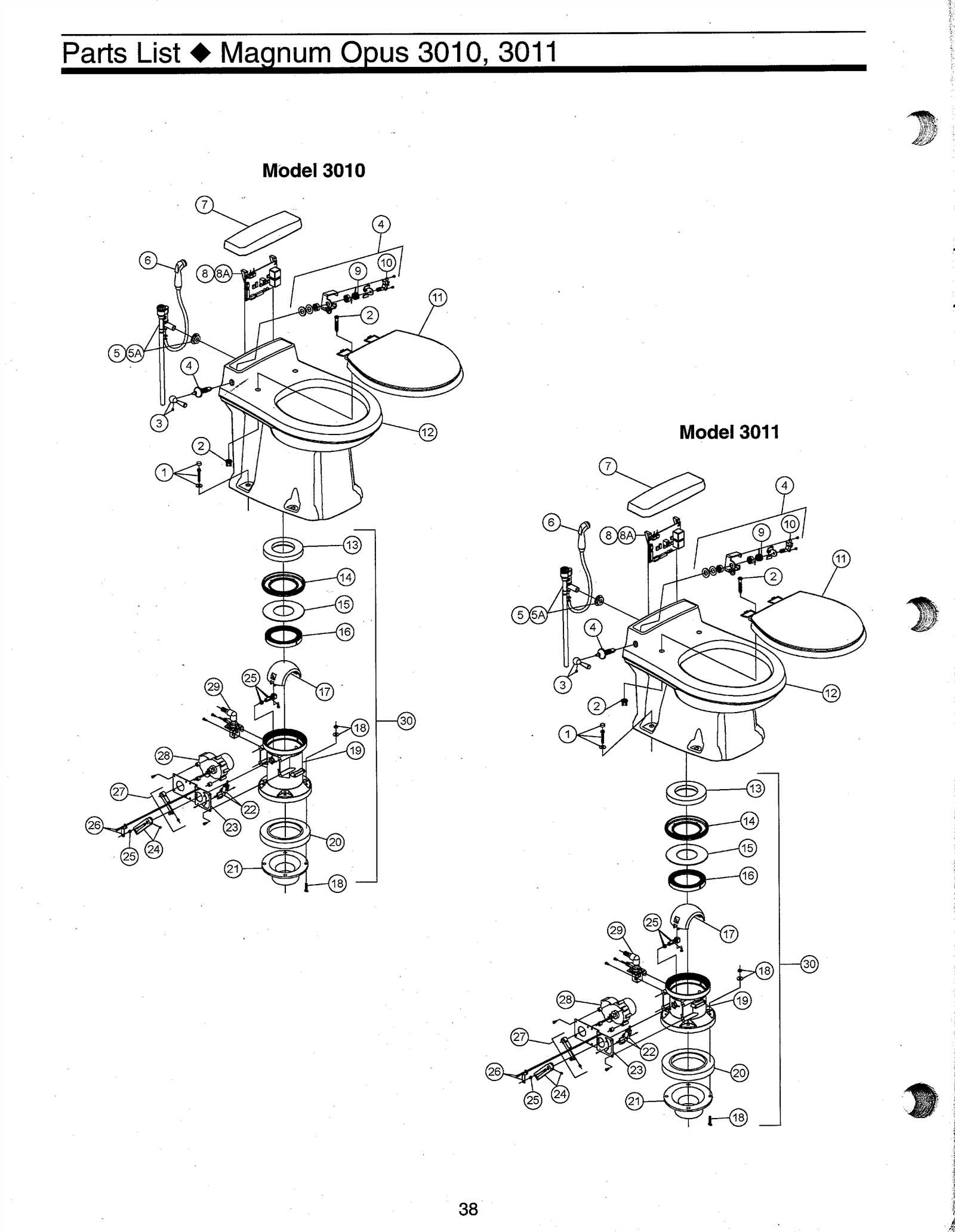

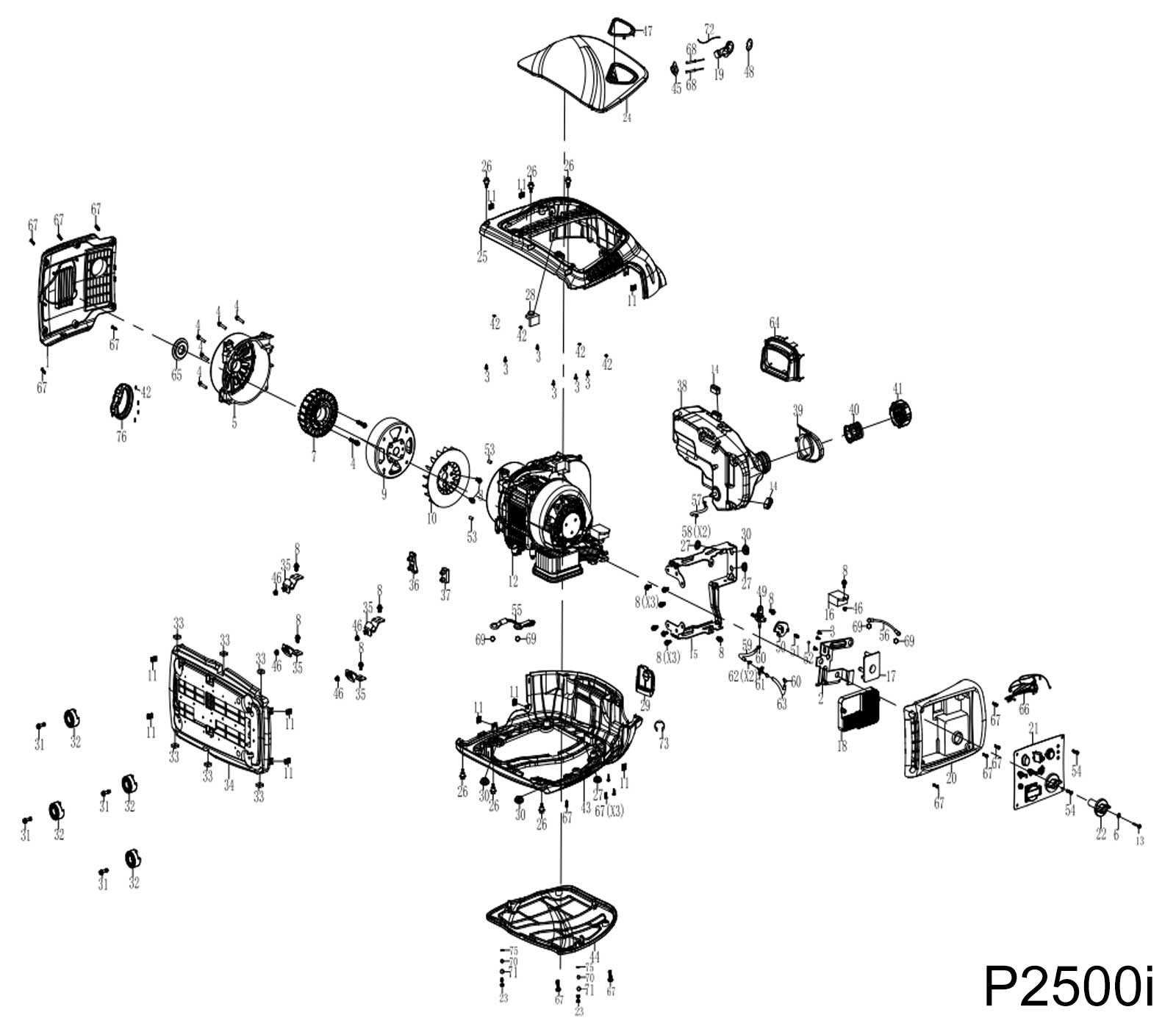

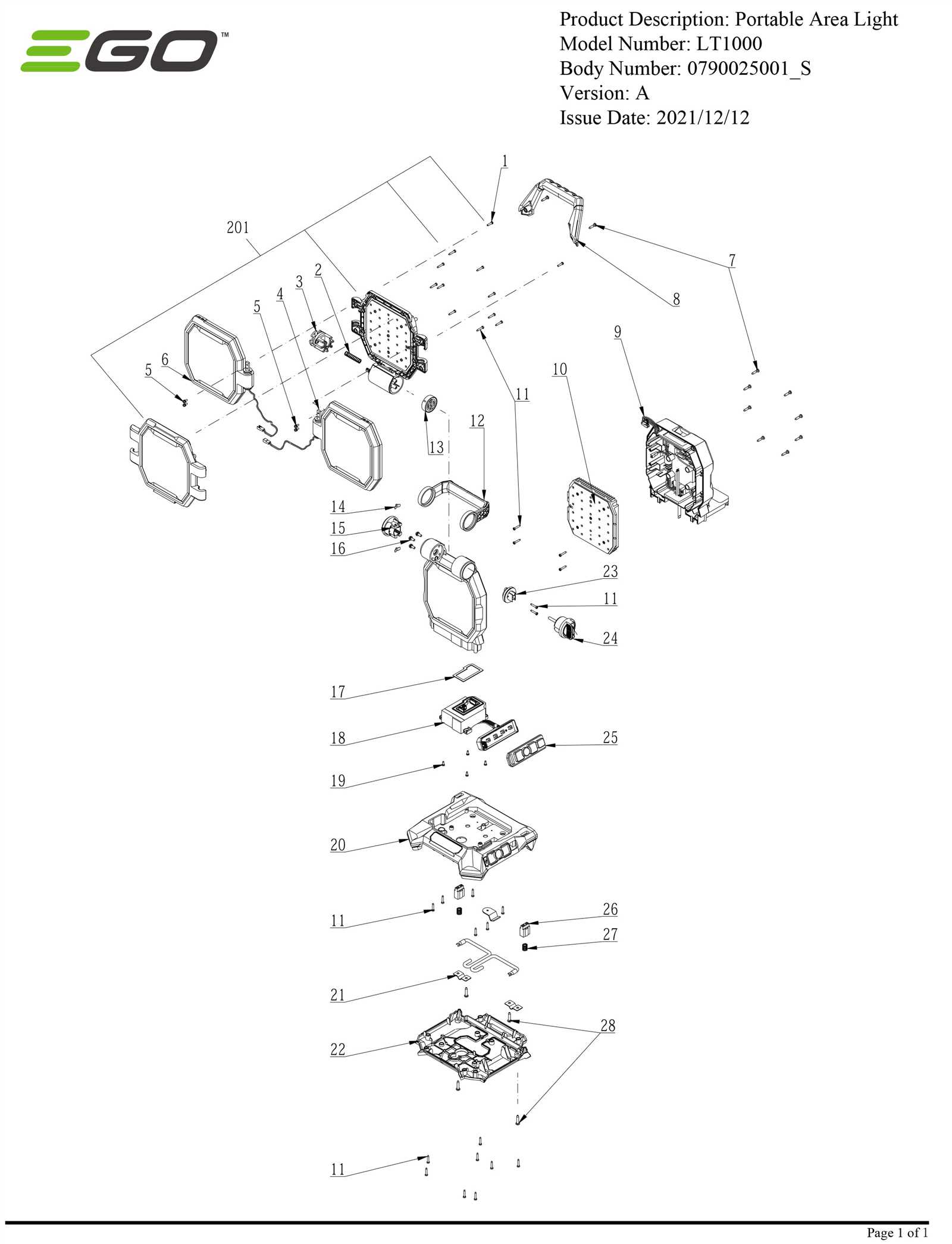

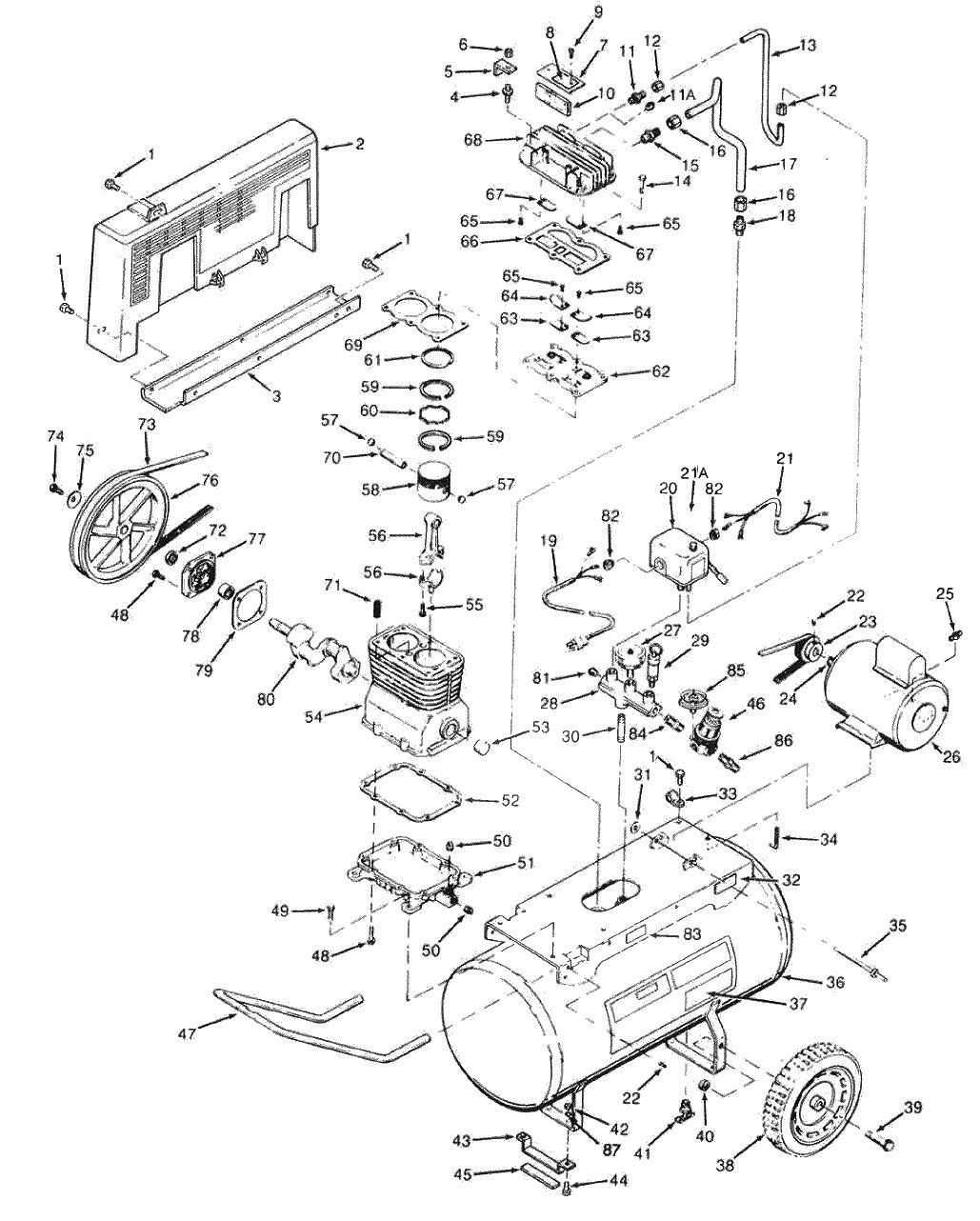

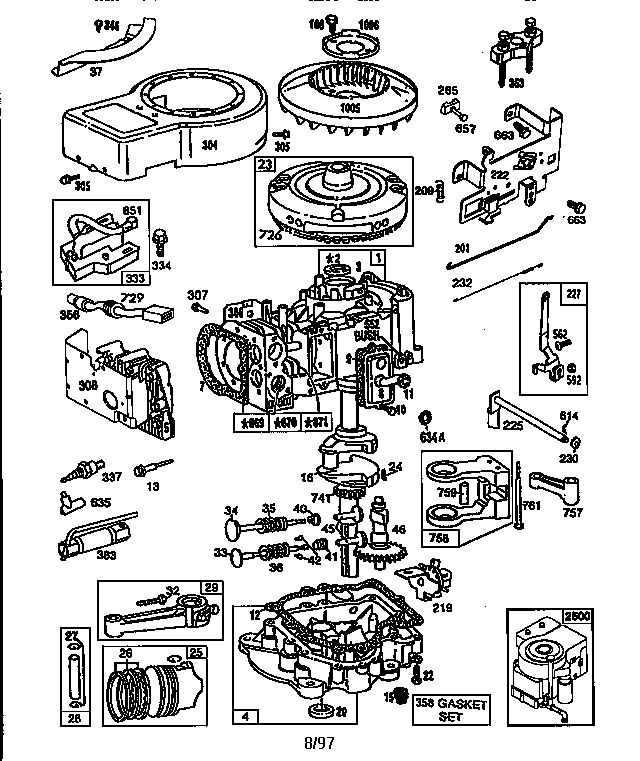

The intricacies of mechanical devices can often seem daunting, yet a thorough comprehension of their essential components is crucial for effective maintenance and repair. Each element plays a vital role in the overall functionality, and recognizing their arrangement can significantly enhance troubleshooting skills. This exploration provides insights into how these pieces fit together, offering clarity to both novice and experienced users.

By delving into the configuration of these mechanical systems, one can gain a deeper appreciation for their design and operation. A visual representation of these elements not only aids in identifying individual components but also serves as a roadmap for any necessary repairs or replacements. Understanding the relationship between these parts fosters a more intuitive grasp of the machinery.

