When it comes to maintaining and optimizing your outdoor equipment, having a clear understanding of its internal structure is essential. This knowledge not only aids in effective repairs but also enhances your ability to perform routine maintenance. By familiarizing yourself with each element, you can ensure the longevity and performance of your machine.

Within the intricate assembly of these devices, various components work in harmony to deliver peak performance. Each piece serves a specific purpose, contributing to the overall functionality and efficiency. Knowing how these elements interact can empower you to tackle issues with confidence and precision.

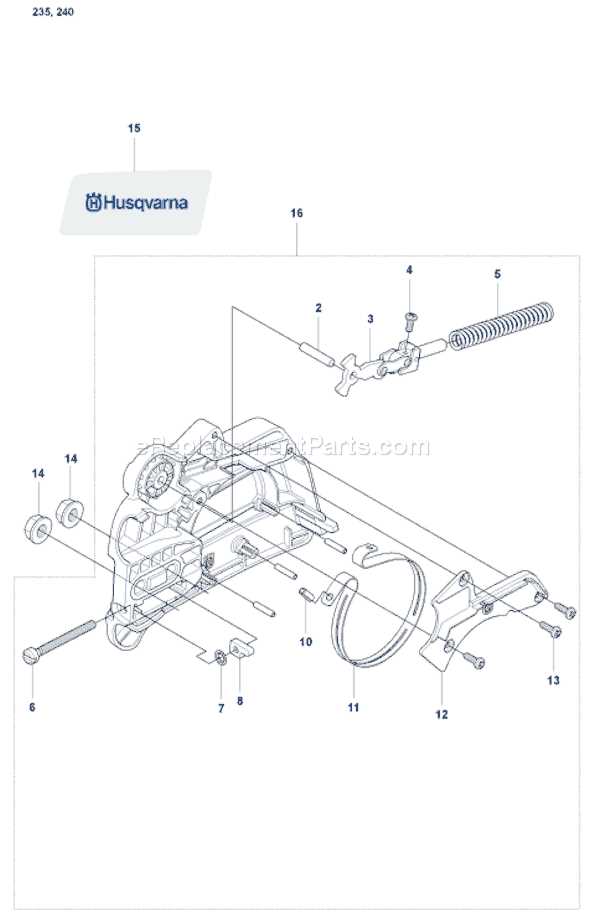

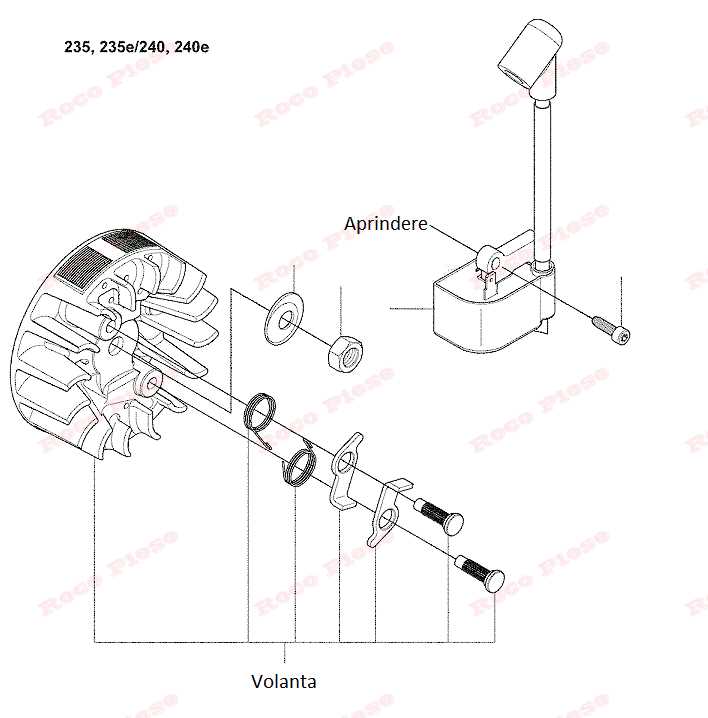

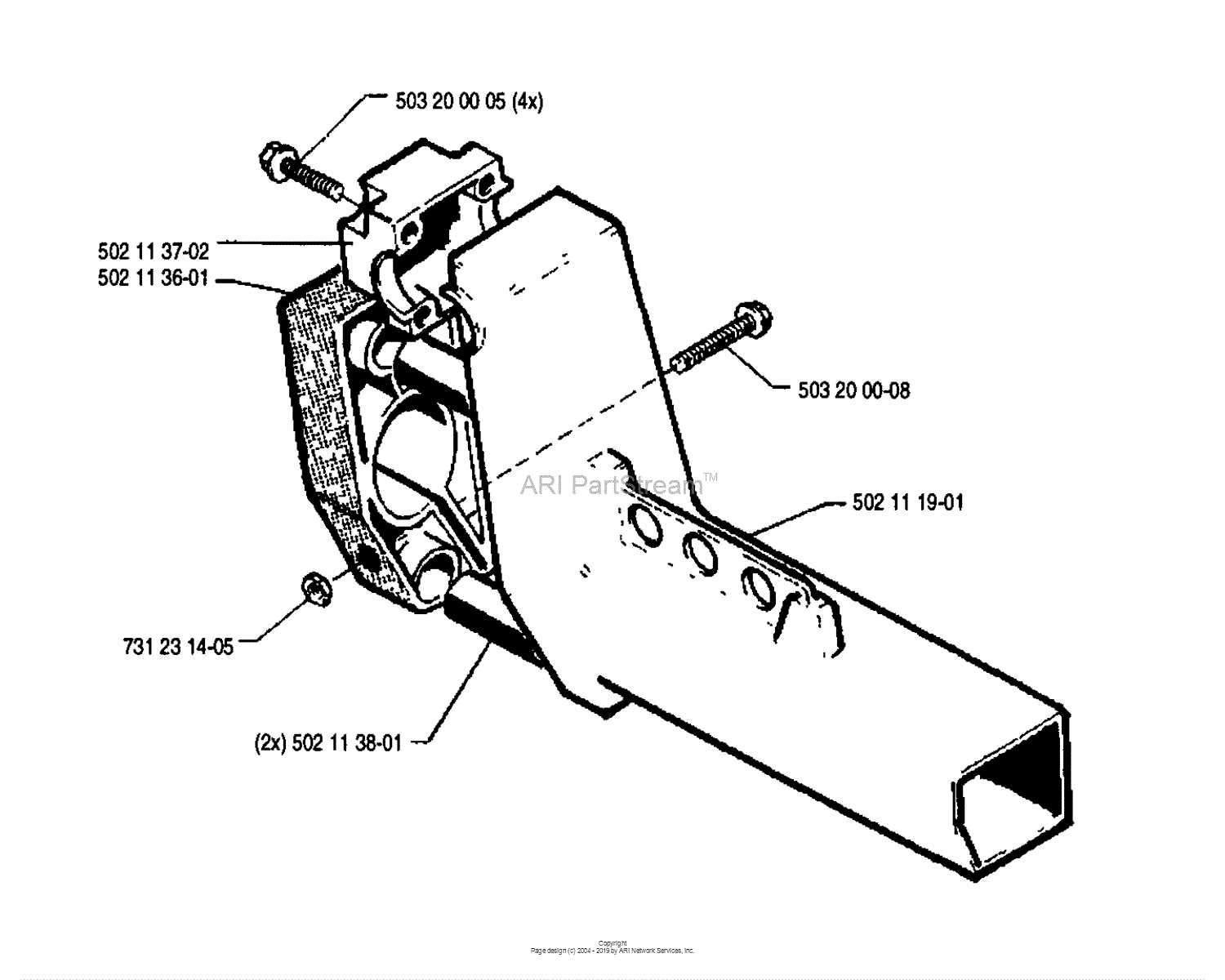

Visual aids, such as detailed illustrations, can significantly enhance your comprehension of these mechanical systems. They allow you to identify parts easily and understand their relationships within the assembly. This insight is invaluable for both novice users and seasoned professionals looking to streamline their maintenance practices.

Understanding Husqvarna 240 Chainsaw Components

This section aims to explore the essential elements that contribute to the functionality and performance of a specific model of cutting equipment. Each component plays a vital role in ensuring the tool operates smoothly and efficiently, making it crucial to grasp their individual functions and relationships.

Key Elements Overview

The primary segments of this machinery include the power unit, cutting mechanism, and safety features. Each of these areas holds specific components that work harmoniously to achieve optimal performance.

| Component | Function |

|---|---|

| Engine | Drives the entire system and provides necessary power. |

| Bar | Supports the cutting chain and allows for smooth operation. |

| Chain | Engages with the bar to cut through materials effectively. |

| Safety Switch | Prevents accidental starts for user protection. |

Conclusion

Understanding these components enables users to appreciate the intricate design of this tool, enhancing their ability to maintain and operate it efficiently.

Importance of Parts Diagrams

Understanding the layout and functionality of components within machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that facilitate comprehension, enabling users to quickly identify each element’s role and interconnections. This clarity not only enhances the efficiency of repairs but also reduces the risk of errors during assembly or disassembly.

