When it comes to maintaining or enhancing performance, understanding the core elements of a machine is essential. Every mechanical system is composed of a multitude of interconnected parts, each playing a vital role in the overall functionality. Knowing how these components align and interact ensures smooth operation and timely troubleshooting.

Whether you’re repairing or optimizing, having a clear visual representation of the structure is invaluable. This not only provides clarity but also assists in identifying specific elements for replacement or adjustment. Each element works in harmony, contributing to the efficiency and reliability of the equipment.

Exploring the configuration and placement of these essential elements will help you unlock a deeper understanding of the system, enabling more informed decisions when it comes to care, repair, or upgrades. With the right knowledge, you’ll be better equipped to handle any challenges that may arise.

Overview of the Craftsman DYS 4500 Lawn Tractor

This model of lawn tractor stands out for its robust performance and versatility, offering a solution for various outdoor tasks. It is designed to handle expansive lawns and uneven terrain, making it suitable for both residential and commercial use. With a powerful engine and reliable build, this machine ensures smooth operation and durability, even under challenging conditions.

Performance and Engine Specifications

The machine features an efficient powertrain that delivers consistent results in both mowing and towing applications. Its design includes features that provide ease of use, ensuring that users can manage large areas without strain. The engine offers ample horsepower to cut through thick grass and handle other demanding yard chores.

Durability and Design

Built with longevity in mind, the tractor’s frame is engineered to endure regular use, including in tough environments. The cutting deck is designed for precision and

