Understanding the layout of key mechanical assemblies is essential for effective maintenance and troubleshooting. This guide provides a clear overview of the essential components that form the structure of various machinery models, focusing on the inner workings and their interactions. With the correct visualization, users can easily identify specific elements and their connections, streamlining repairs and replacements.

In the following sections, we will examine the detailed structure, highlighting critical elements that ensure smooth operation. Through this breakdown, you can become familiar with the main mechanical units and their respective roles in the overall system’s functionality.

Whether you are maintaining, repairing, or simply seeking to better understand the machinery, this guide will serve as a valuable resource. By following the organized layout and identifying each element, you’ll enhance your knowledge and efficiency in working with complex equipment.

Overview of the Case 480C Backhoe Components

The machine is built with a range of interconnected systems designed to handle various tasks efficiently. Each part of the structure contributes to its overall functionality, ensuring reliable performance during heavy-duty operations. In this section, we’ll explore the main components, focusing on their individual roles and how they work together to form a seamless system.

| Component | Description | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | The powerhouse that drives the equipment, providing the necessary force for digging, lifting, and moving. | ||||||||||||

| Hydraulic System | Operates the various movable parts

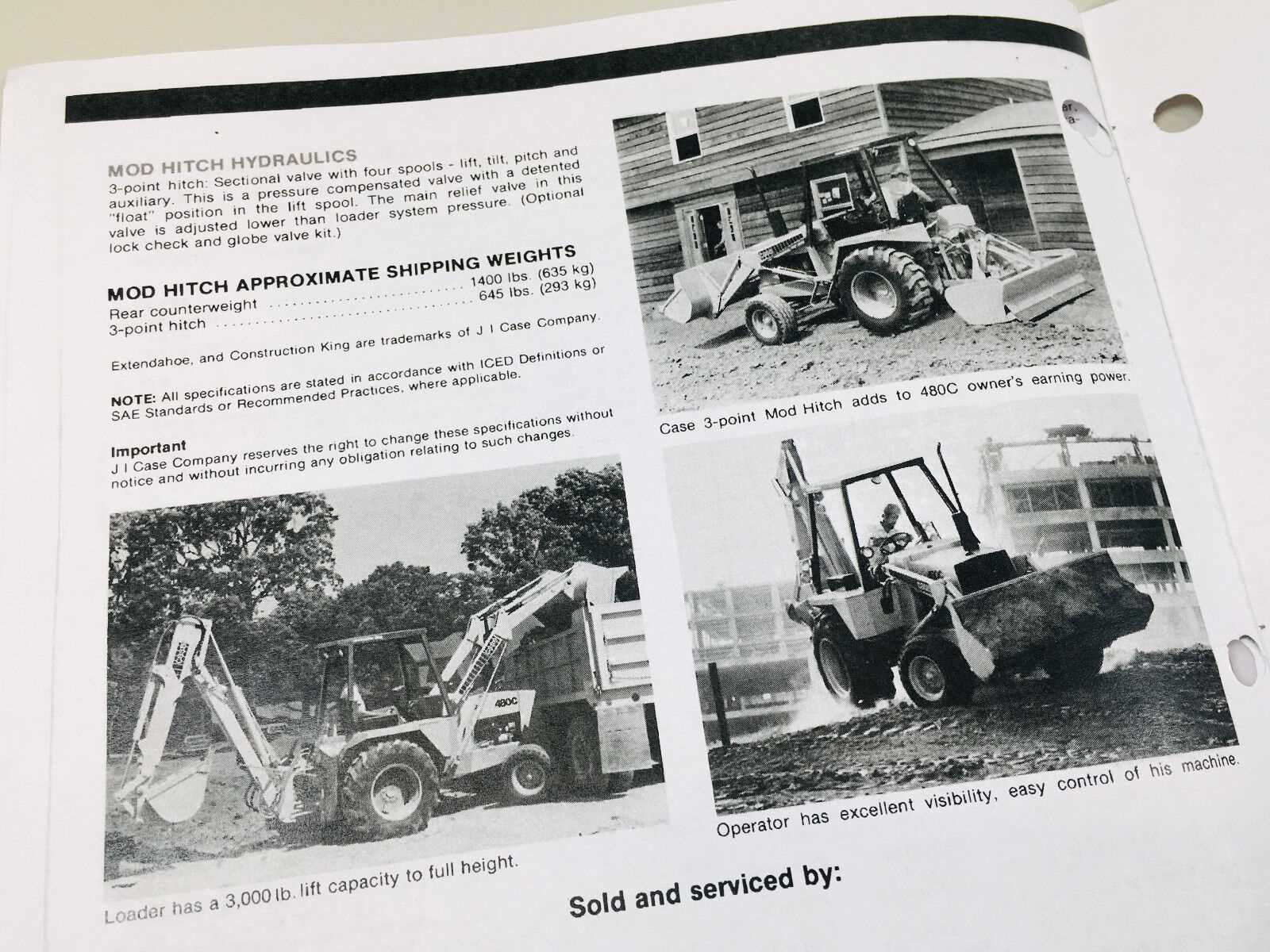

Main Hydraulic System BreakdownThe hydraulic system plays a crucial role in ensuring the effective operation of various mechanical components. It allows for the transfer of power through fluid dynamics, enabling precise control of movements and actions. Understanding the structure and flow within this system is essential for diagnosing and maintaining its efficiency. Key Components of the Hydraulic Network

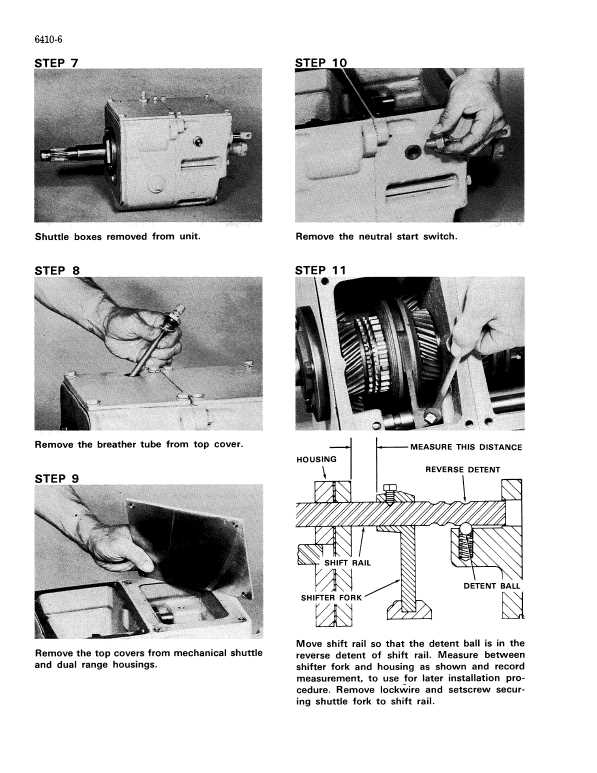

The primary elements include pumps, valves, cylinders, and hoses. The pump generates pressure by moving fluid through the system, while valves control the direction and flow of the liquid. Cylinders are responsible for converting hydraulic energy into mechanical force, enabling the machine’s movements. Fluid Flow and Control MechanismThe hydraulic circuit is designed to manage fluid flow efficiently. This ensures that power is delivered to the right components when needed. Leaks or blockages in the system can lead to pressure loss, reducing