The intricate world of heavy machinery encompasses various components that work in harmony to perform complex tasks. Each element plays a pivotal role in ensuring efficiency and reliability on the job site. Grasping how these components interconnect is crucial for anyone involved in maintenance or operation.

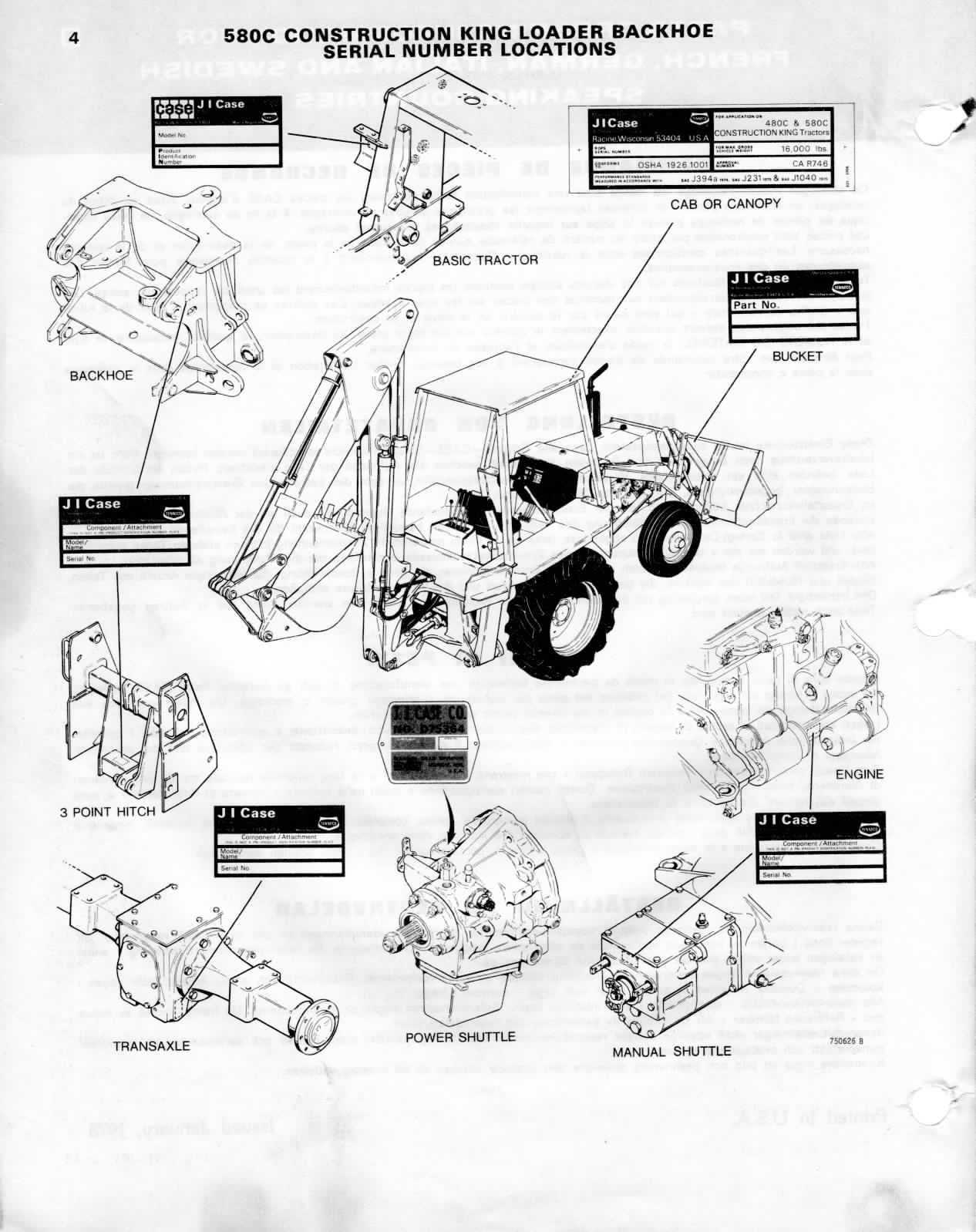

Detailed visual representations serve as valuable tools for understanding the arrangement and function of each segment. By examining these illustrations, operators and technicians can pinpoint issues and facilitate effective repairs. This knowledge ultimately enhances productivity and extends the lifespan of the equipment.