Equipped with knowledge about the layout and function of each element, users are better prepared to tackle maintenance challenges. This exploration emphasizes the importance of having a clear reference that outlines how everything interconnects, paving the way for successful troubleshooting and efficient repairs.

Understanding Craftsman Generator Basics

To fully appreciate the functionality of portable energy devices, it’s essential to grasp their fundamental components and operation. A thorough understanding of these essentials enhances both usage and maintenance, ensuring longevity and efficiency.

| Component | Function |

|---|---|

| Engine | Drives the system, converting fuel into mechanical energy. |

| Alternator | Transforms mechanical energy into electrical energy. |

| Fuel System | Stores and delivers fuel to the engine. |

| Control Panel | Allows user interaction for settings and monitoring output. |

| Chassis | Houses and supports the entire unit for stability. |

Understanding these key elements provides insight into their operation and maintenance, facilitating a more informed and effective use of energy solutions.

Importance of Generator Maintenance

Regular upkeep of power equipment is essential for ensuring reliability and longevity. Neglecting this vital aspect can lead to unexpected failures and costly repairs, disrupting essential services and activities. Proper maintenance not only enhances performance but also guarantees safety during operation.

Timely inspections help identify potential issues before they escalate, minimizing downtime and maintaining efficiency. Routine tasks, such as cleaning filters and checking fuel levels, are crucial in keeping machinery running smoothly. By investing time in care, users ultimately secure their investment and ensure optimal functioning.

Moreover, consistent maintenance practices contribute to the overall safety of the equipment. Faulty machinery poses significant risks, including accidents and injuries. By adhering to maintenance schedules, individuals can prevent hazardous situations and promote a safer environment.

Common Parts of Craftsman Generators

This section explores the essential components found in portable power units, highlighting their functions and significance in ensuring efficient operation. Understanding these elements is crucial for maintenance and troubleshooting.

| Component | Description |

|---|---|

| Engine | The heart of the unit, responsible for converting fuel into mechanical energy. |

| Fuel Tank | Holds the necessary fuel for operation, often designed for easy access and refilling. |

| Control Panel | Interface for the user, featuring switches and outlets for managing power output. |

| Chassis | The frame that supports all components, providing stability and protection. |

| Cooling System | Prevents overheating, ensuring the unit runs efficiently over extended periods. |

| Exhaust System | Directs harmful gases away from the unit and user, promoting safety during use. |

How to Read a Parts Diagram

Understanding a schematic representation of components can greatly enhance your ability to maintain and repair machinery. These visual aids break down complex systems into manageable sections, making it easier to identify and locate individual elements.

