Every mechanic or DIY enthusiast knows the importance of understanding the intricate workings of their equipment. This knowledge not only aids in efficient operation but also enhances maintenance practices. Whether you are a seasoned user or a newcomer, familiarizing yourself with the inner mechanisms of your power tool is crucial for optimal performance.

Visual aids play a significant role in grasping the arrangement and function of various elements within your device. By examining detailed illustrations, you can easily identify each segment’s purpose and how they interact. Such insights pave the way for effective troubleshooting and repairs, ensuring longevity and reliability.

Furthermore, having a clear representation of components allows for informed decision-making when it comes to replacements or upgrades. As you delve deeper into the specifics, you’ll gain confidence in handling your tool, leading to improved safety and efficiency during use. Whether for routine maintenance or more extensive repairs, this knowledge will serve you well.

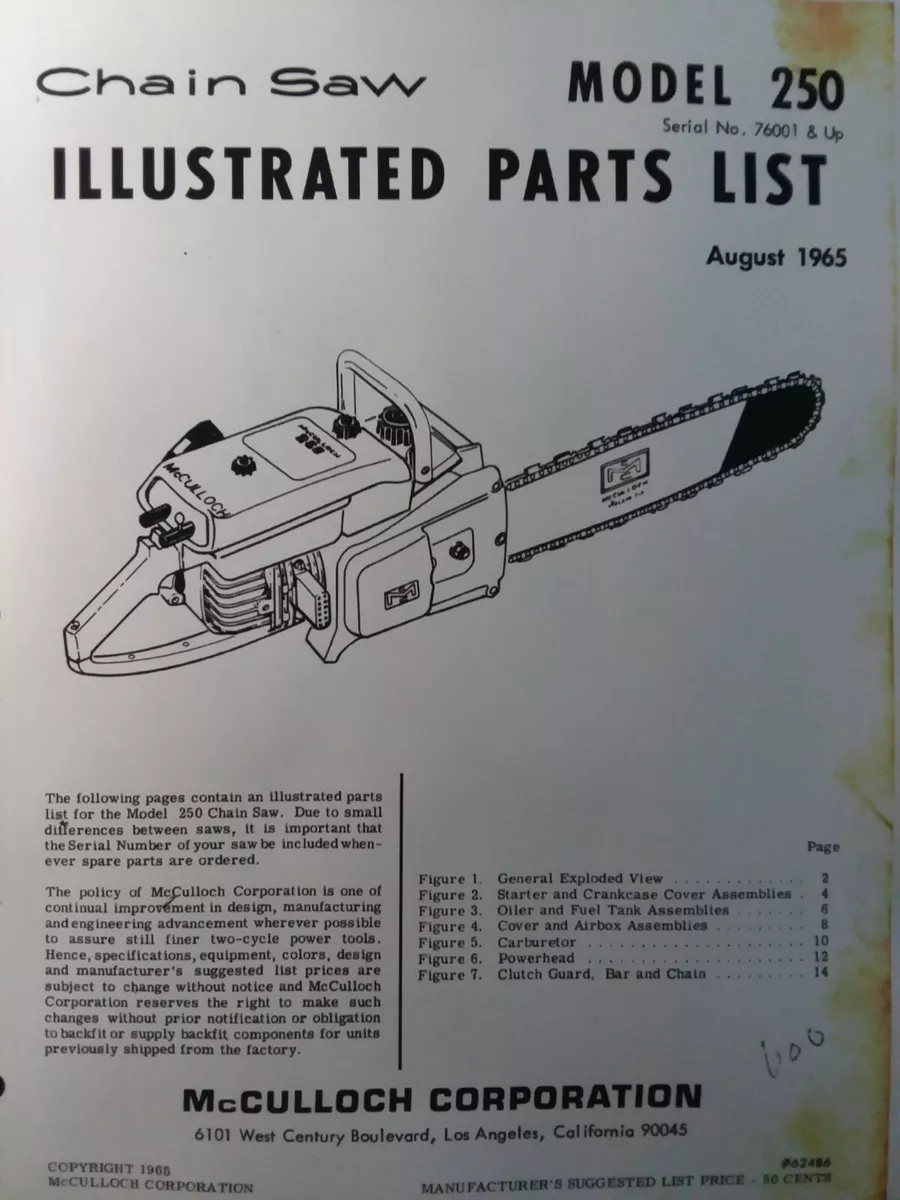

Mcculloch 250 Chainsaw Overview

This section provides an insightful look into a well-regarded tool known for its efficiency and reliability in the realm of outdoor equipment. Renowned among enthusiasts and professionals alike, this device has made a mark due to its robust construction and user-friendly features, making it a go-to choice for various tasks.

