In the realm of outdoor equipment, the intricate system responsible for slicing through various materials is essential for effective operation. A closer examination reveals how different elements interact to ensure precision and efficiency during use. Grasping these relationships is crucial for anyone looking to enhance their familiarity with such tools.

Each individual segment plays a vital role in the overall functionality of the device. From the sharp, rotating elements designed for penetration to the supporting structures that provide stability and control, understanding these components can significantly impact maintenance and performance. Knowledge of how these pieces fit together allows users to optimize their experience and prolong the lifespan of their equipment.

Moreover, a detailed exploration of these features can uncover insights into the mechanics at play, offering enthusiasts and professionals alike the opportunity to deepen their expertise. Emphasizing the importance of each unit not only aids in troubleshooting but also enhances the ability to make informed choices when it comes to repairs or upgrades.

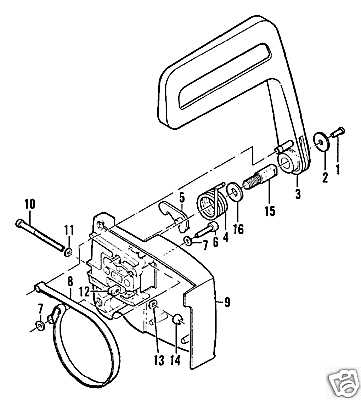

Understanding Chainsaw Chain Components

This section explores the essential elements that constitute the cutting mechanism of a power tool. By examining these components, one gains insight into their functionality and significance in achieving optimal performance.

Main Elements

- Drive Links: These are the connectors that enable movement along the guide.

- Cutter Teeth: Designed for cutting, these are the sharpened edges responsible for the actual slicing action.

- Rivets: These secure the various components together, ensuring stability during operation.

- Depth Gauge: Controls the depth of each cut, impacting efficiency and smoothness.

Importance of Each Component

- Ensures safety by maintaining stability.

- Affects cutting efficiency and speed.

- Impacts the overall lifespan of the tool.

Essential Parts of a Chainsaw Chain

Understanding the key components that contribute to the functionality of a cutting mechanism is crucial for effective operation and maintenance. Each element plays a vital role in ensuring performance and safety.

- Cutting Links: These are responsible for slicing through wood, featuring sharp edges for efficient cutting.

- Drive Links: These elements engage with the guide bar, facilitating movement and stability during operation.

- Rivets: Connecting the cutting links, rivets ensure a secure assembly while allowing necessary flexibility.

- Depth Gauges: These components control the cutting depth, preventing over-penetration and ensuring smooth operation.

- Bar Nose: The rounded tip of the guide bar assists in maneuverability, especially in tight spaces.

Each component is designed to work in harmony, ultimately enhancing the efficiency and safety of the entire system.

How Chainsaw Chain Works

Understanding the mechanics behind a cutting tool’s functionality is essential for both efficiency and safety. This tool operates through a series of interconnected elements that work in harmony to achieve effective cutting. Each component plays a crucial role in the overall performance, ensuring smooth operation during use.

Components and Their Functions

The cutting mechanism is primarily composed of sharp edges that rotate rapidly. These edges are designed to penetrate wood fibers, allowing for precise and efficient cuts. The movement is facilitated by a drive system, which generates the necessary power and speed. In addition, a tensioning mechanism ensures that the elements remain securely in place, preventing any disruptions during operation.

Maintenance and Performance

Regular upkeep is vital for maintaining optimal performance. Keeping the sharp edges properly honed is essential, as dull tools can lead to increased effort and potential accidents. Additionally, ensuring that all components are free from debris and functioning smoothly will extend the tool’s lifespan and improve its cutting efficiency.

Types of Chainsaw Chains Explained

Understanding the various types of cutting loops is essential for optimizing performance and ensuring safety during usage. Each variant is designed for specific applications, making it crucial to select the right one for your needs. This section delves into the characteristics and benefits of different types of these essential tools.

