The intricate machinery that powers your vehicle is composed of various essential elements, each playing a crucial role in performance and efficiency. Grasping the layout and function of these components can significantly enhance your maintenance and repair experience.

By examining the arrangement of these vital structures, you can better appreciate how they interact and contribute to the overall functionality of your automobile. This knowledge not only empowers you to troubleshoot issues but also aids in optimizing your vehicle’s capabilities.

In this section, we will delve into a detailed exploration of the various segments that make up the heart of your vehicle, providing clarity and insight into their specific functions. Understanding these components is the ultimate key to ensuring longevity and reliability.

Understanding the Chevy Colorado Engine

This section delves into the fundamental components and workings of a specific vehicle’s propulsion system. By grasping the various elements and their functions, enthusiasts and owners can better appreciate how performance and efficiency are achieved.

Key Components

- Block: The core structure housing various essential elements.

- Cylinder Head: A crucial component that manages airflow and combustion processes.

- Crankshaft: Transforms linear motion into rotational force, driving the vehicle.

- Pistons: Move within cylinders, creating the necessary pressure for ignition.

Functionality Overview

- Intake Stroke: Air-fuel mixture enters the combustion chamber.

- Compression Stroke: The mixture is compressed to enhance combustion efficiency.

- Power Stroke: Ignition occurs, pushing the piston down and generating power.

- Exhaust Stroke: Expulsion of combustion gases prepares for the next cycle.

Understanding these fundamental aspects can significantly aid in troubleshooting and maintenance, ensuring optimal performance over time.

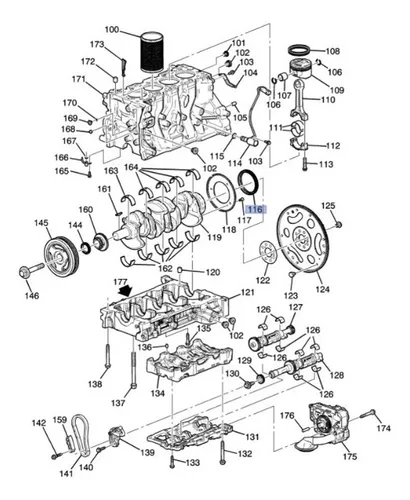

Key Components of the Engine System

The intricate assembly of a vehicle’s power unit consists of several essential elements that work in harmony to deliver optimal performance. Understanding these critical components is vital for maintaining efficiency and longevity. Each part plays a specific role, contributing to the overall functionality of the propulsion system.

| Component | Function |

|---|---|

| Block | The main structure housing various components, providing support and stability. |

| Cylinders | Hollow chambers where fuel and air mixture combusts to create power. |

| Pistons | Move up and down within the cylinders, converting pressure into mechanical energy. |

| Crankshaft | Transforms linear motion from pistons into rotational force for the drivetrain. |

| Camshaft | Controls the opening and closing of valves, regulating airflow in and out of the cylinders. |

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber for optimal combustion. |

| Valves | Allow the intake of air and fuel while enabling exhaust gases to exit the combustion chamber. |

