The efficient operation of heavy machinery relies heavily on the understanding of its various elements. By examining detailed illustrations of these components, users can gain insights into the arrangement and functionality of each section. Such visual aids serve as a crucial tool for both novice operators and experienced technicians alike, facilitating better maintenance and troubleshooting practices.

Understanding the layout of the machinery’s components is essential for ensuring optimal performance. These illustrations not only depict the physical arrangement but also highlight the connections and interactions between different sections. This knowledge can enhance the operator’s ability to identify potential issues and implement effective solutions swiftly.

In addition to improving operational knowledge, these visual representations play a significant role in training and educational contexts. They enable learners to visualize complex systems, making it easier to grasp intricate mechanical relationships. As a result, individuals can develop a more comprehensive understanding of machinery functionality and contribute to its longevity through proper care and management.

Importance of Parts Diagrams

Understanding the assembly of machinery components is crucial for effective maintenance and repair. Visual representations provide insights into the arrangement and relationship between various elements, enhancing the user’s ability to troubleshoot and fix issues efficiently.

These illustrations serve several significant purposes:

- Facilitating accurate identification of components.

- Streamlining the disassembly and reassembly processes.

- Assisting in the diagnosis of mechanical failures.

- Enhancing communication between technicians and engineers.

Utilizing these visuals can lead to improved operational efficiency and reduced downtime, ultimately saving time and resources in maintenance practices.

Overview of Case Skid Steers

This section provides an insight into versatile machinery designed for various tasks in construction and agriculture. These compact loaders are known for their maneuverability and efficiency, making them invaluable in numerous applications.

Typically equipped with powerful engines, these machines excel in performing heavy-duty operations. They can handle a variety of attachments, allowing users to adapt them to specific needs. The following points highlight their key features:

- Compact size for easy navigation in tight spaces

- Powerful hydraulic systems for enhanced lifting capabilities

- Diverse attachment options for multi-functional use

- Operator-friendly controls for improved usability

- Durable construction to withstand harsh working conditions

In summary, this type of loader stands out due to its ability to perform numerous tasks efficiently. Understanding its capabilities and features can help users maximize its potential in various settings.

Common Issues with Skid Steer Parts

Many operators encounter a variety of challenges when working with machinery components. Understanding these frequent problems can help ensure efficient operation and minimize downtime. Identifying and addressing issues early is crucial for maintaining the overall functionality of the equipment.

Wear and Tear: Over time, components can experience significant wear, leading to diminished performance. Regular inspections can help detect signs of deterioration before they escalate into more serious concerns.

Hydraulic Failures: Hydraulic systems are essential for the operation of various machinery elements. Common issues include leaks, low fluid levels, and pump malfunctions, which can disrupt functionality and reduce power output.

Electrical Malfunctions: Electrical issues, such as faulty wiring or blown fuses, can cause machinery to operate improperly. Ensuring that the electrical systems are in good condition is vital for reliable performance.

Improper Maintenance: Neglecting routine maintenance can lead to a multitude of problems, from engine troubles to component failures. Adhering to a regular maintenance schedule is crucial for prolonging the lifespan of the equipment.

Compatibility Issues: Using non-compatible components can lead to significant operational challenges. It is important to ensure that all parts are suitable for the specific machinery to prevent performance issues.

Key Components in Operation

Understanding the essential elements involved in machinery operation is crucial for effective performance and maintenance. Each component plays a vital role in ensuring that the equipment functions smoothly, enhancing overall productivity and efficiency.

The primary elements that contribute to the effective operation of this type of machinery include the following:

| Component | Function |

|---|---|

| Engine | Provides the necessary power to operate all mechanical systems. |

| Hydraulic System | Transfers power through fluid movement, enabling lifting and digging actions. |

| Transmission | Controls the speed and torque, allowing for smooth maneuverability. |

| Frame | Houses all components, providing structural integrity and support. |

| Tracks or Tires | Facilitates mobility across various terrains, ensuring stability and traction. |

Familiarity with these core components aids operators in troubleshooting and performing necessary upkeep, thereby extending the life and functionality of the equipment.

Maintenance Tips for Skid Steers

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. By implementing a systematic maintenance routine, you can prevent unexpected failures and enhance efficiency. Here are some valuable suggestions for maintaining your equipment effectively.

Check Fluid Levels: Regularly inspect hydraulic fluid, engine oil, and coolant levels. Keeping these fluids at the appropriate levels helps in maintaining the efficiency of your machinery and prevents overheating or other operational issues.

Inspect Filters: Ensure that air and oil filters are clean and free from debris. Dirty filters can restrict airflow and oil flow, leading to reduced performance. Replace them as needed to ensure smooth operation.

Tire and Track Maintenance: Regularly check the condition of tires or tracks. Proper inflation and tread depth are vital for traction and stability. Rotate or replace them when necessary to avoid uneven wear.

Lubrication: Keep all moving parts well-lubricated to minimize friction and wear. Regularly grease pivot points and joints as per the manufacturer’s recommendations to extend the life of your machinery.