Standard and Low-Profile Options

Standard cutting loops are typically used for general tasks, offering a balance between speed and control. They are ideal for heavier jobs and can handle larger materials effectively. In contrast, low-profile versions are designed with safety in mind, featuring shorter teeth that reduce kickback risks. These are perfect for novice users or those working in tighter spaces.

Specialized Variants

For specific tasks, specialized designs exist. Ripping versions are crafted for making long cuts along the grain, ideal for milling lumber. Additionally, skip-tooth models reduce friction, making them suitable for larger logs and faster cutting. Understanding these variations can enhance efficiency and improve results in your projects.

Importance of Chain Maintenance

Proper upkeep of your cutting equipment is essential for ensuring optimal performance and longevity. Neglecting regular care can lead to diminished efficiency, increased wear, and even safety hazards. Understanding the significance of maintenance can help users enjoy a smoother and safer experience during operation.

Regular inspections allow for the early detection of wear and tear, preventing potential breakdowns and costly repairs. By keeping components clean and lubricated, you enhance their functionality, which translates to better cutting precision and reduced effort. Furthermore, well-maintained tools reduce the risk of accidents caused by unexpected failures, ensuring a safer work environment.

Investing time in routine checks not only prolongs the lifespan of your equipment but also improves overall productivity. By adhering to a consistent maintenance schedule, operators can maximize their investment and ensure that their tools remain reliable and efficient for years to come.

Identifying Chain Damage Signs

Recognizing signs of wear and tear is crucial for maintaining optimal performance. Various indicators can signal that the components are not functioning as intended, which may affect efficiency and safety during use.

Visual Inspection

Begin by conducting a thorough visual assessment. Look for any noticeable nicks, cracks, or uneven wear on the links. Discoloration can also be a warning sign, indicating excessive heat or stress.

Performance Issues

Pay attention to any unusual behavior during operation. If the equipment struggles to cut through material or produces excessive vibrations, this may indicate underlying damage. Regular maintenance can help mitigate these problems before they escalate.

