When working with heavy equipment, a thorough comprehension of its components is essential for efficient operation and maintenance. Each machine consists of various elements that interact to ensure optimal functionality. Recognizing these elements allows operators and technicians to troubleshoot issues and perform repairs more effectively.

Identifying each component helps in diagnosing problems that may arise during use. By understanding the roles of different parts, users can enhance their skills in maintenance and repairs. This knowledge not only prolongs the lifespan of the equipment but also improves overall performance.

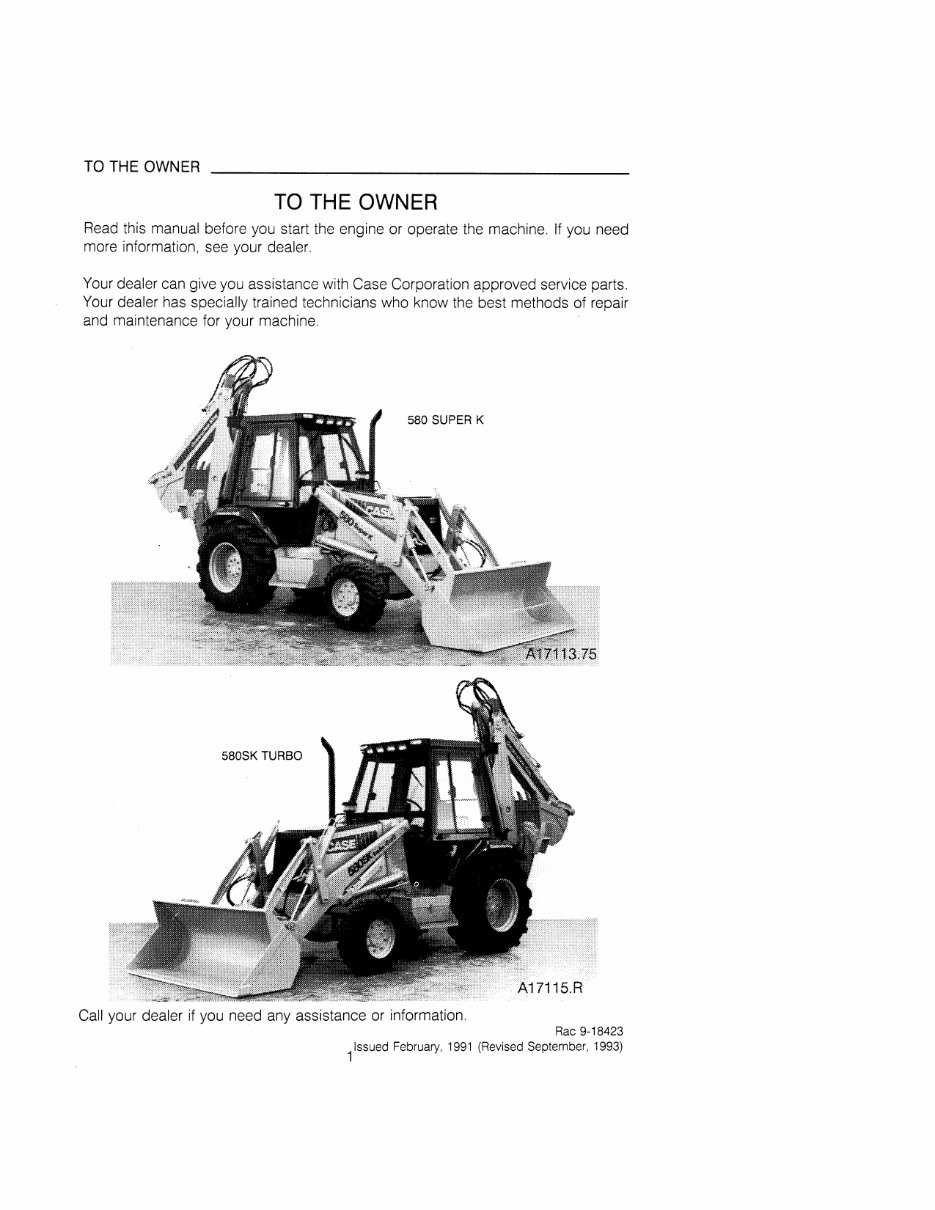

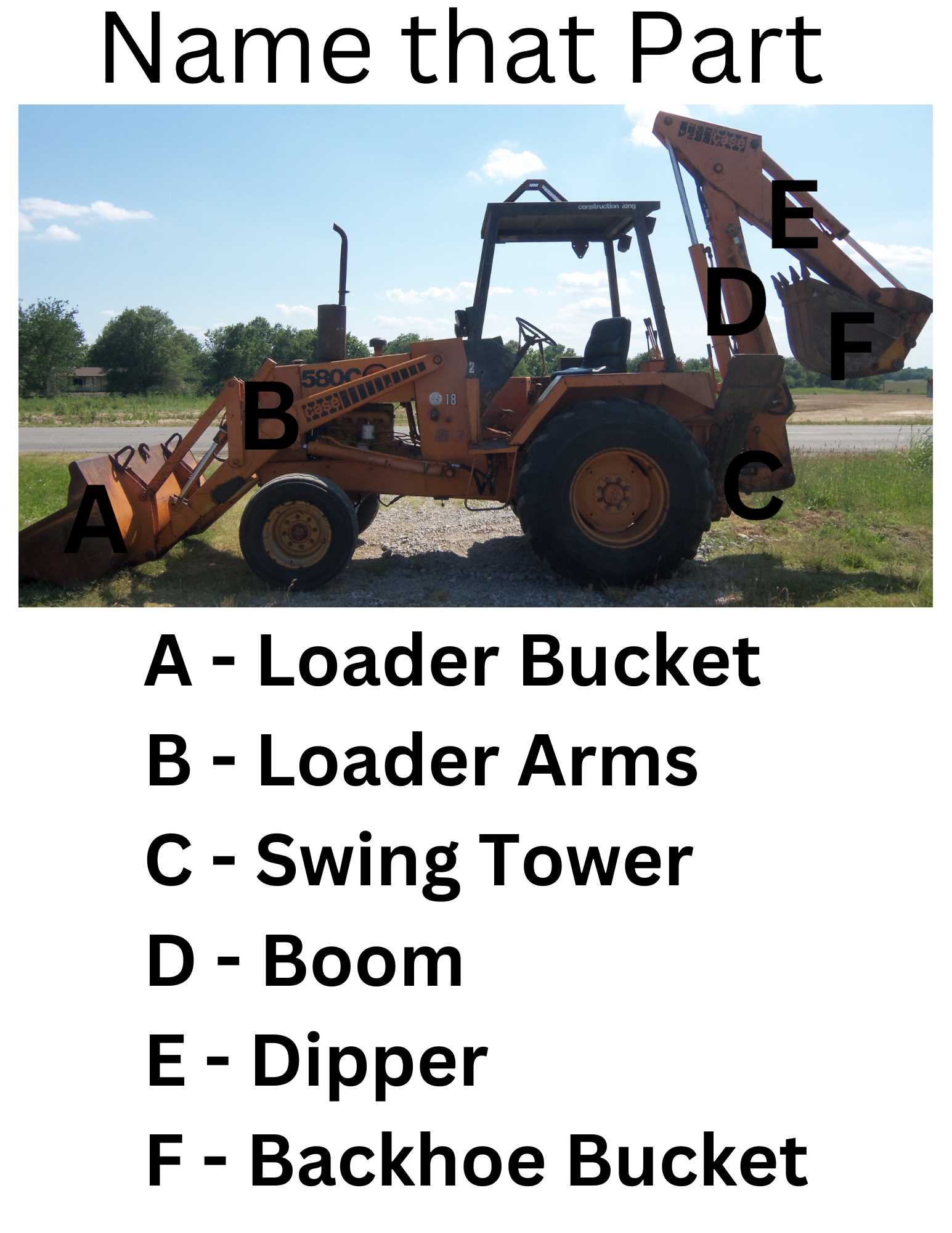

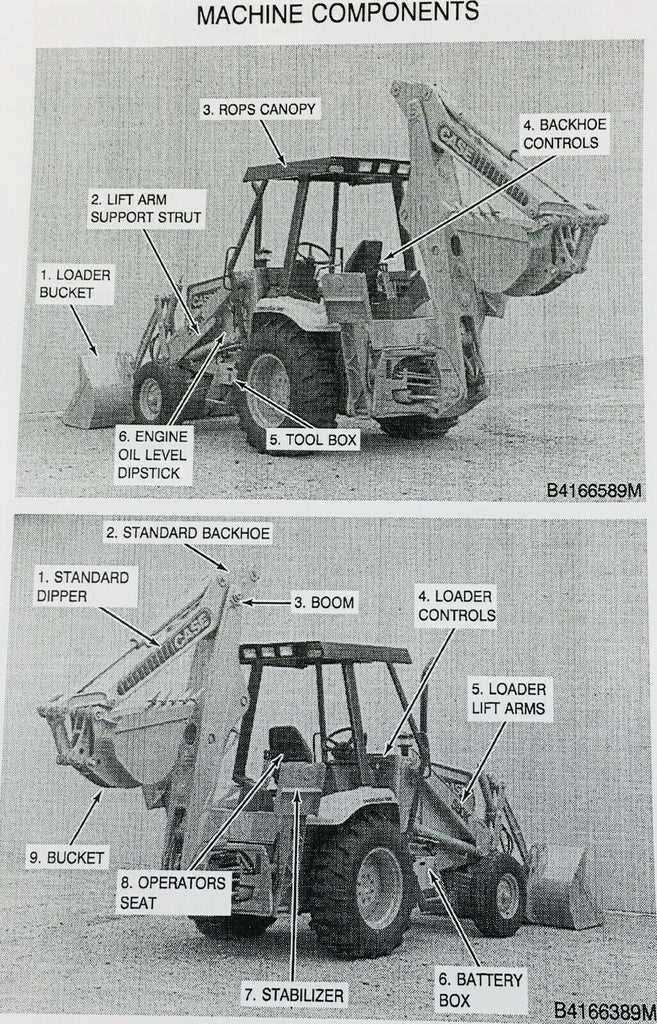

Additionally, having a visual representation of the machine’s structure can significantly aid in learning. It serves as a valuable reference point for both novice and experienced operators, facilitating a better grasp of how each element contributes to the machinery’s operation.