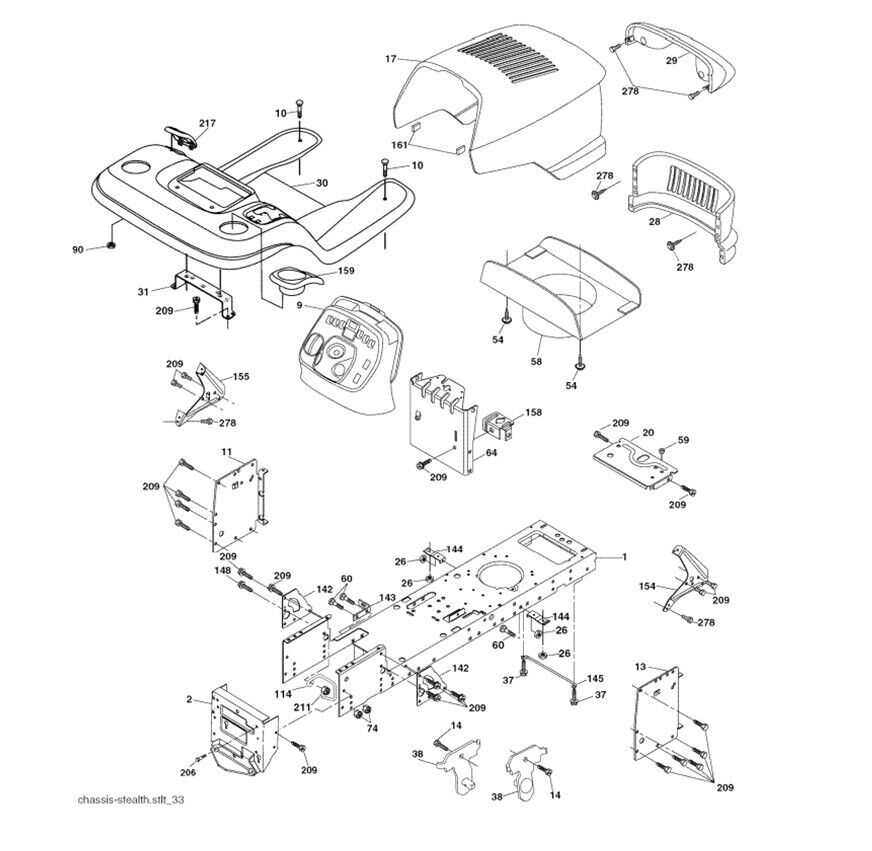

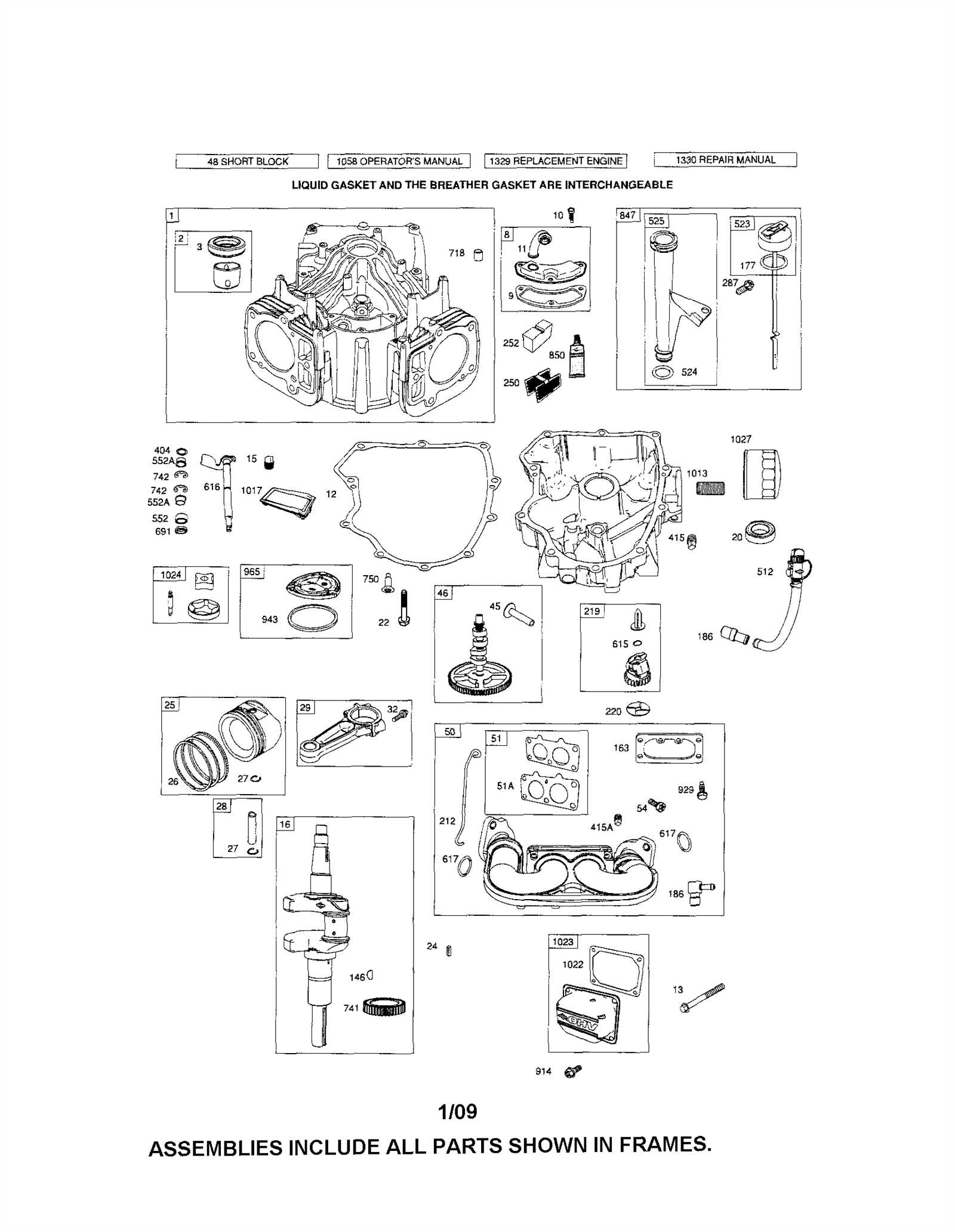

Understanding the Engine Components and Layout

The engine system is a complex configuration where various elements work together to power the entire machine. Each part has a specific role, and their arrangement ensures efficient operation. By looking at how these components are organized, we can gain a deeper insight into the machine’s overall performance and functionality.

