When it comes to maintaining and enhancing the longevity of your machinery, a comprehensive understanding of its individual elements is essential. Each component plays a pivotal role in ensuring smooth operation, and recognizing how they interact can lead to improved performance and efficiency.

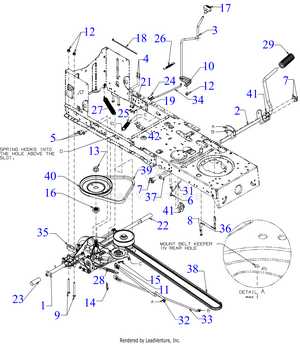

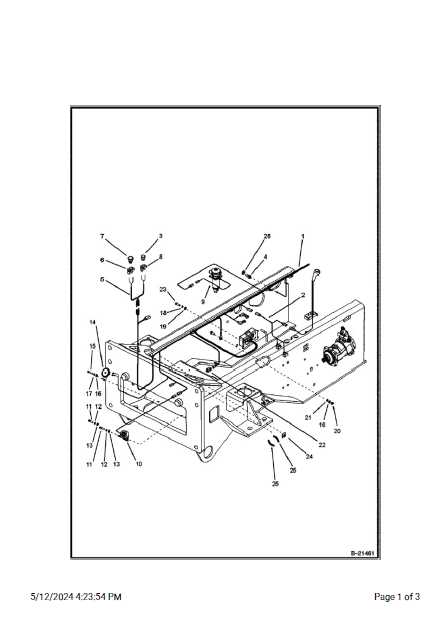

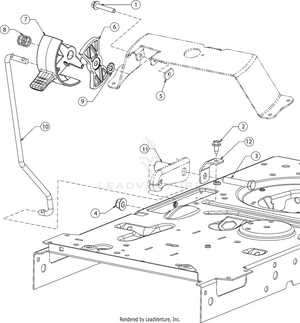

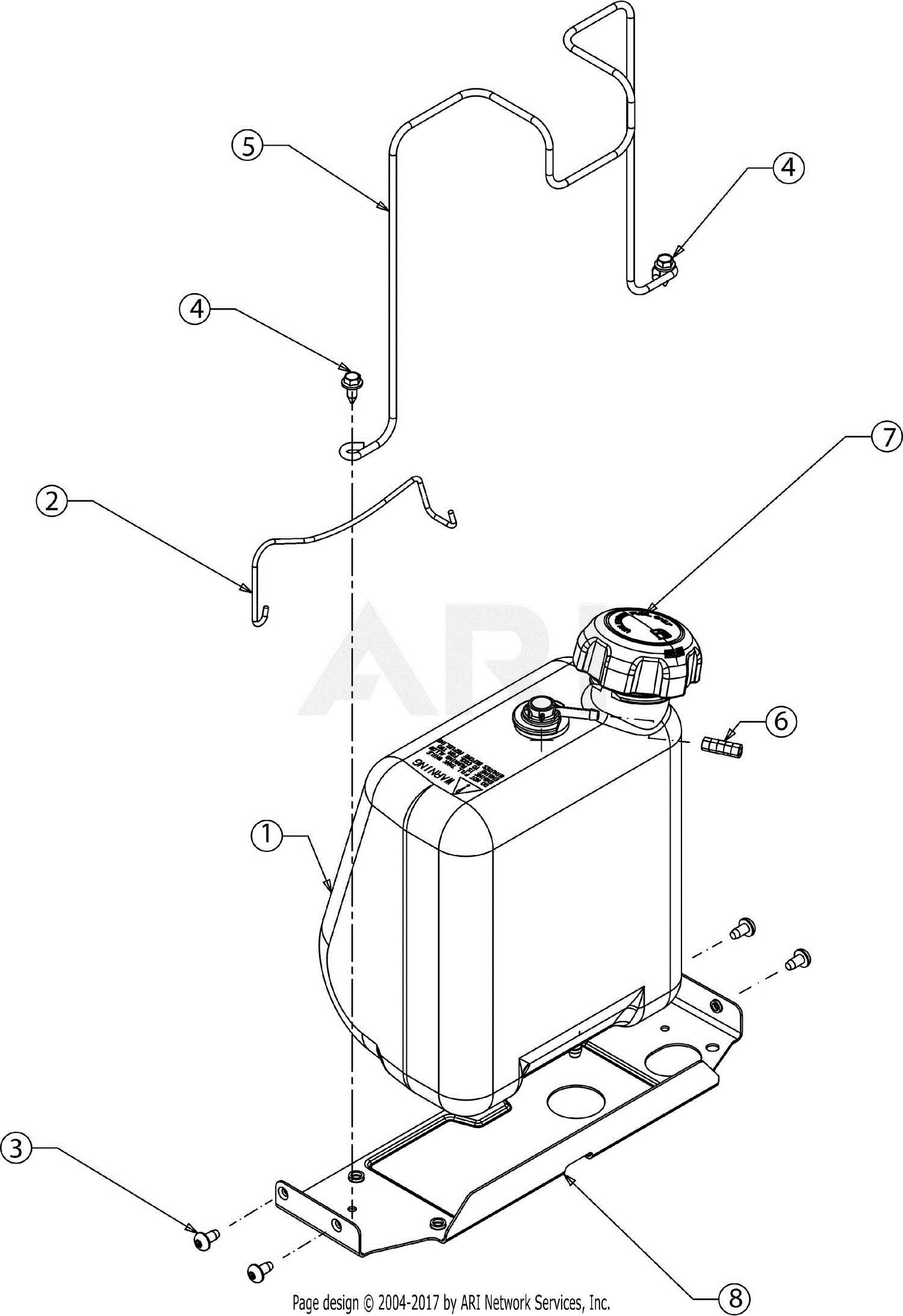

To fully appreciate the intricacies of your device, it’s beneficial to explore a visual representation that highlights each section and its function. This approach not only aids in identifying parts that may require attention but also empowers users to undertake repairs or upgrades with confidence.

By delving into the specifics of these components, you equip yourself with the knowledge needed to make informed decisions about maintenance and replacement. Whether you are a seasoned user or a novice, having access to this information can ultimately enhance your experience and the functionality of your equipment.

Understanding Craftsman T110 Parts Diagram

Gaining insight into the components of your equipment is essential for maintenance and repair. Familiarity with the visual representation of each element allows for better troubleshooting and efficiency in handling tasks.

Importance of Component Identification

Recognizing individual parts can enhance your overall experience. Here are key reasons for understanding these elements:

- Facilitates quick repairs

- Improves maintenance routines

- Enhances safety during operation

Tips for Utilizing the Visual Guide

To effectively navigate the illustration, consider the following tips:

- Familiarize yourself with each section

- Cross-reference with the user manual

- Keep the guide accessible during repairs

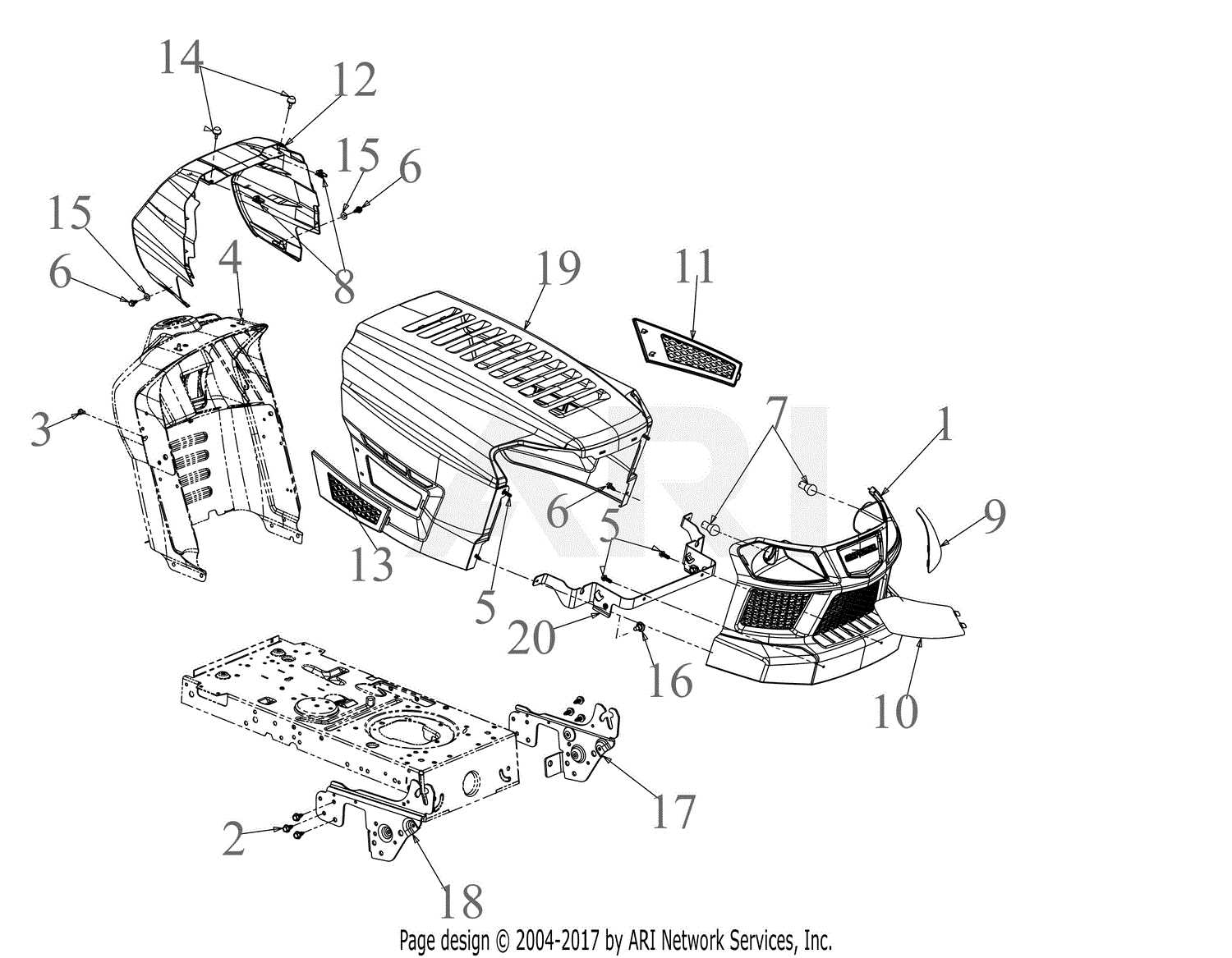

Key Components of the T110 Model

This section explores the essential elements that contribute to the functionality and performance of this specific model. Understanding these crucial components can enhance the user experience and maintenance of the device.

Engine: The power source is vital for overall operation, delivering the necessary energy to perform various tasks efficiently.

Transmission: This mechanism plays a critical role in transferring power from the engine to the wheels, ensuring smooth movement and control.

Chassis: The framework provides structural integrity and houses essential parts, supporting the overall design and stability during use.

Controls: User interfaces, including levers and switches, enable operators to manage functions effectively, enhancing usability.

Wheels: These components are integral for mobility, designed to withstand various terrains while providing optimal traction.

Safety Features: Built-in mechanisms and systems are essential for protecting users, ensuring safe operation under various conditions.