Routine Inspections: Conduct periodic inspections to identify any signs of wear or damage. Addressing small issues promptly can prevent them from escalating into significant problems.

Identifying Replacement Parts

Understanding the components of machinery is essential for effective maintenance and repair. Recognizing the right elements for substitution can ensure optimal performance and longevity of your equipment. Familiarity with the various sections and their respective functions aids in identifying what needs to be replaced when issues arise.

To assist in this process, a detailed reference can be highly beneficial. Below is a table that outlines common elements found in machinery, along with their respective identifiers and possible indicators for replacement.

| Component | Identifier | Replacement Indicators |

|---|---|---|

| Hydraulic Cylinder | HC-1001 | Leaks, reduced performance |

| Drive Belt | DB-2003 | Cracks, excessive wear |

| Oil Filter | OF-5006 | Clogs, discolored oil |

| Cooling Fan | CF-3309 | Noisy operation, overheating |

| Electrical Relay | ER-4004 | Intermittent failure, burn marks |

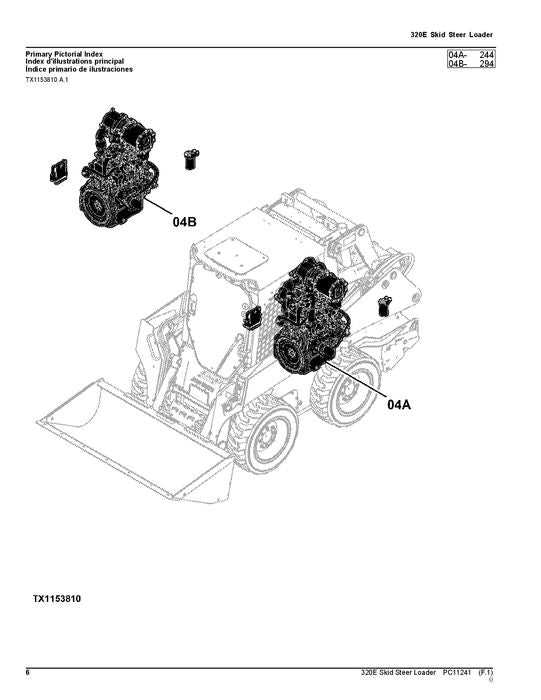

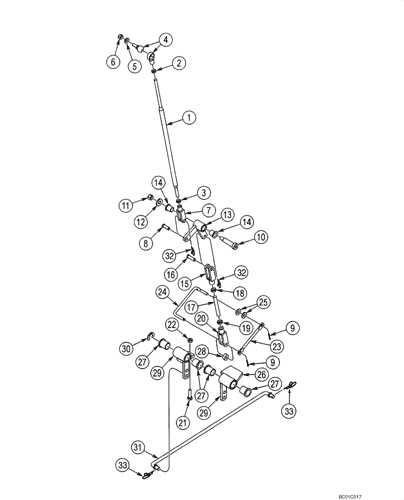

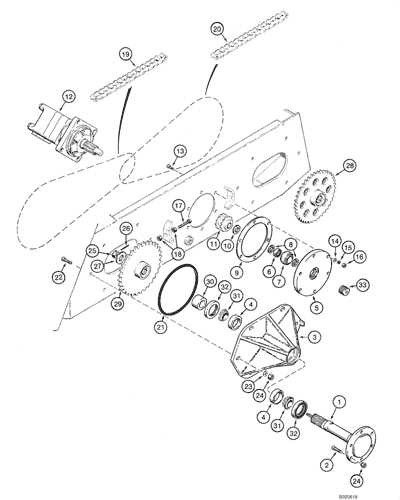

How to Read Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repair. Familiarizing oneself with the visual representations can significantly enhance your ability to identify and source necessary components. This section outlines the fundamental approaches to interpreting these illustrations effectively.

Firstly, begin by examining the overall structure of the illustration. Recognize how various elements are organized and labeled. Each section typically corresponds to specific functions or groups of components, which aids in quickly locating the required information.

Next, pay attention to the annotations that accompany each element. These notes often provide crucial details, such as part numbers or descriptions. Understanding these references is vital for accurate identification and procurement of components when needed.

Lastly, it is beneficial to cross-reference the information from the visual representation with the manufacturer’s documentation. This practice ensures that you have a comprehensive understanding of how individual elements interact within the machinery, facilitating a more informed approach to repairs and upgrades.

