The intricate world of machinery often relies on a comprehensive understanding of its individual elements. Each component plays a vital role in the overall functionality and efficiency of the system. This section delves into the specifics of a well-known model, highlighting its essential features and how they interconnect to create seamless operation.

By exploring the various constituents that make up this machinery, users can gain valuable insights into maintenance and troubleshooting. Recognizing the arrangement and function of each segment not only enhances operational knowledge but also facilitates more effective repairs and upgrades. This exploration serves as a foundational resource for both novice users and seasoned professionals alike.

As we dissect the arrangement of these crucial elements, the importance of each piece becomes evident. Understanding how they work in harmony allows for improved performance and longevity of the equipment. Whether you’re aiming for optimal output or addressing specific issues, familiarity with the internal layout is indispensable.

Understanding the Ms 311 Parts

Comprehending the individual components of a machine is essential for optimal performance and maintenance. Each element plays a crucial role in the overall functionality, contributing to efficiency and reliability.

Key Components

- Engine: The heart of the device, responsible for power generation.

- Transmission: Facilitates the transfer of power to the wheels.

- Frame: Provides structural integrity and support.

- Electrical System: Powers various functions and controls.

Maintenance Tips

- Regularly check fluid levels to ensure smooth operation.

- Inspect belts and hoses for wear and tear.

- Clean or replace filters to maintain efficiency.

- Schedule periodic professional inspections for in-depth assessments.