Main Components of the Engine

The core of the engine includes the cylinder block, which houses several key components like pistons and connecting rods. These elements are responsible for the combustion process, transforming fuel into mechanical energy. Additionally, the crankshaft is crucial, converting the pistons’ motion into rotational energy that drives the machine forward.

Auxiliary Systems and Functions

Other vital systems include the cooling system, which prevents the engine from overheating, and the fuel system, which delivers fuel to the engine efficiently. The ignition system is another essential part, sparking

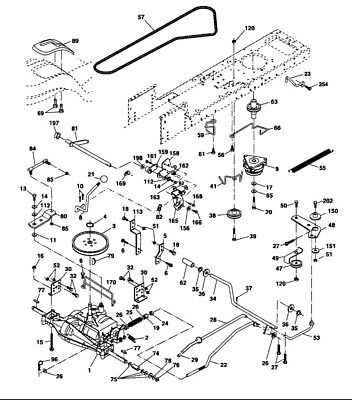

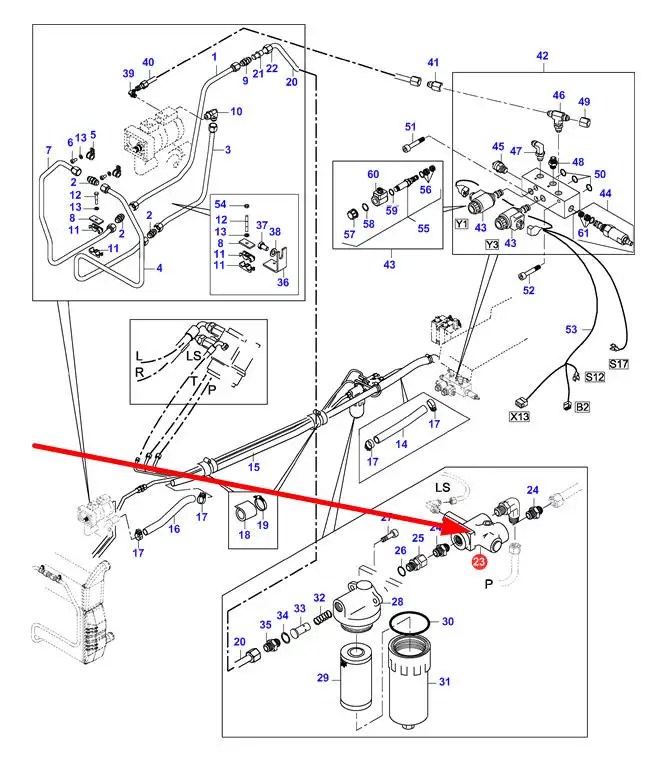

Exploring the Transmission System of the DYS 4500

The transmission mechanism plays a vital role in ensuring smooth operation and efficient performance of the machine. Understanding how this system works can help you maintain it properly, avoid potential issues, and ensure optimal functioning over time. This section provides a detailed look into the various components involved in this crucial system.

Main Components

- Drive Belt: Transfers power from the engine to the wheels, ensuring smooth movement.

- Transmission Gears: Responsible for controlling the speed and torque of the wheels, allowing adjustments based on the terrain.

- Shift Lever: Enables the user to change gears, providing control over the speed and direction.

How the System Operates

- The engine generates power that is transmitted through the belt.

- This power is then directed to the gears, which adjust the output to the wheels.

