In the realm of modern equipment, understanding the intricacies of machinery is essential for effective maintenance and operation. Familiarity with the various elements that constitute these devices can significantly enhance their functionality and longevity. This section aims to illuminate the essential components involved in high-performance tools, focusing on the intricacies that support their operation.

Components breakdown is crucial for both enthusiasts and professionals. By exploring the various segments and their specific roles, users can gain insights into how to optimize their equipment’s performance. Knowledge of these components not only aids in troubleshooting but also empowers individuals to make informed decisions regarding repairs and upgrades.

Moreover, having a visual representation of the inner workings provides a comprehensive understanding of the assembly and connection of parts. This ultimate guide serves as a valuable resource, enabling users to delve into the complexities of their devices with confidence and clarity.

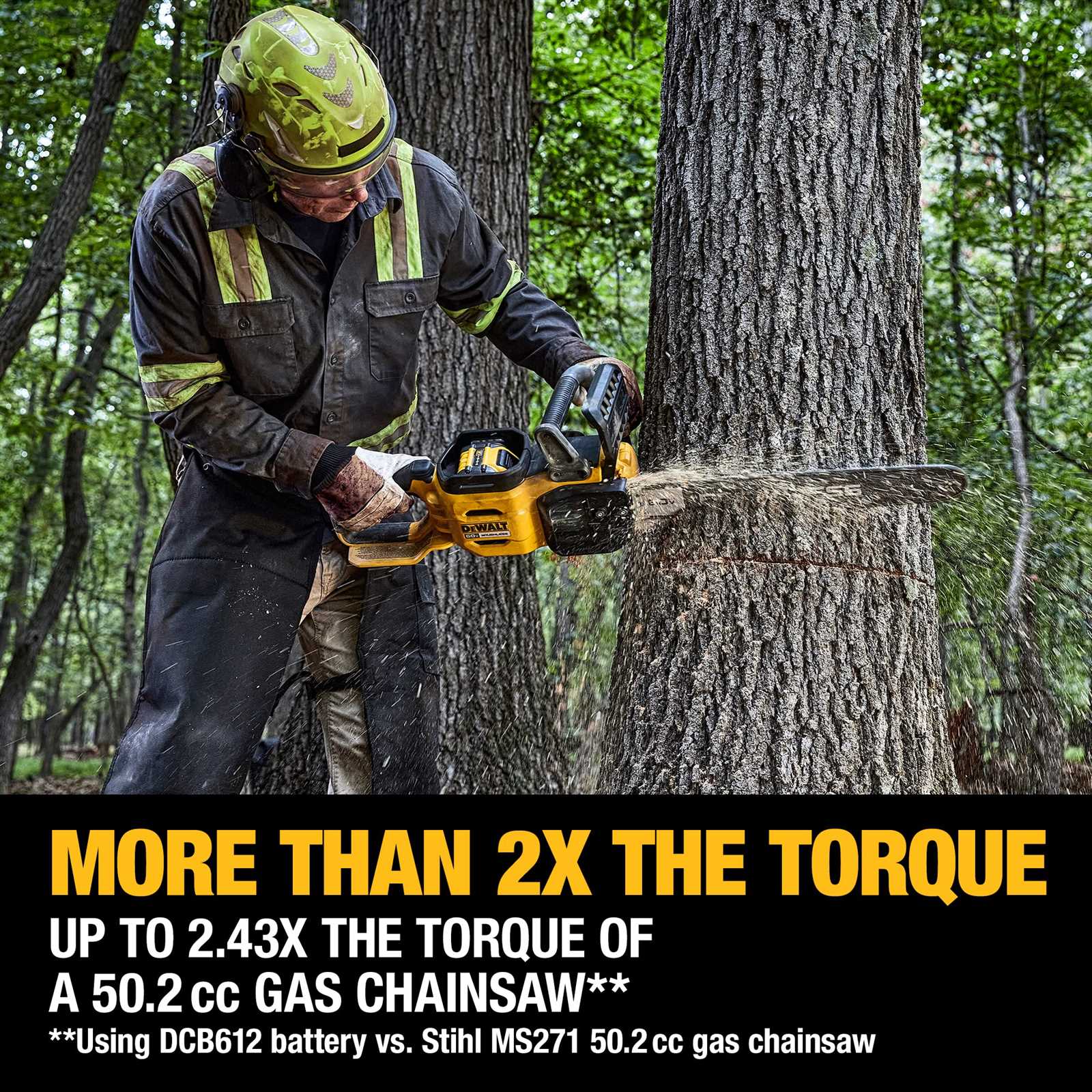

Dewalt 60V Chainsaw Overview

This section offers a comprehensive look at a powerful tool designed for cutting tasks. With advanced technology and robust performance, it caters to both professional users and DIY enthusiasts alike. Understanding its features and capabilities can enhance your overall experience and efficiency.

Key Features

Equipped with a high-capacity battery, this equipment ensures prolonged usage without interruptions. The lightweight design and ergonomic handle provide superior control, making it suitable for various applications. Additionally, the tool boasts a rapid charging system, allowing for minimal downtime.

Performance Insights

Users can expect remarkable cutting efficiency, enabling seamless operation through tough materials. The incorporation of innovative safety features enhances user confidence while working, making it an ideal choice for both novice and seasoned users. Ultimately, exploring these aspects will help potential buyers make informed decisions.

Key Features of Dewalt Chainsaw

This powerful cutting tool is designed for efficiency and versatility, catering to both professionals and DIY enthusiasts. With a blend of advanced technology and user-friendly design, it offers exceptional performance for a variety of tasks.

- High-Performance Motor: Equipped with a robust motor that delivers impressive power, enabling swift cutting through tough materials.

- Lightweight Design: Engineered to be portable, ensuring ease of maneuverability during extended use without causing fatigue.

- Tool-Free Chain Tensioning: Allows for quick adjustments to the chain, enhancing user convenience and safety.

- Low Kickback Chain: Designed to minimize kickback, promoting safer operation, especially for novice users.

- Extended Battery Life: Utilizes advanced battery technology, providing longer run times for uninterrupted work sessions.

- Ergonomic Handle: Features a comfortable grip that reduces strain, facilitating better control and accuracy while cutting.

These attributes combine to create a reliable tool that meets the demands of various cutting tasks, ensuring optimal performance and user satisfaction.