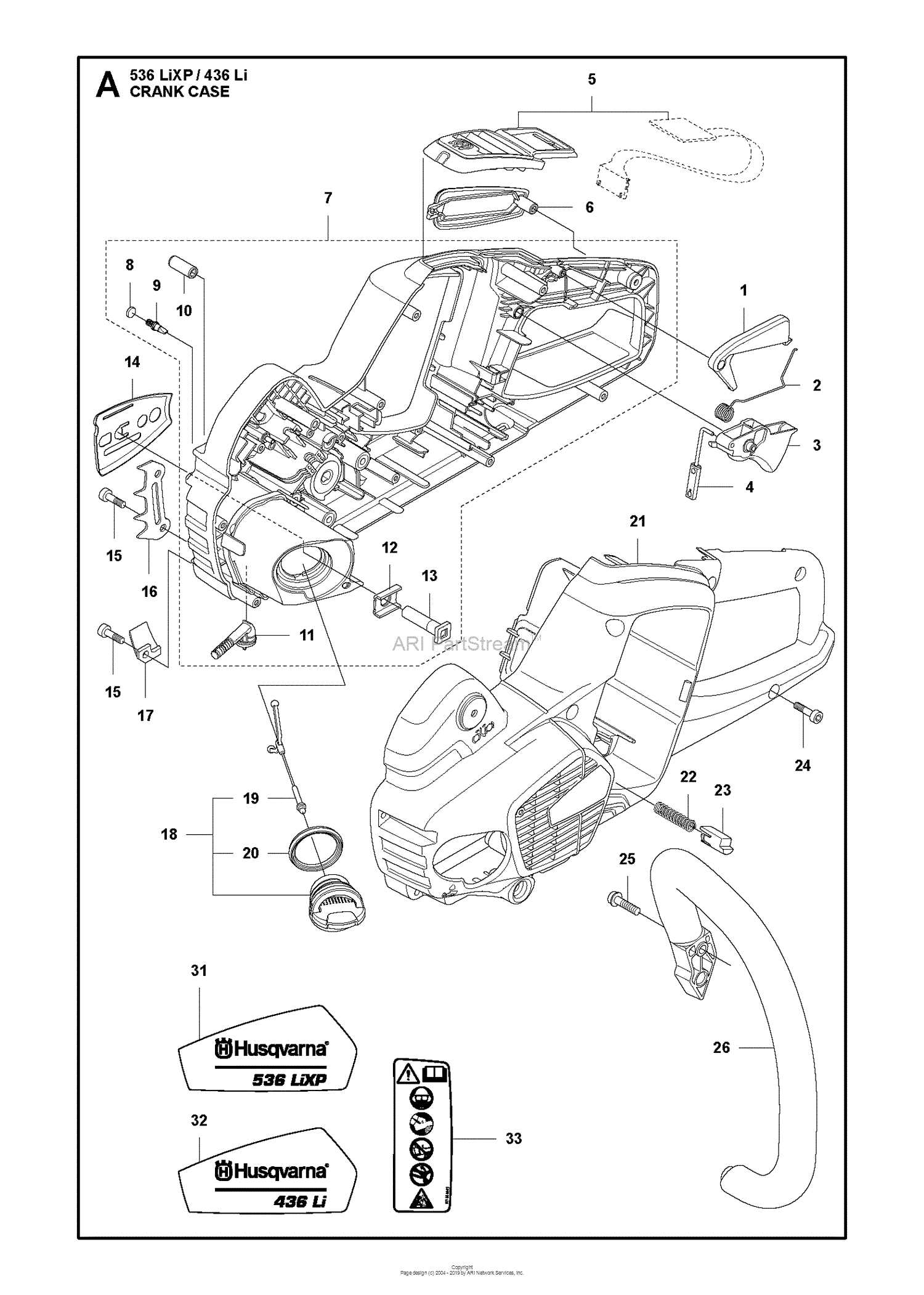

Key Components of Ms 311

The Ms 311 model comprises several essential elements that contribute to its overall functionality and performance. Understanding these components can enhance your ability to maintain and operate the machine effectively.

- Engine: The heart of the system, providing the necessary power.

- Transmission: Facilitates smooth power transfer between the engine and wheels.

- Hydraulic System: Essential for various operational tasks, ensuring efficient movement.

- Chassis: The structural framework that supports all other components.

- Control Panel: Interface for the operator, allowing for easy command and monitoring.

Each of these components plays a vital role in ensuring the reliability and effectiveness of the entire system.

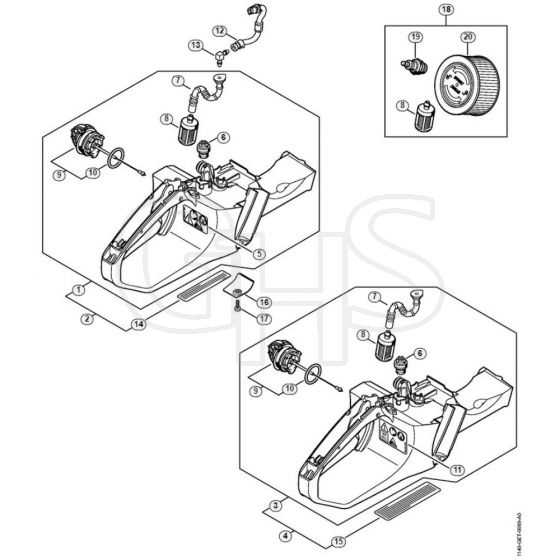

How to Access Parts Diagram

Gaining insights into the components of machinery is essential for effective maintenance and repairs. This guide will help you navigate the process of locating visual aids that illustrate the various elements of your equipment. Understanding these resources can greatly enhance your troubleshooting and replacement efforts.

To find the necessary resources, follow these steps:

| Step | Action |

|---|---|

| 1 | Visit the manufacturer’s official website. |

| 2 | Navigate to the support or resources section. |

| 3 | Look for links related to manuals or technical documentation. |

| 4 | Enter the model number of your equipment for tailored results. |

| 5 | Download or view the provided visual resources. |

By following these steps, you will be well-equipped to locate the visual references needed to understand your equipment’s structure and functionality. This knowledge is invaluable for both routine maintenance and unexpected repairs.

Common Issues with Ms 311 Parts

Understanding the typical challenges associated with various components can greatly enhance maintenance and operational efficiency. Frequent problems may arise due to wear and tear, improper installation, or lack of regular upkeep, leading to decreased performance and potential breakdowns.

| Issue | Description |

|---|---|

| Wear and Tear | Over time, certain elements can deteriorate, impacting functionality. |

| Installation Errors | Incorrect assembly can lead to malfunctions and inefficiencies. |

| Lack of Maintenance | Neglecting routine checks can exacerbate existing problems. |

| Compatibility Issues | Using non-original components may result in poor performance. |

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of machinery requires regular upkeep and attention to detail. Proper maintenance not only enhances functionality but also extends the lifespan of equipment. By implementing a few simple strategies, users can avoid common pitfalls and ensure their tools remain in peak condition.

