Exploring the intricacies of a handheld finishing device unveils a world of precision engineering designed for smooth and refined surfaces. Each component plays a vital role in the overall functionality, ensuring optimal performance in various woodworking tasks. Familiarity with these elements can greatly enhance both maintenance and user experience.

The significance of comprehending how these individual pieces interact cannot be overstated. Whether you’re a seasoned craftsman or a novice DIY enthusiast, recognizing the assembly and purpose of each part can lead to more effective use and troubleshooting. This knowledge allows for better decision-making when it comes to repairs or upgrades.

In this section, we will delve into a detailed breakdown of the essential elements that comprise this versatile tool. By visualizing these components, users can gain insights into their operations, enabling a deeper appreciation for the craftsmanship behind effective woodworking equipment.

Dewalt Palm Sander Overview

This section provides a comprehensive look at a popular tool designed for smoothing surfaces and achieving a polished finish. Known for its efficiency and user-friendly features, this device is a favorite among both professionals and DIY enthusiasts. Understanding its components and functionalities can enhance your sanding experience and improve project outcomes.

Key Features

The tool boasts several essential characteristics that set it apart in the market. These features contribute to its overall performance, making it suitable for various tasks.

| Feature | Description |

|---|---|

| Compact Design | Easy to maneuver in tight spaces and control during use. |

| Dust Collection | Integrated systems help maintain a clean workspace by minimizing debris. |

| Variable Speed | Adjustable settings allow for versatility across different materials. |

Maintenance Tips

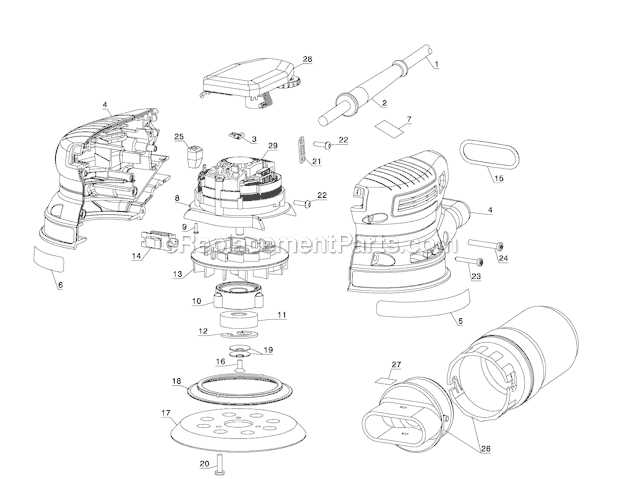

Understanding Palm Sander Components

To effectively utilize a handheld finishing tool, it is crucial to comprehend the various elements that comprise its design. Each component plays a significant role in the overall functionality and performance, impacting both efficiency and results in surface preparation tasks.

Motor: At the heart of this tool lies the motor, which provides the necessary power for operation. The strength and speed of the motor dictate how quickly and smoothly surfaces can be refined.

Base Plate: The base plate, often made of durable material, is the part that makes direct contact with the workpiece. Its design influences the tool’s ability to reach tight corners and uneven surfaces.

Sandpaper: The abrasive material attached to the base plate is essential for material removal. Different grits serve various purposes, from aggressive sanding to fine finishing.

Dust Collection: An efficient dust collection system is integral for maintaining a clean workspace. This component minimizes airborne particles, promoting a healthier environment while enhancing visibility during use.

Grip: A comfortable grip is vital for user control and precision. The ergonomic design of this feature ensures that the operator can use the tool for extended periods without discomfort.

Understanding these critical components not only aids in selecting the right tool but also enhances the overall experience of surface finishing, leading to superior results in projects.