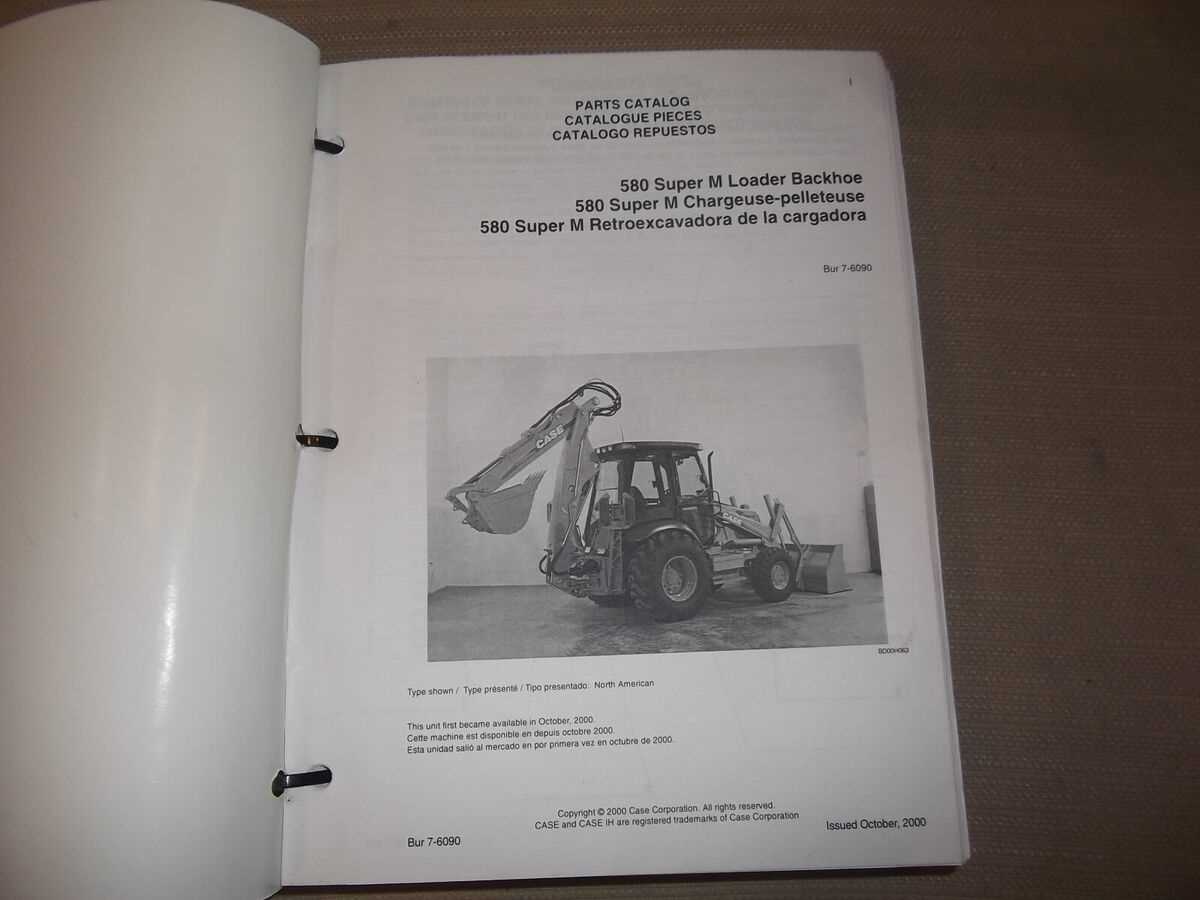

This section aims to provide an insightful look into a specific model of heavy machinery, focusing on its key components and functionalities. Understanding the various elements that contribute to its operation is essential for maintenance and repair, ensuring optimal performance in various applications.

The following outline highlights the crucial aspects of this equipment:

- Introduction to the Machinery

- Purpose and applications

- Historical significance in the industry

- Specifications

- Engine details

- Operating weight

- Hydraulic system overview

- Key Components

- Structural framework

- Transmission system

- Control mechanisms

- Maintenance Tips

- Regular checks and servicing

- Common issues and their solutions

- Replacement Parts

- Types of components available

- Choosing quality replacements

- Assembly Guidelines

- Step-by-step assembly process

- Tools required for assembly

- Safety Precautions

- Operational safety measures

- Protective gear recommendations

- Common Upgrades

- Performance enhancements

- Modern technology integrations

- Comparative Analysis

- Comparison with similar models

- Advantages and disadvantages

- User Testimonials

- Real-world performance feedback

- Maintenance experiences from operators

- Conclusion

- Summary of key points

- Future trends and innovations

Key Components of the Model

This section explores the essential elements that contribute to the functionality and performance of the machinery in question. Understanding these components is crucial for effective operation and maintenance.

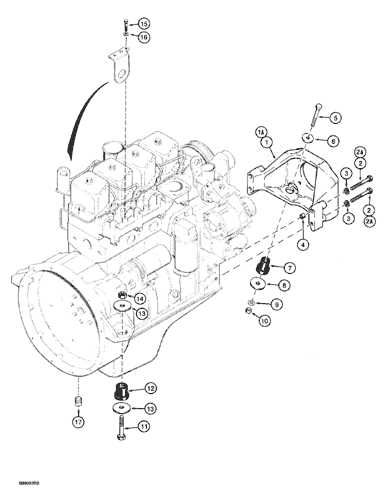

Engine: The powerhouse of the equipment, providing the necessary energy for various tasks. Its efficiency directly affects the overall performance.

Transmission System: This system ensures smooth power transfer from the engine to the wheels, allowing for optimal speed and maneuverability.