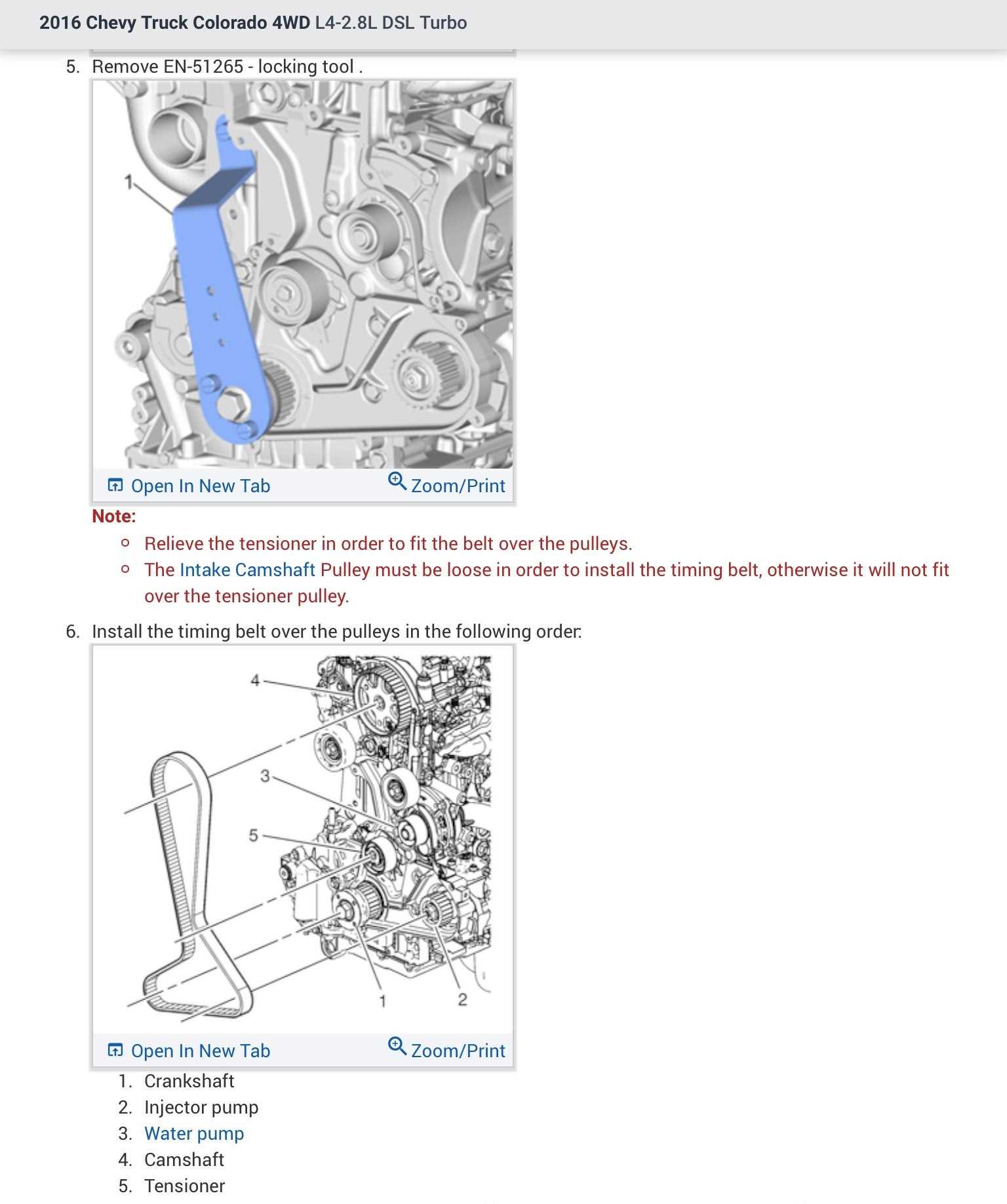

| Timing Belt/Chain | Synchronizes the movement of the crankshaft and camshaft for efficient operation. |

Importance of Engine Diagrams

Visual representations of mechanical systems play a crucial role in understanding their complex structures. These illustrations serve as essential tools for both professionals and enthusiasts, providing clarity and insight into the arrangement and function of various components.

One significant advantage of these visuals is their ability to simplify intricate concepts. By breaking down information into manageable parts, users can easily grasp how different elements interact within a system.

Moreover, having access to such representations can enhance maintenance and troubleshooting efforts. When issues arise, referring to these guides allows for a quicker diagnosis and more effective repairs, ultimately leading to improved performance and longevity of the machinery.