performance. Regular checks and maintenance of hoses and seals are vital for preventing such issues. Detailed View of the Engine AssemblyThe engine assembly is a critical component of any heavy machinery, ensuring optimal performance and durability. A close examination of its structure reveals the interconnected systems that contribute to the machine’s power and efficiency. Understanding the layout of these elements is essential for maintenance and troubleshooting. Key Components OverviewWithin the engine, several vital systems work together. The combustion system, for example, powers the machine through a sequence of fuel ignition. The cooling system ensures that the temperature remains at optimal levels during operation, preventing overheating. System Connections and FunctionsThe assembly includes various interconnected parts that regulate fuel flow, manage exhaust, and maintain pressure. Regular inspection of these components, along with proper lubrication, helps ensure the engine runs smoothly and avoids breakdowns. Familiarity with each system is essential for those performing repairs or upgrades. Transmission and Drive Train LayoutThe transmission and drive train system play a crucial role in ensuring the smooth and efficient operation of the machine. These components are responsible for transferring power from the engine to the wheels, enabling movement and performance under various working conditions. A well-designed layout ensures minimal power loss and optimal coordination between different mechanical parts. Transmission serves as the heart of the system, managing power distribution between different gears, allowing for flexibility in speed and torque. It ensures that the machine can operate efficiently whether at low speeds for precision tasks or higher speeds for quicker mobility. Drive Train components, including axles, differentials, and shafts, work together to convert the transmitted power into forward or backward motion. These elements must be properly aligned and maintained to prevent Electrical System and Wiring MapThe electrical system plays a crucial role in ensuring smooth operation and control of various components. A clear understanding of the wiring connections is essential for efficient troubleshooting and maintenance. This section outlines the key elements of the electrical layout, providing a comprehensive guide to the internal connections and flow of electrical currents. Key Components of the Electrical SystemThe electrical network consists of several vital elements that interact to manage power distribution and functionality. These components work together to deliver electricity to essential parts and ensure the machine operates correctly.

|