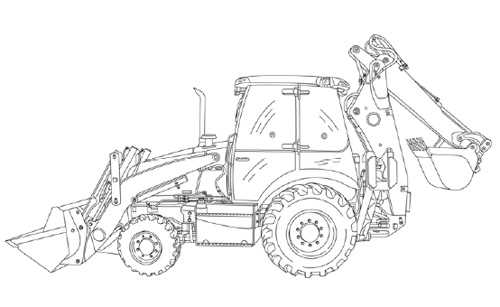

Understanding the intricacies of heavy equipment is essential for operators and technicians alike. This section delves into the various elements that make up a specific model of construction machinery, offering insights into their functionality and interconnectivity. By breaking down the individual components, we can gain a clearer picture of how these machines work together to accomplish demanding tasks.

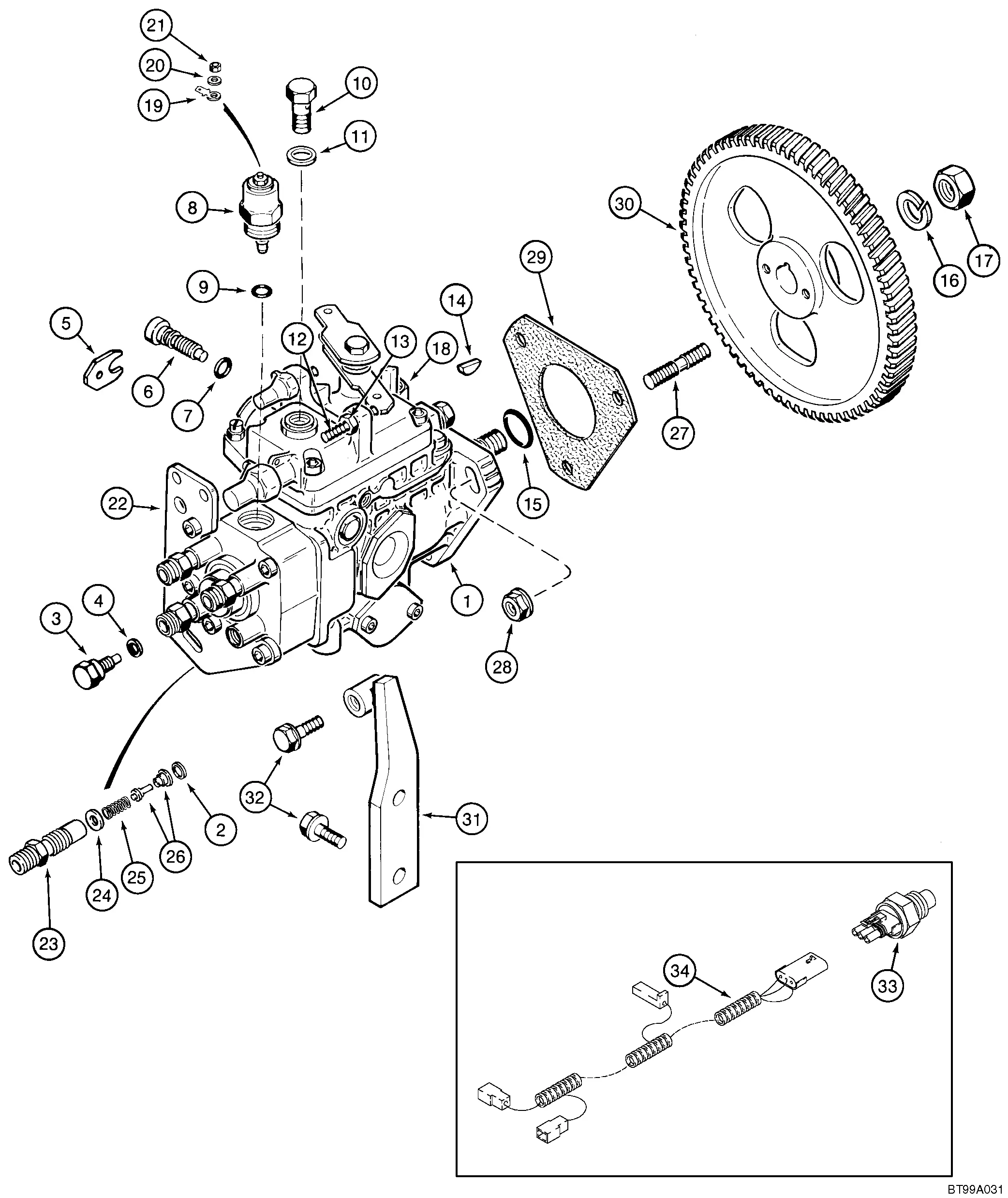

