When it comes to maintaining and enhancing the performance of outdoor machinery, having a clear visual representation of its individual components is essential. This section aims to provide valuable insights into the various elements that make up your equipment, enabling users to navigate through its assembly with confidence.

Exploring the intricate network of mechanisms within your machine can significantly aid in identifying parts that require attention or replacement. By familiarizing yourself with each component’s layout and function, you can ensure your equipment operates smoothly and efficiently. A comprehensive overview not only enhances your understanding but also empowers you to take proactive steps in maintenance and repair.

Whether you’re a seasoned user or new to lawn care equipment, recognizing the significance of each element fosters better care and extends the longevity of your investment. This guide serves as a resource to help you connect with the essential aspects of your machinery, ensuring you are well-equipped to address any issues that may arise.

Understanding the Craftsman YT 4000

This section delves into the intricate features and functionalities of a specific lawn care machine designed for residential use. With its robust design and user-friendly characteristics, this model has become a popular choice among homeowners looking to maintain their outdoor spaces effectively.

Key Features

- Powerful engine designed for optimal performance.

- Ergonomic controls for ease of use.

- Durable construction materials for longevity.

- Efficient cutting system for a clean finish.

- Adjustable settings for various terrains.

Benefits of Usage

- Reduces the time spent on yard maintenance.

- Enhances the aesthetic appeal of your lawn.

- Provides versatility for different gardening tasks.

- Minimizes physical effort required for lawn care.

By understanding the various components and advantages of this machine, users can maximize its potential and ensure effective lawn management. Proper familiarity with its features will lead to improved performance and satisfaction.