Accurate schematics empower individuals to navigate complex systems confidently. When faced with issues, having a detailed visual reference allows for quicker diagnostics, streamlining the troubleshooting process. Moreover, it can significantly extend the lifespan of equipment by ensuring that replacements are made correctly and efficiently.

In essence, these illustrations are invaluable resources for both novices and experienced technicians alike. They promote a deeper understanding of machinery, ultimately leading to more informed decisions during maintenance and repair tasks.

Identifying Major Parts of the Chainsaw

Understanding the essential components of a cutting tool is crucial for effective operation and maintenance. Each element plays a specific role in ensuring the device functions smoothly and efficiently. Familiarity with these key sections can significantly enhance your overall experience and prolong the lifespan of the equipment.

Power Unit

The power unit serves as the heart of the mechanism, generating the energy required for operation. Typically powered by a combustion engine or electric motor, this section dictates the tool’s performance and efficiency. Regular inspection and maintenance of the power unit are vital to prevent issues that could lead to decreased functionality.

Cutting Assembly

The cutting assembly includes components that interact directly with the material being worked on. This typically consists of a blade or bar and a chain designed for precision cutting. Understanding the configuration and condition of these elements is essential for achieving optimal cutting performance and ensuring safety during use.

Common Issues with Husqvarna 240 Parts

Understanding frequent challenges associated with various components can significantly enhance the maintenance and performance of any outdoor power equipment. Users often encounter several recurring problems that can hinder efficiency and usability.

- Fuel System Problems:

- Clogged fuel filters leading to reduced power.

- Inconsistent fuel delivery affecting operation.

- Starting Difficulties:

- Worn spark plugs causing ignition issues.

- Issues with the recoil starter leading to failure to engage.

- Chain Issues:

- Chain tension problems resulting in poor cutting performance.

- Wear and tear on the bar affecting overall operation.

- Electrical Failures:

- Battery drainage affecting performance in electric models.

- Faulty wiring leading to intermittent issues.

Addressing these common challenges promptly can lead to a more efficient and reliable experience.

Maintenance Tips for Your Chainsaw

Regular upkeep is essential for ensuring the longevity and efficiency of your cutting tool. Proper care not only enhances performance but also promotes safety during operation. Implementing a routine maintenance schedule can prevent costly repairs and unexpected breakdowns.

Routine Cleaning

Keeping the tool clean is fundamental. After each use, remove sawdust and debris from the exterior, air filter, and guide bar. This prevents buildup that can impair functionality and cause overheating.

Regular Inspections

Conduct frequent checks on the cutting chain, tension, and lubrication system. Ensuring that these components are in optimal condition minimizes wear and tear. Address any signs of damage immediately to maintain peak performance.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a guide, showcasing how various elements interact and fit together. Mastering this skill enhances your ability to identify, locate, and replace individual pieces when necessary.

To interpret these visuals accurately, follow these steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout, noting the arrangement of different sections. |

| 2 | Identify the labels and numbers that correspond to each component. |

| 3 | Refer to the accompanying list for detailed descriptions of each item. |

| 4 | Cross-reference with your specific model to ensure accuracy. |

With practice, you will ultimately find this skill invaluable for efficient repairs and replacements.

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing suitable components is crucial for optimal performance. Whether you’re looking for specific elements to restore functionality or enhance efficiency, there are several avenues to explore.

Online Retailers: Numerous websites specialize in outdoor equipment supplies, providing a vast selection of components. Shopping online often allows for easy comparison of prices and availability.

Local Dealers: Authorized retailers in your area can offer genuine components, along with expert advice on installation and maintenance. Building a relationship with a local dealer can ensure reliable support.

Second-Hand Markets: Platforms such as auction sites or classified ads can yield affordable options, though it’s important to assess the condition and compatibility of used items.

Manufacturer’s Website: Visiting the official site may lead you to a comprehensive catalog of available components, ensuring you find what you need directly from the source.

Exploring these resources will help you locate the right elements to keep your equipment in top shape.

Tools Needed for Repairs

When undertaking maintenance or repair tasks on your equipment, having the right tools at your disposal is essential for achieving optimal results. A well-equipped workspace can make the difference between a smooth repair process and a frustrating experience. Understanding the necessary instruments not only enhances efficiency but also ensures safety during operations.

Basic Hand Tools: Start with fundamental hand tools such as screwdrivers, wrenches, and pliers. These are indispensable for loosening or tightening various components. A good quality set will serve you well over time.

Specialized Tools: Depending on the model, you may need specialized instruments like a spark plug socket or a bar wrench. These tools are designed to fit specific parts and simplify the repair process significantly.