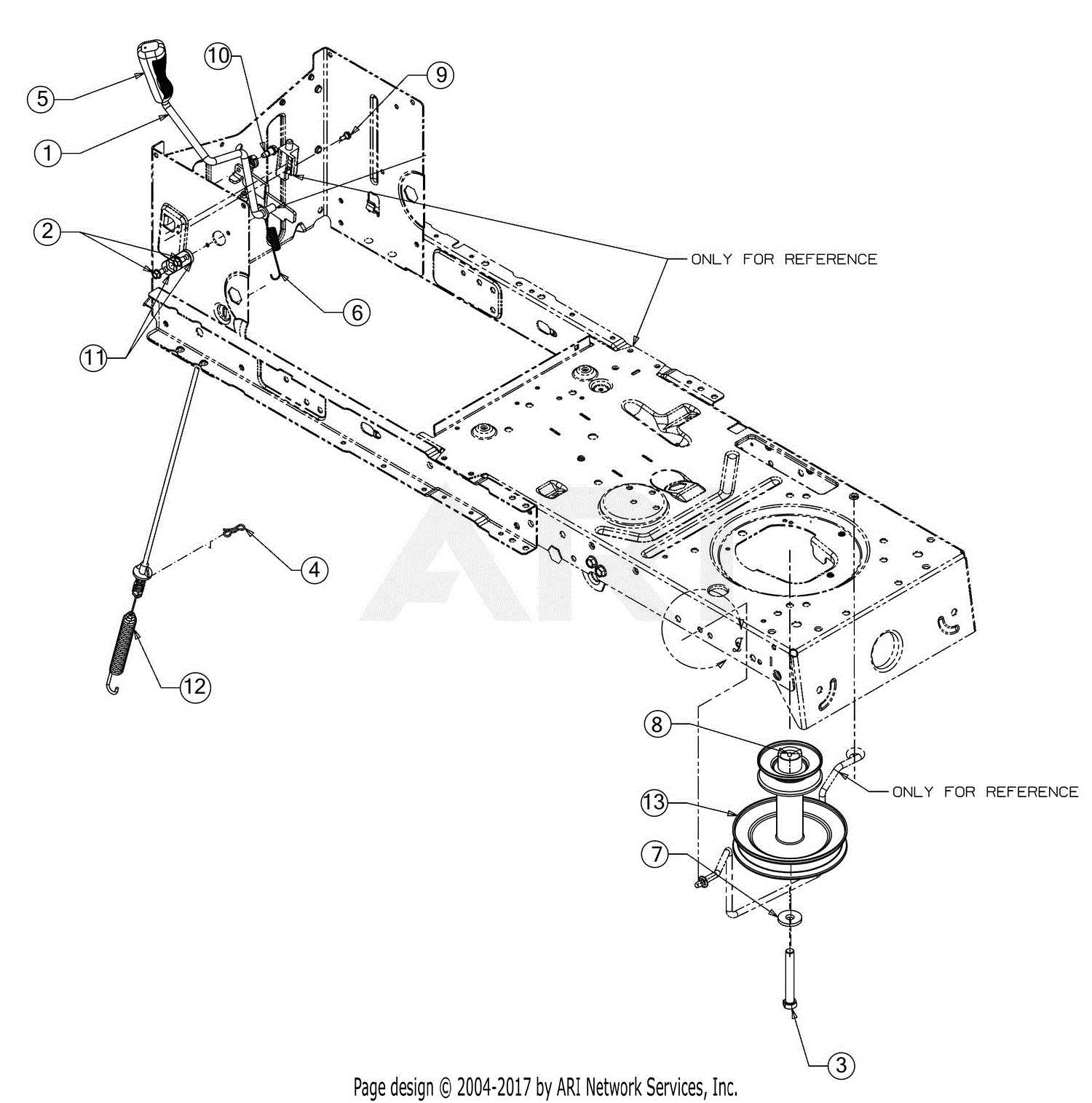

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone looking to repair or maintain equipment effectively. These illustrations provide a comprehensive overview of components, helping users identify specific elements and their functions within a larger assembly. Mastering the interpretation of these visuals can significantly streamline the repair process and enhance overall comprehension.