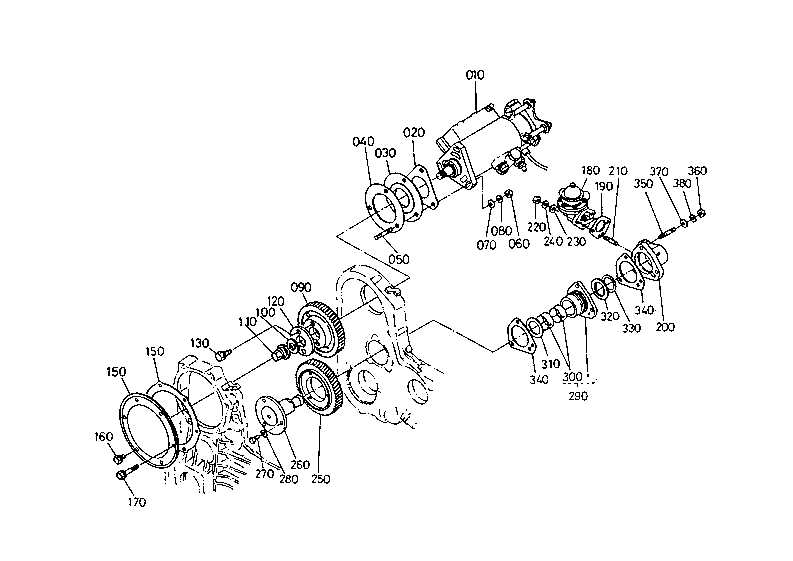

How to Read Engine Schematics

Understanding the layout and function of a vehicle’s internal components is essential for effective maintenance and repairs. Familiarizing oneself with technical drawings can greatly enhance one’s ability to diagnose issues and identify necessary components. This guide provides insights into interpreting these complex illustrations.

Engine schematics typically employ a standardized set of symbols and notations, which represent various elements and their interconnections. Learning these symbols is crucial for deciphering the information conveyed in the drawings. Below is a brief overview of common symbols used in these illustrations.

| Symbol | Description |

|---|---|

| ⚙️ | Gear mechanism or component |

| Electrical connection or terminal | |

| Adjustment or service point | |

| Vehicle or system representation |

In addition to symbols, the flow of lines in these illustrations indicates how systems interact. Solid lines usually represent physical connections, while dashed lines often indicate electrical pathways. Recognizing these distinctions will assist in navigating the complexities of mechanical systems.

To effectively utilize these schematics, start by identifying the main components outlined in the drawing. Trace each connection to understand the relationships between parts. This methodical approach will aid in grasping the overall functionality and diagnosing potential problems.

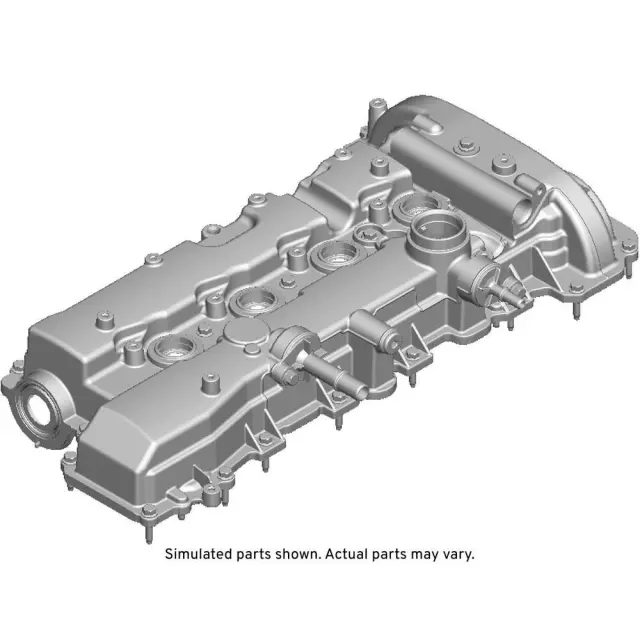

Common Engine Parts Explained

Understanding the fundamental components of a motor is essential for anyone interested in automotive mechanics. Each element plays a crucial role in ensuring optimal performance and reliability. This section provides insights into these vital components, their functions, and how they work together to facilitate smooth operation.

Key Components Overview

Among the principal elements are the crankshaft, which converts linear motion into rotational force, and the camshaft, responsible for regulating the timing of valve movements. Additionally, the pistons create pressure within the cylinders, allowing for the combustion process to take place efficiently. These components must function harmoniously to achieve peak efficiency and power output.