Regular Inspections

Frequent checks can help identify issues before they escalate. Focus on the following:

- Look for signs of wear and tear.

- Check for loose components.

- Inspect seals and gaskets for leaks.

Proper Cleaning Techniques

Keeping machinery clean is crucial for preventing buildup that can lead to malfunctions. Consider these cleaning practices:

- Use appropriate cleaning agents to avoid damaging surfaces.

- Remove debris and dust from all accessible areas.

- Ensure all moving parts are lubricated to minimize friction.

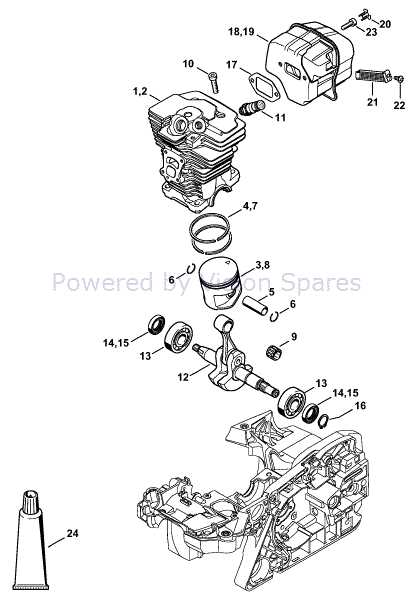

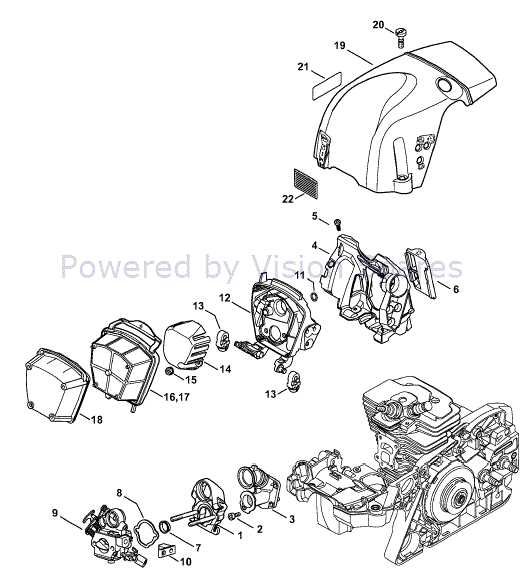

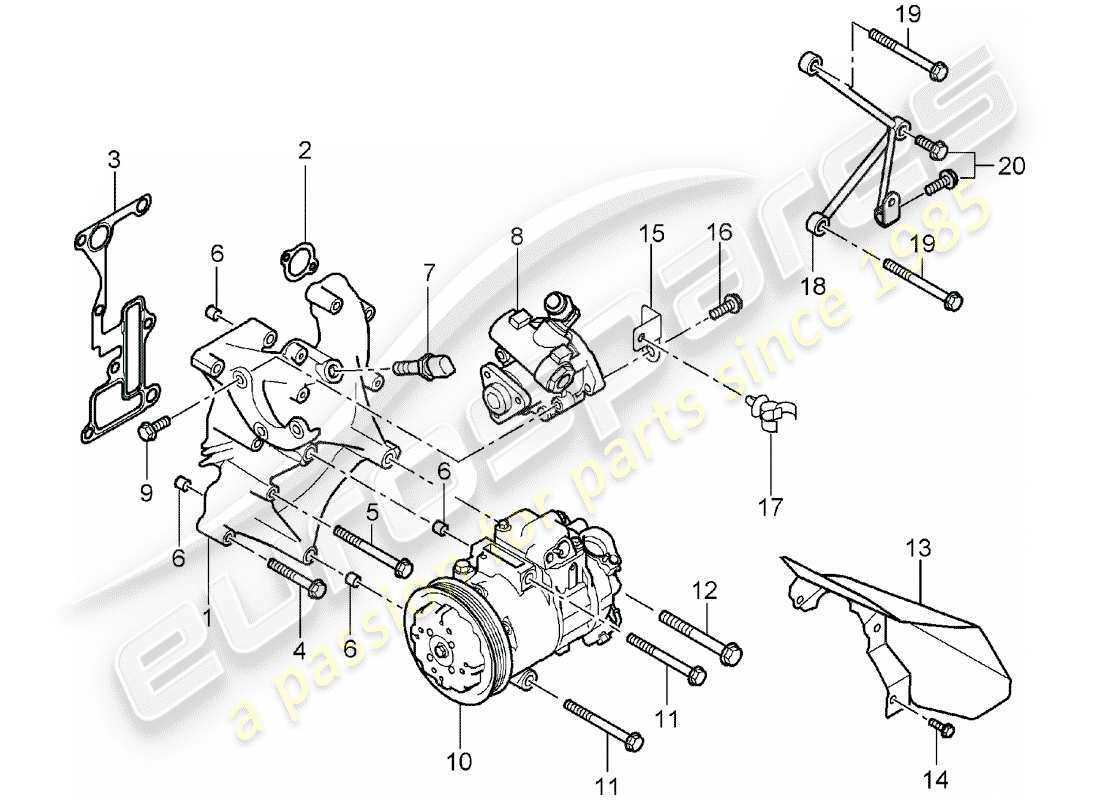

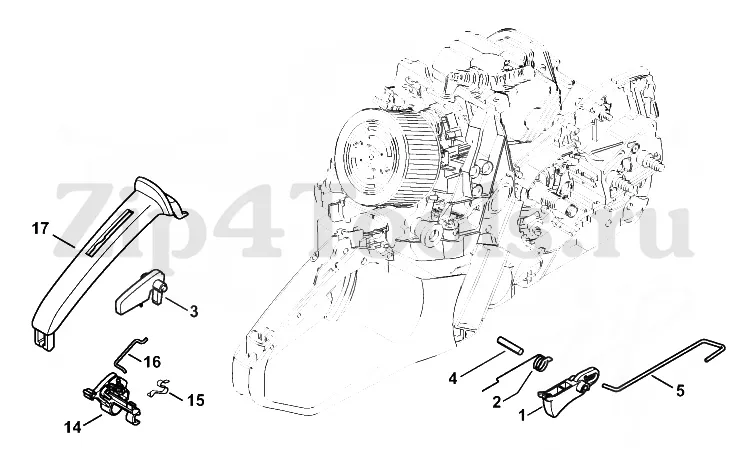

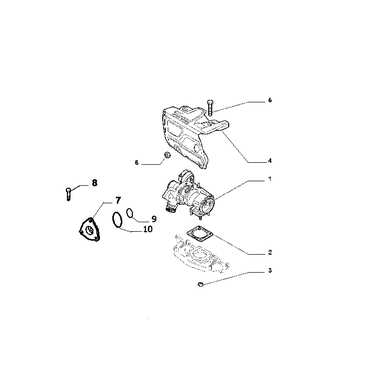

Identifying Each Part’s Function

Understanding the role of each component in a mechanical assembly is crucial for effective maintenance and troubleshooting. By exploring the specific functions of various elements, one can enhance operational efficiency and prolong the lifespan of the system.

Core Components

The primary elements serve essential purposes, such as power generation, movement, and control. Identifying these components allows for targeted interventions during repairs or upgrades, ensuring optimal performance.

Supporting Elements

Auxiliary components, while not always in the spotlight, play significant roles in supporting the main functions. These parts often contribute to safety, stability, and overall system harmony, making their understanding equally important.

Tools Required for Assembly

To ensure a successful assembly process, having the right instruments at your disposal is crucial. These tools not only facilitate a smoother workflow but also guarantee precision and efficiency in every step.

| Tool | Description |

|---|---|

| Wrench Set | Essential for tightening and loosening bolts and nuts. |

| Screwdriver Set | Variety of types for different screw heads. |

| Pliers | Useful for gripping, twisting, and cutting materials. |

| Measuring Tape | Important for ensuring accurate dimensions during assembly. |

| Level | Helps in checking the alignment and balance of components. |

Where to Find Replacement Parts

Finding suitable components for your equipment can be essential for maintaining its functionality and longevity. Whether you are a seasoned professional or a novice, knowing where to look for these essential items can save you time and effort. Here are some effective resources to consider when searching for replacements.