Whether you’re a seasoned professional or a novice, exploring these schematics can provide deeper insights into the functionality of your machinery. Empower yourself with the information necessary to optimize performance and tackle challenges confidently.

Understanding Case 580K Backhoe Parts

Having a comprehensive knowledge of the components of heavy machinery is essential for effective operation and maintenance. Each element plays a vital role in the overall functionality, ensuring that the equipment performs at its best. Familiarity with these components not only aids in troubleshooting but also enhances the ability to execute repairs efficiently.

Key Components Overview

Heavy machinery consists of several integral parts, each contributing to its performance. Understanding these components can greatly improve operational efficiency:

- Engine: The heart of the machine, providing the necessary power for operation.

- Hydraulic System: Responsible for lifting and digging, utilizing fluid power for movement.

- Transmission: Facilitates the transfer of power from the engine to the wheels or tracks.

- Chassis: The framework that supports all other components and provides stability.

- Cab: The operator’s space, designed for comfort and visibility while working.

Maintenance Considerations

Regular upkeep is crucial for prolonging the life of heavy equipment. Key maintenance practices include:

- Routine Inspections: Regular checks for wear and tear can prevent unexpected breakdowns.

- Fluid Changes: Keeping hydraulic fluid and engine oil at proper levels ensures optimal performance.

- Component Replacement: Timely replacement of worn parts minimizes the risk of failure.

- Cleaning: Regular cleaning of filters and surfaces prevents dirt buildup that can impair function.

By understanding these essential components and maintenance practices, operators can enhance their machinery’s performance and longevity, ensuring successful operations for years to come.

Overview of Backhoe Functionality

Heavy machinery designed for excavation and construction tasks serves a vital role in various projects. These versatile machines combine multiple functions, making them invaluable on job sites. By integrating a digging arm and a loading bucket, they can efficiently perform a wide range of operations, from trenching to material handling.

At the heart of this equipment’s efficiency lies its ability to maneuver in tight spaces while maintaining power and precision. The digging mechanism allows for deep excavation, essential for foundations and utilities, while the loading component facilitates the movement of soil and debris. This dual capability not only saves time but also reduces the need for multiple machines, streamlining workflow.

Additionally, modern innovations have enhanced the functionality of these machines. With advanced hydraulic systems and controls, operators can execute tasks with greater accuracy and ease. The integration of various attachments further expands the range of applications, enabling users to adapt to different project requirements seamlessly.

In summary, the unique design and multifunctional nature of this equipment make it an essential asset in the construction and excavation industries. Its ability to combine strength and versatility ensures efficiency and productivity across various tasks.

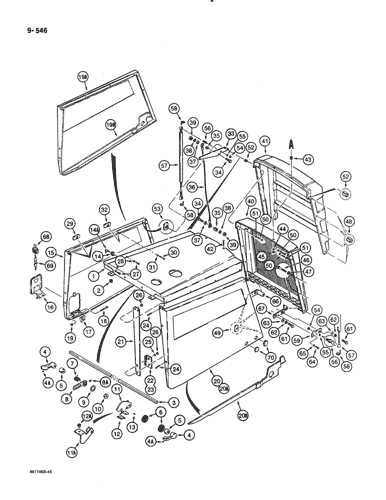

Importance of Accurate Parts Diagrams

Detailed illustrations of components are crucial for efficient maintenance and repair processes. They serve as essential references, providing clarity and ensuring that all elements are correctly identified and understood. By utilizing precise representations, technicians can streamline their work, reduce the likelihood of errors, and enhance overall productivity.

Furthermore, having a reliable visual guide allows for better communication among team members. It aids in the training of new employees, enabling them to quickly grasp the intricacies of the machinery. When everyone is on the same page, the risk of miscommunication diminishes significantly.

| Benefit | Description |

|---|---|

| Efficiency | Reduces time spent on identifying and locating components. |

| Accuracy | Minimizes the chance of mistakes during repairs and replacements. |

| Training | Facilitates quicker onboarding for new technicians. |

| Collaboration | Enhances teamwork by providing a common reference point. |

In conclusion, well-crafted visual representations are indispensable tools in the maintenance toolkit. They not only promote efficiency and accuracy but also foster an environment of collaboration and continuous learning.

Key Components of Case 580K

Understanding the fundamental elements of this powerful machine is essential for effective operation and maintenance. Each component plays a vital role in its overall functionality, ensuring optimal performance in various tasks.

- Engine: Provides the necessary power to operate various attachments and functions.

- Hydraulic System: Facilitates movement and operation of the loader and excavator arms.