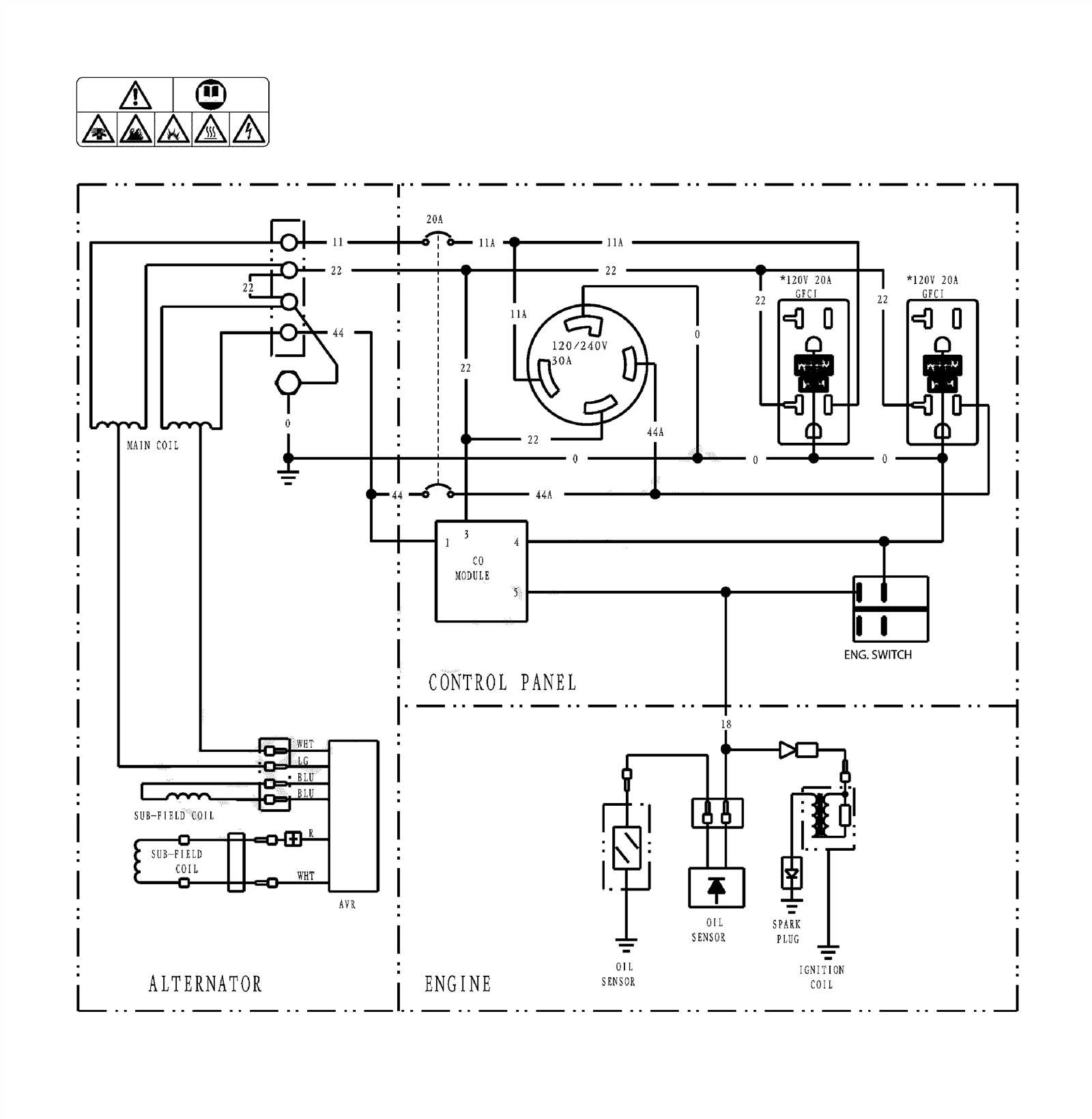

Familiarizing Yourself with Symbols

Each illustration utilizes specific symbols to represent various elements. Take the time to familiarize yourself with these icons, as they convey essential information about the function and connection of each component. Pay attention to the legends or keys provided, as they will guide your understanding of the entire setup.

Interpreting Connections and Relationships

Look closely at how the components are linked. Lines and arrows often indicate connections, while groupings of elements can show how they interact. This insight is crucial for troubleshooting issues and planning repairs, allowing you to delve deeper into the mechanical relationships at play.

Identifying Electrical Components

Understanding the various elements within electrical systems is essential for effective maintenance and troubleshooting. Recognizing these components enables users to ensure optimal functionality and longevity of their equipment.

Common Electrical Elements

Among the most frequently encountered components are resistors, which regulate current flow, and capacitors, which store electrical energy. Switches are also vital, allowing for the control of power to different parts of the system.

Recognizing Signs of Wear

Identifying signs of wear and tear on these elements can prevent larger issues. Look for discoloration, corrosion, or physical damage, which may indicate that replacement or repair is necessary to maintain performance.

Fuel System Components Explained

The fuel system plays a crucial role in the overall functionality of any machinery, ensuring that the engine receives the necessary energy source for optimal performance. Understanding its various elements helps in maintaining and troubleshooting issues effectively.

At the core of this system is the fuel tank, which stores the liquid energy before it is directed to the engine. Attached to the tank is the fuel line, a conduit that transports the fuel, ensuring a steady flow for combustion. A filter is often integrated to remove impurities, safeguarding the engine’s internal components.

Next, the fuel pump is vital for creating the pressure needed to push the fuel through the lines. In many designs, a carburetor or fuel injector is employed to mix the fuel with air, enabling efficient combustion. Finally, various sensors and valves monitor and regulate the flow, contributing to the system’s overall efficiency and safety.

Cooling System Parts Overview

The efficiency and longevity of an engine largely depend on its ability to manage temperature. An effective cooling mechanism prevents overheating and ensures optimal performance by dissipating excess heat generated during operation. Understanding the components involved is crucial for maintenance and troubleshooting.

Key Components

- Radiator: Facilitates heat exchange and cooling of the coolant.

- Water Pump: Circulates coolant throughout the system.

- Thermostat: Regulates coolant flow based on temperature.

- Cooling Fan: Enhances air circulation to the radiator.

- Hoses: Transport coolant to and from the engine.