| Resource Type | Description |

|---|---|

| Manufacturer’s Website | The first place to check is often the official site of the maker, where you can find specific recommendations and original items. |

| Local Retail Stores | Visit nearby hardware or specialty shops that may carry a range of necessary components for your machinery. |

| Online Marketplaces | Websites like Amazon or eBay can be useful for locating both new and used items from various sellers. |

| Forums and Community Groups | Online communities often share resources and links to trusted suppliers, making it easier to find hard-to-locate components. |

| Repair Shops | Local repair services might offer spare items or can direct you to reliable sources for purchasing what you need. |

By utilizing these avenues, you can efficiently locate the necessary components to keep your equipment running smoothly and effectively.

Comparing Models of Ms Series

In the diverse landscape of Ms Series offerings, each variant presents unique features and capabilities tailored to specific needs. Understanding these differences allows users to make informed choices based on performance, functionality, and suitability for their intended applications.

Key Variations

Each model within the series showcases distinct specifications and enhancements. For example, certain models prioritize energy efficiency, while others excel in high-performance tasks. By examining these variations, potential buyers can determine which version aligns best with their operational requirements.

Performance Metrics

Ultimately, analyzing performance metrics such as speed, durability, and user-friendliness is crucial. Choosing the right model not only impacts productivity but also enhances overall user satisfaction, making a detailed comparison essential for optimal decision-making.

DIY Repairs for Ms 311

Performing maintenance and repairs on your equipment can seem daunting, but with the right guidance, it becomes a manageable task. This section aims to empower you with the knowledge and techniques needed to tackle common issues effectively. By understanding the components and how they function together, you can enhance the longevity of your device and save on professional repair costs.

Identifying Common Issues

Before diving into repairs, it’s crucial to recognize the typical problems that might arise. Unusual noises, difficulty starting, or inconsistent performance can all signal a need for attention. Conducting a thorough inspection can help you pinpoint the exact source of the trouble, allowing for more targeted fixes.

Step-by-Step Repair Guide

Once you’ve identified the issue, you can proceed with a structured approach to repair. Gather the necessary tools and materials to ensure a smooth process. Begin by disassembling the relevant sections carefully, documenting each step for easy reassembly. Replace any faulty components and make sure to clean all parts thoroughly before putting everything back together. Finally, test the unit to ensure it operates as expected.

Importance of Accurate Diagrams

Having precise representations is crucial in various fields, serving as a fundamental tool for understanding complex structures and systems. These visual aids provide clarity and streamline communication among stakeholders.

- Enhanced Understanding: Clear visuals help users grasp intricate details quickly.

- Efficient Troubleshooting: Accurate depictions allow for quicker identification of issues.

- Consistent Communication: They ensure all parties share a common reference point, reducing misunderstandings.

- Effective Training: New users benefit from clear visuals that guide them through processes.

Ultimately, the precision of these representations not only aids in daily operations but also contributes to the overall success of projects and initiatives.

Upgrading Ms 311 Components

Enhancing the elements of a specific machine can significantly improve its overall performance and longevity. This section explores various strategies for modernizing key components, ensuring optimal functionality and efficiency.

Consider the following aspects when upgrading:

- Material Quality: Opt for higher-grade materials to withstand wear and tear.

- Technological Advances: Incorporate the latest innovations for enhanced capabilities.

- Compatibility: Ensure new components align well with existing systems.

Implementing these upgrades can lead to:

- Improved operational efficiency.

- Extended lifespan of the machine.

- Enhanced user experience and satisfaction.

Careful planning and execution will ultimately yield the best results in upgrading your machine.

Safety Precautions During Maintenance

Ensuring a secure working environment is crucial when performing upkeep tasks on machinery. Adhering to specific guidelines minimizes the risk of accidents and promotes effective operation. Awareness of potential hazards and preparation can significantly enhance safety during these activities.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as gloves, goggles, and helmets to protect against injuries. |

| Tool Inspection | Check all tools for damage before use to ensure they function correctly and safely. |

| Area Cleanliness | Maintain a tidy workspace to prevent tripping hazards and facilitate safe movement. |

| Electrical Safety | Disconnect power sources before commencing work to avoid electric shock. |

| Emergency Preparedness | Have first aid kits and emergency contacts readily available to address any incidents quickly. |