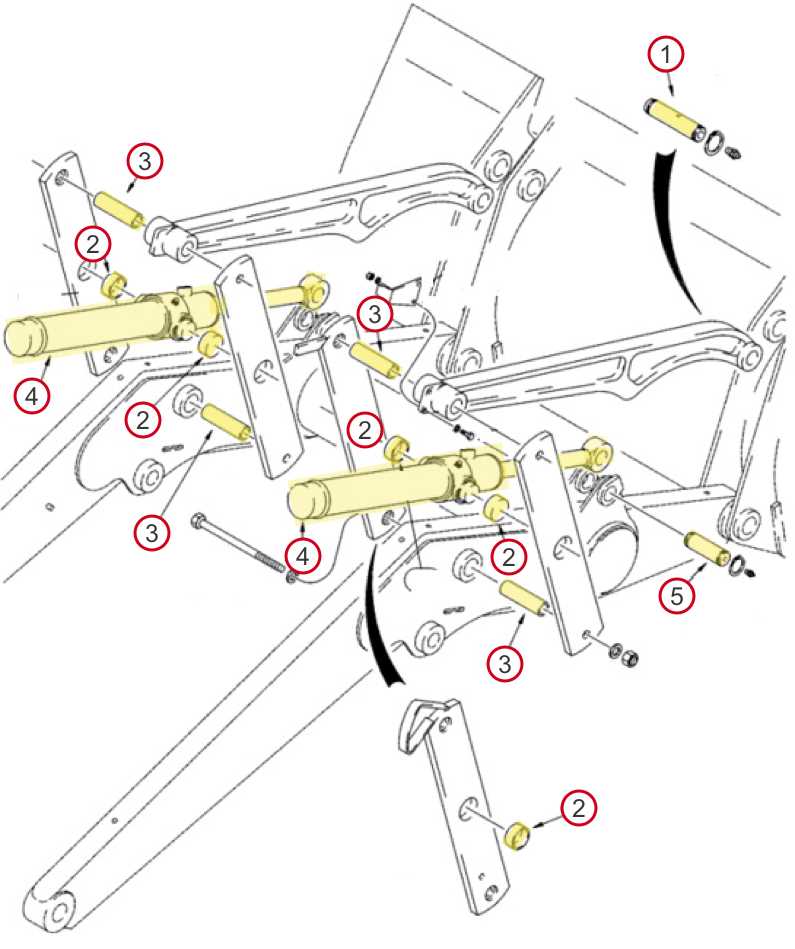

Hydraulic Components: Vital for enabling lifting and digging functions, these parts play a key role in enhancing the machine’s versatility and efficiency.

Chassis: The framework that supports all other components, contributing to the stability and durability of the model.

Control Systems: These allow the operator to manage the machine’s functions easily, ensuring precise movements and operations.

Electrical System: Responsible for powering lights, indicators, and other electronic features, this system enhances safety and usability during operation.