- Transmission: Ensures efficient power transfer from the engine to the wheels.

- Frame: Offers structural integrity and support for all other components.

- Controls: Allow the operator to manage the machine’s functions effectively.

By delving into these crucial parts, operators can enhance their understanding and maintain the equipment in optimal condition.

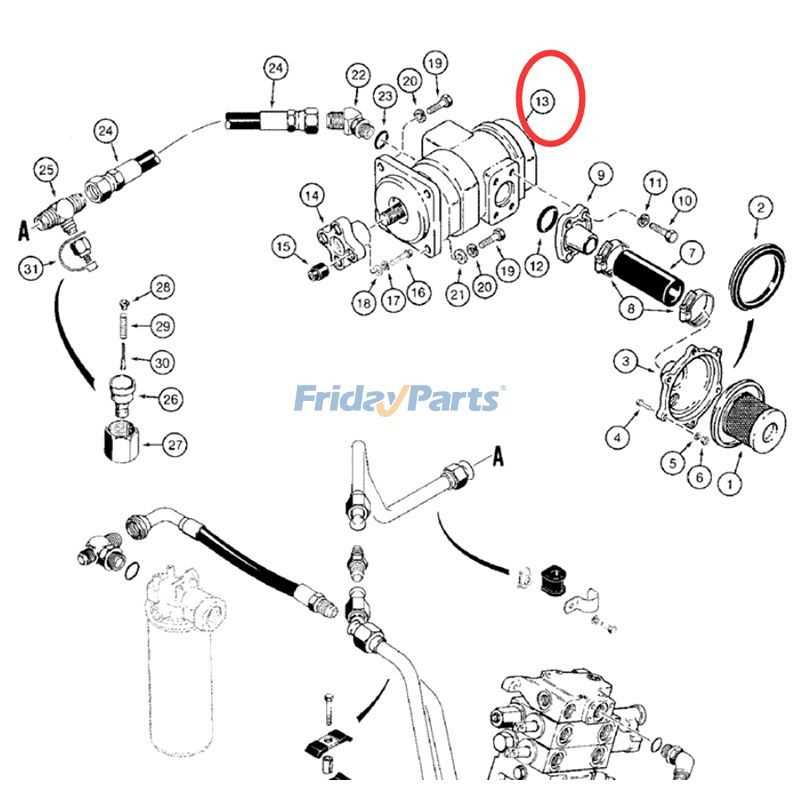

Hydraulic System Explained

The hydraulic system is a fundamental component in heavy machinery, enabling powerful and precise movements through the use of fluid pressure. This system transforms mechanical energy into hydraulic energy, allowing operators to perform various tasks with ease and efficiency. Understanding its components and functionality is essential for maintaining optimal performance and ensuring safety during operations.

At the heart of this system are the hydraulic fluid, pumps, and cylinders. The hydraulic fluid, typically oil, transmits force and provides lubrication to the system. Pumps generate the necessary pressure to move the fluid, while cylinders convert this hydraulic pressure into linear motion, facilitating various operations such as lifting, digging, and pushing.

Moreover, the system incorporates valves that control the flow of fluid, directing it to specific components as needed. These valves ensure that the machine operates smoothly and can respond swiftly to the operator’s commands. Regular maintenance and checks are vital to prevent leaks and ensure that all parts function harmoniously, thereby extending the life of the equipment.

In summary, a well-functioning hydraulic system is crucial for the effective operation of heavy machinery, allowing for powerful and controlled movements essential for various construction and excavation tasks.