Additional Vital Elements

Supporting these main components are various other structures, such as the intake and exhaust manifolds, which manage airflow in and out of the combustion chambers. The cooling system, including the radiator and water pump, plays a vital role in maintaining optimal temperatures, preventing overheating. Understanding these parts is key to grasping how a motor operates and responds to driver inputs.

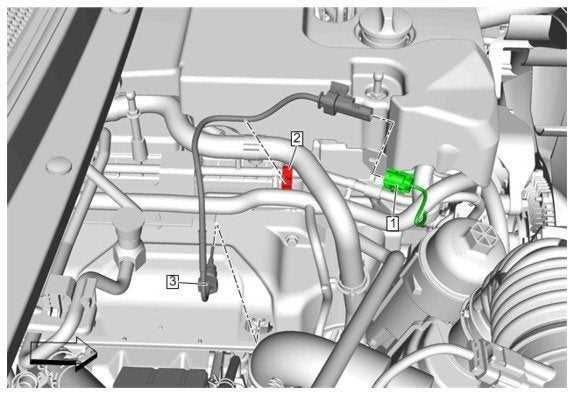

Fuel System Overview in Colorado

The fuel system plays a crucial role in the overall performance and efficiency of vehicles, ensuring that the right mixture of fuel and air reaches the combustion chamber. This system comprises various components that work in unison to deliver optimal energy output and maintain reliability.

Key elements of this system include the fuel tank, fuel pump, injectors, and filters, each serving a specific function to ensure a smooth operation. The fuel tank stores the liquid energy source, while the pump facilitates its movement through the system.

Injectors are responsible for atomizing the fuel for efficient combustion, and filters help maintain the cleanliness of the fuel, preventing contaminants from causing damage. Understanding these components is essential for troubleshooting and maintenance, ultimately enhancing the vehicle’s longevity and performance.

Electrical Components and Their Functions

Understanding the various electrical elements within a vehicle’s system is essential for ensuring optimal performance and reliability. Each component plays a pivotal role, working together to facilitate communication and control across multiple functions. This section delves into the critical electrical components, highlighting their significance and operation.

Key Electrical Components

Electrical systems consist of several integral parts, each serving a distinct purpose. Here are some of the primary components and their functionalities:

| Component | Function |

|---|---|

| Battery | Stores electrical energy and provides power to start the vehicle and operate electrical systems. |

| Alternator | Generates electrical power while the vehicle is running, recharging the battery and powering systems. |

| Starter Motor | Engages the engine to initiate the combustion process when starting the vehicle. |

| Fuses | Protect electrical circuits by breaking the connection in case of overload, preventing damage. |

| Relays | Act as switches that control high-power circuits using low-power signals, ensuring efficient operation. |

Importance of Electrical Components

The reliability of a vehicle heavily relies on the proper functioning of its electrical components. Regular maintenance and timely replacements of these parts can prevent unexpected failures and ensure a smooth driving experience. Understanding their roles helps in troubleshooting and optimizing overall performance.

Cooling System: A Detailed Breakdown

The cooling system is crucial for maintaining optimal temperatures within the vehicle’s powertrain. Its primary function is to dissipate excess heat generated during operation, preventing overheating and ensuring efficient performance. A thorough understanding of its components and functionality is essential for effective maintenance and troubleshooting.

Key Components of the Cooling System

The main elements that make up this system include the radiator, water pump, thermostat, and cooling fans. Each component plays a vital role in circulating coolant and regulating temperature. The radiator serves as a heat exchanger, allowing heat to dissipate into the air. The water pump is responsible for circulating the coolant throughout the engine and radiator. Meanwhile, the thermostat acts as a gatekeeper, controlling the flow of coolant based on temperature readings. Finally, cooling fans assist in enhancing airflow through the radiator when necessary.

Functionality and Maintenance Tips

Understanding how these components interact is essential for maintaining a well-functioning system. Regular checks of coolant levels and inspections for leaks can prevent major issues. Additionally, flushing the coolant periodically helps remove debris and maintain optimal thermal conductivity. Keeping an eye on the temperature gauge can also provide early warnings of potential overheating problems, allowing for timely intervention and repair.