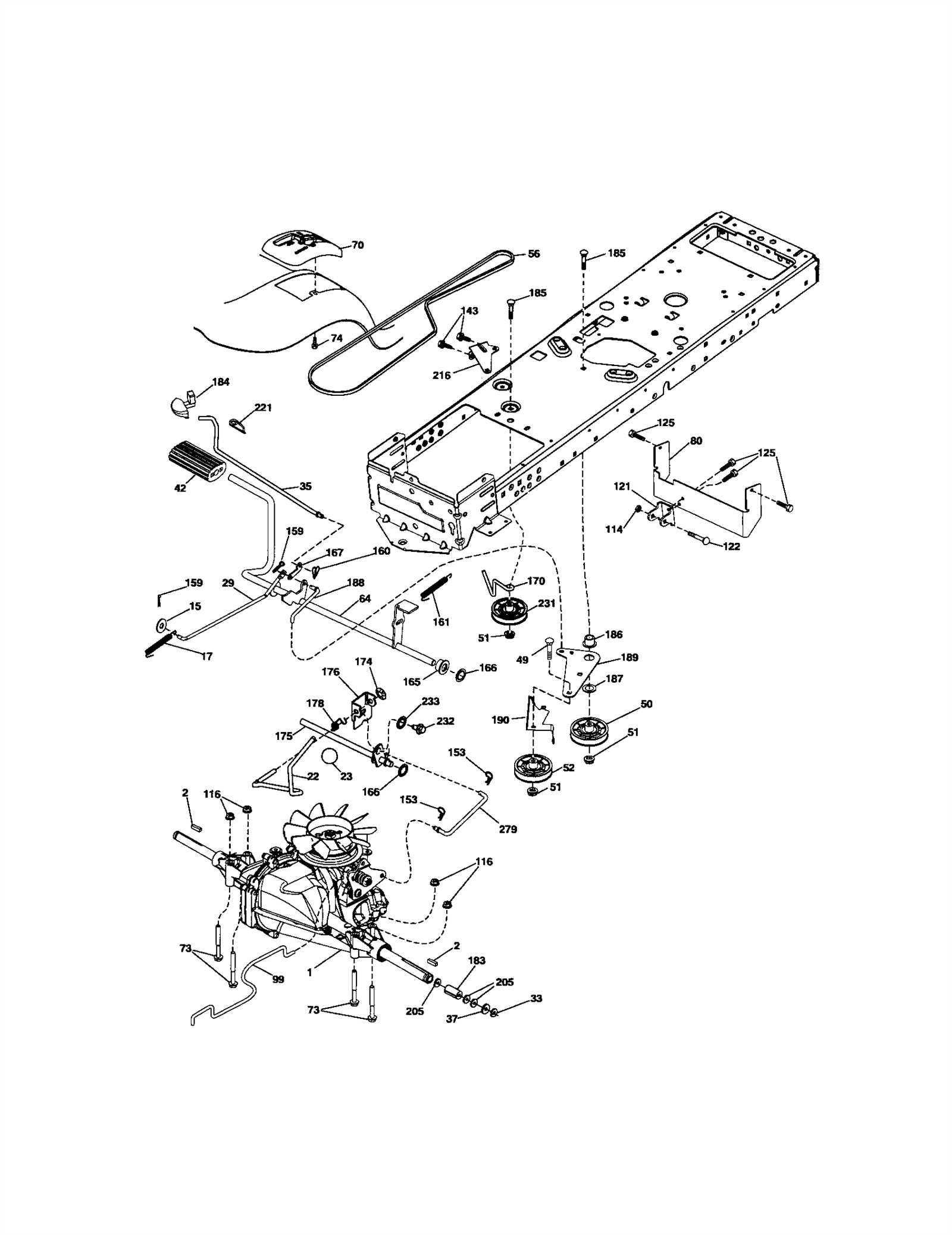

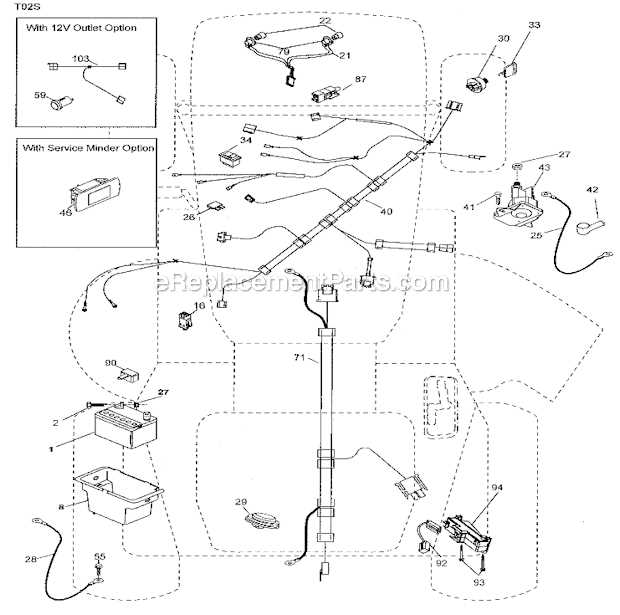

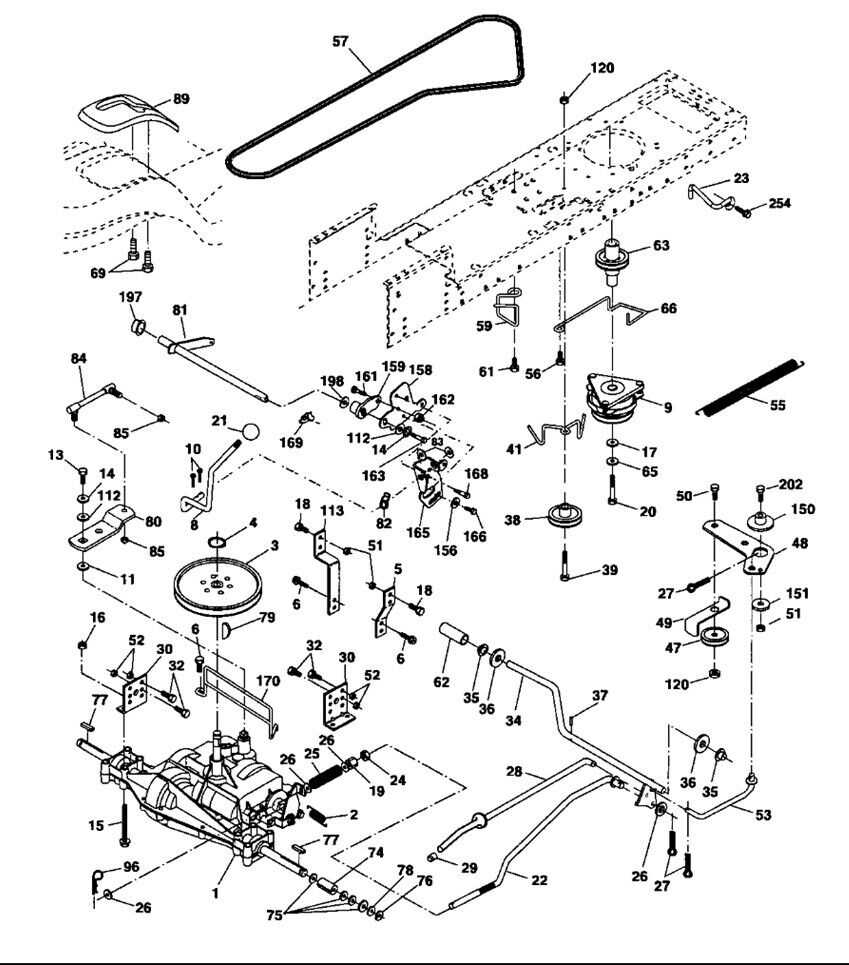

Overview of Parts and Components

This section provides a comprehensive look at the various elements that comprise the machine, highlighting their functionality and importance in the overall operation.

The components can be categorized into several key groups:

- Engine Assembly: This is the heart of the machine, responsible for power generation and performance.

- Transmission System: Facilitates the transfer of power from the engine to the wheels, ensuring smooth operation.

- Chassis and Frame: Provides structural integrity and support for all other components.

- Control Mechanisms: Includes steering, braking, and throttle controls, allowing the operator to manage the machine effectively.

- Fuel System: Responsible for storing and delivering fuel to the engine for combustion.

- Electrical System: Powers various features, including lights, ignition, and electronic controls.

- Cooling System: Maintains optimal operating temperatures to prevent overheating and ensure longevity.

Understanding the function of each component is essential for maintenance, troubleshooting, and enhancing performance.

Importance of Parts Diagrams

Understanding the structure and components of any mechanical device is crucial for effective maintenance and repair. Visual representations serve as invaluable tools for both professionals and enthusiasts, enabling them to identify each element’s role and position within the overall assembly. Such illustrations facilitate a clearer comprehension of the device’s functionality, streamlining the troubleshooting process and enhancing the user experience.

Enhanced Clarity and Navigation

Illustrative representations allow users to quickly locate specific components, eliminating confusion and saving time during repairs. When a detailed visual guide is available, individuals can avoid the frustration of searching for misplaced or damaged elements, thereby increasing efficiency. This clarity is especially beneficial in complex mechanisms where multiple parts interact closely.

