The world of motor engineering is vast, with various elements working in harmony to ensure smooth operation and performance. Understanding the key components and their relationships within a vehicle’s system is crucial for maintaining and enhancing functionality. These intricate designs provide insight into how each element plays a role in the overall structure.

By breaking down the internal connections, we gain a deeper understanding of how these systems interact. Clear visual representations serve as a roadmap, guiding enthusiasts and mechanics alike through the complex network of mechanical pieces. Such visual aids are invaluable for those looking to repair, modify, or upgrade their machine.

Whether you’re a seasoned mechanic or a hobbyist, familiarizing yourself with the key elements and their arrangements is essential for ensuring that every aspect of the machine is in optimal condition. This knowledge empowers individuals to tackle challenges with confidence and precision.

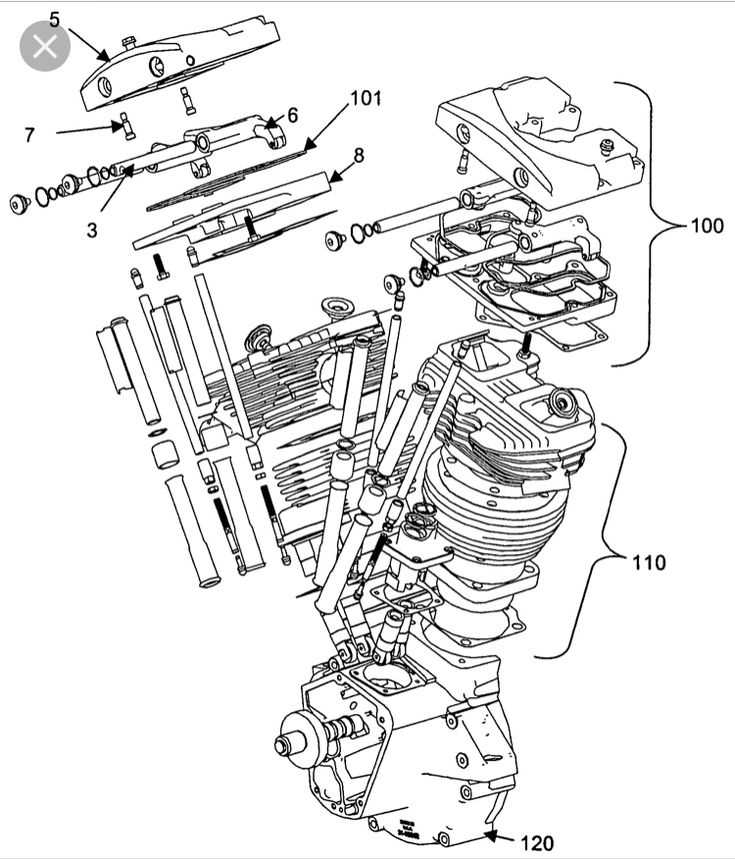

Harley Davidson Parts Diagrams

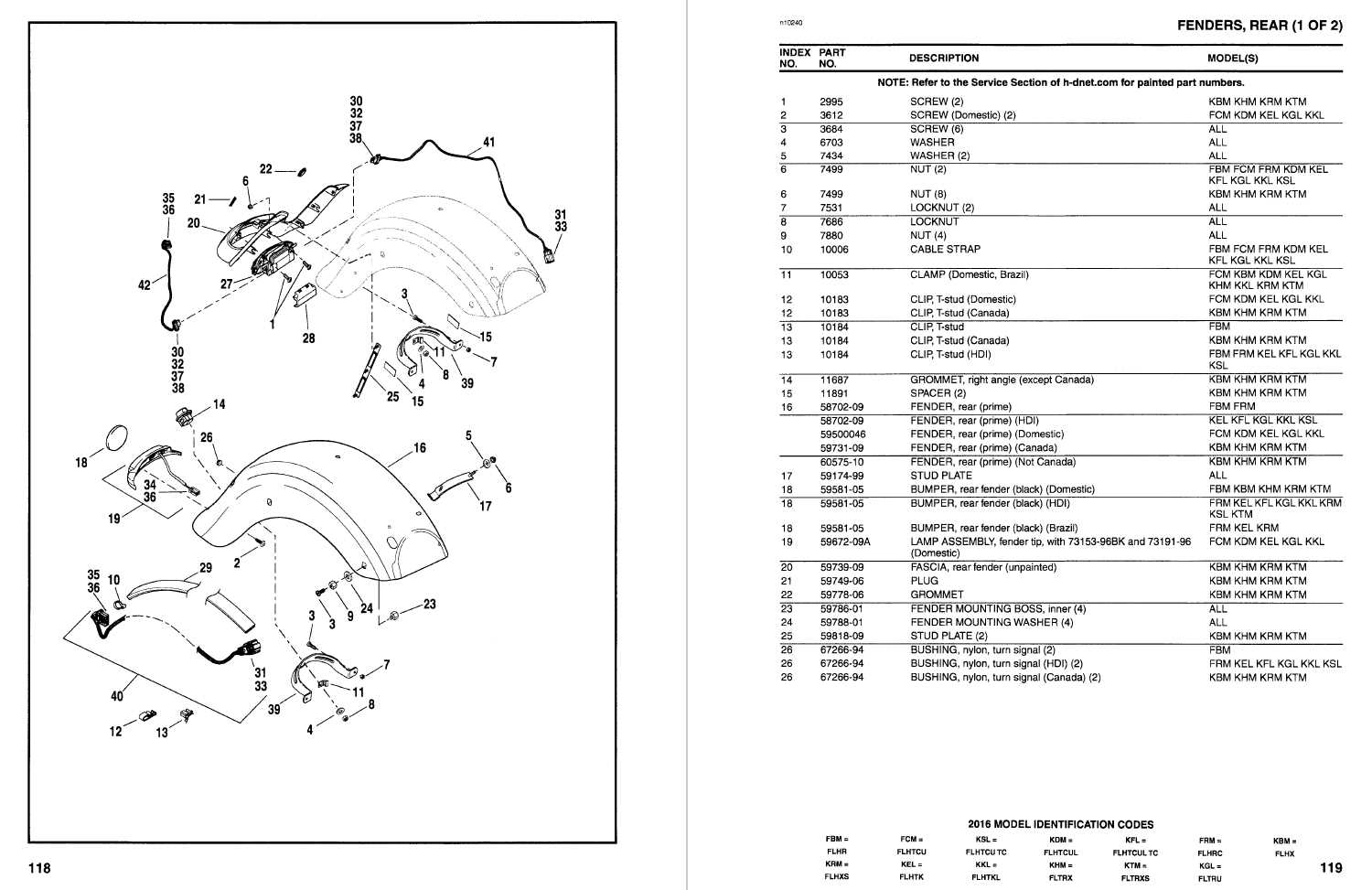

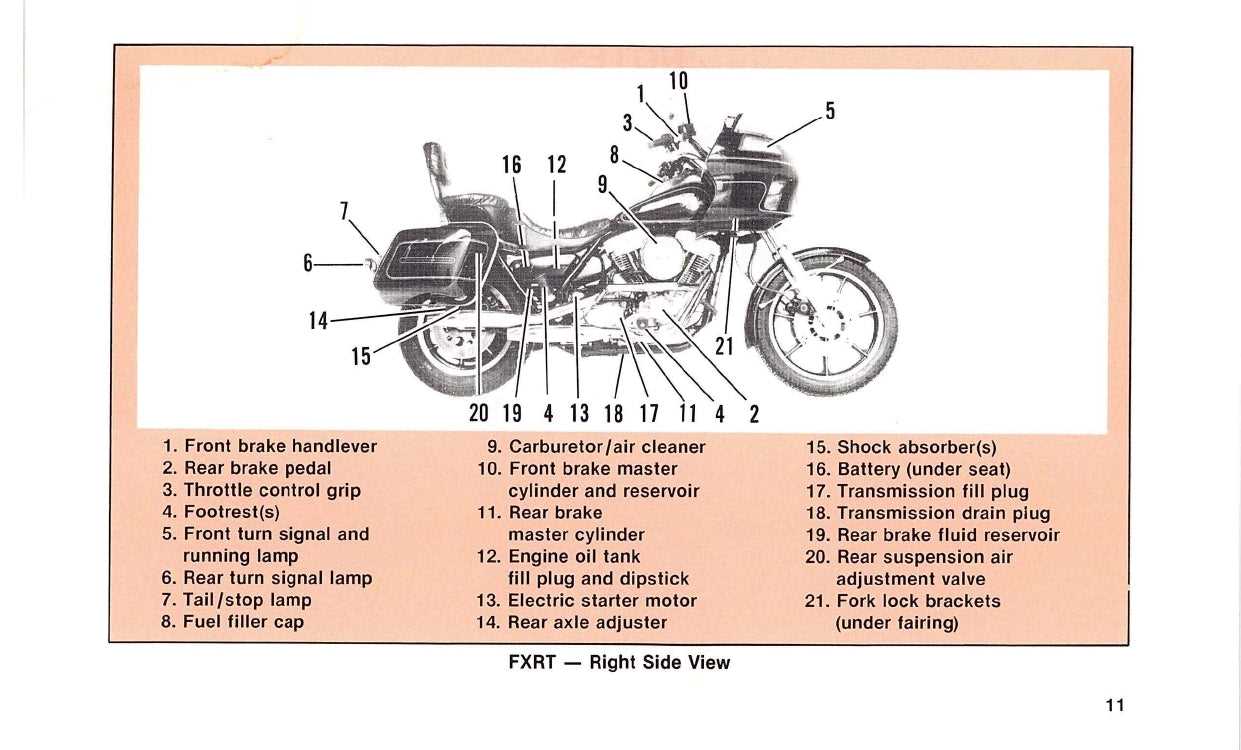

Understanding the layout and configuration of essential components in your vehicle can significantly enhance maintenance and repair efficiency. By exploring the structure of various elements, you can gain a deeper insight into how these mechanisms work together.