Identifying Components

Each illustration typically labels various elements, often accompanied by reference numbers or letters. Familiarizing yourself with these markings is crucial, as they directly correlate to a list that details each item. Pay close attention to the layout, as it usually reflects the arrangement of parts in the actual device.

Understanding Relationships

In addition to recognizing individual components, it’s important to grasp how they interact. Look for connecting lines or arrows that indicate relationships or pathways. These symbols can reveal how certain elements work together, providing insight into the assembly’s functionality. With practice, interpreting these visuals will become second nature, making repairs quicker and more efficient.

Common Issues with T110 Parts

Understanding the frequent challenges associated with components is essential for maintenance and longevity. Various factors can lead to malfunctions, which may affect performance and usability.

Frequent Challenges

- Wear and Tear: Over time, components may deteriorate, resulting in decreased efficiency.

- Misalignment: Incorrect installation can lead to improper functioning.

- Contamination: Dust and debris can impede movement and cause overheating.

Signs of Problems

- Unusual noises during operation.

- Inconsistent performance or power loss.

- Visible damage or wear on the exterior.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward task if you know where to look. There are various resources available, from online retailers to local suppliers, that can help you find what you need to keep your tools running efficiently.

Online Retailers

The internet is a treasure trove of options when it comes to sourcing components. Major e-commerce platforms often carry a wide array of items suitable for numerous brands. Make sure to check product specifications and customer reviews to ensure compatibility and quality.

Local Hardware Stores

Your neighborhood hardware store can be an excellent resource. Many shops maintain a selection of essential components and can order specific items if they’re not in stock. Don’t hesitate to ask staff for assistance; their expertise can guide you to the right solutions.

Additionally, consider contacting the manufacturer directly. They can provide insights on authorized dealers or offer original items that meet your requirements. Using these resources will make finding replacements easier and more efficient.

Tips for Maintaining Your Craftsman T110

Proper upkeep of your equipment ensures its longevity and optimal performance. Following a few essential practices can help keep your machine in top shape, ultimately saving you time and money.

- Regularly inspect and clean all moving parts to prevent buildup and wear.

- Change the oil and replace filters as needed to maintain engine efficiency.

- Sharpen blades consistently to achieve the best cutting results.

- Check tire pressure and tread for safe operation on various terrains.

- Store your equipment in a dry, sheltered area to protect it from the elements.

By adhering to these guidelines, you can ensure that your machinery operates smoothly and remains reliable for years to come.

Tools Needed for T110 Repairs

When it comes to maintaining and fixing your equipment, having the right instruments is crucial for a successful outcome. A variety of tools can make the process smoother and ensure that all necessary adjustments are carried out efficiently.

Wrenches are essential for loosening and tightening bolts, while screwdrivers of various sizes help in managing screws with precision. Additionally, pliers can aid in gripping and manipulating small components.

For more intricate tasks, socket sets are invaluable, providing the versatility needed for different fasteners. To ensure accurate measurements, a tape measure and calipers are recommended for precise adjustments.

Finally, safety gear such as gloves and goggles should not be overlooked, as they protect you from potential hazards during repair work. Equipped with these tools, you can tackle any task with confidence.

Identifying Parts by Diagram Symbols

Understanding the visual representations used in technical illustrations is essential for effectively navigating assembly or repair tasks. These symbols serve as a universal language, providing insight into each component’s function and relationship within the overall system. By familiarizing oneself with these representations, users can streamline their work processes and enhance their troubleshooting skills.

Common Symbols and Their Meanings

Technical illustrations often utilize specific symbols to denote various elements. For instance, circles may represent connectors or joints, while squares could signify structural components. Arrows frequently indicate directionality or flow, aiding in understanding the operational dynamics. Recognizing these common symbols allows individuals to quickly interpret the visual information and apply it practically.