Key Features

Equipped with a range of functionalities, this machine excels in delivering optimal performance. Below is a summary of its standout characteristics:

| Feature | Description |

|---|---|

| Engine Power | Designed with a high-output engine for superior cutting capability. |

| Weight | Lightweight construction enhances maneuverability and reduces user fatigue. |

| Fuel Efficiency | Optimized for reduced fuel consumption while maintaining power. |

| Durability | Built with high-quality materials to withstand rigorous use. |

Usage Applications

This versatile tool is suitable for a variety of applications, including trimming, felling, and firewood preparation. Whether in a residential setting or on a professional job site, its effectiveness is appreciated across different user levels.

Key Features of the Mcculloch 250

This section highlights the distinctive attributes of a particular power tool renowned for its reliability and efficiency in various cutting tasks. Users appreciate its robust design and advanced technology, which contribute to optimal performance in demanding conditions.

Performance and Efficiency

The tool is equipped with a high-output engine that ensures quick and effective operation. Its lightweight construction enhances maneuverability, allowing for precise handling and reduced fatigue during extended use.

Durability and Maintenance

Built with high-quality materials, this equipment is designed to withstand wear and tear. Routine upkeep is straightforward, featuring accessible components that facilitate easy repairs and replacements, ensuring longevity and sustained performance.