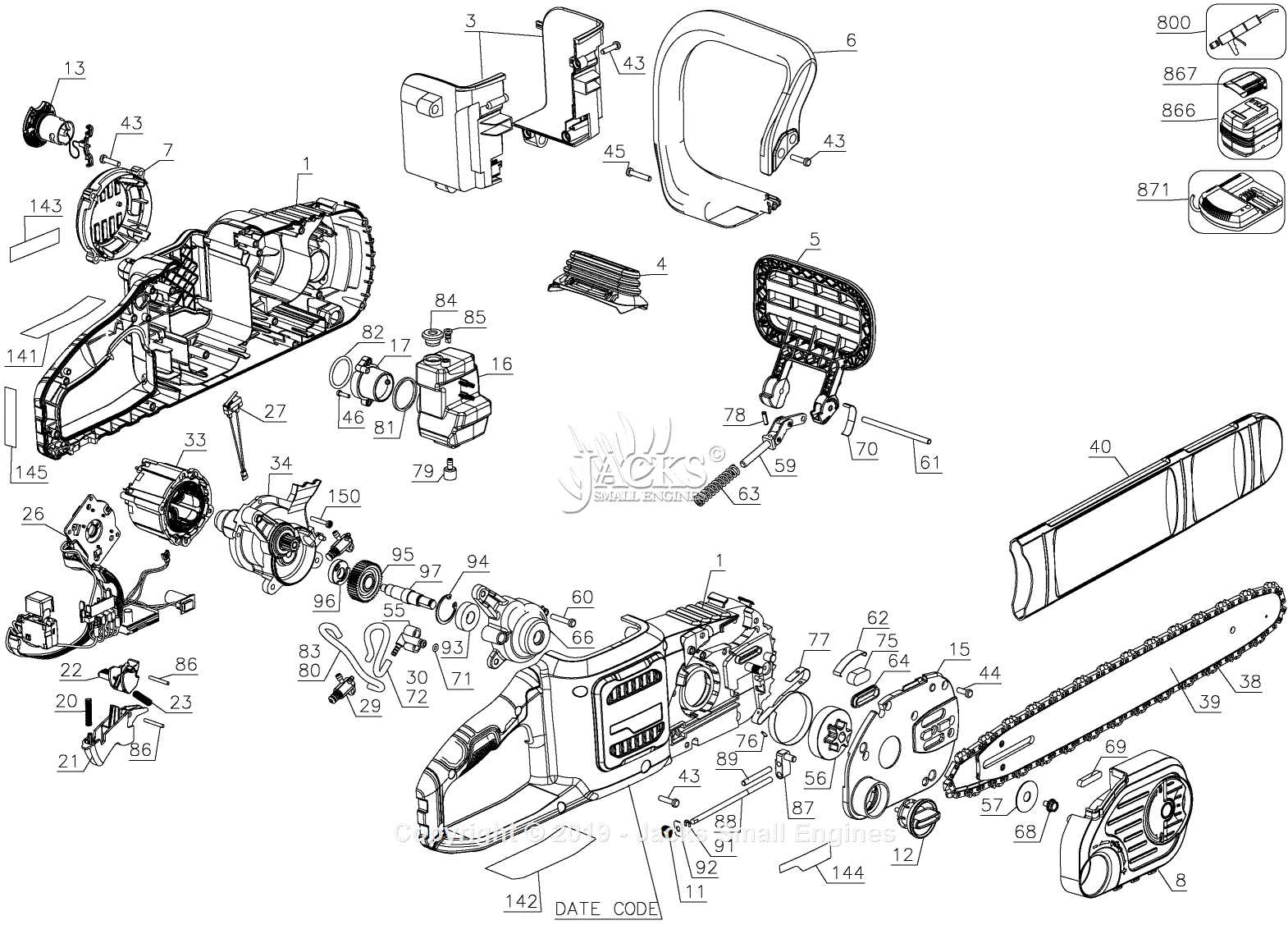

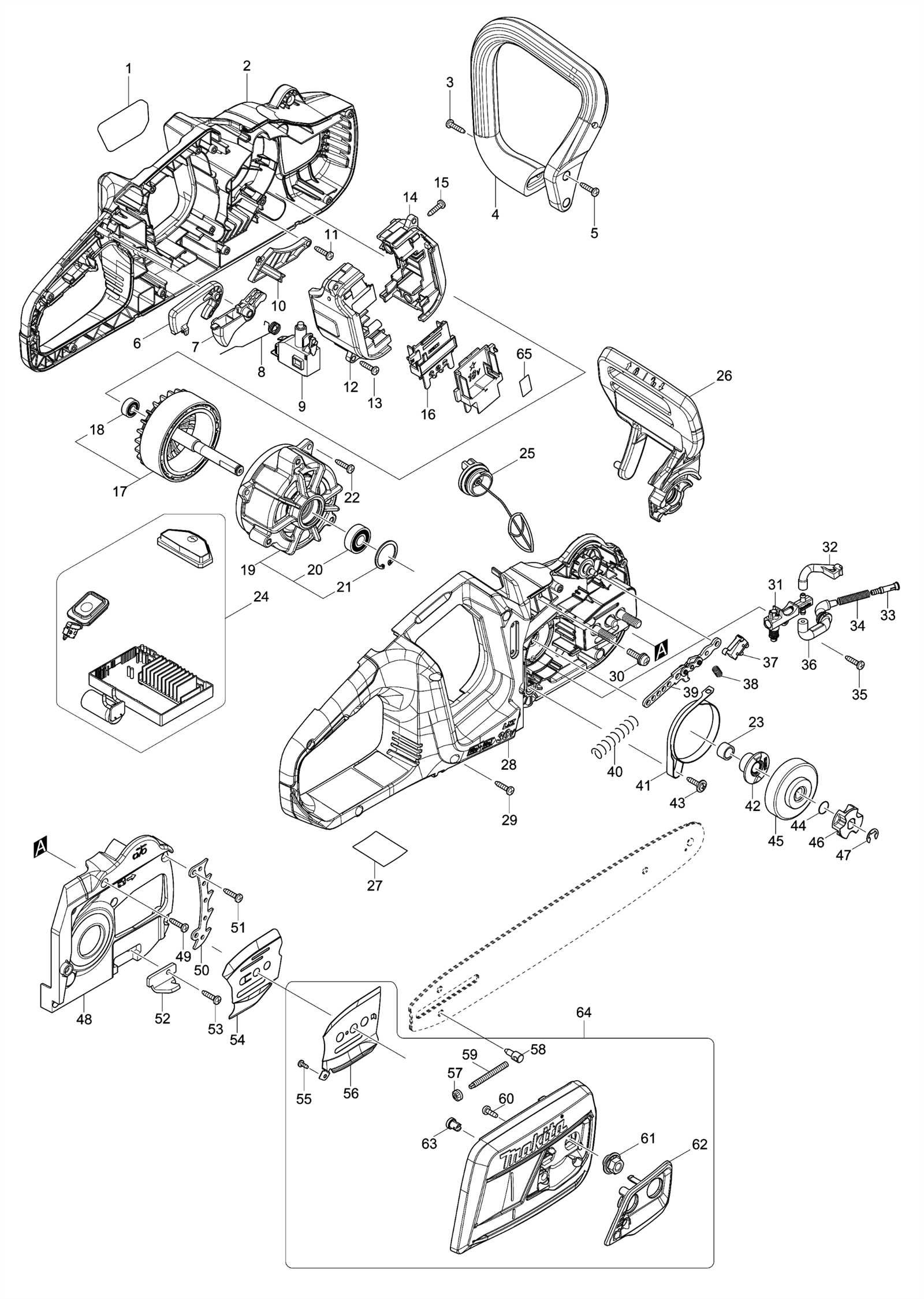

Importance of Parts Diagram

Understanding the layout and components of any mechanical device is crucial for effective maintenance and repair. A well-structured visual representation can streamline troubleshooting processes and enhance the user’s overall experience. By providing clarity, it allows users to identify and locate necessary elements with ease.

Benefits of Visual Guides

- Facilitates efficient repairs and replacements.

- Reduces the likelihood of errors during assembly.

- Enhances comprehension for both novice and experienced users.

Key Features to Look For

- Clear labeling of all components.

- Logical organization of parts for quick reference.

- Detailed illustrations that highlight connections and interactions.

Common Parts in Chainsaws

Understanding the key components of cutting tools is essential for both maintenance and effective use. Each unit consists of various elements that work together to ensure optimal performance and safety during operation.

The motor is the powerhouse, providing the necessary energy for the device to function. The guide bar serves as a support structure, guiding the cutting chain. The cutting chain itself features sharp teeth that engage with the material, enabling efficient slicing through wood or other substances.

An oiling system plays a crucial role in lubrication, preventing friction and wear on the moving parts. Additionally, a safety brake is vital for protecting the user from accidents by stopping the chain quickly if needed. These components, along with others like the throttle and air filter, create a harmonious system that enhances functionality and user experience.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations provide a visual guide to the elements involved, enabling users to identify and manage each piece efficiently. By mastering this skill, you can streamline your repair process and ensure that you have all the necessary elements at hand.