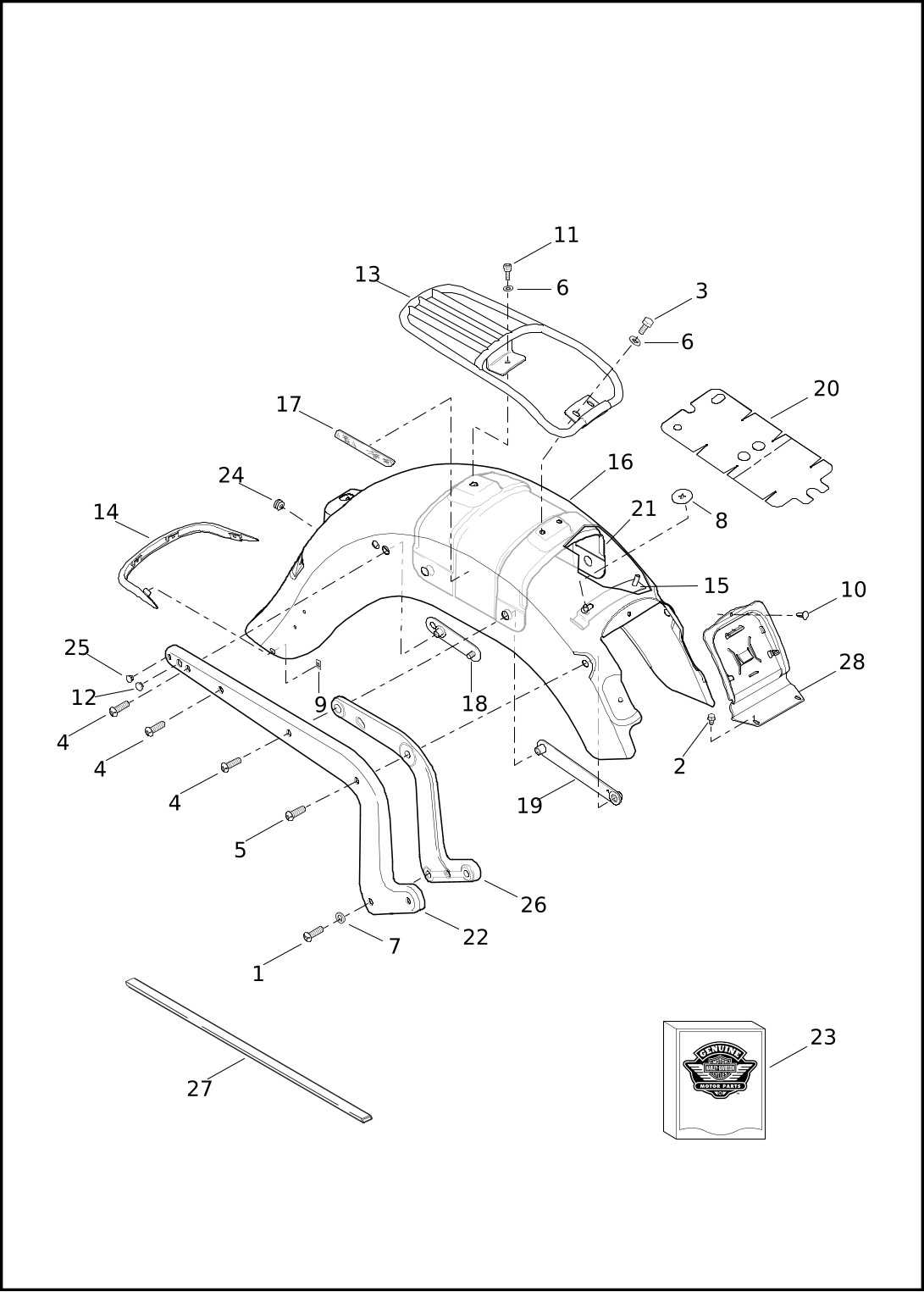

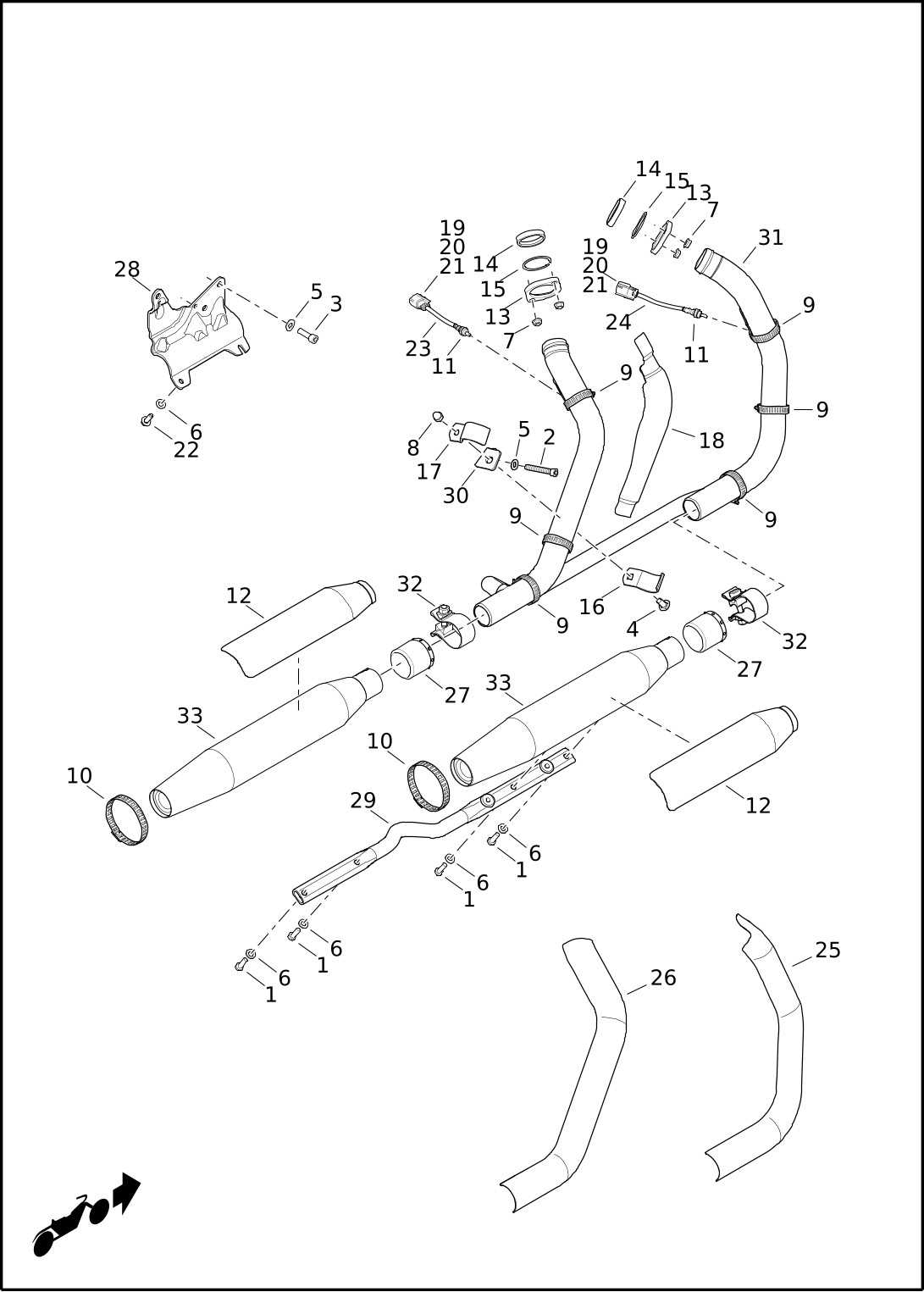

Visual Representation of Component Layout

A graphical breakdown of mechanical systems offers an intuitive way to comprehend the placement and interconnection of various modules. This method of illustration allows users to identify each element’s role within the broader system, ensuring a more accurate approach to repairs and upgrades.

Detailed Breakdown for Easy Identification

Using a detailed scheme, it becomes easier to locate specific modules and understand their relationship to other parts. Whether for routine upkeep or diagnosing a technical issue, having access to this kind of representation makes the process far more streamlined.

Understanding Engine Component Layouts

The arrangement of key mechanical elements within a motor system plays a critical role in ensuring efficient operation and longevity. Knowing how each piece fits together helps to understand the overall structure and function of the machinery. The layout reveals how energy flows and is transformed within the system.

Key Mechanical Structures

Each engine is composed of several essential elements that work together to generate power. These components are carefully positioned to maximize efficiency and minimize wear. The placement of these parts can vary, but their interaction remains crucial for smooth operation.

| Component | Function | |

|---|---|---|

| Cylinder | Houses the piston and enables the combustion process. | |

| Piston | Moves within the cylinder to compress fuel and air, generating power. | |

| Crankshaft | Converts the linear motion of the piston into rotational force. |

| Aspect | Importance | Impact on Performance |

|---|---|---|

| Wheel Size | Influences handling and ride comfort | Affects acceleration and braking capabilities |

| Tire Type | Determines traction and grip | Influences stability in various conditions |

| Alignment | Ensures even tire wear and stability | Enhances maneuverability and reduces friction |

| Pressure | Critical for safety and fuel efficiency | Affects handling and longevity of tires |

