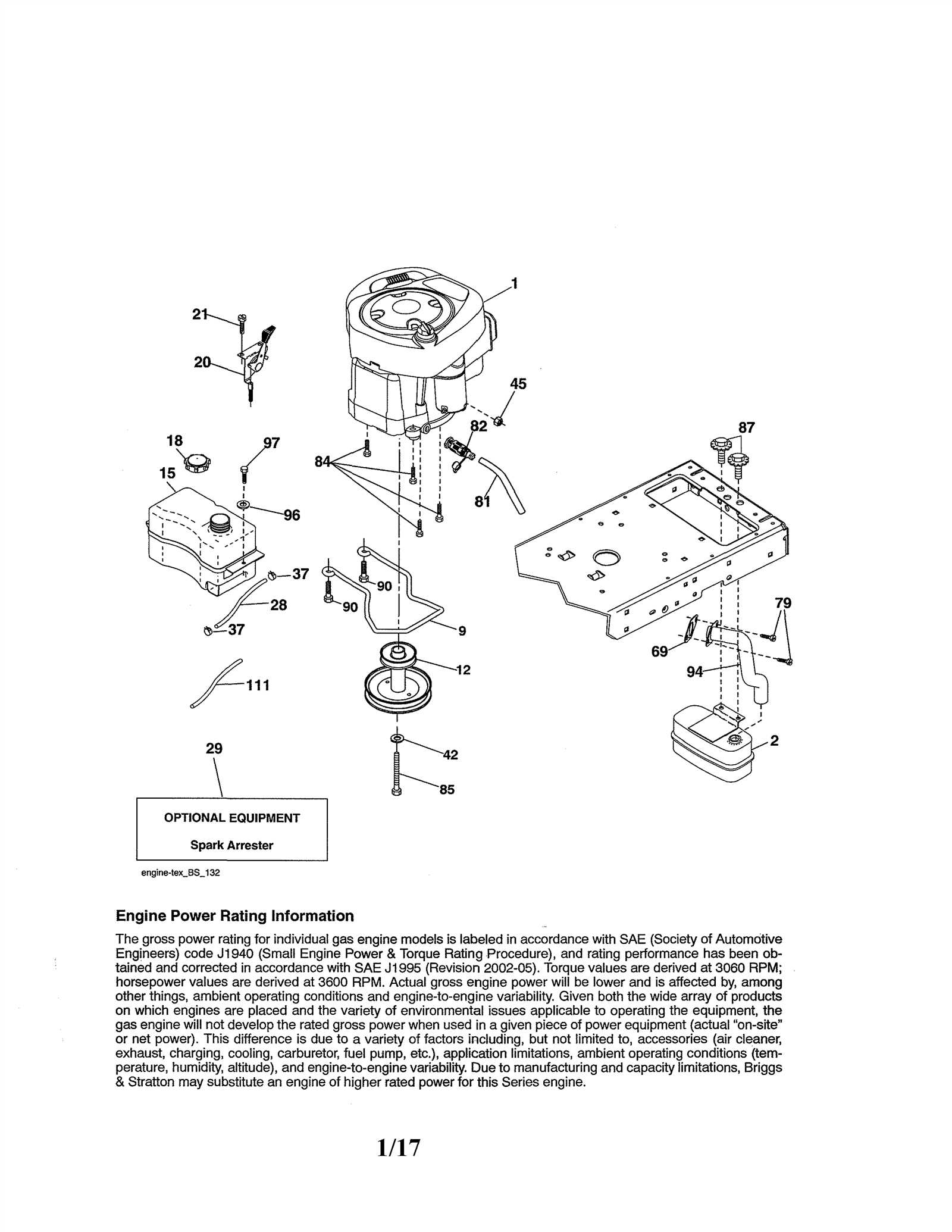

The functionality and efficiency of a lawn maintenance system largely depend on the quality and arrangement of its essential elements. A well-organized structure not only enhances performance but also simplifies maintenance and repairs. This section delves into the various components that contribute to a successful lawn care experience.

By examining the configuration and relationships among these elements, users can gain valuable insights into their operation. Identifying the specific roles of each component allows for more effective troubleshooting and can significantly extend the lifespan of the equipment. Knowledge of how these parts interact is crucial for any operator aiming to achieve optimal results.

In addition, understanding the layout of these components can empower users to make informed decisions regarding replacements or upgrades. With the right information, maintaining and improving the efficiency of a lawn care system becomes a more manageable task, ensuring that it remains in peak condition for years to come.

Key Parts of the Mower Deck

Understanding the essential components of a cutting apparatus is vital for effective maintenance and operation. Each element plays a crucial role in ensuring the device functions smoothly and efficiently, contributing to a well-manicured lawn. This section highlights the main components that make up this vital gardening tool.

Essential Components

Here are the key elements that contribute to the overall performance:

- Blades: These sharp elements rotate to cut grass, providing a clean and even finish.

- Spindles: These components support the blades and enable their rotation, ensuring optimal cutting speed.

- Housing: The protective casing that encases the blades and spindles, directing the cut grass downward.

