Maintaining a well-functioning lawn mower is essential for achieving a pristine outdoor space. Knowledge of the individual elements that contribute to the overall performance of these machines can greatly enhance their longevity and efficiency. This section aims to provide insight into the various components of a popular model, facilitating better care and repair.

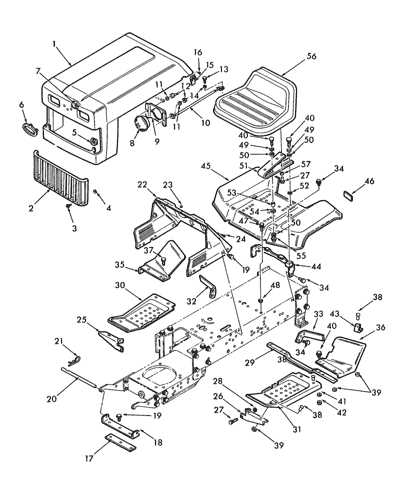

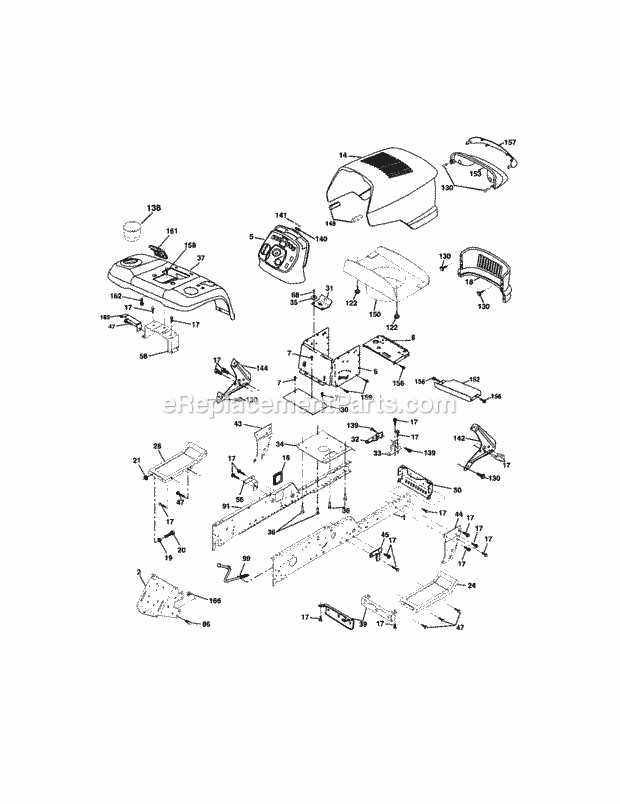

Identifying the specific features and functions of each section can be quite beneficial for both seasoned users and newcomers alike. By exploring the intricate layout of the machinery, one can gain a clearer understanding of how to troubleshoot issues and perform maintenance tasks effectively. The visual representation of the assembly serves as a valuable reference tool.

Whether you’re looking to replace worn-out elements or simply wish to familiarize yourself with the equipment, having a clear overview of the configurations can simplify the process. Engaging with the detailed illustrations will empower you to make informed decisions, ensuring your mowing experience is both efficient and enjoyable.

Understanding Craftsman GT5000 Parts

Gaining insight into the various components of a riding mower is essential for maintenance and performance enhancement. Familiarity with each element not only aids in troubleshooting but also ensures longevity and optimal functionality of the machine.

Key Components

- Engine: The powerhouse responsible for driving the mower.

- Transmission: Manages power transfer to the wheels for smooth operation.

- Blades: Crucial for cutting grass efficiently.

- Chassis: The framework that supports all other components.

Maintenance Tips

- Regularly inspect the engine for any signs of wear.

- Change the oil to keep the engine running smoothly.

- Sharpen the blades frequently to ensure a clean cut.

- Check tire pressure to maintain proper handling.

Importance of Deck Maintenance

Proper upkeep of the cutting apparatus is crucial for ensuring optimal performance and longevity. Regular care not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By attending to this essential component, users can achieve a clean and even cut, which significantly impacts the overall appearance of the landscape.

Neglecting maintenance can lead to various issues, including uneven wear, decreased effectiveness, and even costly repairs. A well-maintained system will operate more smoothly and provide better results, making it vital for users to prioritize this aspect of their machinery.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect and clean | After each use | Prevents buildup and promotes efficiency |

| Sharpen blades | Every 20-25 hours | Ensures clean cuts and reduces stress on the motor |

| Check for damage | Weekly | Identifies issues before they escalate |

| Lubricate moving parts | Monthly | Reduces friction and prolongs lifespan |

In conclusion, dedicated attention to maintenance tasks is vital for achieving the best performance and extending the life of the machinery. By adopting a proactive approach, users can enjoy a more efficient and effective operation.