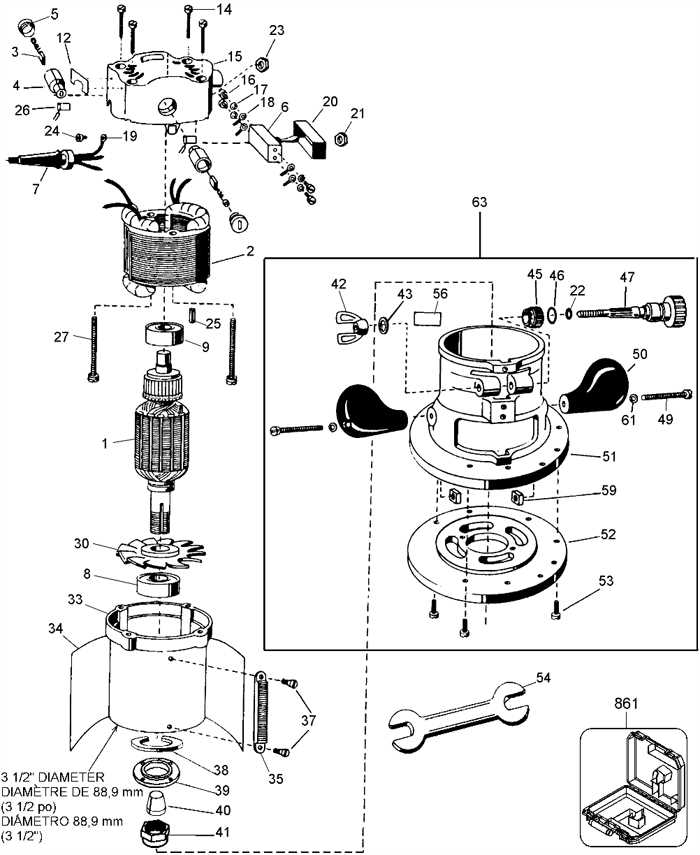

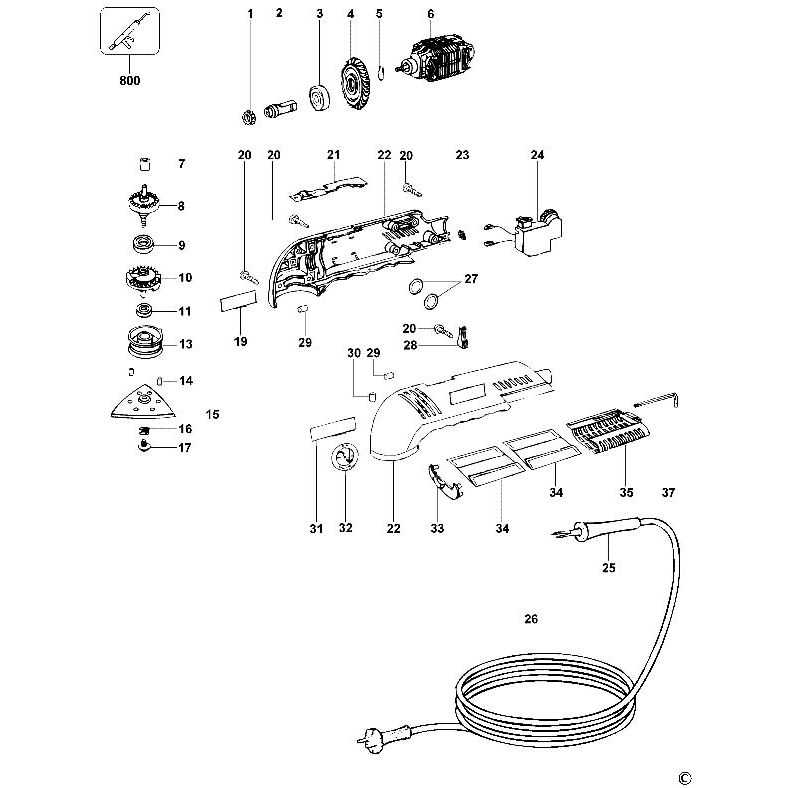

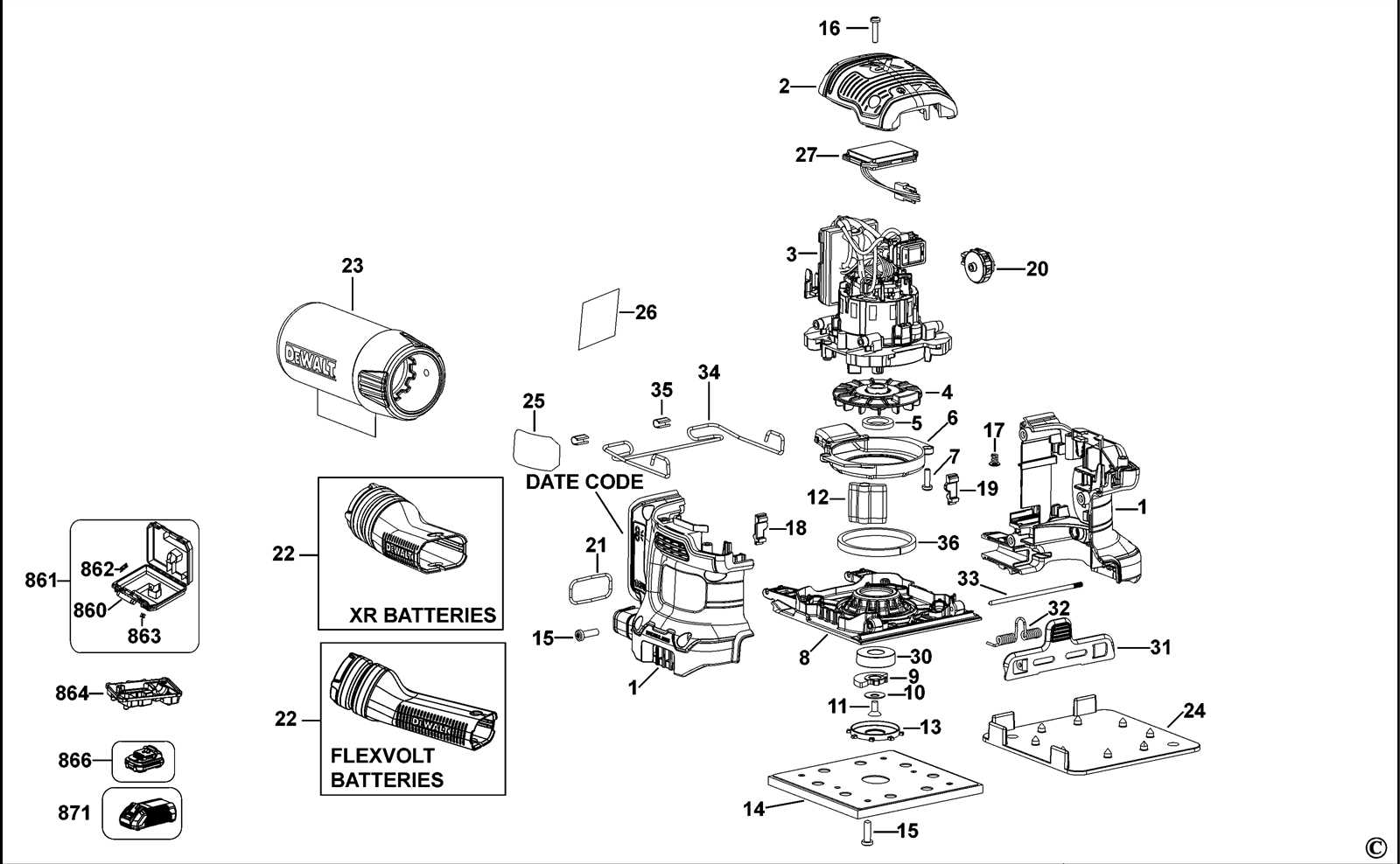

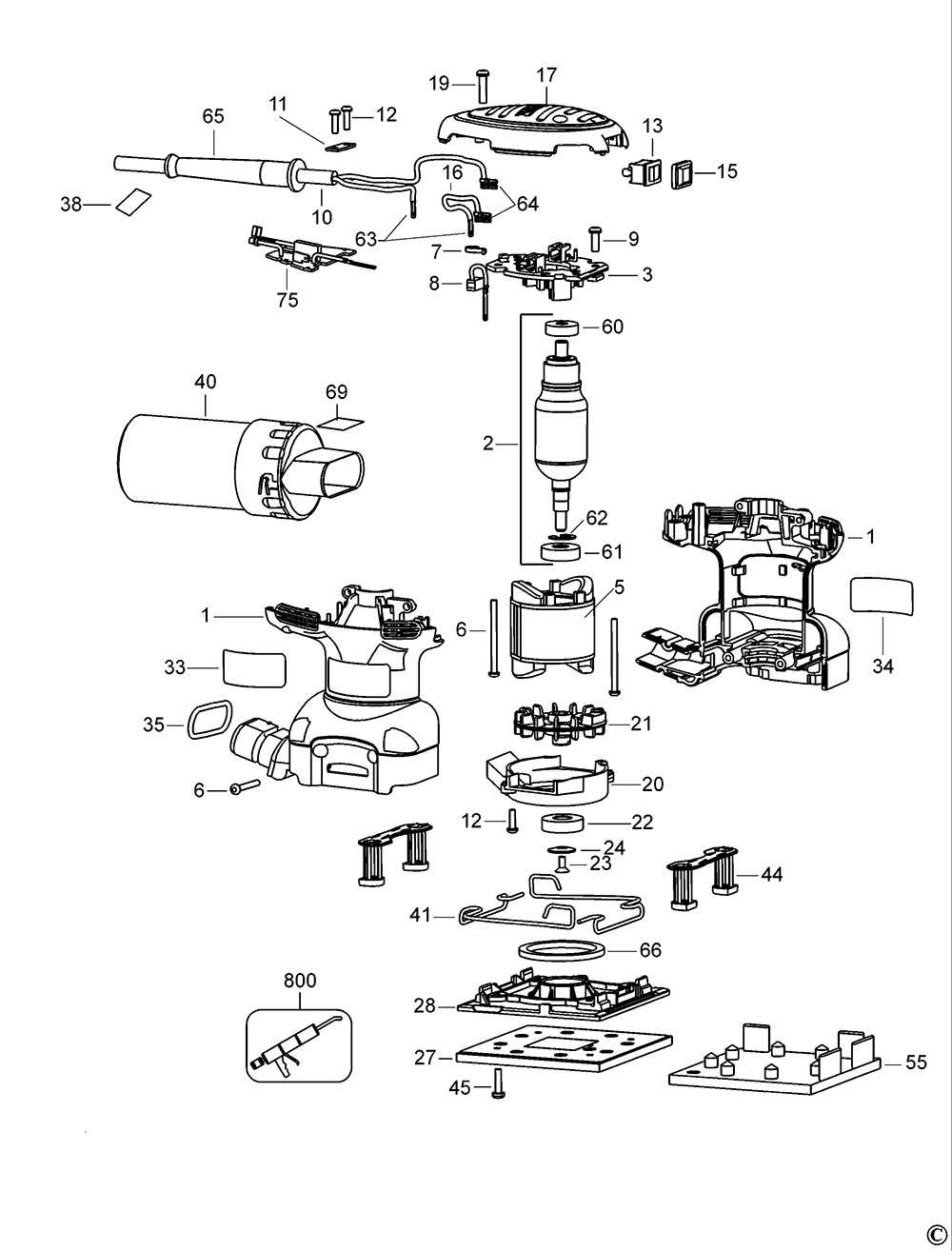

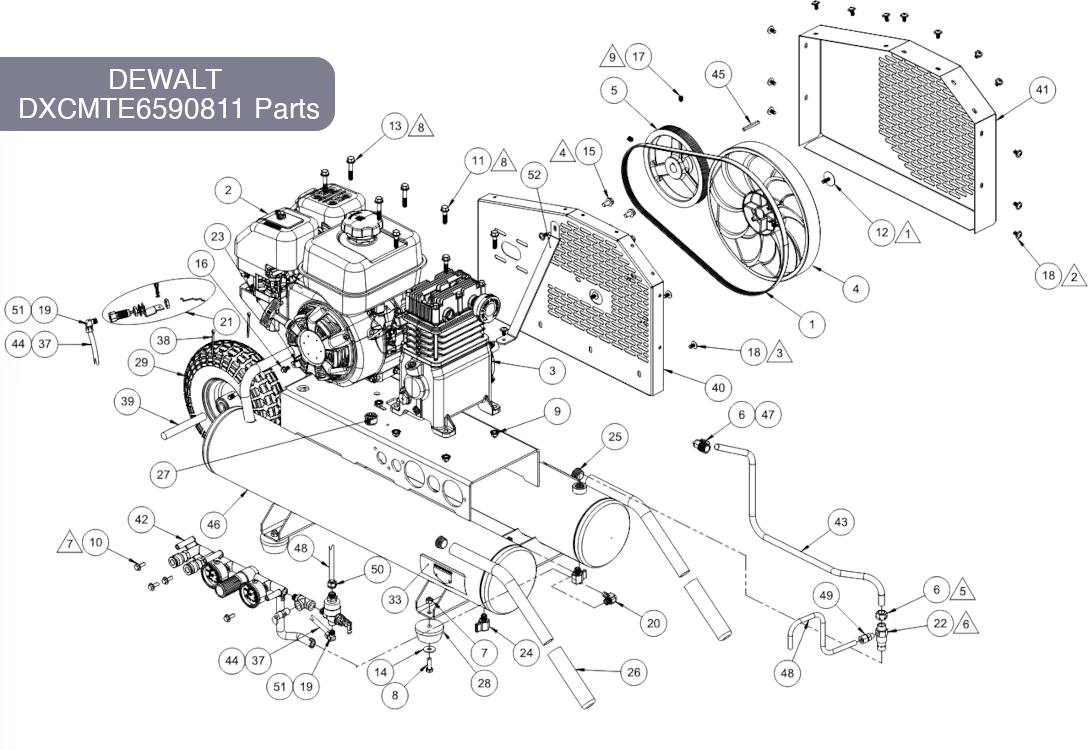

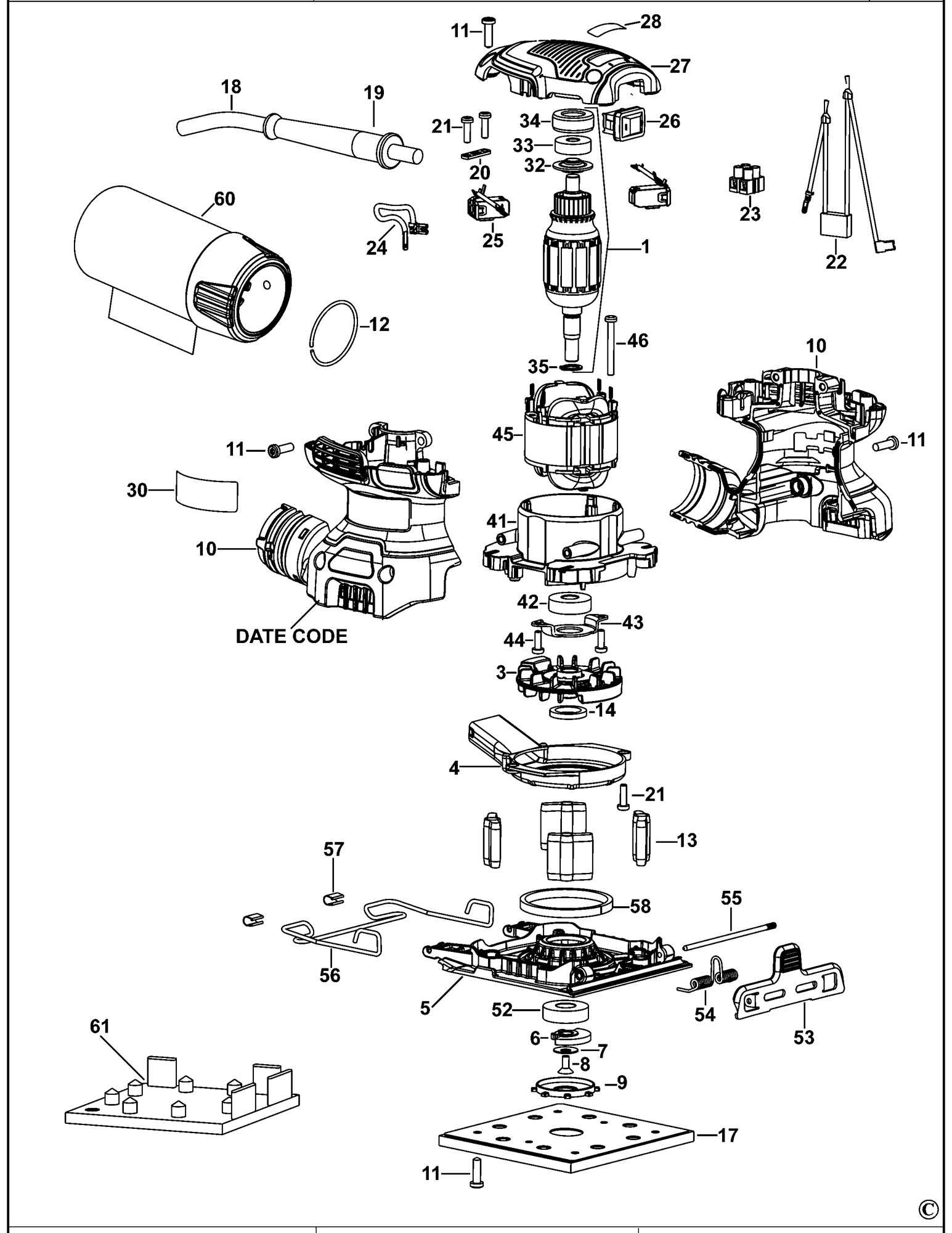

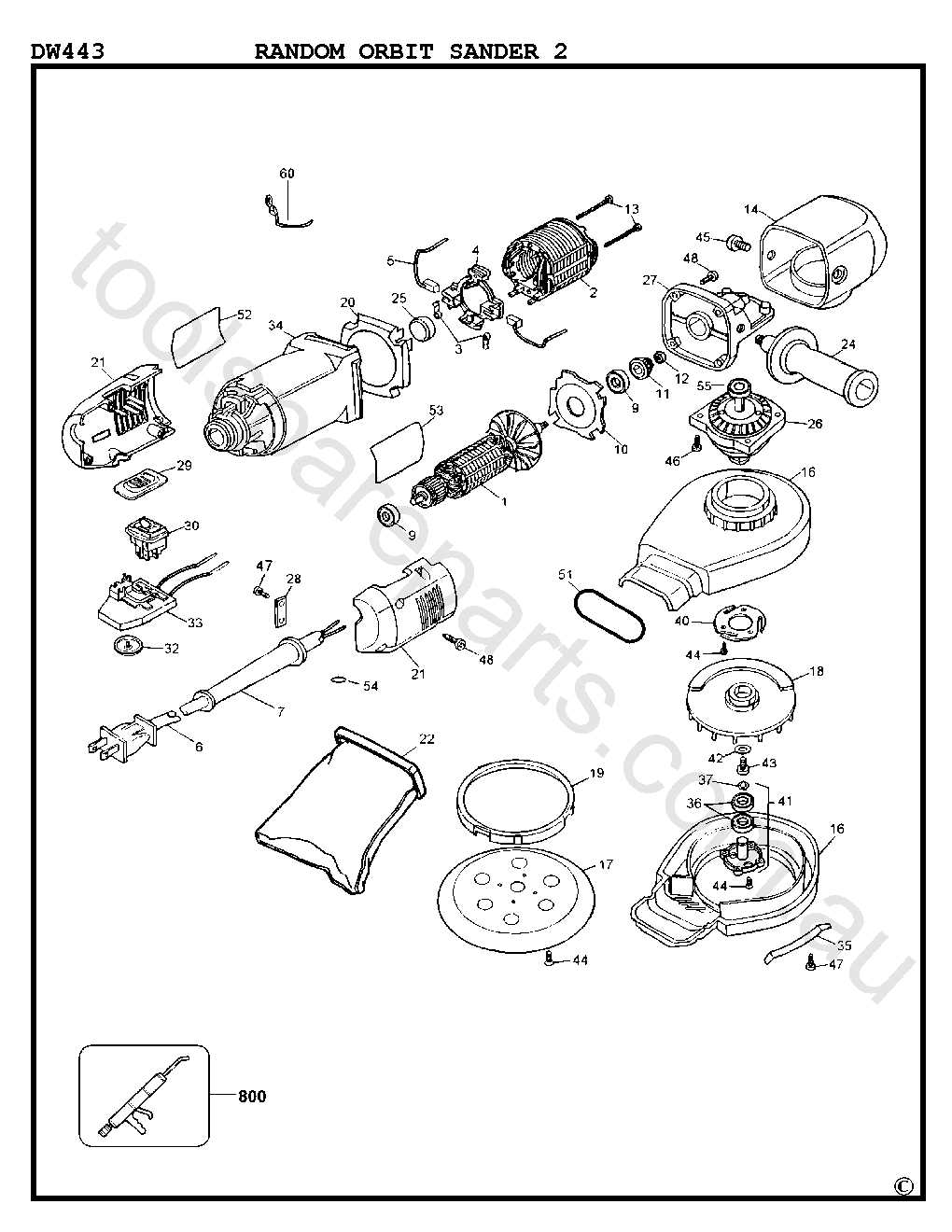

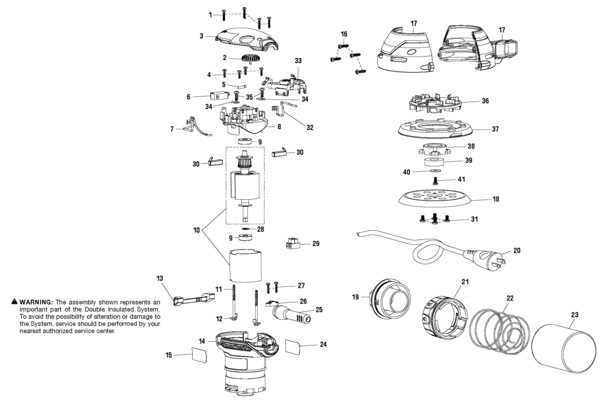

How to Read Parts Diagrams

Understanding illustrations of components is essential for effective repairs and maintenance. These visual guides provide a clear representation of each element within a device, enabling users to identify, locate, and understand the function of every part. Mastering the ability to interpret these visuals can significantly simplify troubleshooting and replacement processes.

Identifying Components

When analyzing a visual representation, begin by familiarizing yourself with the key elements. Look for labels and corresponding numbers that denote specific parts. Typically, these will be referenced in an accompanying list or table, which correlates with the visual layout.

Utilizing Reference Tables

| Part Number | Description | Notes |

|---|---|---|

| 001 | Main Housing | Contains internal mechanisms |

| 002 | Power Switch | Controls the on/off function |

| 003 | Motor Assembly | Drives the entire device |

| 004 | Base Plate | Supports stability during operation |

By combining the information from the illustrations with reference tables, you can gain a comprehensive understanding of the system. This approach will facilitate more informed decisions regarding repairs and ensure that you can efficiently order replacements as needed.