- The shift lever allows the

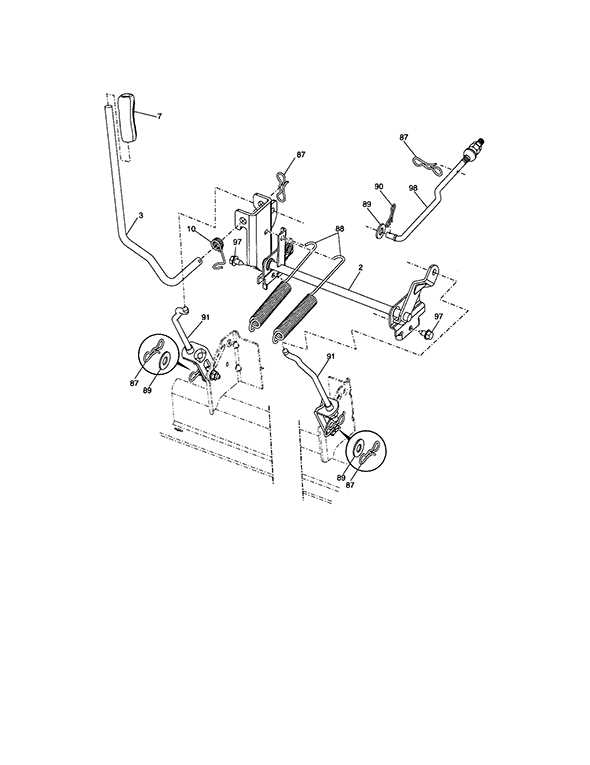

Key Parts of the Steering Mechanism

The steering system is an essential component that ensures smooth and responsive control over the machine’s direction. It involves several interconnected elements, each playing a role in transmitting the driver’s input to the wheels. Understanding these key elements is crucial for maintaining and troubleshooting the system effectively.

- Steering Wheel: The main point of contact for the operator, providing the initial input for directional changes.

- Steering Shaft: A critical link between the steering wheel and the lower mechanisms, transferring the rotational force downward.

- Gear Sector: Converts the rotational motion of the steering shaft into lateral movement, which helps in turning the wheels.

- Drag Link: Connects the gear sector to the steering arms, facilitating the motion between components.

- Steering Arms: Attached to the wheels, these parts receive the force from the drag link and move the wheels accordingly.

Front Axle and Wheel Assembly Breakdown

The front axle and wheel system plays a crucial role in maintaining the balance and movement of the vehicle. Understanding the different elements of this mechanism can help ensure smooth operation and identify any necessary adjustments or repairs.

Main Components Overview

This section covers the key parts that make up the front axle and wheel setup. Each component works together to provide stability and steering control, allowing for smooth driving and turning efficiency.

- Axle Beam: The central support structure that holds the wheels and allows them to rotate while bearing the vehicle’s weight.

- Steering Knuckle: Connects the wheel assembly to the suspension and allows the wheels to