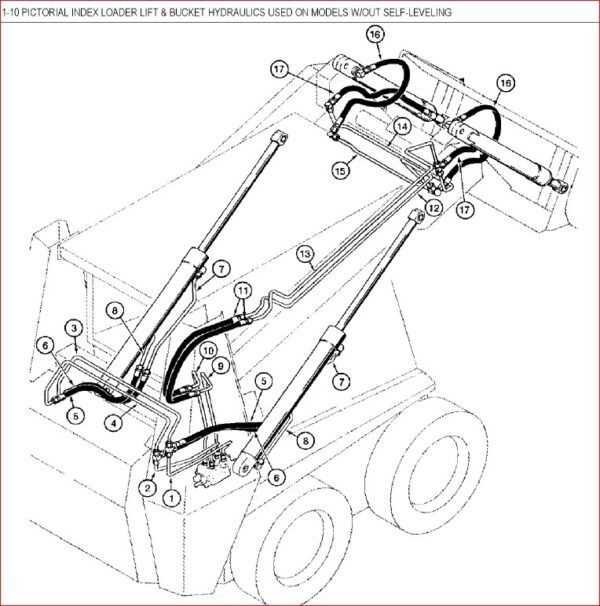

Hydraulic System Explained

The hydraulic mechanism in compact machinery plays a crucial role in facilitating movement and power transfer. It operates by using fluid dynamics to generate force, allowing various attachments and components to function efficiently. Understanding this system is essential for optimal performance and maintenance of the equipment.

Key Components of the Hydraulic Mechanism

- Hydraulic Pump: This component generates pressure by pushing fluid from the reservoir into the system.

- Hydraulic Fluid: The medium that transmits power within the system, it is essential for smooth operation and heat dissipation.

- Actuators: These elements convert hydraulic energy into mechanical motion, enabling various movements of the equipment.

- Valves: Control the flow and pressure of the hydraulic fluid, directing it to specific components as needed.

Functionality Overview

The hydraulic system operates through a series of interconnected components that work in harmony. When the pump pressurizes the fluid, it travels through the valves to the actuators. As the actuators receive this pressurized fluid, they create movement, allowing the machinery to perform tasks like lifting, pushing, or tilting.

Regular maintenance of the hydraulic system is vital to ensure longevity and prevent breakdowns. This includes checking fluid levels, inspecting for leaks, and replacing worn components. Understanding the mechanics of this system can greatly enhance the efficiency and reliability of the equipment.

Electrical Components and Their Functions

In modern machinery, the electrical system plays a crucial role in ensuring optimal performance and functionality. Understanding the various electrical components is essential for efficient operation and maintenance. Each element contributes to the overall system, facilitating communication and power distribution throughout the equipment.

Power Supply: The power supply serves as the backbone of the electrical system, converting energy into a usable form for various components. It ensures that all parts receive the necessary voltage and current for proper operation.

Control Module: The control module is the brain of the system, managing the operation of various components based on user inputs and environmental conditions. It processes signals and sends commands to other parts to execute specific functions.

Sensors: Sensors are vital for monitoring conditions within the machinery. They provide real-time data, allowing the system to adjust performance based on factors such as temperature, pressure, and load. This feedback loop enhances safety and efficiency.

Actuators: Actuators convert electrical signals from the control module into mechanical movement. They are responsible for moving components such as valves, levers, and other mechanisms that require motion to perform tasks.

Wiring Harness: The wiring harness connects all electrical components, providing pathways for electrical signals and power. A well-designed harness ensures that components communicate effectively and minimizes the risk of electrical faults.

By understanding these essential elements, operators and technicians can ensure the reliable performance of machinery, making informed decisions during maintenance and troubleshooting.

Using Parts Diagrams for Repairs

Utilizing visual representations of components can significantly enhance the repair process. These illustrations provide a comprehensive overview of individual elements and their interconnections within a machine. By examining these visual aids, technicians can gain valuable insights into assembly, disassembly, and maintenance tasks.

Furthermore, these resources assist in identifying specific items needed for replacements. With clear depictions of various components, it becomes easier to locate the exact parts required, minimizing downtime and streamlining the repair process. Understanding the layout of each element allows for more efficient troubleshooting, enabling quick diagnosis of issues that may arise.

Moreover, having access to these graphical resources can boost confidence in performing repairs. Technicians can refer to these diagrams to ensure proper reassembly, reducing the likelihood of errors. This fosters a greater sense of competence and encourages individuals to undertake maintenance tasks that they might otherwise avoid.

In summary, leveraging visual aids in the repair process not only facilitates a deeper understanding of machinery but also empowers technicians to carry out tasks effectively and efficiently.

Where to Find Accurate Diagrams

Locating reliable visual representations of machinery components is essential for maintenance and repair tasks. Accurate illustrations provide users with the necessary information to understand the assembly and functionality of various elements. These resources can greatly enhance the efficiency of repairs and help in identifying the correct components for replacements.

Online Resources

Numerous websites specialize in providing detailed schematics for various equipment. These platforms often include user manuals, technical guides, and community forums where enthusiasts share their experiences and insights. Some notable options are:

| Website | Description |

|---|---|

| PartsCatalog.com | A comprehensive site offering a vast array of schematics and component lists for various machines. |

| ManualsLib.com | A library of user manuals and technical documents, providing detailed breakdowns of equipment. |

| OEMPartsOnline.com | Official parts retailers often have detailed illustrations for identifying components accurately. |

Local Dealerships and Workshops

Visiting local dealerships or repair shops can also be a fruitful approach. Many authorized service centers have access to official resources and can provide customers with accurate representations. Engaging with professionals in these establishments can lead to valuable insights and recommendations on where to find precise information.