Key Elements to Look For

- Labels: Each component typically has a specific label or number corresponding to its position in the drawing.

- Connections: Observe how parts are linked or interact with each other, which can provide insights into assembly and functionality.

- Legend: Some diagrams include a legend explaining symbols or color coding used within the illustration.

Steps to Interpret the Illustration

- Start by familiarizing yourself with the overall layout. Identify major sections and how they relate to one another.

- Locate the labels or numbers next to each item and cross-reference them with a parts list if available.

- Pay attention to the direction of arrows or lines, which often indicate movement or flow.

- Note any special symbols that may indicate specific features, such as pivot points or attachment mechanisms.

By following these guidelines, you will gain confidence in navigating through the schematic, making your repair tasks more manageable and efficient.

Replacing Worn-Out Components

Maintaining optimal performance requires timely replacement of aging parts in power tools. Regular inspections can help identify components that have deteriorated, ensuring safety and efficiency in operation.

Signs of Wear

Common indicators that parts may need replacement include unusual noises, decreased performance, and visible damage. Addressing these issues promptly can prevent further complications.

Replacement Process

When replacing components, follow manufacturer guidelines for disassembly and reassembly. This ensures proper function and longevity of the tool.

| Component | Common Issues | Replacement Tips |

|---|---|---|

| Bar | Uneven cuts | Check for straightness before installing a new one. |

| Chain | Frequent jamming | Ensure proper tension is maintained after replacement. |

| Motor | Overheating | Inspect for debris and clean regularly. |

Maintaining Your Dewalt Chainsaw

Proper upkeep of your power tool is essential for optimal performance and longevity. Regular care not only ensures efficiency but also enhances safety during use. Establishing a maintenance routine can significantly reduce wear and tear, making your equipment more reliable.

Regular Inspections

Frequent checks of the machine’s components are crucial. Look for signs of damage, wear, or any obstructions that might hinder operation. Ensure all parts are securely attached and functioning properly to avoid accidents and enhance performance.

Cleaning and Lubrication

Keeping the tool clean is vital for its efficiency. After each use, remove debris and residue to prevent buildup. Additionally, apply appropriate lubricants to moving parts to ensure smooth operation and prevent rust, which can lead to premature failure.

Identifying Faulty Parts Easily

Recognizing malfunctioning components can significantly enhance the longevity and performance of your equipment. By understanding the key indicators of wear and damage, you can address issues promptly and avoid costly repairs. This section will guide you through the process of spotting problematic elements in your tools, making maintenance more efficient.

Visual Inspection: Begin with a thorough visual examination. Look for signs of wear such as cracks, discoloration, or unusual wear patterns. Components that are out of alignment or show uneven surfaces may also signal a deeper issue.

Functionality Tests: Conduct simple operational checks. If a component fails to perform as expected, it may be an indicator of malfunction. Listen for irregular noises or observe any erratic movements, which could suggest underlying problems.

Component Comparison: Having reference parts available can be invaluable. Compare the suspected faulty item with a new or functioning counterpart to identify discrepancies in size, shape, or wear.

Regular Maintenance: Implementing a routine inspection schedule can help in early detection of issues. Keeping a log of your findings will assist in tracking performance over time, enabling you to spot trends that indicate the need for replacement.

By following these methods, you can efficiently identify compromised components and maintain optimal functionality in your equipment.

Where to Find Replacement Parts

Finding the right components for your equipment can be crucial for maintaining its performance and longevity. There are several avenues you can explore to source quality replacements, ensuring your tools remain in optimal working condition.

Online Retailers

Numerous online platforms specialize in selling various components. These websites often provide a wide range of options, from original equipment to aftermarket alternatives. Make sure to check customer reviews to gauge the reliability of the supplier.