Importance of Maintenance

Regular inspection and maintenance of these elements are vital. Neglecting any part can lead to inefficiencies, ultimately affecting the engine’s performance. Ensuring that each component functions correctly will enhance reliability and extend the lifespan of the machinery.

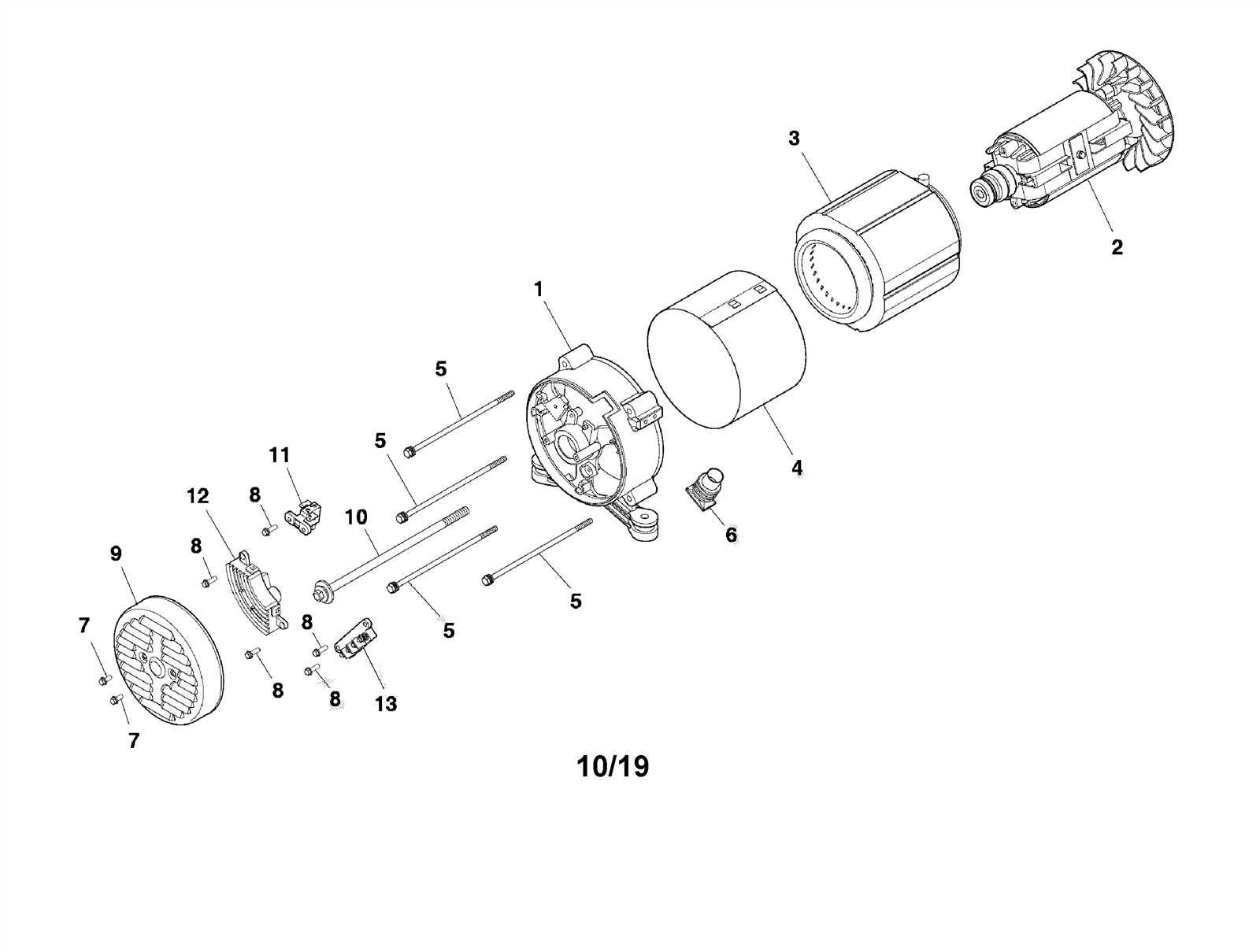

Understanding the Starter Mechanism

The starter mechanism is a crucial component that initiates the operation of small engines. It converts electrical energy into mechanical motion, ensuring the engine fires up efficiently. A thorough comprehension of this mechanism can enhance maintenance practices and improve overall performance.

Components of the Starter System

This system typically comprises several key elements, including a motor, a solenoid, and a drive gear. Each part plays a vital role in the successful engagement and disengagement process, facilitating a seamless start-up of the engine.