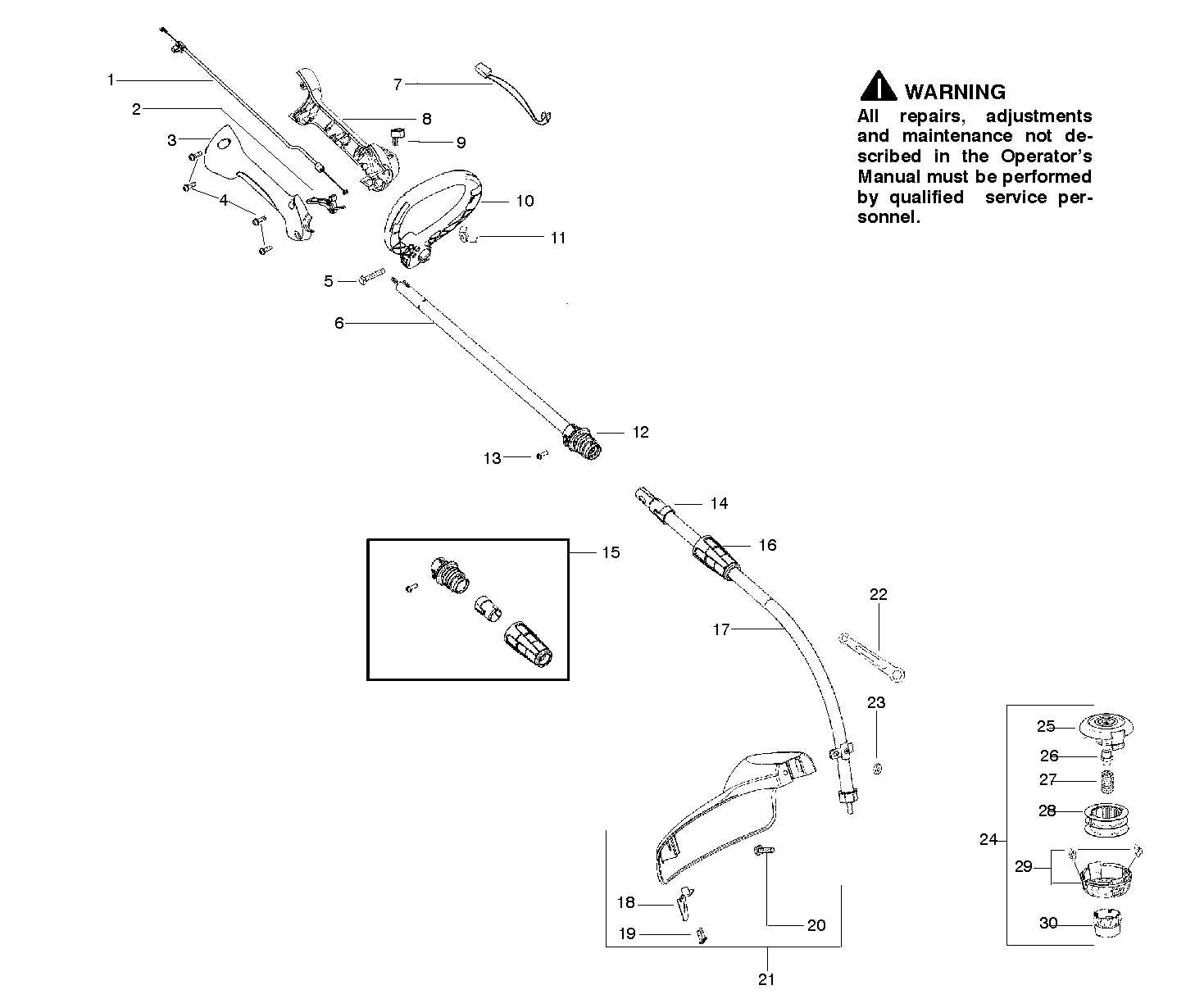

Understanding Chainsaw Parts Functionality

In any cutting tool, each component plays a vital role in its overall performance. Recognizing the specific functions of these elements can enhance your experience and efficiency. By examining how they interact, users can better maintain and troubleshoot their equipment.