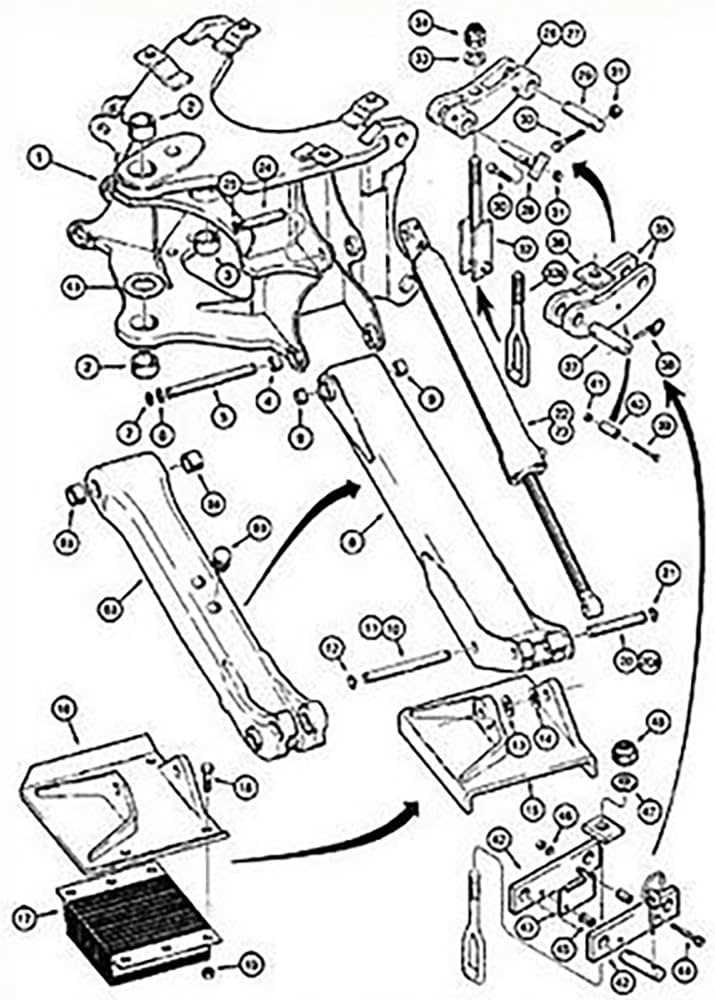

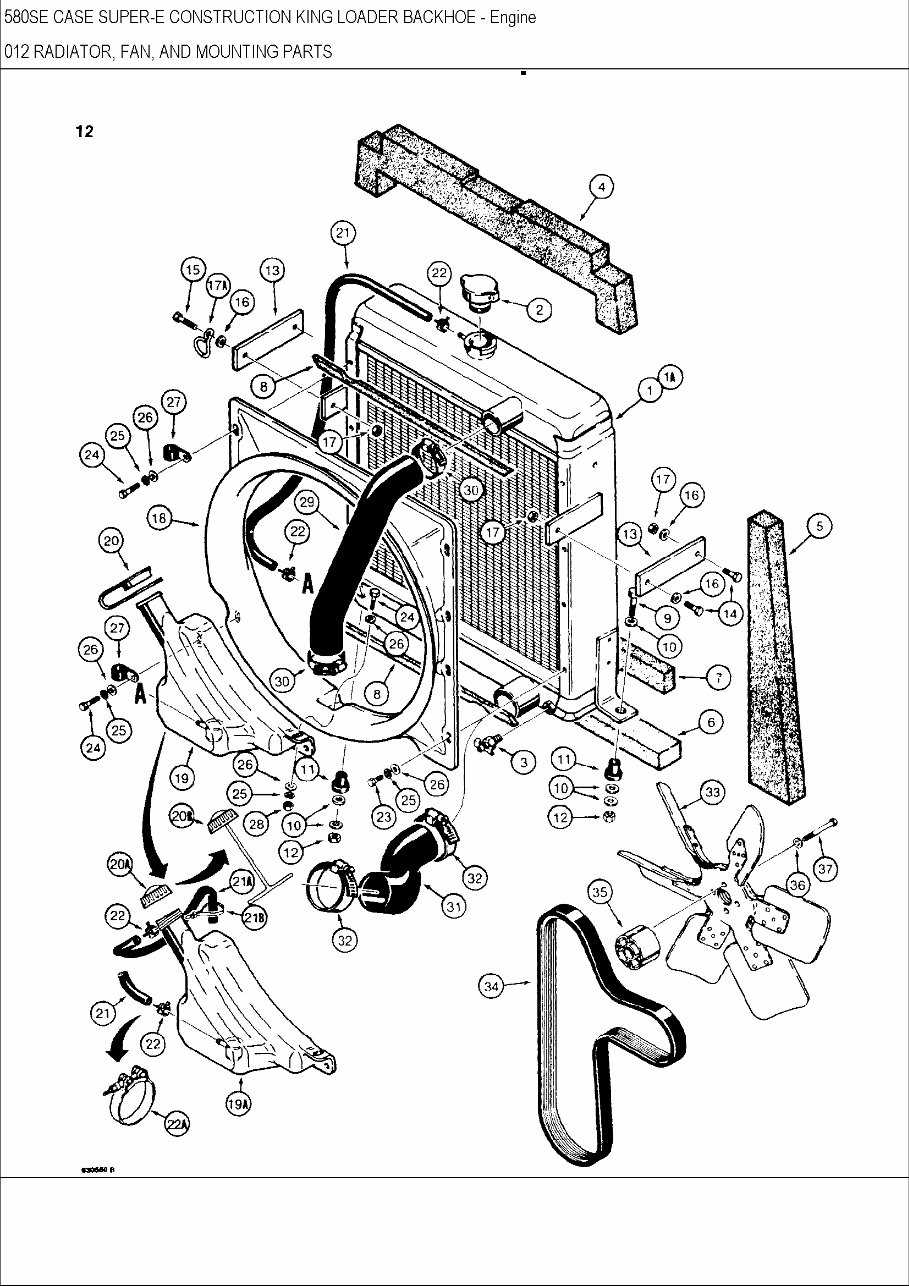

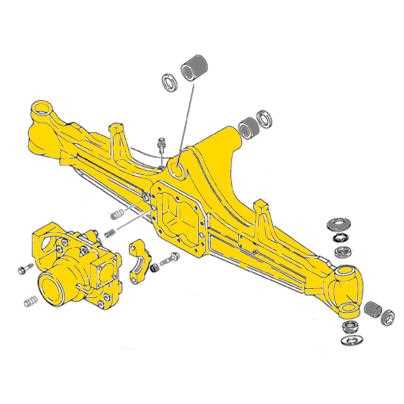

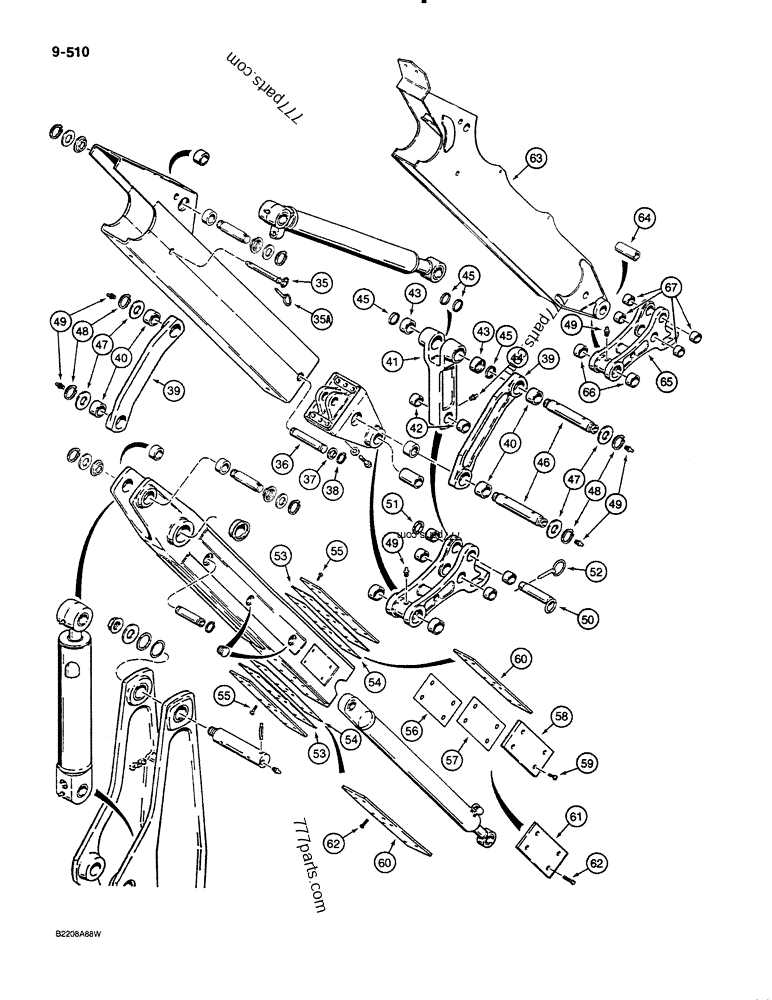

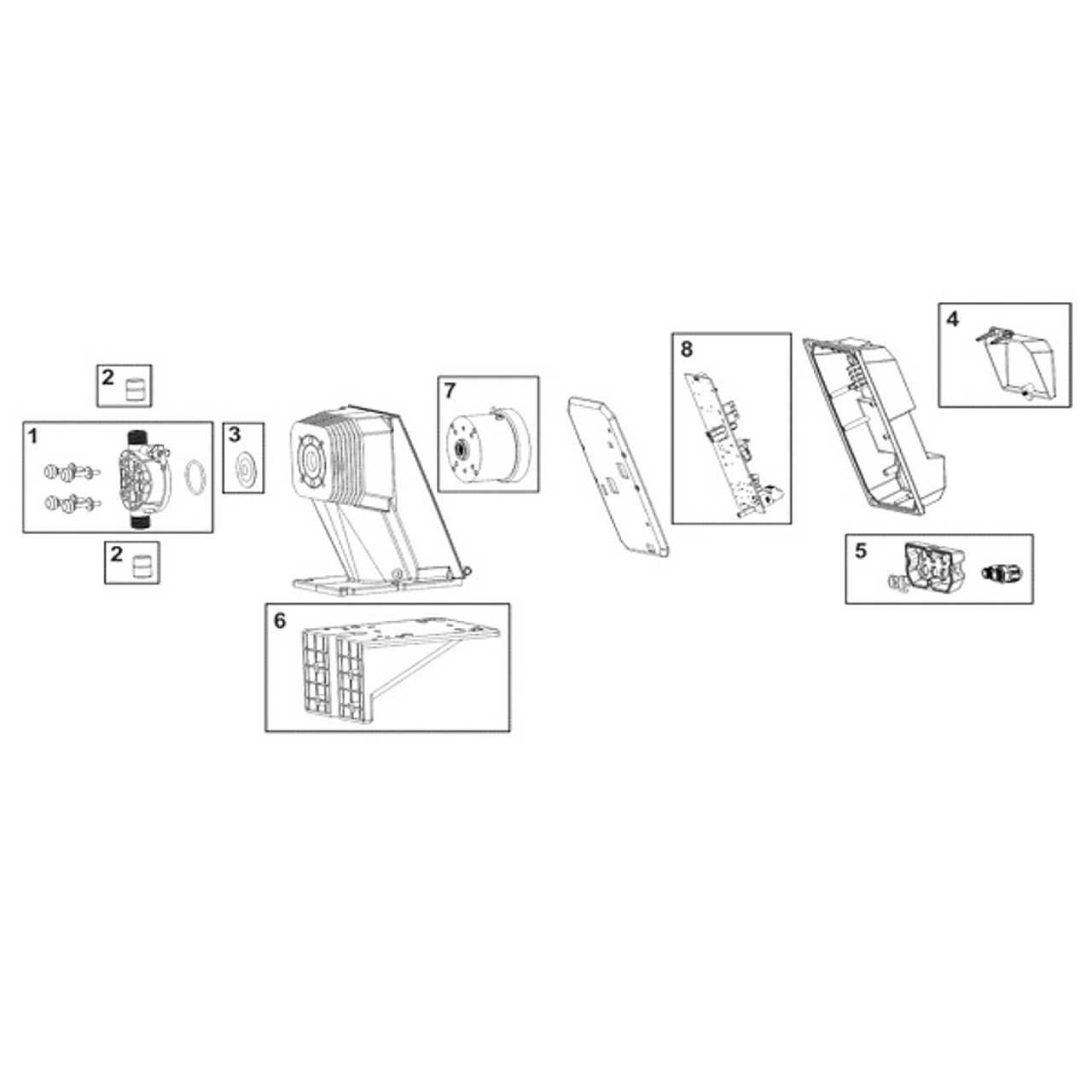

Visual representations serve as invaluable tools for those looking to maintain or repair their equipment. They provide a detailed overview of each part’s location and its role within the larger system. Such illustrations can significantly enhance comprehension and assist in troubleshooting issues effectively.