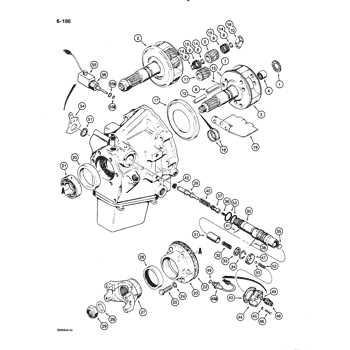

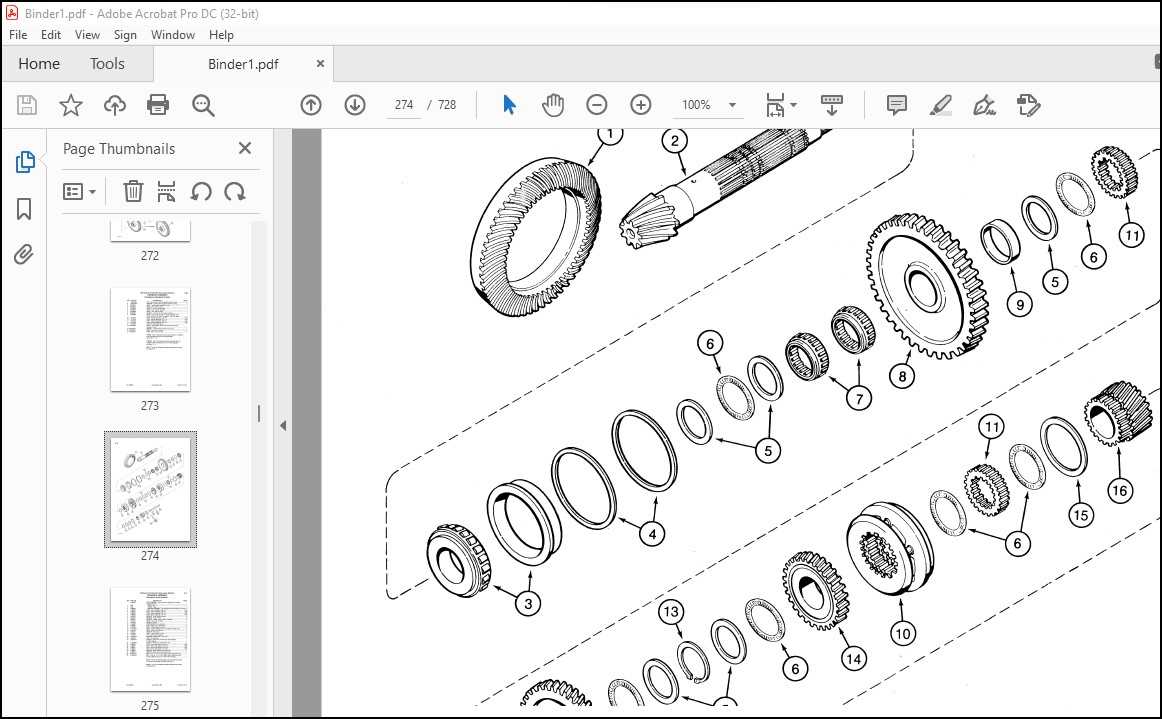

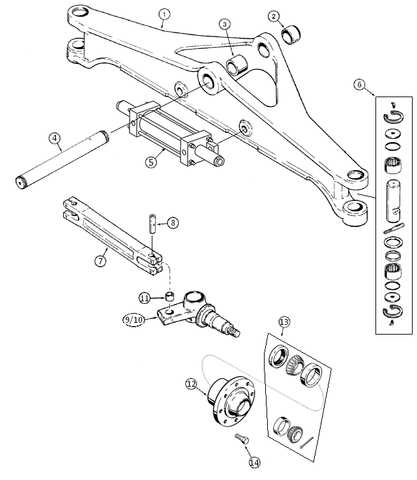

Understanding the Parts Diagram

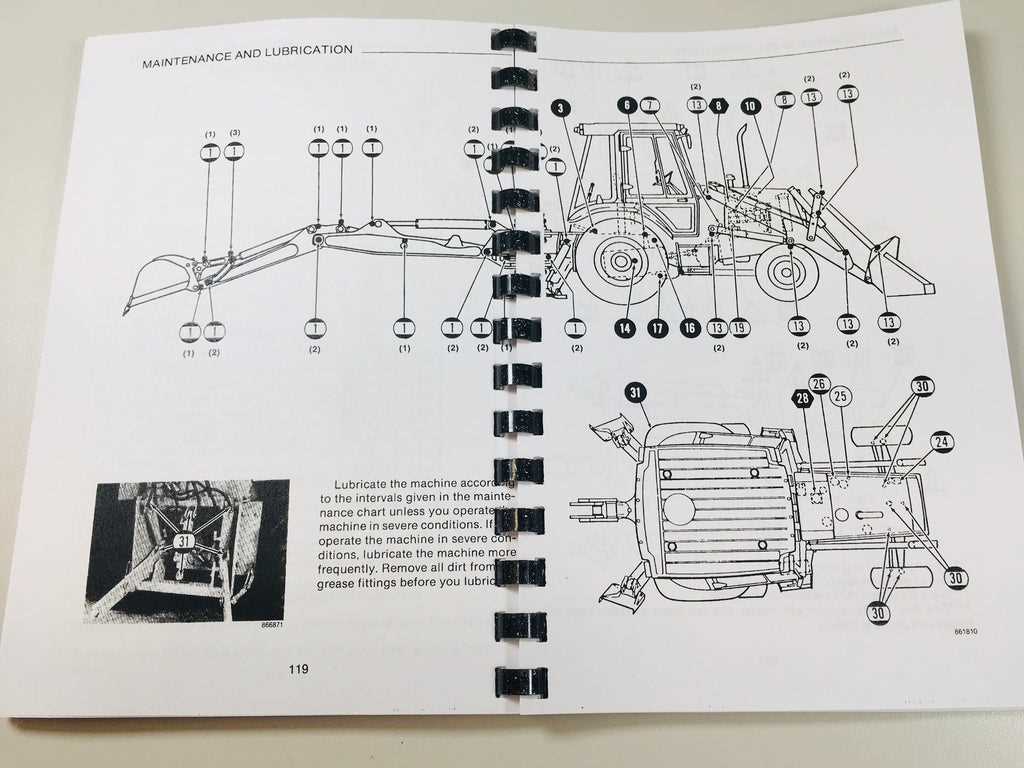

Comprehending the schematic representation of components is essential for efficient maintenance and repair. This illustration serves as a vital tool, providing a clear overview of the individual elements and their interconnections. By analyzing this representation, operators can identify parts, understand their functions, and locate them within the machinery.