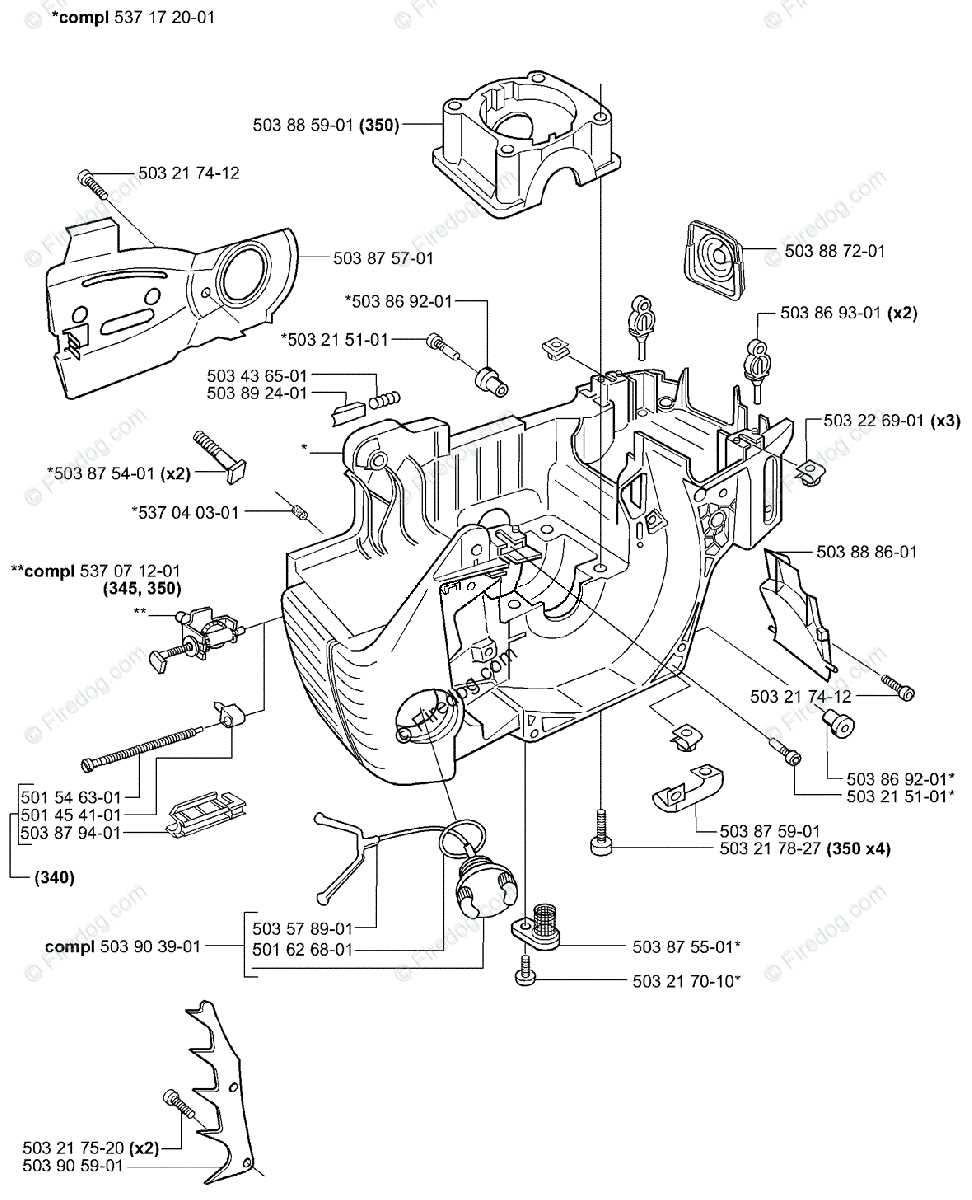

Tools for Chainsaw Chain Repair

Effective maintenance of cutting tools requires specific instruments designed for precision and durability. These essentials ensure that your equipment remains in optimal condition, extending its lifespan and enhancing performance.

| Tool | Purpose |

|---|---|

| File | Sharpening teeth to maintain cutting efficiency. |

| Depth Gauge Tool | Measuring and adjusting the depth of the cutting teeth. |

| Wrench | Tightening or loosening components for assembly. |

| Cleaning Brush | Removing debris and residue for better performance. |

| Protective Gear | Ensuring safety during maintenance activities. |

Choosing the Right Chain Type

Selecting the appropriate type of cutting loop is essential for optimal performance and efficiency. Various designs are tailored to meet different needs, whether for trimming branches, felling trees, or milling wood. Understanding the specifications and features of these loops can significantly enhance your experience and results.

Understanding Different Designs

Different configurations are available, each suited for specific tasks. For instance, some are designed for quick cuts and maneuverability, while others focus on durability and power. Assessing your primary activities and requirements will help in making an informed decision.

Factors to Consider

When choosing a cutting loop, consider factors such as the material being worked on, the desired cut quality, and the frequency of use. Additionally, take into account the compatibility with your equipment, as not all loops will fit every model. Proper alignment with your cutting goals ensures that you achieve the best possible performance.

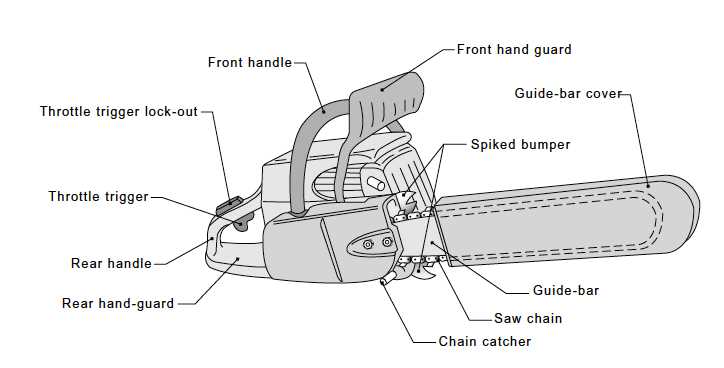

Installing a Chainsaw Chain Properly

Proper installation of the cutting loop is crucial for optimal performance and safety during operation. Ensuring that every component is correctly aligned and secured not only enhances efficiency but also minimizes the risk of accidents. Follow the steps outlined below to achieve a seamless setup.