In this guide, we will navigate through a comprehensive illustration, highlighting critical aspects and offering explanations of the key features. This exploration aims to empower users with the knowledge necessary to ensure optimal performance and longevity of their machinery.

Understanding Case 580 Super E Parts

Grasping the components of heavy machinery is essential for maintenance and optimal performance. This section will explore the various elements that constitute these robust machines, highlighting their functions and significance in overall operation.

Key Components Overview

Every robust machine comprises multiple crucial elements, each serving specific purposes. From hydraulic systems to engine mechanisms, understanding each segment allows operators to ensure effective functionality and longevity.

Importance of Proper Maintenance

Regular upkeep of these components is vital for preventing breakdowns and enhancing efficiency. Knowledge of each element aids in timely repairs and replacements, ultimately contributing to smoother operations and reduced downtime.

Overview of the Equipment

This piece of machinery represents a vital component in the realm of construction and agriculture, providing versatile solutions for various tasks. Its robust design and advanced features ensure efficiency and reliability, making it a preferred choice among professionals.

Engineered for Performance: The equipment is equipped with a powerful engine that delivers optimal performance across a range of applications. Its capabilities include excavation, loading, and material handling, enabling users to tackle demanding projects with ease.

Design and Functionality: The layout of this machine emphasizes user-friendly operation. The ergonomic controls and intuitive interface facilitate seamless handling, allowing operators to focus on their tasks without unnecessary distractions.

Maintenance and Longevity: Regular upkeep is essential for ensuring the longevity of the equipment. With accessible components and a straightforward maintenance schedule, users can keep the machinery in top condition, minimizing downtime and maximizing productivity.

In summary, this equipment stands out as a reliable and efficient tool in its category, combining power, usability, and durability to meet the demands of modern operations.

Key Components Explained

This section provides an overview of essential elements that play a crucial role in the functionality and performance of heavy machinery. Understanding these components enhances maintenance and operational efficiency.

- Engine: The powerhouse responsible for providing the necessary energy to perform various tasks.

- Hydraulic System: A vital system that utilizes fluid pressure to enable movement and lifting capabilities.

- Transmission: This component transfers power from the engine to the wheels, facilitating movement.

- Chassis: The framework that supports all other parts and provides stability during operation.

Grasping the functions and interconnections of these elements allows for effective troubleshooting and enhances overall performance.

Benefits of Using Original Parts

Utilizing components from the manufacturer ensures optimal performance and longevity of machinery. These elements are specifically designed to fit seamlessly, providing reliability that aftermarket alternatives often cannot match.

- Quality Assurance: Original components undergo rigorous testing to meet strict standards.

- Perfect Fit: Engineered to match the specifications of your equipment precisely, reducing the risk of malfunctions.

- Warranty Protection: Using genuine parts often preserves warranty coverage, safeguarding your investment.

- Enhanced Performance: These components typically lead to improved efficiency and operation of the machinery.

- Increased Resale Value: Equipment maintained with original components tends to retain a higher market value.

Common Maintenance Practices

Regular upkeep is essential for ensuring the longevity and optimal performance of machinery. Implementing effective routines not only minimizes downtime but also enhances overall efficiency. Understanding and applying key maintenance strategies can lead to smoother operations and reduced repair costs.

1. Routine Inspections: Conducting frequent evaluations of components helps identify wear and tear before it escalates into major issues. Pay special attention to fluid levels, filters, and moving parts.

2. Lubrication: Proper lubrication of parts is crucial to prevent friction and overheating. Use recommended lubricants and adhere to scheduled application intervals.

3. Cleaning: Keeping the equipment clean is vital. Dirt and debris can lead to mechanical failures. Regularly clean surfaces, filters, and any areas prone to buildup.

4. Fluid Checks: Regularly monitor hydraulic and engine fluids to ensure they are at the correct levels and free from contamination. Replace fluids as needed to maintain peak performance.

5. Component Replacement: Proactively replacing worn-out parts can prevent unexpected breakdowns. Keep a log of parts that require replacement and address them promptly.

By incorporating these practices into a maintenance schedule, operators can significantly extend the life and efficiency of their machinery.

How to Identify Genuine Components

Ensuring the authenticity of machinery components is crucial for maintaining performance and longevity. Genuine items often exhibit specific characteristics that set them apart from counterfeit alternatives.

Examine the Packaging: Authentic products typically come in high-quality packaging, featuring clear branding and product information. Look for any inconsistencies in logos or text.

Check for Serial Numbers: Most genuine components will have a unique serial number or barcode. Verifying this number with the manufacturer can confirm authenticity.