Common Issues and Troubleshooting

Common Issues with Generator Parts

In the realm of power supply devices, various components may encounter challenges that hinder their efficiency and functionality. Understanding these common complications is essential for maintaining optimal performance and longevity.

Frequent Complications

- Fuel Supply Problems: Inadequate fuel flow can lead to starting difficulties and operational inconsistencies.

- Electrical Connections: Loose or corroded wiring may result in erratic performance and potential safety hazards.

- Overheating: Insufficient ventilation or clogged air filters can cause overheating, affecting the device’s reliability.

- Battery Issues: Deteriorating batteries often result in power loss or failure to start the unit altogether.

Maintenance Tips

- Regularly check and clean fuel lines to ensure unobstructed flow.

- Inspect electrical connections for signs of wear and secure any loose fittings.

- Ensure proper airflow by cleaning filters and maintaining adequate ventilation.

- Monitor battery health and replace it as necessary to avoid starting issues.

Addressing these common issues proactively can enhance the reliability and effectiveness of power supply systems, ultimately leading to improved user satisfaction and reduced downtime.

Replacement Parts: What to Consider

When it comes to maintaining equipment, understanding what to look for in new components is crucial. Choosing suitable alternatives can significantly affect performance and longevity. It’s essential to ensure that the selected items meet the necessary specifications and quality standards.

Compatibility is a primary factor; ensure the new components fit seamlessly with your existing setup. Additionally, quality plays a vital role; opting for high-grade materials can enhance durability and reduce the frequency of replacements.

Furthermore, cost-effectiveness should not be overlooked. While cheaper options may seem attractive, they can lead to more frequent issues down the line. It’s often wiser to invest in reliable components that promise long-term benefits.

Lastly, consider warranty and customer support. Reputable manufacturers often provide guarantees, offering peace of mind with your investment. Thorough research and careful selection will ultimately yield the best results for your equipment.

Tools Needed for Repairs

When it comes to maintenance and fixing equipment, having the right instruments is essential for efficiency and precision. The proper tools not only streamline the repair process but also enhance safety and accuracy, making it easier to tackle various tasks effectively.

Essential Instruments

To start, you’ll need basic hand tools such as screwdrivers, wrenches, and pliers. These instruments are fundamental for disassembling components and performing minor adjustments. Additionally, a reliable socket set can greatly aid in loosening or tightening bolts.

Advanced Equipment

For more intricate repairs, consider acquiring specialized tools like a multimeter for electrical diagnostics and a torque wrench for ensuring that fasteners are tightened to the correct specifications. A repair manual can also be invaluable, guiding you through the necessary steps for effective troubleshooting.

Safety Tips During Repairs

When undertaking maintenance or repairs on machinery, ensuring safety is paramount. Proper precautions not only protect the individual working on the device but also prevent potential accidents that could affect bystanders. Adhering to established safety protocols can significantly reduce risks associated with mechanical tasks.

Always begin by disconnecting the power source before starting any repair work. This simple step helps to avoid unintended activation of the equipment, which could lead to serious injuries. Additionally, using personal protective equipment, such as gloves and safety goggles, is crucial to safeguard against sharp edges and flying debris.

Organizing your workspace can enhance safety as well. Keep tools and materials neatly arranged to prevent tripping hazards and ensure that everything is easily accessible. It is also wise to familiarize yourself with the machinery’s manual, as it often contains important safety instructions and specifications.

Finally, never hesitate to seek assistance if needed. Having a partner or someone knowledgeable nearby can provide support and advice, ensuring that repairs are conducted safely and effectively. Remember, prioritizing safety can make the difference between a successful repair and an unfortunate incident.

Where to Find Replacement Parts

Locating the necessary components for your equipment can significantly enhance its performance and longevity. Understanding where to source these items is crucial for maintaining optimal functionality. Here are some reliable options to consider when searching for your replacements.

| Source | Description | Advantages |

|---|---|---|

| Official Retailers | Authorized sellers provide original items that match your device. | High quality and compatibility assurance. |

| Online Marketplaces | Websites such as eBay or Amazon offer a wide selection from various vendors. | Competitive pricing and customer reviews to aid in decision-making. |

| Local Repair Shops | Nearby technicians often have access to a variety of replacements. | Personalized service and expert advice. |

| Salvage Yards | Used components can often be found at reduced prices. | Cost-effective solutions for those on a budget. |

| Manufacturer’s Website | Direct online resources for ordering specific items. | Access to the latest components and updates. |