- Lift Mechanism: This system allows the user to raise and lower the cutting apparatus for varying grass heights.

- Wheels: Positioned around the perimeter, these facilitate movement across different terrains and enhance stability.

Maintenance Tips

Regular upkeep is essential for these components to function effectively. Consider the following practices:

- Inspect and sharpen blades periodically to maintain cutting efficiency.

- Check spindles for wear and ensure they are lubricated for smooth operation.

- Clean the housing after each use to prevent grass buildup and rust.

- Adjust the lift mechanism to match the desired cutting height for optimal results.

- Ensure wheels are properly inflated and aligned to avoid uneven cutting.

Exploring Deck Assembly Functions

The assembly of cutting equipment plays a crucial role in the overall functionality and performance of lawn maintenance tools. Understanding the various components and their respective roles can enhance user experience and ensure efficient operation. This section delves into the key elements involved in the assembly of such equipment and their individual contributions to effective grass management.

Key Components and Their Roles

Each component within the assembly serves a distinct purpose, contributing to the machine’s overall efficacy. The following list outlines the primary elements:

- Support Structure: Provides stability and alignment for the cutting mechanism.

- Rotating Blades: Designed to efficiently cut grass to the desired length.

- Spindle Assembly: Houses the blades and allows for their rotation.

- Height Adjustment Mechanism: Facilitates customization of cutting height.

- Deflector: Directs clippings away from the operator and enhances cutting efficiency.

Functionality Insights

Understanding how these components interact can lead to better maintenance practices. Here are some insights into their functions:

- Regular inspections of the support structure can prevent misalignment.

- Sharpening blades ensures optimal cutting performance and prolongs lifespan.

- Greasing the spindle assembly reduces wear and enhances rotation efficiency.

- Adjusting the height correctly promotes healthier grass growth.

- Cleaning the deflector helps maintain effective clipping management.

Essential Hardware for Mower Maintenance

Proper upkeep of your cutting equipment requires specific tools and components that ensure efficient performance. Having the right hardware at hand can greatly enhance the longevity and functionality of your machinery. This section highlights the essential items needed for regular maintenance tasks.

Blades: Sharp and well-maintained blades are crucial for achieving a clean cut. Regularly inspecting and replacing blades when necessary will ensure optimal performance and prevent damage to the turf.

Filters: Air and fuel filters are vital for maintaining engine efficiency. Clean filters allow for better airflow and fuel delivery, which contributes to smoother operation and reduced wear on engine parts.

Belts: The drive and cutting belts are essential for transferring power within the equipment. Checking for wear and replacing frayed or damaged belts is important to maintain smooth operation and prevent breakdowns.

Lubricants: Using the appropriate lubricants on moving parts helps reduce friction and wear. Regular lubrication can prevent rust and corrosion, extending the life of your machinery.

By ensuring these essential components are maintained and replaced as needed, operators can significantly enhance the performance and reliability of their cutting equipment.

Identifying Wearable Parts in Decks

Understanding the components of a cutting apparatus is crucial for maintaining optimal performance. Certain elements of this machinery experience regular contact with the ground and other surfaces, leading to inevitable wear over time. Recognizing these consumable components helps ensure that the equipment operates efficiently and extends its lifespan.

Common Wearable Components

Among the most frequently replaced elements are the blades, which endure significant strain during operation. Regular inspection for dullness or damage is essential, as sharp blades are vital for effective cutting. Additionally, wheel assemblies and bearings can deteriorate, impacting maneuverability and stability. Keeping these areas well-maintained contributes to a smoother experience.

Signs of Wear and When to Replace

Identifying indicators of wear can save time and prevent larger issues. If the blades produce uneven cuts or if unusual noises arise during operation, it may signal that replacement is necessary. Likewise, if any components exhibit visible signs of rust or cracking, prompt attention is advised. Regular maintenance checks can help mitigate risks and ensure the longevity of the machinery.

Importance of Spindle Assembly

The spindle assembly plays a crucial role in the overall functionality and efficiency of lawn maintenance equipment. This component serves as the central hub that connects various elements, ensuring smooth operation during use. A well-functioning spindle is essential for maintaining optimal cutting performance and achieving a clean finish on the grass.

Regular maintenance and timely replacement of the spindle assembly are vital for preventing wear and tear that can lead to reduced efficiency and potential breakdowns. Without proper attention, issues such as uneven cutting or excessive vibrations may arise, ultimately impacting the overall performance of the machine. Therefore, understanding the significance of this assembly is essential for anyone looking to keep their equipment in top condition.

Blade Types for Mower Decks

Choosing the right cutting implements is essential for achieving optimal performance in lawn care. Various configurations and materials are available, each designed to handle specific types of vegetation and terrain. Understanding these options helps users select the most effective tools for their needs.

Here are the primary blade types commonly used:

- Standard Blades: Ideal for general grass cutting, these blades offer a balanced performance suitable for most lawns.

- Mulching Blades: Designed with a unique shape to chop grass into fine pieces, these blades return nutrients to the soil.

- High-Lift Blades: Engineered to create greater suction, these blades elevate clippings for a cleaner cut and efficient bagging.