Assess Material Quality: Authentic items are usually made from superior materials. Feel the weight and texture; fakes often feel lighter or have inferior finishes.

Consult Authorized Dealers: Purchasing from recognized retailers or directly from manufacturers reduces the risk of acquiring counterfeit components. Always verify the seller’s credibility.

Look for Warranty Information: Genuine products often come with warranties. Check the terms to ensure they align with manufacturer standards.

By delving into these details, one can confidently differentiate between authentic and imitation components, ensuring the ultimate performance of machinery.

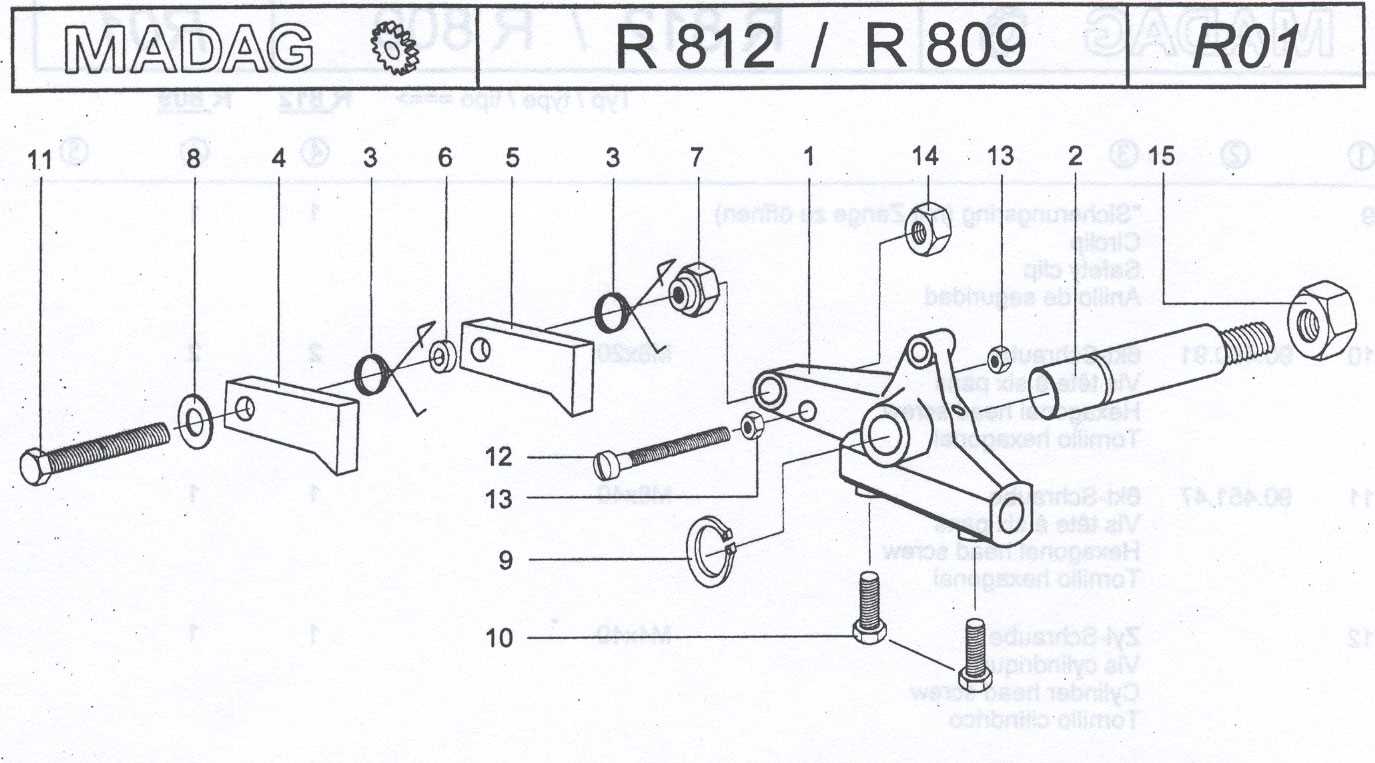

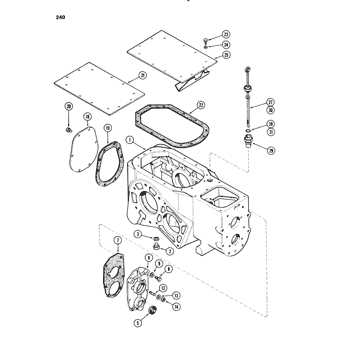

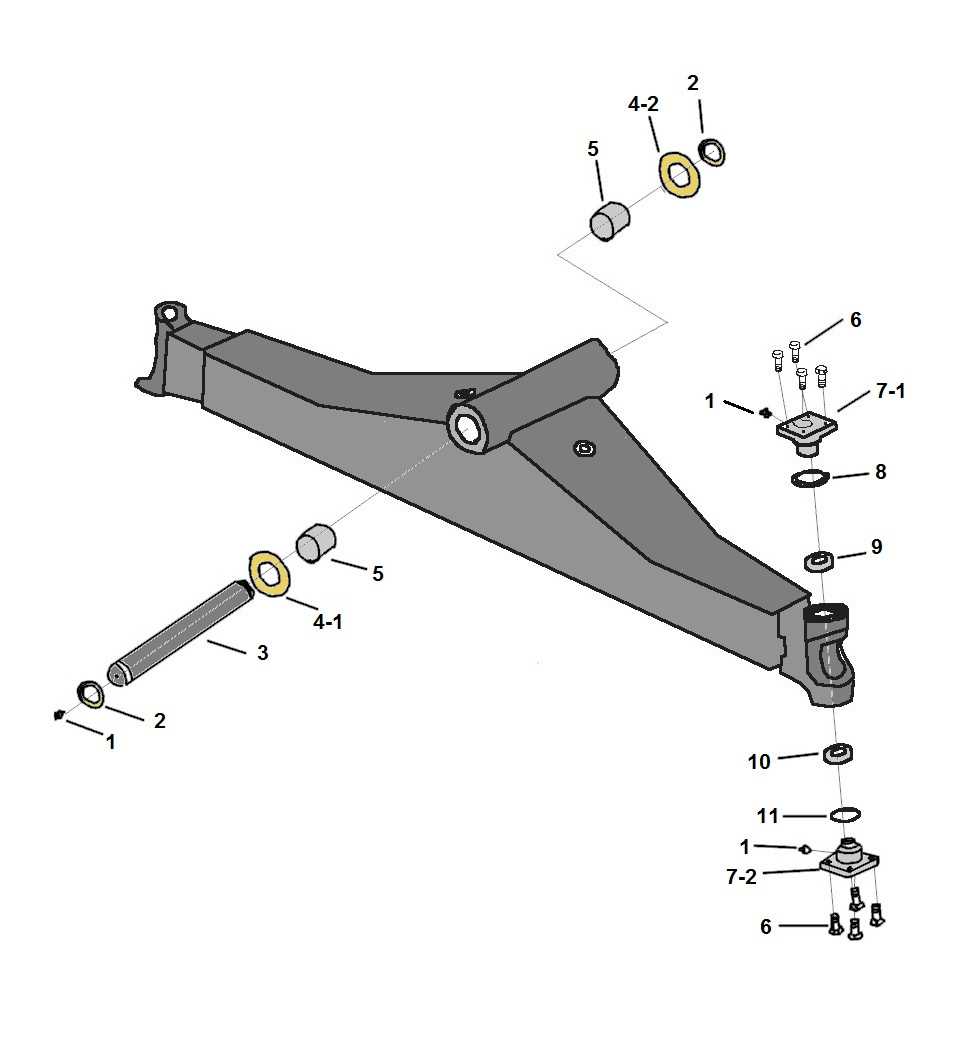

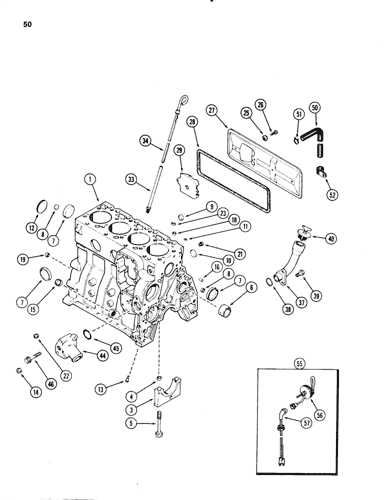

Parts Diagram Interpretation Tips

Understanding the layout of machinery components is crucial for effective maintenance and repair. A clear grasp of how each element fits together can significantly enhance troubleshooting and part replacement processes.

Key Approaches for Effective Understanding

- Familiarize yourself with common symbols used in schematics.

- Identify the major assemblies and their functions within the system.

- Pay attention to the connections and pathways between components.

Practical Steps to Enhance Comprehension

- Use a high-resolution version of the schematic for clarity.

- Take notes on parts and their respective roles as you analyze the layout.

- Refer to the machinery manual for detailed explanations of complex systems.