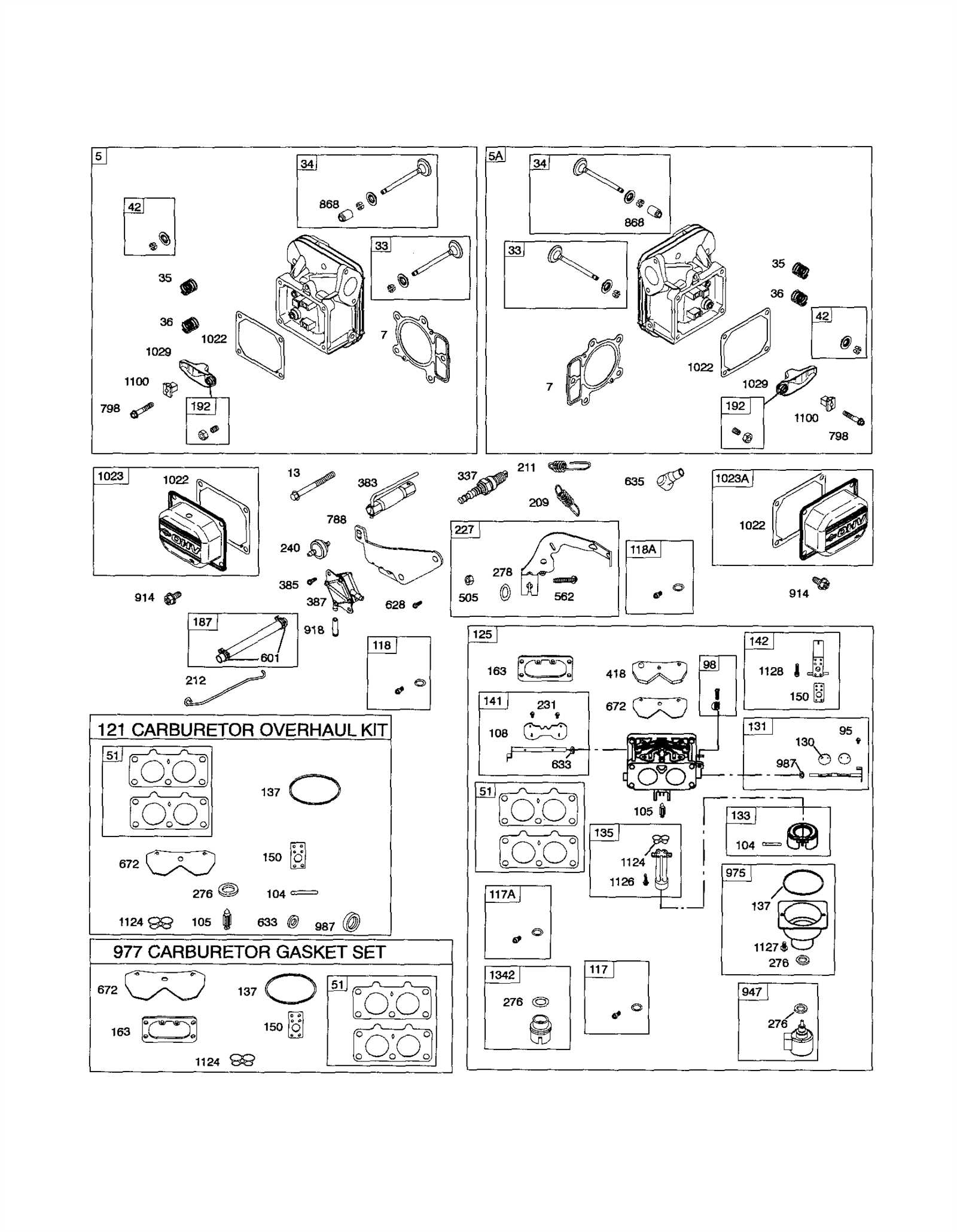

Detailed Look at the Cutting Deck Parts

The cutting mechanism of any riding lawn mower plays a crucial role in ensuring efficient grass trimming. Each component in this system is designed for precision and durability, making it essential to understand how they interact and contribute to the overall performance of the machine. In this section, we will explore the main elements that make up the cutting deck and their specific functions.

- Blades: These are responsible for cutting the grass evenly. The shape and sharpness of the blades greatly influence the quality of the cut.

- Spindles: These components connect the blades to the motor, ensuring smooth rotation and stability during operation.

- Deck Shell: The metal frame that houses all parts of the cutting system, providing protection and support for the components inside.

- Belts: These

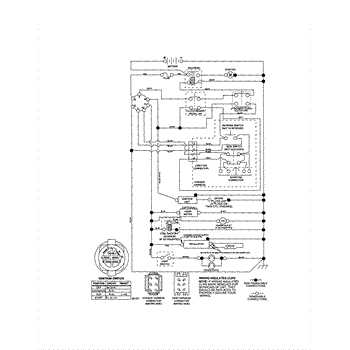

Electrical System Overview and Wiring Diagram

The electrical system is a crucial component, ensuring the proper functioning of various mechanisms. Understanding how the wiring is organized allows for efficient troubleshooting and maintenance. This section provides a comprehensive look at the connections and flow within the system, helping you navigate its structure with ease.

Key Components of the Electrical System

- Power Source: Supplies energy to the entire system.

- Control Panel: Manages the distribution of electricity to different parts.

- Wires and Connectors: Serve as the main pathways for electrical flow.

Wiring Layout

The wiring is arranged to connect all critical e

How the Fuel System is Configured

The fuel system plays a crucial role in ensuring the engine operates efficiently by delivering the necessary fuel for combustion. It consists of several interconnected components that work together to supply fuel from the tank to the engine in the right proportions. This system is designed to provide a consistent flow of fuel, regardless of the machine’s workload.

Component Function Fuel Tank Stores the fuel before it is sent to the engine. Fuel Filter Removes impurities from the fuel to prevent engine damage. Fuel Pump Ensures a steady flow of fuel from the tank to the engine. Fuel Lines Connect the various components and direct the fuel through the system. Brake and Clutch Mechanisms Explained

The braking and clutch systems play a crucial role in controlling the motion and stopping of a vehicle. These mechanisms are essential for ensuring smooth operation, allowing for controlled speed changes and safe halts. Understanding how they function together helps in maintaining balance and safety during use.