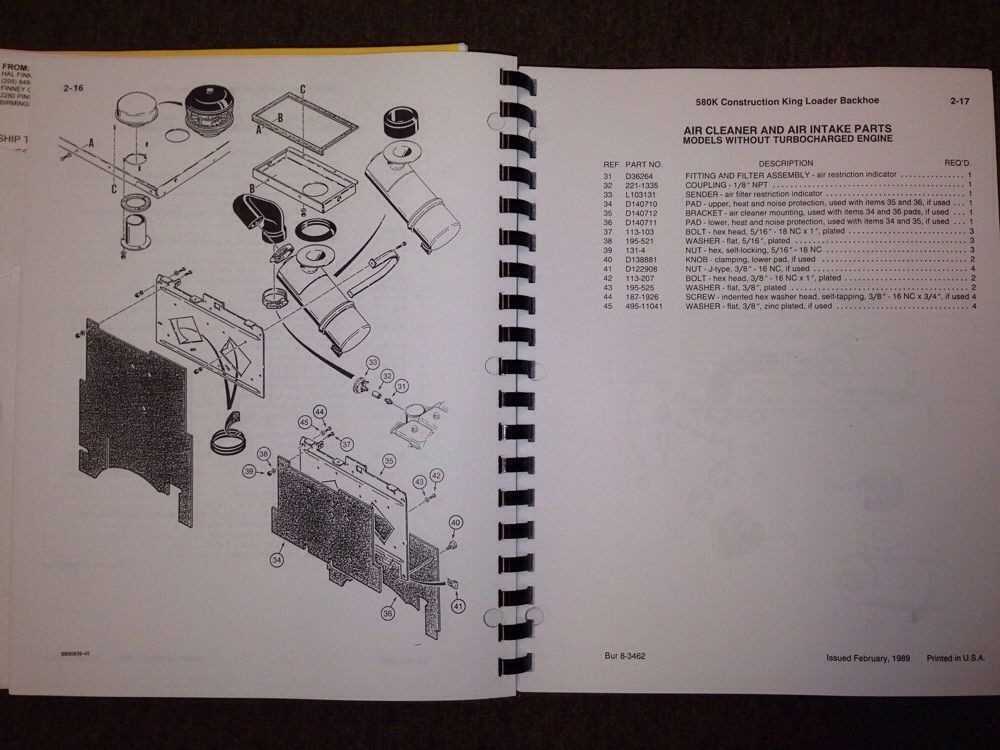

Engine Parts and Specifications

This section focuses on the various components and technical specifications that contribute to the functionality and performance of the engine system. Understanding these elements is crucial for effective maintenance and operation.

| Component | Description | Specifications |

|---|---|---|

| Cylinder Block | The main structure housing the cylinders. | Material: Cast Iron; Configuration: Inline 4 |

| Piston | Moves within the cylinder to create compression. | Diameter: 4.0 in; Stroke: 4.4 in |

| Crankshaft | Converts linear motion of the pistons into rotational motion. | Material: Forged Steel; Configuration: 5 Bearing |

| Camshaft | Controls the timing of valve opening and closing. | Material: Alloy Steel; Type: Overhead |

| Fuel Injector | Delivers fuel into the combustion chamber. | Type: Electronic; Flow Rate: 200 cc/min |

Transmission and Drive Assembly Details

The transmission and drive assembly plays a critical role in the functionality of heavy machinery, ensuring efficient power transfer and movement. This system consists of various components that work in harmony to facilitate smooth operation, allowing for precise control and performance under demanding conditions.

Key Components

Central to the assembly are the gears and shafts, which transmit power from the engine to the wheels. Clutches enable the operator to engage or disengage the power flow, while transmission fluid maintains optimal performance and cooling. Additionally, the drive belts provide flexibility and assist in power distribution across different parts of the machinery.

Maintenance Considerations

Regular inspection and maintenance of the transmission and drive assembly are essential for longevity. Key practices include checking fluid levels, inspecting for leaks, and ensuring all components are free from wear and damage. Prompt attention to these details can prevent costly repairs and enhance the machine’s overall performance.

Loader and Excavator Attachments

In the realm of construction machinery, various implements enhance the versatility and efficiency of earth-moving equipment. These attachments transform standard machines into specialized tools, enabling operators to tackle a wide range of tasks with ease and precision.

Types of Attachments

Different types of attachments cater to specific functions, such as digging, lifting, and grading. Common options include buckets for scooping materials, grapples for handling debris, and augers for drilling holes. Each implement is designed to optimize performance, depending on the job requirements.

Benefits of Using Attachments

Utilizing specialized implements increases productivity and reduces operational costs. By equipping machinery with the right attachments, operators can complete diverse projects efficiently, maximizing both time and resources. This adaptability is essential in today’s competitive construction landscape.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your machinery requires a systematic approach to upkeep. Regular maintenance not only extends the lifespan of your equipment but also enhances its efficiency and reliability. Adopting good practices will help you avoid costly repairs and downtime.

Regular Inspections

Conducting frequent checks is crucial for identifying potential issues before they escalate. Focus on key components such as hydraulic systems, engines, and electrical parts. Keeping a detailed log of inspections can help track performance over time.