Local Hardware Stores

Visiting a nearby hardware store can also yield positive results. Many stores carry essential items and may even order specific components upon request. Building a relationship with local retailers can help you gain access to expert advice and recommendations.

| Source | Pros | Cons |

|---|---|---|

| Online Retailers | Wide selection, convenience | Shipping time, potential for incorrect parts |

| Local Hardware Stores | Immediate access, expert advice | Limited stock, potentially higher prices |

| Manufacturer Websites | Genuine components, reliability | Higher cost, limited availability |

Assembly Instructions for Beginners

Starting with new equipment can be a daunting task, especially when it involves mechanical components. This section aims to simplify the assembly process for novices, ensuring that each step is clear and manageable. Understanding how to correctly put together your device will not only enhance its performance but also prolong its lifespan.

1. Gather Your Tools: Before you begin, make sure you have all necessary tools at hand. This may include wrenches, screwdrivers, and safety gear. A well-prepared workspace will make the process smoother.

2. Read the Manual: Familiarize yourself with the user guide. It provides vital information about each component and its function, helping you understand the assembly sequence.

3. Organize the Components: Lay out all parts in an orderly fashion. This will help you visualize the assembly and ensure you don’t miss any pieces.

4. Start with the Base: Typically, assembly begins with the foundation of the unit. Securely attach the base to ensure stability for the subsequent steps.

5. Follow the Steps Sequentially: Proceed with assembly as per the instructions in the manual. Each part should be attached in the order specified to avoid confusion and ensure proper alignment.

6. Check for Tightness: After assembling, go through each connection to ensure everything is tightly secured. Loose components can lead to malfunction or safety hazards.

7. Safety First: Always prioritize safety. Wear protective gear, and never skip steps that ensure the device is properly assembled before use.

8. Test the Assembly: Once fully assembled, conduct a test to ensure everything functions correctly. If something seems off, revisit the assembly steps to identify any mistakes.

By following these straightforward instructions, even beginners can successfully assemble their new equipment with confidence and ease.

Tips for Safe Operation

Ensuring a secure working environment is essential when using power tools designed for cutting tasks. Adhering to proper safety measures not only protects the operator but also those nearby. This section outlines key practices to enhance safety during operation.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always don appropriate safety equipment, including goggles, gloves, and a helmet, to guard against flying debris. |

| Maintain a Clear Workspace | Ensure that the area around the tool is free of obstacles to prevent trips and falls. |

| Check Equipment Before Use | Inspect the tool for any signs of wear or damage. Address any issues prior to operation to ensure functionality. |

| Follow Manufacturer Guidelines | Consult the user manual for specific instructions regarding operation and maintenance to ensure proper use. |

| Be Aware of Your Surroundings | Stay alert to your environment, including potential hazards like power lines, and ensure bystanders are at a safe distance. |

| Use Both Hands | Always grip the tool with both hands to maintain control and stability during operation. |

Frequently Asked Questions About Chainsaws

This section addresses common inquiries regarding the use and maintenance of cutting tools designed for wood processing. Understanding these aspects can enhance safety and efficiency for users, whether they are professionals or hobbyists.

Common Queries

| Question | Answer |

|---|---|

| How do I choose the right tool for my needs? | Consider the size of the tasks you plan to undertake, the type of wood, and your experience level. Lighter models are ideal for smaller jobs, while heavier-duty options suit larger projects. |

| What maintenance is required for optimal performance? | Regularly check the chain tension, oil levels, and sharpen the cutting blade. Cleaning the air filter and inspecting the power source are also essential for longevity. |

Safety Considerations

| Safety Tip | Description |

|---|---|

| Wear Protective Gear | Always wear safety goggles, gloves, and sturdy footwear to protect yourself from debris. |

| Keep a Safe Distance | Ensure that bystanders are at a safe distance while operating the tool to avoid accidents. |