Brakes are designed to reduce speed by applying pressure to certain components, ultimately halting movement. This system ensures that the operator can stop the vehicle effectively when needed. Different types of brakes may be used depending on the vehicle’s needs, but their goal remains the same: to provide safe and reliable deceleration.

Clutch mechanisms, on the other hand, allow for the smooth engagement and disengagement of power between the engine and the wheels. By managing this connection, the clutch helps regulate acceleration and deceleration, ensuring that transitions between gears are seamless and efficient.

Both the braking and clutch systems require regular maintenance to ensure they function properly and extend

Seat and Safety Switch Components

The seat and safety switch system plays a crucial role in ensuring secure operation by preventing unintended movements or actions when the operator is not in the correct position. These components are designed to enhance protection, working seamlessly together to detect the presence of the driver and immediately trigger safety mechanisms if needed.

Seat Sensor Functionality

The seat sensor detects whether the operator is seated properly, enabling or disabling certain functions accordingly. This sensor is sensitive to weight and position, providing an additional layer of control during operation. If the sensor detects an absence, key features will automatically deactivate to avoid accidents.

Safety Switch Mechanism

The safety switch works in conjunction with the seat sensor to cut power or halt critical functions when certain safety conditions are not met. Its primary purpose is to stop movement or engine activity if the operator stands or leaves the seat, preventing potential hazards in these moments.

Battery and Charging System Insights

The power supply and charging mechanism play a crucial role in ensuring consistent operation and longevity. Without a well-maintained energy system, performance may degrade, and interruptions could occur during usage. Understanding the key elements of how energy is stored and replenished helps prevent potential issues and enhances reliability.

Battery Maintenance

Proper care of the power unit is essential for extending its life span. Regular inspections for corrosion or wear, as well as checking the connections, contribute to optimal performance. Keeping the unit fully charged during periods of inactivity ensures readiness when needed.

Charging System Components

The energy replenishment process involves several important elements, including the alternator and related wiring. A fully functional charging setup ensures the power unit remains at peak efficiency during operation, avoiding any unexpected power loss. Monitoring and maintaining these components ensures smooth functioning of the entire system.

Blades, Belts, and Pulley Setup

Understanding the arrangement and functionality of cutting components, transmission elements, and rotational systems is essential for optimal performance. Proper alignment and maintenance of these parts ensure efficiency and longevity, making it crucial for users to familiarize themselves with their roles.

Importance of Blades

The cutting edges play a pivotal role in achieving precise results. Regular inspection and sharpening of the blades not only enhance performance but also reduce wear on other mechanical components. It is vital to select the appropriate blade type based on the material being processed.

Belts and Pulleys Coordination

Transmission systems consist of belts and pulleys that facilitate power transfer between various elements. Proper tensioning of belts is critical to prevent slippage and excessive wear. Additionally, the alignment of pulleys must be checked periodically to ensure smooth operation and to minimize the risk of component failure.

Regular maintenance of these systems is essential for preventing breakdowns and ensuring safe operation. Staying informed about the specific requirements and configurations will lead to more efficient use and a longer lifespan of your equipment.

Maintenance Tips for the Craftsman DYS 4500

Proper upkeep of your lawn care equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also helps prevent unexpected breakdowns. Here are some key practices to keep your machine running smoothly.

Regular Checks

- Inspect the oil level frequently and change it as needed to maintain engine health.

- Clean or replace the air filter periodically to ensure proper airflow.

- Examine the blades for sharpness and wear; sharpen or replace as necessary for effective cutting.

Seasonal Maintenance

- At the start of each season, perform a comprehensive check of all moving parts.

- Inspect the tires for proper inflation and tread wear.

- Store the equipment in a dry place during the off-season to prevent rust and damage.

By adhering to these maintenance guidelines, you can ensure that your equipment remains reliable and efficient throughout its lifespan.