance.

Follow these steps to streamline your ordering experience:

- Identify Your Needs:

Clearly determine which elements are required. This includes assessing the model and specifications to avoid mismatches.

- Research Reliable Suppliers:

Look for vendors known for quality and reliability. Check reviews and recommendations from other users.

- Utilize Resource Materials:

Make use of user manuals and online catalogs to gather information about the required items. This ensures accuracy in your selection.

- Compare Prices:

Shop around to find competitive pricing. Some suppliers may offer discounts or bulk purchasing options.

- Check Availability:

Before placing an order, confirm that the items are in stock. Delays can disrupt your project timelines.

- Review Order Details:

Double-check quantities, specifications, and shipping options to avoid issues during fulfillment.

- Track Your Order:

After placing your order, monitor its progress to ensure timely delivery and address any potential issues promptly.

By following these guidelines, you can simplify the process of acquiring components, ensuring your machinery operates efficiently and effectively.