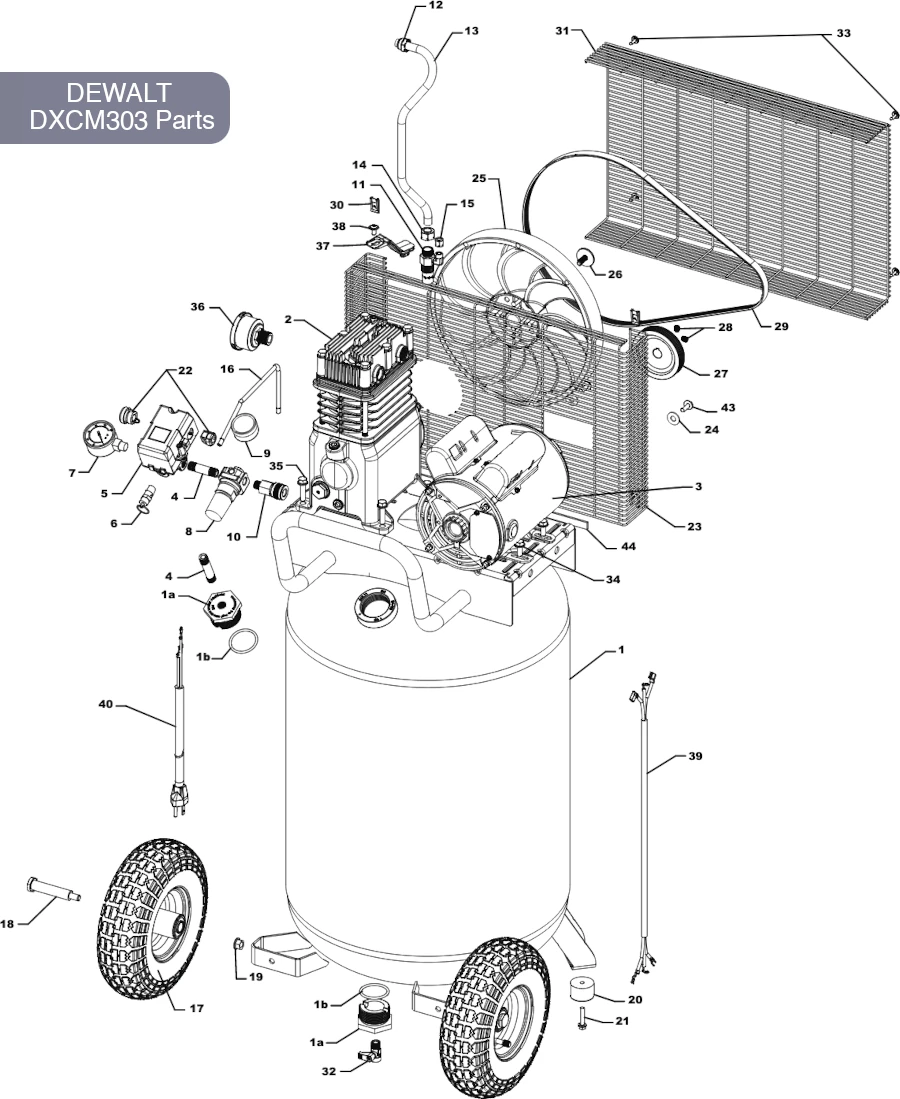

Identifying Common Dewalt Models

When working with power tools, recognizing the different variants available in the market can enhance your efficiency and ensure you have the right equipment for your tasks. This section focuses on some of the widely used models, offering insights that help in distinguishing their unique features and specifications.

Popular Variants

- Model A: Known for its lightweight design, this variant is perfect for delicate tasks.

- Model B: Offers enhanced power and is ideal for heavy-duty applications.

- Model C: Features a dual-speed setting, providing versatility for different materials.

Key Features to Look For

- Power rating: Check the wattage for understanding its capability.

- Size: Consider the dimensions for accessibility in tight spaces.

- Handle design: Ergonomics can significantly impact comfort during prolonged use.

- Dust collection: An effective system can help maintain a clean workspace.

By familiarizing yourself with these common models and their key attributes, you can make informed decisions when selecting the right tool for your projects.

Essential Tools for Maintenance

Having the right equipment is crucial for effective upkeep and repair tasks. A well-equipped toolkit not only enhances efficiency but also ensures that projects are completed to a high standard. Understanding the basic tools needed for routine maintenance can make a significant difference in achieving optimal results.

Key Instruments for Upkeep

Among the most vital tools for any maintenance job are those designed for precision and durability. A reliable handheld device for smoothing surfaces can greatly improve the quality of finishes. Additionally, versatile tools that allow for easy swapping of accessories will enable users to tackle a variety of tasks without needing multiple devices.

Additional Accessories

Complementing the main tools with essential accessories can elevate the maintenance experience. Replacement pads and attachments are indispensable, allowing for tailored solutions based on the specific requirements of each task. Keeping these items well-organized ensures that any maintenance activity can be conducted smoothly and effectively.

Replacing Sanding Pads Efficiently

Maintaining optimal performance during woodworking projects often relies on the condition of the abrasive surfaces used. Replacing these elements efficiently not only enhances the quality of your work but also prolongs the life of your equipment. Understanding the steps and best practices for this process can lead to a more productive experience and improved results.

Steps for Effective Replacement

When it comes to switching out the abrasive surfaces, following a structured approach is essential. Here’s a straightforward guide to ensure a smooth transition:

| Step | Description |

|---|---|

| 1 | Power off the tool and disconnect from the power source to ensure safety. |

| 2 | Remove the worn-out pad by detaching any fasteners or clips holding it in place. |

| 3 | Clean the base where the pad attaches to remove any dust or debris. |

| 4 | Align the new abrasive surface correctly and secure it using the appropriate method. |

| 5 | Reconnect the tool and perform a test run to ensure everything functions properly. |

Tips for Choosing the Right Abrasive Surfaces

Selecting the correct type of abrasive material can significantly impact your project’s outcome. Consider the following factors:

- Grain type: Choose between aluminum oxide or silicon carbide based on the material you’re working with.

- Grit size: Finer grits are ideal for finishing touches, while coarser grits are suited for material removal.

- Attachment style: Ensure compatibility with your tool’s design for easy installation.