Practical Application of Symbols

When approaching a task, one can refer to the symbolic guide to identify the required components efficiently. This understanding not only assists in locating parts but also fosters a deeper comprehension of the assembly process. By leveraging this knowledge, users can enhance their repair accuracy and ultimately ensure optimal functionality of the system in question.

Frequently Asked Questions About T110

This section addresses common inquiries related to a specific model, providing insights that can assist users in understanding its functionality and maintenance. Below are frequently asked questions that highlight essential information for both new and experienced users.

-

What types of maintenance are recommended?

Regular upkeep includes:

- Cleaning components to prevent buildup.

- Inspecting belts and blades for wear.

- Changing fluids as per the manual guidelines.

-

Where can I find replacement components?

Replacement items can be sourced from:

- Authorized dealers.

- Online retailers specializing in outdoor equipment.

- Local hardware stores with a selection of machinery parts.

-

How can I troubleshoot common issues?

For basic troubleshooting, consider the following:

- Check fuel levels and connections.

- Inspect electrical components for damage.

- Review the user manual for specific error codes.

-

Are there any safety precautions to keep in mind?

Always remember to:

- Wear appropriate safety gear while operating.

- Keep hands and loose clothing away from moving parts.

- Follow the operational guidelines in the manual.

Upgrades Available for Craftsman T110

Enhancing your machine can significantly improve performance and longevity. Various modifications are available that can elevate functionality, making your tasks easier and more efficient. Whether you’re looking to boost power, improve comfort, or increase versatility, there are plenty of options to consider.

Performance Enhancements

One of the most popular upgrades includes the installation of a more powerful engine or enhanced transmission system. These changes can result in greater speed and efficiency, allowing for faster completion of tasks. Additionally, high-quality blades or attachments can also contribute to improved cutting precision and durability.

Comfort and Usability Improvements

Upgrading the seat or adding ergonomic handles can greatly enhance user comfort during extended use. Accessories such as cup holders and tool trays can also add convenience, making your experience more enjoyable and streamlined. Investing in these modifications ultimately leads to a more productive working environment.

Comparison with Other Craftsman Models

This section explores the differences and similarities between various models produced by the brand, focusing on their features, performance, and design. Understanding these distinctions can help users make informed choices based on their specific needs.

Feature Comparison

When analyzing the range of models, several key attributes stand out. While some units prioritize power and efficiency, others may emphasize compact design and versatility. Here’s a comparative look at essential features:

| Model | Power (HP) | Weight (lbs) | Max Speed (RPM) |

|---|---|---|---|

| Model A | 3 | 150 | 4500 |

| Model B | 2.5 | 120 | 4000 |

| Model C | 4 | 180 | 5000 |

Design Considerations

The design elements across these different units reflect the intended usage scenarios. Some models feature a more ergonomic structure, while others boast durability and ruggedness suited for heavy-duty tasks. This analysis highlights the variety in design philosophy and user focus.

Online Resources for T110 Support

Finding reliable assistance and information online can greatly enhance your experience with tools and machinery. Numerous platforms are dedicated to providing guidance, troubleshooting tips, and community support for users seeking to maintain and repair their equipment.

- Official Manufacturer Website: Start with the official site, where you can find manuals, FAQs, and contact information for customer support.

- User Forums: Join online communities where enthusiasts share their experiences, tips, and solutions. These forums are invaluable for troubleshooting and advice.

- Video Tutorials: Websites like YouTube offer a plethora of instructional videos that visually guide you through repairs and maintenance procedures.

- Social Media Groups: Platforms such as Facebook and Reddit host groups focused on specific brands and models, allowing for real-time advice and shared experiences.

- Retailer Support Pages: Many retailers have dedicated sections for support, offering additional resources like chat support and live Q&A.

Utilizing these resources can empower you to confidently tackle any issues and maximize the longevity of your equipment.