Facilitating Efficient Repairs

Having access to visual guides significantly improves the repair process. Users can follow step-by-step instructions more easily, ensuring that each component is addressed systematically. This organized approach not only minimizes the risk of errors but also promotes confidence in carrying out maintenance tasks. Ultimately, well-illustrated resources empower users to keep their devices in optimal condition.

Identifying Key Components

Understanding the primary elements of a machine is crucial for effective maintenance and operation. Each component plays a specific role in ensuring the functionality and efficiency of the equipment. By recognizing these essential parts, users can troubleshoot issues more effectively and enhance overall performance.

The following table outlines the major components typically found in such machinery, providing insights into their functions and importance:

| Component | Description |

|---|---|

| Engine | The heart of the equipment, responsible for providing the necessary power to operate. |

| Transmission | This system transfers power from the engine to the wheels, enabling movement. |

| Chassis | The framework that supports various components and provides structural integrity. |

| Electrical System | Includes the battery and wiring that supply power to lights, ignition, and other accessories. |

| Fuel System | Responsible for storing and delivering fuel to the engine for combustion. |

| Cooling System | Helps regulate the engine temperature to prevent overheating. |

| Wheels and Tires | Provide traction and support for movement over various terrains. |

Common Issues with Parts

When working with various machinery, it’s not uncommon to encounter certain difficulties related to components. Understanding these issues can help users troubleshoot effectively and maintain optimal performance. This section highlights frequent problems and offers guidance on how to address them.