The schematic layout is divided into several sections, each highlighting different categories of elements. This organization facilitates easy navigation and understanding of complex systems, ensuring users can quickly locate specific components when needed.

| Component | Description | Function |

|---|---|---|

| Engine | Primary power source | Generates energy for operation |

| Transmission | Power transfer unit | Transmits engine power to wheels |

| Hydraulic System | Fluid-driven mechanism | Controls movement of attachments |

| Chassis | Structural framework | Supports all other components |

| Operator’s Cabin | Control area for the user | Provides comfort and control |

Importance of Maintenance Parts

Regular upkeep is crucial for ensuring the longevity and efficiency of machinery. This involves not only routine inspections and adjustments but also the timely replacement of various components. Failing to address worn or damaged elements can lead to more significant issues, impacting performance and safety.

Enhancing Performance

Utilizing high-quality replacement components can significantly enhance the overall functionality of equipment. When essential items are maintained, machines operate at optimal levels, reducing downtime and improving productivity. This proactive approach not only safeguards against unexpected failures but also contributes to smoother operations.

Cost Efficiency

Investing in reliable replacement components can lead to substantial long-term savings. By preventing major breakdowns through regular maintenance, operators can avoid expensive repairs and prolonged downtime. Additionally, efficient machinery consumes less energy, further lowering operational costs.

Common Issues and Solutions

This section addresses frequently encountered challenges faced by users of heavy machinery and offers practical solutions to enhance performance and longevity.

-

Engine Overheating

Overheating can occur due to several factors. Regular maintenance is essential to prevent this issue.

- Check coolant levels and ensure proper circulation.

- Inspect the radiator for blockages or damage.

- Examine the water pump functionality.

-

Hydraulic System Failure

A malfunctioning hydraulic system can lead to decreased efficiency. Common causes include leaks and low fluid levels.

- Inspect hydraulic hoses for wear or damage.

- Ensure proper fluid levels and quality.

- Check for leaks in the pump and cylinder connections.

-

Transmission Issues

Problems with the transmission may manifest as slipping or unusual noises during operation.

- Check fluid levels and quality.

- Inspect the filter for clogs.

- Evaluate the condition of the transmission seals.

-

Electrical Failures

Electrical components may fail due to faulty wiring or connections, leading to operational issues.

- Examine wiring for signs of wear or damage.

- Check battery voltage and connections.

- Test fuses and relays for continuity.

How to Interpret the Diagram

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide a detailed overview of component relationships and functions, enabling users to troubleshoot and identify issues efficiently. Proper interpretation of such illustrations can save time and resources by streamlining the repair process.

Recognizing Symbols and Notations

Every schematic includes specific symbols and notations that represent various elements. Familiarizing oneself with these icons is crucial for decoding the information presented. Each symbol corresponds to a particular part or function, allowing users to grasp the overall system layout and interactions.

Following the Flow of Components

Analyzing the connectivity between different elements is key to understanding the overall design. Pay attention to the lines connecting the symbols, as they indicate the flow of operations and signals. Tracing these connections helps identify potential points of failure and enhances troubleshooting efforts.

In summary, mastering the interpretation of technical illustrations involves recognizing symbols and understanding the flow of components. By honing these skills, users can improve their efficiency in maintenance and repair tasks.

Aftermarket Parts and Compatibility

When considering alternatives for equipment components, understanding the availability and compatibility of these replacements is crucial. The market offers a wide range of aftermarket solutions that can often meet or exceed the quality of original manufacturer products. This section will delve into the significance of these alternatives, highlighting their benefits and potential challenges in achieving a perfect fit and function.

Benefits of Aftermarket Solutions

One of the primary advantages of opting for alternative components is cost savings. These substitutes are frequently priced lower than their original counterparts, making maintenance more affordable for operators. Additionally, aftermarket items may provide enhanced performance features or improved durability, which can lead to greater efficiency in operations.

Challenges and Considerations

Despite their benefits, it’s essential to approach aftermarket solutions with caution. Not all alternatives guarantee the same level of reliability as original components. Operators should conduct thorough research to ensure compatibility and assess the reputation of manufacturers. Additionally, verifying warranty implications is vital, as some replacements might void existing guarantees on the machinery.

Tools Needed for Repairs

Proper maintenance and restoration of machinery require specific tools to ensure efficiency and effectiveness. Having the right equipment at hand not only streamlines the repair process but also enhances safety and accuracy in your work. Below are essential implements that should be included in your toolkit for optimal repairs.

Essential Hand Tools

- Wrenches: A variety of sizes to accommodate different fasteners.

- Screwdrivers: Both flathead and Phillips types for versatile applications.