Key Features of Dewalt Sanders

This section explores the essential attributes that make these power tools highly effective for smoothing surfaces. Each characteristic contributes to their performance and user satisfaction, enabling craftsmen to achieve superior finishes with ease.

| Feature | Description |

|---|---|

| Powerful Motor | Delivers high performance for efficient material removal. |

| Ergonomic Design | Ensures comfortable handling during prolonged use. |

| Variable Speed Control | Allows users to adjust speed for different materials and tasks. |

| Dust Collection System | Minimizes mess and improves visibility while working. |

| Durable Construction | Built to withstand tough working conditions for longevity. |

Common Repair Issues and Solutions

In any power tool, certain challenges may arise over time, affecting performance and usability. Understanding these common problems and their respective remedies can significantly extend the lifespan of the equipment and ensure it operates at peak efficiency.

Frequent Issues

| Issue | Possible Cause | Solution |

|---|---|---|

| Overheating | Clogged ventilation | Clean air vents regularly |

| Uneven surface finish | Worn abrasive pad | Replace the abrasive pad |

| Tool not turning on | Faulty switch | Inspect and replace switch if necessary |

| Excessive vibration | Loose components | Tighten all screws and fittings |

Maintenance Tips

Regular maintenance is key to preventing issues. Ensure thorough cleaning after each use and check for any signs of wear and tear periodically. By addressing minor problems promptly, you can avoid more significant repairs down the line.

Benefits of Regular Maintenance

Consistent upkeep of tools is crucial for their longevity and performance. By implementing routine checks and care, users can enhance efficiency and prevent unexpected breakdowns.

Improved Performance

- Regular cleaning ensures optimal functionality.

- Timely replacement of worn components maintains peak operation.

- Consistent adjustments can enhance precision and reliability.

Cost Efficiency

- Preventive care reduces the risk of costly repairs.

- Extending the lifespan of equipment leads to savings on replacements.

- Efficient tools consume less energy, lowering operating costs.

Where to Find Replacement Parts

When it comes to maintaining your tools, sourcing components can be crucial for optimal performance. Several avenues exist for obtaining the necessary items, ensuring your equipment remains functional. Local hardware stores often carry a selection of essentials, while online retailers provide a broader range of options, allowing for easy comparison of prices and availability.

Additionally, manufacturer’s websites frequently offer direct access to their inventory, ensuring you receive genuine items. Online marketplaces also host a variety of sellers, which can lead to competitive pricing. Lastly, consider specialized repair shops, as they may have expertise in sourcing hard-to-find components that suit your specific model.

Comparing Dewalt to Other Brands

When evaluating tools from different manufacturers, it’s essential to consider performance, durability, and user experience. While some brands may excel in innovation, others may offer superior reliability or cost-effectiveness. This comparison helps users make informed choices based on their specific needs and preferences.

Performance and Reliability

Performance often dictates a tool’s usability across various projects. While some companies focus on high-end features, others prioritize robust construction for longevity. Users should assess how each option meets their demands in both professional and DIY applications.

Cost vs. Value

Value is a crucial aspect, where cost does not always equate to quality. It’s vital to analyze the balance between the price and the functionality offered. Users should identify which brand provides the ultimate solution for their investment, ensuring they receive the best return in terms of efficiency and satisfaction.

Safety Tips When Using Sanders

Using power tools effectively requires attention to safety to prevent accidents and injuries. Proper precautions can significantly enhance your experience while ensuring a secure work environment.

Always wear protective gear, such as safety goggles and dust masks, to shield your eyes and lungs from harmful particles. Hearing protection is also advisable, especially for prolonged use.

Ensure your workspace is clean and free from any obstructions. This helps maintain focus and reduces the risk of tripping or falling while operating equipment.

Inspect the tool before each use. Check for any signs of wear or damage, and ensure all components are securely attached. A malfunctioning device can lead to serious accidents.

Follow the manufacturer’s guidelines and recommendations for operation. Understanding the tool’s functions can help you utilize it safely and efficiently.

Never bypass safety features designed to protect the user. These mechanisms are essential for reducing the risk of injury and should always be in place during operation.

Maximizing Performance of Your Tool

To ensure your equipment operates at its best, regular maintenance and proper usage techniques are essential. Understanding how to care for your device can significantly enhance its efficiency and lifespan.

Regular Cleaning: Keeping the tool free from dust and debris is crucial. This prevents overheating and ensures optimal functionality. Make it a habit to wipe down surfaces after use.

Quality Materials: Utilizing high-grade abrasives and accessories can make a noticeable difference in performance. Invest in materials that are designed for your specific tasks.

Proper Technique: Employing the correct grip and pressure can greatly impact the results. Delve into best practices to achieve a smoother finish and reduce wear on your tool.

Routine Inspections: Periodically check for signs of wear and tear. Identifying issues early can save you from costly repairs and downtime. Make it a practice to inspect components regularly.

By following these guidelines, you can ultimately elevate the performance of your device, ensuring it serves you well for years to come.