Key Features of the GT5000

This section highlights the essential characteristics that set this model apart from others in its category. With a combination of robust design and advanced functionality, it delivers exceptional performance for various outdoor tasks.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a high-performance engine for enhanced efficiency and reliability. |

| Wide Cutting Width | Designed for expansive coverage, reducing mowing time significantly. |

| Comfortable Seating | Features ergonomic seating for improved comfort during extended use. |

| Easy Maneuverability | Offers exceptional control and handling, even in tight spaces. |

| Durable Build | Constructed with high-quality materials to withstand rigorous tasks. |

Common Deck Issues Explained

Maintaining a lawn mower’s cutting assembly is crucial for optimal performance. Over time, various problems may arise, affecting the effectiveness of the machine. Understanding these issues can help in timely repairs and prolong the lifespan of the equipment.

Uneven Cutting can often occur due to misalignment or worn-out components. If the blades are not at the correct height, they may leave patches of grass untrimmed. Regular checks and adjustments are necessary to ensure uniformity.

Clogging is another frequent concern, especially when dealing with wet grass or debris. This can impede the flow of cuttings and lead to poor performance. Regular cleaning of the assembly after use can mitigate this issue.

Vibration might indicate loose or damaged elements. Excessive shaking can lead to further wear and tear, necessitating a thorough inspection to identify the source and ensure everything is secure.

Rust and Corrosion can develop on metal surfaces, especially in humid conditions. Protective coatings and timely maintenance can help in preventing this deterioration.

Addressing these common problems promptly will not only enhance functionality but also contribute to a more efficient mowing experience.

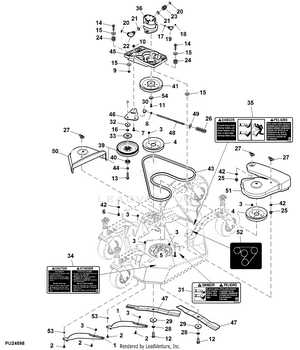

Parts Overview for the 48” Deck

This section provides a comprehensive look at the essential components that contribute to the functionality and efficiency of the mower’s cutting system. Understanding these elements will help you maintain and troubleshoot effectively, ensuring optimal performance throughout the mowing season.

Key Components

- Blades: Critical for achieving a clean cut, these elements come in various styles to accommodate different grass types.

- Spindles: These support the blades and allow for smooth rotation, playing a vital role in the overall cutting action.

- Belts: Connecting various mechanical parts, these ensure power transmission from the engine to the cutting mechanism.

- Frame: The sturdy structure that houses all other elements, providing stability during operation.

Maintenance Tips

- Regularly inspect the blades for wear and replace them when necessary to maintain cutting quality.

- Check the spindles for any signs of damage or wear to ensure proper blade rotation.

- Inspect the belts for fraying or cracking, replacing them to prevent unexpected breakdowns.

- Keep the frame clean and free from debris to prevent rust and prolong its lifespan.

How to Identify Replacement Parts

Finding the right components for your equipment can be a daunting task. It requires a keen eye and some basic knowledge of the machinery involved. Understanding how to recognize and select the necessary items will ensure that your tools operate efficiently and safely.

Examine the User Manual

Your first step should be to consult the user manual. This document often contains a wealth of information, including diagrams and specifications for each element of the machine. Pay attention to the model number and any related identifiers that will help you locate the correct replacements.

Utilize Online Resources

In addition to printed materials, numerous online platforms offer parts catalogs and forums for discussion. These resources can provide insights from other users who may have faced similar challenges. Searching for specific terms related to your equipment will yield valuable results, allowing you to compare and select the right items with confidence.

Keep in mind that ensuring compatibility is crucial. Always double-check measurements and specifications to avoid any potential issues during installation. With the right approach, identifying the necessary components will become a more straightforward and rewarding process.

Tools Needed for Deck Repair

When it comes to restoring outdoor machinery, having the right tools on hand is essential for effective and efficient repairs. Proper preparation can make the difference between a smooth process and a frustrating experience. Below is a list of necessary implements that will help ensure your restoration project is successful.

Essential Hand Tools

Start with basic hand tools, which are fundamental for any repair task. Screwdrivers in various sizes will allow you to tackle screws of different types and lengths. A good set of wrenches will be crucial for loosening and tightening bolts. Additionally, a hammer can assist in aligning components or removing stubborn parts.

Power Tools for Efficiency

For more demanding tasks, consider incorporating power tools into your toolkit. A drill will help you quickly create holes or drive screws, while a saw can be invaluable for cutting materials to the appropriate size. Investing in a socket set will also streamline the process of working with nuts and bolts, making adjustments easier and quicker.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues that may arise in your outdoor machinery. Following these steps will ensure a systematic and efficient resolution, enhancing the longevity and performance of your equipment.