Typical Problems Encountered

- Wear and Tear: Over time, components may deteriorate due to regular use, leading to decreased efficiency.

- Misalignment: Incorrect installation can result in parts not fitting together properly, causing operational issues.

- Corrosion: Exposure to moisture can lead to rust and degradation of metal components, affecting performance.

Troubleshooting Tips

- Regular Inspections: Frequently check components for signs of wear, misalignment, or corrosion.

- Proper Lubrication: Ensure that moving parts are well-lubricated to reduce friction and prevent damage.

- Follow Manufacturer Guidelines: Always adhere to the recommended practices for installation and maintenance to avoid issues.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. Such illustrations provide a comprehensive view of the various elements involved in a mechanism, helping users identify and locate each segment efficiently.

Key Elements to Look For

- Labels: Most illustrations will feature labels that correspond to specific parts. These may be numbered or lettered, guiding you to the right section.

- Legend: A legend often accompanies the illustration, explaining the symbols and markings used throughout the image.

- Assembly Order: Some visuals will indicate the order in which components should be assembled or disassembled, which is crucial for proper reassembly.

Steps for Effective Interpretation

- Begin by familiarizing yourself with the overall layout, noting how components relate to one another.

- Reference the labels to pinpoint specific elements you may need to replace or inspect.

- Utilize the legend to decode any unfamiliar symbols or annotations that appear in the illustration.

- Follow any assembly instructions carefully to ensure that everything is correctly aligned during reinstallation.

Replacement Parts Availability

When it comes to maintaining and restoring your equipment, the accessibility of components is crucial. Whether you’re looking to replace worn-out elements or enhance functionality, understanding the options available for acquiring these essential items can make all the difference. Reliable sources offer a range of choices to ensure your machinery continues to operate at peak performance.

Numerous retailers specialize in providing a vast selection of accessories for various models, catering to the needs of users seeking quality replacements. Online platforms often feature extensive catalogs that allow for easy navigation and comparison, ensuring you find precisely what you need. Local shops may also stock commonly required items, making it convenient for immediate repairs.

In addition, many manufacturers have established partnerships with authorized dealers, ensuring that original equipment specifications are met. This commitment to quality guarantees that the components you purchase will fit perfectly and perform optimally, prolonging the lifespan of your equipment. Furthermore, some suppliers provide additional support through guides and customer service, assisting you in making informed decisions.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. By following a few key practices, you can enhance performance and prevent unnecessary breakdowns. Regular maintenance not only safeguards your investment but also optimizes functionality, allowing for smoother operation over time.

Routine Inspections

Conducting frequent checks is crucial. Look for any signs of wear or damage, including loose connections or frayed cables. Early detection of potential issues can save you from more extensive repairs later. Ensure all components are securely fastened and functioning as intended.

Cleaning and Lubrication

Keep all surfaces clean to prevent dust and debris buildup. Regularly wipe down exterior parts and ensure that moving components are properly lubricated. Regular maintenance of these elements minimizes friction and prolongs the life of your machinery, enhancing its efficiency. Remember that a clean machine is a happy machine!

Assembly Instructions for Key Parts

This section provides essential guidance for assembling vital components of your machine. Proper assembly is crucial for ensuring optimal performance and longevity. Follow the instructions carefully to achieve a seamless integration of the parts.

Before you begin, make sure you have all the necessary tools and components at hand. Here are the steps to successfully assemble the key elements:

-

Prepare the Workspace:

- Clear a large, flat surface.

- Organize all components and tools.

- Ensure proper lighting for visibility.

-

Assemble the Frame:

- Start by aligning the base sections.

- Secure the corners with bolts, ensuring a tight fit.

- Double-check that all joints are firm.