Fluid Management

Proper fluid maintenance is essential for the smooth operation of machinery. Regularly check and replace oils, hydraulic fluids, and coolants as recommended by the manufacturer. Clean filters and ensure that levels are adequate to prevent overheating and wear.

| Task | Frequency | Notes |

|---|---|---|

| Inspect hydraulic lines | Monthly | Look for leaks or wear |

| Change engine oil | Every 250 hours | Use manufacturer-recommended oil |

| Check tire pressure | Weekly | Maintain optimal pressure for safety |

| Clean air filters | Every 50 hours | Replace if heavily soiled |

Common Replacement Parts for Repair

When it comes to maintaining heavy machinery, certain components frequently require attention due to wear and tear. Understanding which elements are essential for replacement can significantly enhance performance and longevity. This section focuses on the most commonly needed items that ensure your equipment remains in optimal condition.

Key components include hydraulic cylinders, which are vital for power transfer, and filters that maintain fluid cleanliness. Additionally, seals and gaskets play a crucial role in preventing leaks and ensuring efficient operation. Other significant items are drive belts and hoses, which are often subject to stress and require regular checks and replacements.

Investing in quality replacements not only boosts performance but also minimizes downtime, ultimately contributing to the overall efficiency of your machinery. Being proactive about these common components can lead to smoother operations and extended service life.

Where to Find Diagrams Online

Locating detailed illustrations for heavy machinery components can significantly enhance your understanding of their structure and functionality. Online resources offer a plethora of options for enthusiasts and professionals alike, making it easier to access the information needed for maintenance and repairs. This section will guide you through various platforms where you can find these invaluable resources.

Official Manufacturer Websites

One of the most reliable sources for detailed schematics is the official website of the manufacturer. They often provide technical documentation and resources that can be downloaded or viewed online. This ensures that you are accessing the most accurate and up-to-date information.

Online Forums and Communities

Dedicated forums and online communities can be excellent places to find diagrams shared by other users. These platforms often have sections specifically for technical documents, where members upload and discuss various resources. Engaging in these communities can also provide valuable insights and tips from experienced operators.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official resources offering the latest technical manuals and schematics. |

| Online Forums | Community-driven platforms where users share knowledge and resources. |

| Technical Libraries | Online archives that house a variety of technical documents for machinery. |

| YouTube Channels | Video tutorials and walkthroughs that often include visual guides and diagrams. |

Understanding Part Numbers and Codes

In the realm of machinery components, deciphering the alphanumeric sequences associated with each item is essential for efficient maintenance and repairs. These identifiers serve as a universal language, enabling users to locate specific items quickly and accurately, ensuring compatibility and functionality.

The Structure of Identification Codes

Typically, identification codes consist of various segments that denote specific attributes of the component. For instance, the initial letters often represent the category or type of equipment, while subsequent numbers may indicate dimensions, compatibility, or production batches. Understanding this structure is vital for effective sourcing and inventory management.

Decoding for Optimal Usage

Familiarizing oneself with these identifiers allows operators and technicians to make informed decisions when selecting components. Utilizing accurate codes minimizes the risk of errors during repairs, thus enhancing operational efficiency. Moreover, recognizing variations in coding among different manufacturers can significantly streamline the procurement process.

Resources for DIY Repair Enthusiasts

For those passionate about tackling mechanical challenges, having the right resources is essential. Whether you’re repairing heavy machinery or maintaining smaller equipment, a wealth of information can guide you through the process. From detailed manuals to online communities, these tools not only enhance your skills but also save time and money.

Technical Manuals: Accessing comprehensive manuals is crucial. These documents often contain schematics, troubleshooting tips, and step-by-step procedures that help simplify complex tasks. Many manufacturers provide downloadable versions, making it easier for enthusiasts to reference necessary information anytime.

Online Forums: Engaging with online communities can be incredibly beneficial. Forums dedicated to equipment repairs allow users to share experiences, ask questions, and offer advice. This collaborative environment fosters a sense of camaraderie and can provide insights that you might not find in official documentation.

YouTube Channels: Video tutorials have become a popular resource for DIY repairs. Many channels specialize in mechanical repairs, offering visual guidance that complements written instructions. Watching experts tackle similar issues can boost your confidence and provide practical techniques for effective repairs.

Local Workshops: Participating in workshops or classes can enhance your hands-on skills. Local organizations often host events where you can learn from experienced technicians. These opportunities allow for direct interaction and practical demonstrations, further enriching your understanding.

Parts Suppliers: Building a relationship with reliable suppliers is vital for obtaining quality components. Many suppliers offer not only parts but also expertise and support, helping you choose the right items for your repairs.