Step-by-Step Installation Guide

Begin by ensuring that your equipment is turned off and completely cool. First, remove the cover by loosening the retaining screws. Next, align the new cutting loop with the guide bar, ensuring that the teeth face the correct direction. Place the loop around the sprocket, making sure it fits snugly in the groove.

Final Adjustments and Safety Checks

After securing the loop in place, reattach the cover and tighten the screws. It’s important to check the tension of the loop; it should be tight enough to stay in place but loose enough to move freely. Lastly, conduct a brief inspection to confirm that everything is correctly aligned and secure before proceeding with your task. Proper setup not only enhances performance but also extends the lifespan of your equipment.

Common Mistakes in Chain Use

Using cutting tools effectively requires understanding their components and the proper techniques for operation. Many users encounter issues that stem from common oversights, which can lead to inefficiencies or even hazards. Recognizing and correcting these mistakes is essential for ensuring safety and maximizing performance.

Neglecting Maintenance

One frequent error is overlooking the need for regular upkeep. Failing to clean and lubricate the moving elements can result in decreased efficiency and increased wear. Regular inspections for damage or wear are crucial to prolong the lifespan of the equipment.

Improper Technique

Another significant mistake involves using incorrect methods while operating the tool. Many users apply excessive force or inappropriate angles, which can not only compromise the effectiveness of the task but also pose safety risks. Understanding the correct posture and pressure is vital for optimal results.

Upgrading Your Chainsaw Chain

Enhancing your cutting tool’s performance can significantly improve efficiency and precision during your tasks. Upgrading the components responsible for cutting can lead to smoother operation and increased durability.

Consider the following factors when looking to enhance your tool:

- Material Quality: Opt for higher-grade materials that offer better wear resistance.

- Gauge Selection: Choose the appropriate gauge for compatibility with your existing equipment.

- Pitch Variation: Experiment with different pitch options for varying cutting speeds.

- Tooth Design: Select specific tooth shapes to optimize cutting for different materials.

Ultimately, upgrading these elements can lead to a more efficient and reliable tool, ready for any challenge.

Safety Tips for Chain Handling

When working with cutting implements, it is crucial to prioritize safety to prevent accidents and injuries. Proper handling techniques, along with appropriate protective measures, can significantly reduce risks associated with these tools. Here are essential guidelines to ensure safe operation and maintenance.

| Safety Tip | Description |

|---|---|

| Wear Protective Gear | Always don appropriate clothing, including gloves, goggles, and hearing protection to shield yourself from potential hazards. |

| Inspect Before Use | Check the implement for any signs of wear or damage before each use. Address any issues to ensure safe operation. |

| Maintain a Safe Distance | Keep bystanders and pets at a safe distance while handling cutting tools to avoid accidental injuries. |

| Secure Your Work Area | Clear the workspace of obstacles and debris to create a safe environment for operation. |

| Know Emergency Procedures | Be familiar with first aid measures and emergency contacts in case of an accident or injury. |

| Store Properly | After use, store the equipment in a safe, dry place, ensuring that it is out of reach of children and unauthorized users. |

Frequently Asked Questions About Chains

This section aims to address common inquiries related to the components and functioning of cutting instruments that utilize a loop mechanism. Understanding these aspects can enhance both safety and efficiency during usage.

Common Queries

| Question | Answer |

|---|---|

| What is the lifespan of a cutting loop? | The lifespan varies based on usage and maintenance but typically lasts several months to a few years. |

| How often should I sharpen the teeth? | Sharpening is recommended after every few hours of use, depending on the material being cut. |

Maintenance Tips

Regular inspection and proper lubrication are crucial for ensuring longevity. Additionally, ensure that components are aligned correctly to avoid unnecessary wear.