-

Attach the Motor:

- Position the motor in the designated area.

- Fasten it using the provided screws.

- Connect the electrical wiring according to the schematic.

-

Install Additional Components:

- Refer to the assembly sequence for the next parts.

- Ensure each part clicks into place before securing it.

- Perform a final check to confirm everything is aligned correctly.

Once the assembly is complete, conduct a thorough inspection of the unit to ensure all parts are securely fastened and functioning properly. Proper assembly not only enhances efficiency but also reduces the risk of malfunctions.

Where to Find Quality Parts

When seeking high-grade components for your outdoor equipment, it’s crucial to explore reliable sources that guarantee durability and performance. Ensuring the longevity of your machine relies heavily on the quality of the replacement elements you choose. Various outlets cater to enthusiasts looking for dependable accessories that enhance functionality and ensure optimal operation.

Authorized Dealers and Retailers

One of the most trustworthy options is to visit authorized dealers and specialized retailers. These establishments often have a comprehensive selection of components that meet the manufacturer’s specifications. Additionally, purchasing from recognized vendors provides the assurance of receiving genuine parts that are specifically designed for your machinery.

Online Marketplaces

The internet offers a vast array of platforms where you can discover various components at competitive prices. Reputable online marketplaces allow users to compare different suppliers and read customer reviews, ensuring you make informed decisions. Be cautious, however, and verify the credibility of the sellers to avoid counterfeit items.

DIY Repair vs. Professional Help

When faced with the need for equipment repairs, individuals often weigh the options between tackling the job themselves and seeking assistance from skilled technicians. Each choice comes with its own set of advantages and challenges, which can significantly impact both the outcome of the repair and the overall experience.

Choosing to handle repairs independently can provide numerous benefits:

- Cost Savings: Taking on repairs can save money that would otherwise go towards labor fees.

- Skill Development: DIY projects offer a chance to learn and enhance practical skills, leading to greater self-sufficiency.

- Flexibility: Individuals can work at their own pace and schedule, making it easier to fit repairs into busy lives.

However, there are also significant considerations when opting for self-repair:

- Time Investment: DIY repairs can be time-consuming, particularly for those unfamiliar with the equipment.

- Risk of Mistakes: Lack of experience may lead to errors, potentially causing more damage and increasing repair costs.

- Limited Resources: Access to specific tools and parts may hinder the effectiveness of the repair process.

On the other hand, seeking help from professionals presents its own advantages:

- Expertise: Trained technicians have extensive knowledge and experience, which can lead to quicker and more reliable repairs.

- Warranty Protection: Professional repairs often come with guarantees, providing peace of mind regarding the quality of the work.

- Comprehensive Services: Professionals can identify underlying issues that may not be apparent to the untrained eye, ensuring that all problems are addressed.

Ultimately, the decision between DIY repairs and professional assistance depends on individual circumstances, including budget, time availability, and personal comfort with repair tasks. Evaluating these factors can help determine the most suitable approach for any repair situation.

Cost Considerations for Repairs

When it comes to maintaining and restoring equipment, evaluating the financial implications of repairs is crucial. Understanding the expenses involved can help owners make informed decisions, ensuring their investment remains worthwhile. Various factors influence the total cost, including the nature of the damage, the components needing replacement, and the labor required for the restoration process.

Factors Influencing Repair Costs

Several elements can impact the overall expense of repairs. These may include:

| Factor | Description |

|---|---|

| Type of Damage | Different levels of wear and tear or malfunction will result in varying costs. Minor repairs are usually less expensive than extensive overhauls. |

| Component Availability | The ease of sourcing replacement items affects prices. Common parts tend to be more affordable and readily accessible. |

| Labor Costs | Professional services can add to expenses. Rates may vary depending on the technician’s expertise and geographical location. |

Budgeting for Maintenance

Setting aside a budget for upkeep is advisable. This proactive approach can mitigate the financial strain when repairs are necessary. Regular inspections can also help identify potential issues before they escalate, ultimately saving costs over time. By anticipating future expenses, owners can maintain their equipment efficiently and effectively.