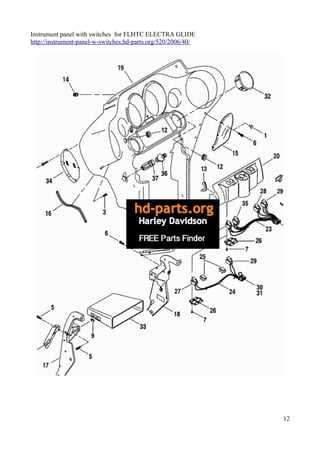

Headlight and Taillight Wiring Breakdown

Understanding the intricacies of lighting systems in motorcycles is essential for effective maintenance and repair. This section delves into the wiring configurations that control both front and rear illumination, providing insight into their functions and connections. Proper comprehension of these electrical layouts can enhance safety and improve the overall performance of the vehicle.

Key Wiring Components

The lighting setup consists of several vital elements, each serving a specific purpose. Identifying these components is crucial for troubleshooting issues or making modifications. Below are the primary elements associated with headlight and taillight connections:

| Component | Description |

|---|---|

| Headlight Bulb | Illuminates the road ahead, enhancing visibility during nighttime or low-light conditions. |

| Taillight Bulb | Provides visibility to vehicles behind, indicating the motorcycle’s presence and intentions. |

| Wiring Harness | Connects all electrical components, allowing for the distribution of power throughout the lighting system. |

| Connectors | Facilitate secure connections between wires and components, ensuring reliable operation. |

Understanding Wiring Connections

Each connection within the lighting system is designed to maximize functionality while ensuring safety. Recognizing the layout and specific roles of each wire can prevent short circuits and enhance the reliability of the illumination features. Diagrams illustrating these connections can serve as valuable references for both novices and experienced mechanics.

Battery Connections and Charging Paths

Understanding the relationship between energy storage and its distribution is crucial for any motorized vehicle. Properly configured connections ensure efficient energy transfer, impacting overall performance and longevity. This section delves into the fundamental aspects of battery integration and the associated pathways for charging.

There are several key components involved in maintaining effective energy flow:

- Battery Terminals: These are the points where electrical connections occur. They must be securely fastened to prevent energy loss.

- Wiring Harness: This collection of wires facilitates the movement of current between the battery and various electrical systems.

- Voltage Regulator: This component maintains the correct voltage levels, ensuring that the battery is charged efficiently without being overworked.

The charging process generally follows a specific route:

- The alternator generates electricity while the engine is running.

- This energy travels through the wiring harness to the voltage regulator.

- The regulator directs the current to the battery terminals, replenishing the stored energy.

Maintaining these connections and understanding their functions can significantly enhance the reliability and efficiency of the electrical system.

Body Frame and Mounting Points Guide

This section provides essential insights into the structural components and attachment locations within the vehicle chassis. Understanding these elements is crucial for ensuring stability and safety, as well as facilitating maintenance and modifications. The framework serves as the foundation upon which various systems and accessories are mounted, making it a vital aspect of vehicle construction.

Key Components of the Frame

- Main Frame: The core structure providing overall strength and support.

- Subframe: Secondary structure that supports additional components like the rear suspension.

- Engine Mounts: Specific points designed to secure the engine, minimizing vibrations.

- Footpeg Mounts: Locations for footpegs that contribute to rider comfort and control.

Understanding Mounting Points

Each attachment point serves a specific function and is engineered to bear certain loads. Proper alignment and installation at these points are essential for optimal performance.

- Front Mounts: Located at the front of the frame, these points often connect to the forks.

- Rear Mounts: Found towards the back, crucial for rear suspension systems.

- Side Mounts: Assist in securing the body panels and other external features.

Properly identifying and utilizing these components ensures the longevity and efficiency of the vehicle, allowing for a more enjoyable riding experience.