Identifying the Problem

Start by thoroughly examining the machine. Look for any visible signs of wear, unusual noises, or performance issues. Take notes on any discrepancies, as this will guide your repair process.

Gathering Necessary Tools

Before diving into repairs, collect all essential tools and replacement components. Having everything on hand will streamline the repair and minimize downtime. Consult your manual for specific requirements related to your equipment model.

By following this guide, you can effectively delve into repairs and achieve ultimate satisfaction with your machinery’s performance.

Safety Tips for DIY Repairs

When undertaking repairs on machinery or equipment, prioritizing safety is crucial. Proper precautions not only protect you from potential injuries but also ensure that the repair process is efficient and effective. By following a few key guidelines, you can create a safe environment for yourself and those around you while working on projects.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) before starting any task. This includes gloves to shield your hands, goggles to protect your eyes from debris, and sturdy footwear to prevent injuries from falling objects. Depending on the nature of your work, a mask may also be necessary to guard against dust and fumes.

Work Area Preparation

Ensure your workspace is clean and organized. Remove any unnecessary tools or materials that could create tripping hazards. Adequate lighting is essential to help you see clearly and avoid mistakes. Always have a first-aid kit accessible, just in case an injury occurs during your repair process.

Where to Find OEM Parts

Locating original equipment manufacturer components can significantly enhance the performance and longevity of your machinery. Reliable sources for these essential items ensure that you maintain quality and compatibility, ultimately preserving the integrity of your equipment.

One of the best avenues to explore is the manufacturer’s official website, which often features a dedicated section for genuine components. Additionally, authorized dealers and service centers can provide expert advice and access to the right items. Online marketplaces also host a variety of vendors specializing in original components, allowing for convenient comparison and selection.

Furthermore, local hardware stores may carry a selection of genuine items or can assist in ordering them directly. Engaging with online forums and communities dedicated to machinery can also yield valuable recommendations and sources. Always prioritize verified sellers to ensure the authenticity of your purchases.

Comparing Aftermarket vs. OEM Components

When considering replacements for essential machinery elements, it’s crucial to weigh the advantages and disadvantages of different types of components. Two main categories emerge in this context: those produced by original manufacturers and those made by third-party companies. Each option presents unique characteristics that can impact performance, durability, and cost.

OEM (Original Equipment Manufacturer) components are typically crafted to match the specifications and quality standards set by the original maker. This ensures compatibility and reliability, making them a preferred choice for many users seeking to maintain their equipment’s integrity. However, they often come at a premium price, reflecting the assurance of quality and performance that OEM parts provide.

On the other hand, aftermarket components can offer a more economical solution. These products are created by independent manufacturers and can vary widely in quality. Some may even exceed the performance of their OEM counterparts, while others may not meet the required standards. This variability allows consumers to choose parts that align with their budget and performance expectations but requires careful research to ensure reliability.

Ultimately, the decision between OEM and aftermarket options hinges on individual priorities. If reliability and warranty are paramount, opting for OEM might be the best route. Conversely, if cost-effectiveness and flexibility are more critical, exploring aftermarket alternatives could yield favorable results.

Maintaining Your Craftsman Lawn Tractor

Regular upkeep of your riding mower is essential to ensure its longevity and optimal performance. By adhering to a maintenance schedule, you can prevent minor issues from escalating into significant problems, ultimately saving time and money. Proper care not only enhances the efficiency of your machine but also contributes to a healthier lawn.

Routine Checks and Cleaning

Begin with frequent inspections of essential components. Examine the air filter, spark plugs, and fuel system for any signs of wear or blockage. Clean the exterior and underside of the machine to remove grass clippings and debris that can affect performance. A clean mower operates more efficiently and provides a better cut.

Lubrication and Seasonal Maintenance

Regularly lubricate moving parts to prevent friction and wear. Pay special attention to the wheels, steering mechanisms, and any pivot points. As seasons change, consider a thorough check of the battery and tires, ensuring they are in good condition for the upcoming months. Emphasizing these practices will extend the life of your equipment and enhance your mowing experience.

Resources for Craftsman Enthusiasts

For those who have a passion for outdoor equipment and maintenance, accessing reliable information and quality resources is essential. Whether you are seeking manuals, spare components, or community support, a wealth of materials is available to enhance your experience and expertise.

Manuals and Guides

Comprehensive manuals and guides serve as invaluable tools for both novice and seasoned users. They provide detailed instructions for operation, troubleshooting, and maintenance. Online platforms often host downloadable versions, ensuring you have the right information at your fingertips whenever needed.

Community Forums and Support

Engaging with fellow enthusiasts can significantly enrich your journey. Online forums and social media groups offer a space to share experiences, ask questions, and exchange tips. Connecting with a community not only fosters knowledge but also encourages camaraderie among those who share a similar interest.