- Pliers: Needle-nose and slip-joint pliers for gripping and twisting.

- Hammer: A claw hammer for driving nails and removing them.

- Socket set: For quick and efficient fastening.

Power Tools and Equipment

- Drill: A reliable power drill for creating holes and driving screws.

- Impact wrench: Essential for loosening tight bolts.

- Angle grinder: Useful for cutting, grinding, and polishing surfaces.

- Cutting torch: For precise metal cutting in heavy repairs.

Safety Precautions During Repairs

When undertaking maintenance or troubleshooting on machinery, adhering to safety protocols is essential to prevent accidents and injuries. A proactive approach to safety ensures that both the operator and the equipment remain unharmed throughout the repair process.

Prioritize Personal Protective Equipment (PPE): Always wear appropriate safety gear, including gloves, goggles, and steel-toed boots. This gear is designed to protect against potential hazards such as sharp edges, flying debris, and heavy objects.

Ensure Proper Ventilation: When working with fuel or chemicals, ensure that the workspace is well-ventilated. This reduces the risk of inhaling harmful fumes and ensures a safer working environment.

Disconnect Power Sources: Before beginning any repair work, disconnect the power supply to the machinery. This simple step prevents accidental activation and protects against electrical hazards.

Use Tools Correctly: Familiarize yourself with the proper use of tools and equipment. Using tools as intended reduces the risk of mishaps and increases the efficiency of the repair process.

Keep Workspace Organized: An orderly work area minimizes the risk of tripping and ensures that tools and materials are easily accessible. This practice enhances overall safety and productivity during repairs.

Be Aware of Surroundings: Stay mindful of your environment and any potential hazards. Regularly assess the work area for obstacles, slippery surfaces, or other risks that could lead to accidents.

By following these essential safety measures, individuals can significantly reduce the likelihood of accidents while ensuring that repairs are carried out effectively and safely.

Upgrading Components for Performance

Enhancing machinery efficiency often involves the careful selection and replacement of various elements within the system. By upgrading specific components, operators can achieve greater reliability, improved power output, and increased overall effectiveness. This process requires a thorough understanding of the existing setup and how new additions will integrate with it.

Common upgrades include engine modifications, hydraulic system enhancements, and improved transmission components. These changes not only boost performance but can also extend the lifespan of the equipment, ensuring it operates at optimal levels for an extended period.

| Component Type | Benefits of Upgrading |

|---|---|

| Engine | Increased horsepower and torque, better fuel efficiency |

| Hydraulic System | Improved lifting capacity and speed |

| Transmission | Smoother shifting and enhanced durability |

| Cooling System | Enhanced temperature regulation, preventing overheating |

Resources for Parts Acquisition

When it comes to sourcing components for machinery, a variety of resources can streamline the process. These avenues not only provide access to necessary elements but also ensure that users can obtain quality items efficiently and effectively. Utilizing the right platforms can significantly enhance the overall maintenance experience.

Online Marketplaces

One of the most convenient options available is the use of online marketplaces. Websites dedicated to construction and agricultural equipment often have extensive inventories, offering everything from replacement items to accessories. Buyers can compare prices, check availability, and read reviews to make informed decisions.

Local Dealers and Distributors

Connecting with local dealers and distributors can also be beneficial. These professionals typically have a wealth of knowledge about the specific machinery and can provide guidance on compatible components. Establishing a relationship with a trusted dealer can lead to reliable service and support.

Additionally, forums and community groups can serve as valuable resources. Engaging with fellow users allows for the sharing of experiences and recommendations on where to find high-quality components.

Owner Experiences and Tips

This section aims to share valuable insights and practical advice gathered from individuals who have worked with similar machinery. Their experiences can provide guidance on maintenance, common challenges, and effective solutions.

Many users emphasize the importance of regular upkeep to extend the lifespan of the equipment. Routine checks on hydraulic fluids and filters can prevent more significant issues down the line. It’s advisable to maintain a detailed log of service intervals to ensure nothing is overlooked.

Furthermore, several operators recommend joining online forums or local groups to connect with fellow users. These communities often share troubleshooting tips and modifications that can enhance performance. For instance, modifications to the hydraulic system have been noted to improve lifting capacity.

Lastly, when sourcing components, it’s beneficial to research reputable suppliers to avoid counterfeit parts that could compromise safety and functionality. Investing in quality parts pays off in the long run, as they tend to offer better durability and efficiency.