| Component | Function |

|---|---|

| Engine | Provides power and drives the cutting mechanism. |

| Bar | Acts as a guide for the cutting chain, ensuring stability. |

| Chain | Contains sharp teeth that perform the actual cutting. |

| Fuel System | Delivers the necessary energy for operation. |

| Brake | Stops the chain rapidly for safety when needed. |

| Handle | Allows for control and maneuverability during use. |

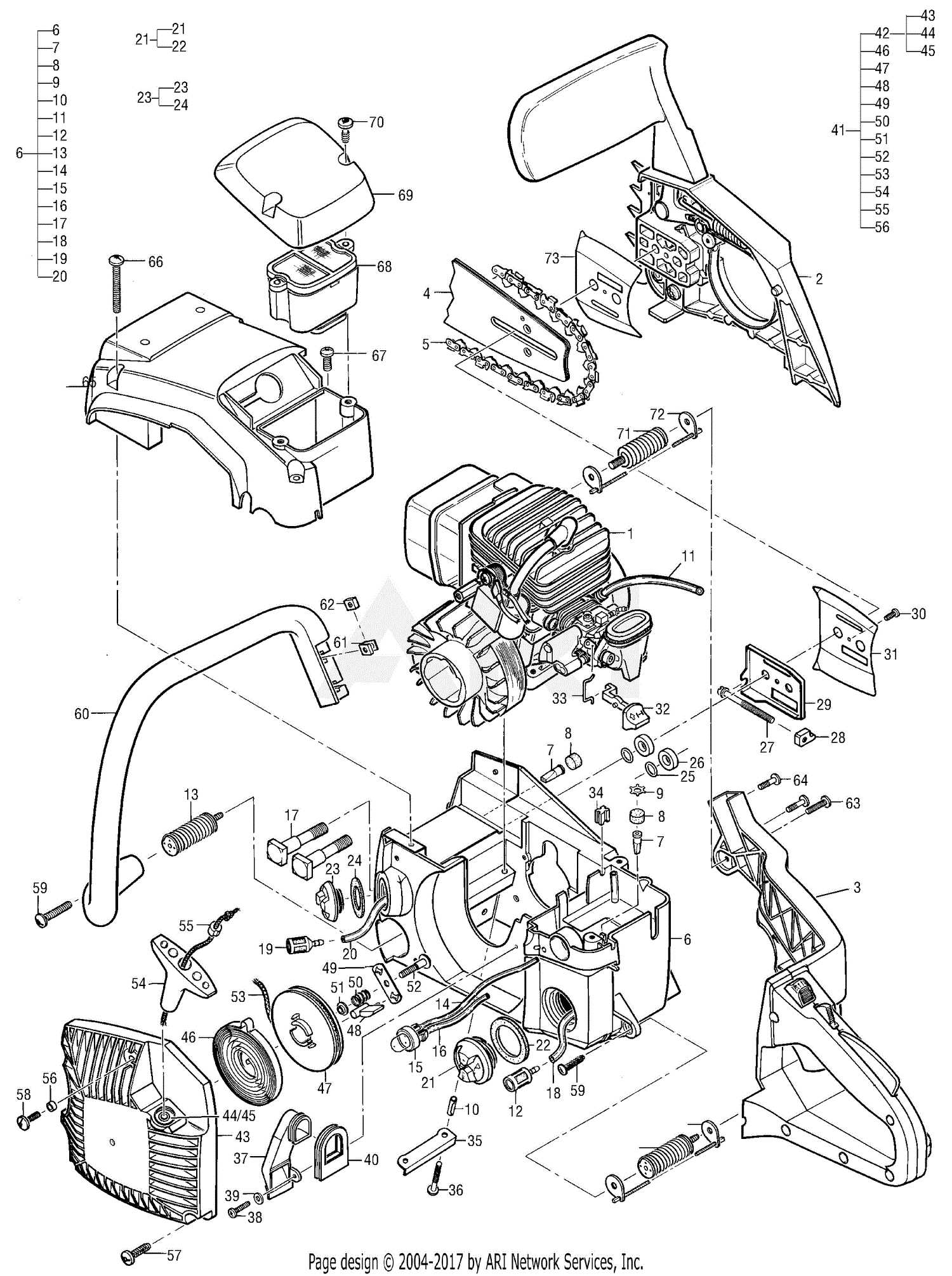

Detailed Parts Diagram Explained

This section aims to provide an in-depth look at the components of a specific tool, enhancing understanding and facilitating maintenance. A visual representation can significantly aid in identifying each element and its function within the overall system.

Key components typically highlighted in such representations include:

- Engine assembly

- Fuel system

- Cutting mechanism

- Safety features

- Housing and supports

By analyzing each section, users can:

- Recognize individual parts and their roles.

- Understand assembly and disassembly procedures.

- Identify potential areas for repair or replacement.

Ultimately, this knowledge empowers users to maintain their equipment effectively, ensuring longevity and optimal performance.

Common Replacement Parts for Mcculloch 250

Maintaining optimal performance in power tools often requires the timely replacement of specific components. Understanding which elements are prone to wear can significantly enhance the longevity and efficiency of the equipment.

Fuel Filter: This essential component ensures that clean fuel reaches the engine, preventing damage from debris.

Air Filter: A vital part that keeps contaminants out of the engine, promoting better airflow and improving performance.

Spark Plug: This element is crucial for ignition, and replacing it can lead to improved starting and efficiency.

Chain Brake: A safety feature that should be checked regularly, as it can wear down over time and affect operation.

Clutch Drum: Subject to wear due to friction, this part can impact cutting efficiency and should be inspected periodically.

Maintenance Tips for Chainsaw Longevity

Proper upkeep is essential for maximizing the lifespan of your cutting tool. Regular attention not only enhances performance but also ensures safety during operation. Here are some key practices to follow.

- Regular Cleaning: Remove debris and sap from the tool after each use to prevent buildup.

- Sharp Blades: Keep the cutting edges well-honed to facilitate smooth operation and reduce strain on the engine.

- Lubrication: Regularly apply oil to the moving parts to minimize friction and wear.

- Check Fuel: Use the appropriate fuel mixture and store it correctly to prevent contamination.

- Inspect Components: Frequently check essential components such as filters and spark plugs for wear and tear.

Adhering to these guidelines will help ensure that your tool remains in excellent condition, providing reliable service for years to come.

How to Identify Faulty Components

Recognizing defective elements in your equipment is crucial for maintaining optimal performance and safety. Various symptoms may indicate underlying issues that need to be addressed promptly.

- Listen for unusual sounds, such as grinding or excessive vibrations, which may signal a malfunction.

- Inspect for visible damage or wear on components, including cracks, rust, or excessive buildup of debris.

- Monitor operational efficiency; a noticeable drop in performance can suggest that a part is failing.

By conducting regular checks and being aware of these warning signs, you can effectively pinpoint and address problematic elements, ensuring your equipment runs smoothly.