Protective Gear: Safety should never be overlooked. Invest in protective eyewear, gloves, and hearing protection to safeguard yourself from potential hazards during repairs.

Cleaning Supplies: Maintaining cleanliness is crucial. Have brushes, cloths, and cleaning solutions on hand to keep components free from debris and ensure optimal functionality.

Lubricants and Oils: Regular lubrication is key to smooth operation. Stock up on appropriate oils and greases to keep moving parts functioning effectively and to prolong the life of your equipment.

By gathering these essential tools, you will be well-prepared to tackle any repair task that comes your way, ensuring both efficiency and safety in your maintenance efforts.

Safety Precautions During Repairs

Ensuring safety during maintenance is crucial to prevent accidents and injuries. Adhering to specific guidelines helps protect both the technician and the equipment being serviced. Proper preparation and awareness of risks play a significant role in achieving a secure working environment.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes gloves, goggles, and ear protection to shield against potential hazards. Investing in quality equipment enhances safety and reduces the risk of injury while working.

Work Area Organization

Maintaining a clean and organized workspace minimizes distractions and hazards. Clear any debris and ensure all tools are readily accessible. A tidy area fosters concentration and reduces the likelihood of accidents during the repair process.

Comparison with Other Chainsaw Models

This section explores the distinctions and similarities between a specific model and other popular cutting tools in the market. Understanding these variations can aid users in making informed decisions based on their needs.

- Power and Performance: Different models offer varying levels of power output and cutting efficiency, impacting their suitability for various tasks.

- Weight and Portability: Some options are lighter and easier to maneuver, while others may provide added stability but at the cost of increased weight.

- Features and Technology: Innovations like anti-vibration systems and automatic oilers can enhance user experience and operational efficiency.

Comparing these aspects can ultimately help in selecting the best tool for specific applications, whether for professional use or home projects.

Upgrades and Customization Options

Enhancing the performance and appearance of your cutting tool can significantly improve its efficiency and user experience. There are numerous possibilities for modifications that cater to various needs and preferences, allowing you to tailor the equipment to your specific requirements. From improving power output to customizing aesthetics, exploring these options can lead to a more satisfying and productive operation.

Power and Performance Enhancements

One of the most common upgrades involves enhancing the engine’s performance. By installing a high-performance air filter or a specialized exhaust system, users can increase airflow and efficiency, leading to better cutting capabilities. Additionally, upgrading the cutting chain to a more aggressive design can result in faster cutting speeds and reduced effort during operation.

Aesthetic Customization

Beyond functionality, many enthusiasts enjoy personalizing the appearance of their tools. This can include changing the color scheme, adding decals, or even swapping out the handle grips for a more ergonomic or visually appealing option. These modifications not only reflect personal style but can also improve comfort during use.

Safety Features

Upgrading safety features is another critical area for consideration. Adding advanced braking systems or enhanced chain guards can provide additional protection, ensuring safer operation. Investing in high-quality protective gear can also complement any upgrades made to the equipment itself.

Overall, exploring these upgrades and customization options can enhance both the functionality and enjoyment of your tool, making it a more effective and personalized asset for your tasks.

Frequently Asked Questions about Parts

This section addresses common inquiries regarding components and their maintenance. Understanding the essentials of these items can enhance performance and longevity, making it vital for users to be well-informed.

What should I do if a component breaks? It’s advisable to replace the damaged item as soon as possible to prevent further issues. Consulting the user manual can provide guidance on the replacement process.

How can I identify the correct component for my model? Refer to the specifications in the manual or seek assistance from authorized dealers to ensure compatibility with your specific unit.

Are aftermarket items a good option? Aftermarket options can be cost-effective, but it’s crucial to verify their quality and compatibility to avoid performance problems.

How often should I check components for wear and tear? Regular inspections are recommended, ideally before each use, to catch any signs of deterioration early and maintain optimal functionality.

Can I perform maintenance myself? Yes, many users can handle basic maintenance tasks. However, for complex issues, seeking professional assistance is recommended to avoid potential damage.

Resources for Husqvarna Owners

For enthusiasts and operators of outdoor power tools, having access to quality information and materials is essential. This section highlights various resources that can enhance your experience, improve maintenance, and ensure optimal performance of your equipment.

Manuals and Guides

Accessing user manuals and maintenance guides is crucial for understanding your equipment’s features and proper care. Many manufacturers provide downloadable resources on their websites, offering step-by-step instructions tailored to specific models.

Online Communities

Joining forums and social media groups dedicated to outdoor equipment can provide valuable insights. Engaging with fellow users allows for sharing experiences, troubleshooting tips, and discovering innovative techniques to enhance your tool’s functionality.