Engine Performance and Efficiency Factors

Understanding the elements that influence power output and fuel consumption is crucial for maximizing vehicle functionality. Various components interact to determine how effectively energy is converted into motion while maintaining optimal use of resources.

Key Elements Influencing Performance

Several aspects contribute to the overall effectiveness of a power unit, including design characteristics, material quality, and technological advancements. Enhancements in these areas lead to significant improvements in responsiveness and economy.

Efficiency Metrics

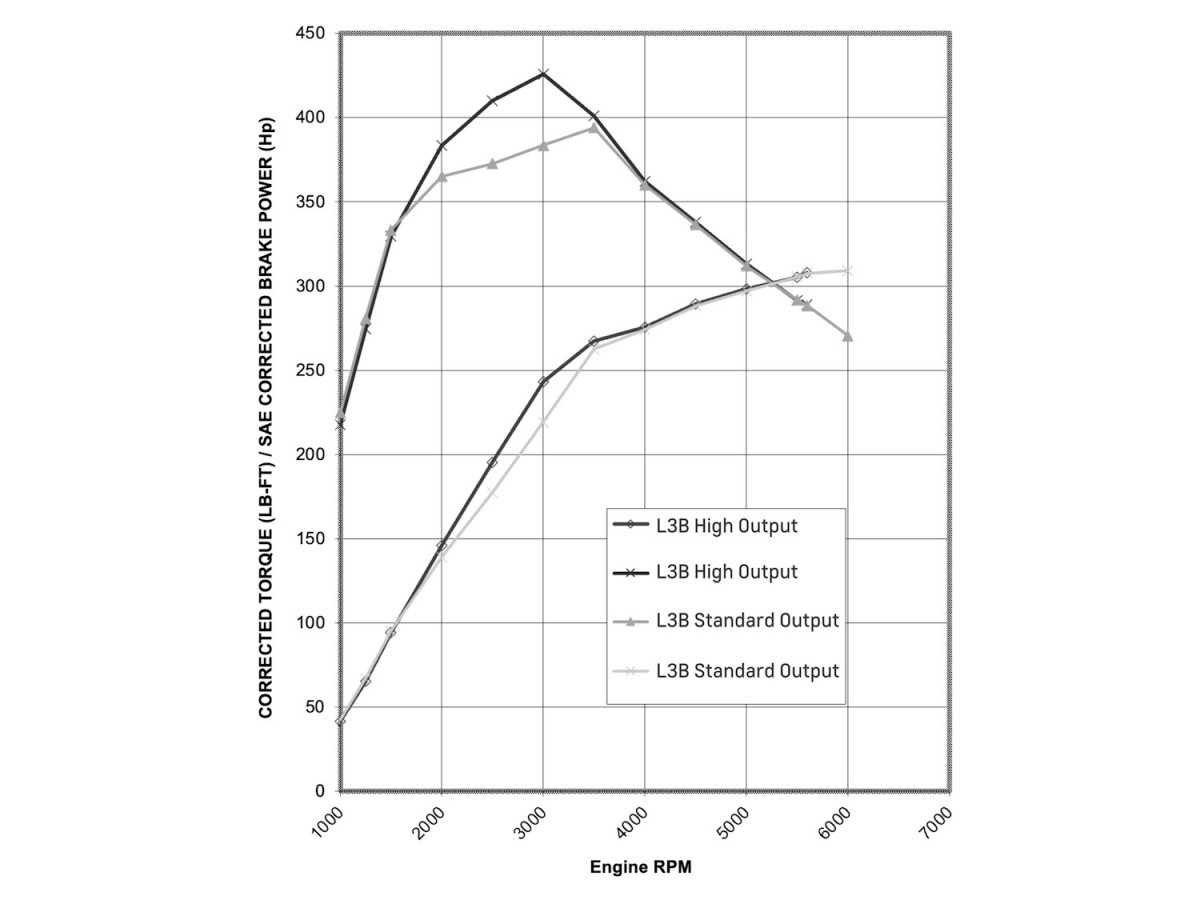

Measuring performance and fuel efficiency involves several metrics, including horsepower, torque, and thermal efficiency. These indicators provide insights into the operational effectiveness of the mechanical system.