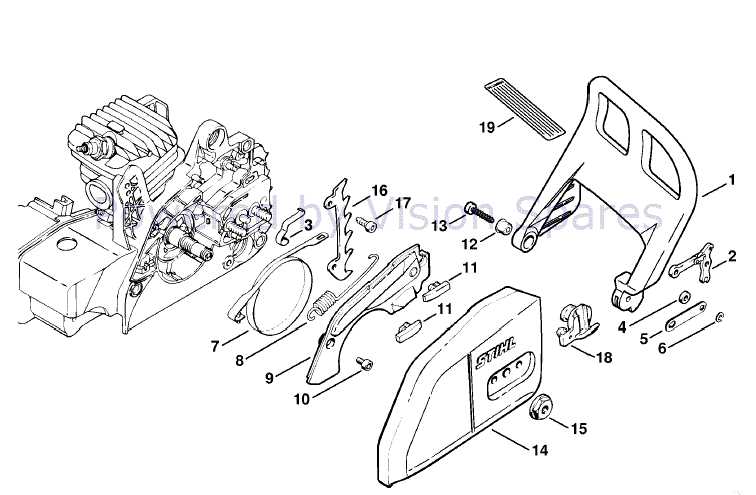

Assembly Guide for Mcculloch 250 Parts

This section provides a comprehensive overview of how to assemble the components of a specific power tool effectively. Proper assembly ensures optimal performance and longevity of the equipment, making it essential for users to understand each step of the process.

Follow these steps for a successful assembly:

- Gather all necessary components and tools.

- Begin with the base unit and secure it on a stable surface.

- Attach the housing by aligning the designated slots and pressing firmly until you hear a click.

- Install the power unit, ensuring the connections are tight and secure.

- Attach any additional accessories, such as guides or protective elements, as specified in the instructions.

- Perform a final check to confirm all components are correctly positioned and secured.

By following these guidelines, users can ensure their equipment is assembled correctly, ready for efficient use.

Where to Buy Replacement Parts

Finding suitable components for your equipment is essential to maintain its efficiency and performance. Numerous sources offer a wide selection of these items, ensuring that you can restore your device to optimal working condition.

Online retailers provide a convenient option, often featuring extensive inventories and detailed descriptions. Websites specializing in outdoor tools and machinery frequently have user-friendly interfaces that make searching for specific components easy. Additionally, many of these platforms offer customer reviews to help you make informed decisions.

Local hardware stores or specialized tool shops can also be valuable resources. Visiting these locations allows you to physically inspect the items and receive personalized assistance from knowledgeable staff. They can guide you in choosing the right components based on your device’s requirements.

Finally, consider checking out second-hand markets or community forums. These platforms might have listings for gently used items at reduced prices, giving you an economical way to acquire what you need while supporting fellow enthusiasts.

Safety Precautions When Using Chainsaws

When operating power tools designed for cutting, prioritizing safety is essential to prevent accidents and injuries. Understanding the risks associated with these devices can significantly enhance user protection and ensure a secure working environment.

Proper Gear and Equipment

Always wear appropriate protective clothing, including gloves, goggles, and sturdy footwear. These items shield against potential debris and reduce the risk of injury. Hearing protection is also recommended to minimize noise exposure during operation.

Understanding the Equipment

Familiarize yourself with the tool’s features and functionality before use. Always consult the manufacturer’s manual for specific guidelines. Regular maintenance ensures the equipment remains in good working condition, further promoting safe operation.

Upgrading Your Mcculloch Chainsaw

Enhancing the performance of your power tool can lead to improved efficiency and longer service life. Whether you aim for better cutting speed or enhanced durability, several upgrades can transform your device into a more powerful ally in your outdoor tasks.

Performance Enhancements

Consider upgrading the motor for increased power output. A more robust engine can handle tougher jobs and provide a smoother experience. Additionally, replacing the existing chain with a high-quality alternative can significantly improve cutting performance. Stronger materials and sharper teeth ensure faster and cleaner cuts.

Maintenance and Longevity

Regular maintenance is essential for prolonging the life of your equipment. Installing a new air filter can enhance airflow, leading to better engine performance. Furthermore, using high-grade lubricants can reduce wear and tear, ensuring that all moving parts function smoothly. Investing in quality components not only boosts efficiency but also minimizes the risk of future repairs.