- Low-Lift Blades: Best for flat terrains, these blades minimize lift to reduce stress on the engine and are suitable for wet conditions.

When selecting cutting implements, consider factors such as:

- Type of grass and vegetation

- Desired finish and cutting height

- Operating conditions and terrain

Making an informed decision on blade types enhances the effectiveness and longevity of the equipment while ensuring a healthy and well-maintained lawn.

Deck Belt Configuration and Maintenance

Ensuring the proper alignment and upkeep of the belt system is crucial for the efficient operation of your lawn equipment. A well-maintained belt not only enhances performance but also prolongs the lifespan of the machinery. Regular checks and adjustments can prevent costly repairs and ensure optimal functionality.

To maintain the belt effectively, consider the following practices:

- Regular Inspection: Check for signs of wear, fraying, or cracking. Replace the belt if any damage is evident.

- Proper Tension: Ensure the belt maintains appropriate tension to avoid slippage or excessive wear. Adjust tensioners as needed.

- Alignment Check: Verify that the belt is correctly aligned with the pulleys. Misalignment can lead to premature wear and malfunction.

- Cleaning: Keep the area around the belt clean and free of debris to ensure smooth operation.

By following these guidelines, you can maintain the belt system in peak condition, ensuring your lawn equipment operates efficiently throughout its use.

Choosing the Right Replacement Parts

Selecting the appropriate components for your lawn care equipment is crucial to maintaining optimal performance and longevity. Ensuring compatibility and quality can help avoid future issues and improve efficiency. Understanding the specifications of the original equipment will guide you in making informed decisions.

Quality Matters: Prioritize high-quality components from reputable manufacturers to ensure durability and effectiveness. Cheaper alternatives may save money initially but could lead to more frequent replacements and repairs.

Compatibility Checks: Before purchasing, verify that the components align with your specific model. Refer to the manufacturer’s guidelines or consult an expert to prevent mismatches that could hinder performance.

Common Issues with Mower Decks

Equipment responsible for grass cutting often experiences wear and tear over time, leading to several operational problems. Understanding these common issues can help prevent further damage and ensure efficient performance.

| Problem | Cause | Solution |

|---|---|---|

| Uneven cutting | Blades may be dull or imbalanced | Sharpen or replace the blades |

| Vibration during operation | Loose or worn components | Inspect and tighten bolts, replace worn parts |

| Grass buildup | Clippings blocking airflow | Regularly clean the underside of the platform |

Tips for Mower Deck Repairs

Maintaining and fixing the cutting platform of your machine is essential for ensuring smooth operation and long-lasting performance. Regular inspection, cleaning, and addressing any issues promptly can prevent costly repairs down the road.

- Inspect Blades Regularly: Ensure the sharpness of the cutting edges and replace any that are bent or damaged to avoid uneven trimming.

- Check Belt Tension: A loose or worn-out belt can cause performance issues. Adjust the tension or replace the belt if necessary.

- Clean After Every Use: Grass clippings and debris can accumulate, leading to rust or clogging. Clean the undersides thoroughly to prevent damage.

- Lubricate Moving Parts: Regularly oil bearings, spindles, and other moving components to reduce friction and prolong their lifespan.

- Examine Pulleys and Spindles: Ensure these components are free of cracks or wear, as they are critical for smooth operation.

By following these tips, you can extend the life of your equipment and avoid significant downtime caused by preventable breakdowns.

Upgrading Mower Deck Efficiency

Improving the performance of your cutting equipment can lead to faster, more precise results while extending the life of its components. Focusing on how to enhance the overall system will ensure smoother operation and better output.

Key Areas for Improvement

Several factors contribute to boosting the efficiency of your cutting system. These include upgrading the cutting blades, optimizing the alignment of rotating parts, and enhancing the belt drive system. Ensuring these elements are well-maintained can significantly affect how well the system performs in varying conditions.

Maintenance and Upgrading Tips

Regular maintenance combined with strategic upgrades can make a substantial difference. Below is a table outlining common upgrades and their benefits:

| Upgrade | Benefit |

|---|---|

| Enhanced Blades | Cleaner, faster cuts |

| Belt Tension Adjustments | Improved power transfer |

| Improved Bearing Alignment | Reduced vibration and wear |

Understanding Deck Lift Mechanism

The lift mechanism is crucial for adjusting the cutting height and maintaining smooth operation. It provides precise control over the platform’s position, enabling users to achieve desired results across various terrain conditions.

Components of the Lift System

The lift system consists of several interrelated parts that work together to raise or lower the platform. Understanding the function of each component can help with effective maintenance and troubleshooting.

- Lift Arms: These connect the platform to the frame and allow for vertical adjustments.

- Height Adjustment Lever: This control enables the operator to modify the cutting height.

- Linkage: These mechanical connections ensure synchronized movement between the adjustment lever and the platform.

Common Lift System Issues

Over time, components of the lift system may experience wear, leading to difficulties in height adjustment or uneven cutting. Regular inspections and timely repairs can prevent these issues.

- Check for worn or damaged