| Metric | Description |

|---|---|

| Horsepower | Measurement of power output. |

| Torque | Indicates rotational force available. |

| Thermal Efficiency | Ratio of work output to heat input. |

Common Repairs and Maintenance Tips

Regular upkeep and timely repairs are essential for ensuring the longevity and performance of any vehicle. Understanding common issues and the necessary interventions can help owners maintain their machines in optimal condition. This section will provide valuable insights into frequent maintenance tasks and repair strategies that can enhance reliability and efficiency.

One of the most important aspects of vehicle care is routine fluid checks. Regularly inspecting and replacing engine oil, coolant, and transmission fluid is crucial to prevent overheating and mechanical failure. Additionally, keeping an eye on the brake fluid level can significantly enhance safety on the road.

Another key area to focus on is the condition of the tires. Ensuring proper inflation and tread depth not only improves fuel efficiency but also contributes to better handling and braking performance. Regular rotations and alignments can further extend the lifespan of the tires.

Electrical components, such as the battery and starter, often require attention as well. Keeping battery terminals clean and testing the battery’s charge can help avoid unexpected breakdowns. Furthermore, checking and replacing worn-out fuses can ensure that all systems operate smoothly.

Lastly, regular inspections of belts and hoses are vital. These components are subject to wear and tear and can lead to significant issues if not monitored. Replacing cracked or frayed belts and hoses promptly can save time and money in the long run.

Aftermarket Parts for the Colorado

Enhancing your vehicle’s performance and aesthetics often involves exploring alternatives to factory components. This section delves into various modifications available to elevate your driving experience. From boosting horsepower to improving suspension, numerous aftermarket options exist to cater to diverse preferences.

Performance Enhancements

Upgrading to high-performance solutions can significantly affect your ride. Turbochargers and cold air intakes are popular choices for those seeking increased power. Additionally, exhaust systems can enhance engine efficiency while providing a more aggressive sound.

Cosmetic Upgrades

Beyond performance, aesthetic modifications can transform the look of your vehicle. Custom grilles, led lighting kits, and aftermarket wheels allow for personalized expression. These enhancements not only improve appearance but can also add functionality, such as improved visibility and off-road capability.

Resources for Engine Part Diagrams

Finding reliable materials to understand the various components of your vehicle’s machinery is essential for maintenance and repairs. Numerous sources offer detailed visual representations and descriptions that can aid in identifying specific elements. These resources can enhance your knowledge and assist in troubleshooting issues effectively.

| Resource Type | Description | Link |

|---|---|---|

| Online Databases | Comprehensive platforms that host extensive catalogs of component illustrations. | Visit Here |

| Manuals | Printed or digital guides offering in-depth insights into vehicle configurations. | Visit Here |

| Forums | Community-driven spaces where enthusiasts share tips and resources. | Visit Here |

Finding OEM vs. Aftermarket Parts

When it comes to sourcing components for your vehicle, the choice between original equipment manufacturer options and alternative solutions is crucial. Each category offers distinct advantages and potential drawbacks that can significantly impact performance, durability, and cost. Understanding these differences will empower you to make an informed decision tailored to your needs.

Benefits of OEM Components

Opting for original parts often ensures a high level of quality and compatibility with your vehicle. These components are designed specifically for your model, which can lead to optimal performance and longevity. Additionally, many manufacturers provide warranties on these items, offering peace of mind regarding their reliability.

Advantages of Aftermarket Solutions

Aftermarket alternatives frequently present a cost-effective option, allowing for significant savings. Many manufacturers offer enhanced performance features that may not be available in original components. However, it is essential to research the reputation of the aftermarket provider to ensure quality and compatibility.

Ultimately, the decision between original and alternative components hinges on individual preferences, budget considerations, and the specific requirements of your vehicle.