Where to Find Replacement Parts

Locating suitable components for your machinery can often be a challenging task. Whether you’re performing routine maintenance or addressing a specific issue, understanding where to source these items is crucial. Numerous avenues exist for acquiring the necessary elements, ensuring your equipment remains operational and efficient.

Authorized Dealers

One of the most reliable sources for obtaining quality components is through authorized distributors. These dealers are recognized by manufacturers and typically offer genuine items that meet the original specifications. Engaging with them not only guarantees compatibility but also provides access to expert advice regarding installation and maintenance.

Online Marketplaces

The internet has transformed the way we shop, providing a vast array of options for purchasing components. Various online platforms cater specifically to machinery needs, allowing users to compare prices and reviews. However, it’s essential to verify the credibility of sellers to ensure you receive quality products. Always check return policies and customer feedback to make informed decisions.

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in various machinery and equipment, utilizing fluid power to perform tasks efficiently. These systems convert mechanical energy into hydraulic energy, enabling the transfer of force through fluid movement. By comprehending their components and functions, one can appreciate their significance in modern engineering.

The primary elements of a hydraulic system include a fluid reservoir, a pump, valves, and actuators. Each component interacts seamlessly to ensure the smooth operation of machinery. For instance, the pump generates flow, while valves control the direction and pressure of the fluid.

Understanding the principles behind hydraulic systems not only aids in troubleshooting but also enhances the design and optimization of these systems for improved performance and safety. Whether in construction, manufacturing, or automotive applications, hydraulic technology remains a vital aspect of industrial operations.

Importance of Regular Inspections

Routine assessments of machinery play a crucial role in ensuring optimal performance and longevity. Regular checks help identify potential issues before they escalate, allowing for timely interventions and minimizing downtime. This proactive approach is essential for maintaining safety and efficiency in operations.

Benefits of Regular Inspections

- Preventative Maintenance: Regular evaluations can reveal wear and tear, enabling timely repairs and replacements.

- Increased Safety: Identifying potential hazards ensures the safety of operators and surrounding personnel.

- Cost Savings: Addressing minor issues early can prevent costly breakdowns and extensive repairs.

- Enhanced Performance: Well-maintained equipment operates more efficiently, leading to better productivity.

- Compliance: Regular checks help ensure adherence to industry regulations and standards.

Best Practices for Conducting Inspections

- Establish a regular inspection schedule based on usage and manufacturer recommendations.

- Keep detailed records of all inspections, maintenance performed, and any issues encountered.

- Train personnel on proper inspection techniques and safety protocols.

- Use a checklist to ensure no component is overlooked during evaluations.

- Review and update inspection procedures as needed to incorporate new technologies and practices.

Aftermarket vs. OEM Parts

The choice between original components and those produced by third-party manufacturers can significantly impact maintenance and repair decisions. Each option presents distinct advantages and disadvantages, influencing both performance and cost-effectiveness.

Original components are designed and manufactured by the same company that produced the machinery. These items ensure compatibility and reliability, often reflecting the same quality standards as the original assembly. However, they tend to come at a higher price point, which may deter some buyers.

On the other hand, third-party components can offer a more affordable alternative, appealing to budget-conscious consumers. While many of these products are engineered to meet or exceed the specifications of their original counterparts, the variability in quality can be a concern. It’s crucial to thoroughly research and select reputable brands to avoid potential issues.

Ultimately, the decision between original and third-party components hinges on individual priorities, including cost, reliability, and the specific requirements of the equipment in question. Weighing these factors will help in making an informed choice that aligns with both performance needs and financial constraints.

Resources for Further Learning

Expanding your knowledge about heavy machinery can greatly enhance your understanding and skills in maintenance and repair. Numerous resources are available to help enthusiasts and professionals alike delve deeper into this field, ensuring they stay informed about the latest techniques and technologies.

Books and Manuals: Numerous publications offer comprehensive insights into machinery operation and troubleshooting. Look for technical manuals and industry-specific guides that provide detailed information.

Online Courses: Various platforms offer courses focused on equipment mechanics and maintenance strategies. These programs can be beneficial for both beginners and seasoned operators looking to sharpen their skills.

Forums and Communities: Engaging in online communities allows for the exchange of knowledge and experiences. Participating in discussions can lead to valuable tips and real-world solutions.

Video Tutorials: Platforms like YouTube host a wealth of visual content demonstrating repair techniques and maintenance processes, making complex tasks easier to understand.

Manufacturer Websites: Many manufacturers provide extensive resources, including technical support and downloadable documents that cover various aspects of machinery management.