Maintaining a well-groomed lawn requires a deep understanding of the various components that contribute to the efficiency and functionality of landscaping machinery. This section aims to provide insights into the essential elements of specific equipment designed for grass management, focusing on their construction and operational aspects.

By exploring the intricate layout of these components, users can gain a clearer perspective on how each piece interacts within the system. A thorough examination not only aids in troubleshooting but also enhances overall performance, ensuring that tasks are executed seamlessly and effectively.

Whether you are a seasoned professional or a passionate homeowner, familiarizing yourself with the specific configurations and relationships among these elements can significantly improve your maintenance practices. Proper knowledge equips you to make informed decisions about repairs and upgrades, ultimately prolonging the life of your machinery.

Understanding John Deere Mower Decks

Exploring the intricacies of lawn care machinery reveals essential components that play a vital role in maintaining efficiency and performance. These assemblies are crucial for achieving optimal results during landscaping tasks. Familiarity with their construction can greatly enhance user experience and functionality.

Components and Functionality

Every assembly consists of various elements, each contributing to the overall operation. Recognizing how these components interact allows for better maintenance practices and prolonged lifespan of the equipment. Key features include cutting blades, housing, and drive systems, all designed for seamless collaboration.

Maintenance and Care

Regular upkeep is essential to ensure longevity and effectiveness. Routine inspections and timely replacements of worn elements not only enhance performance but also prevent potential breakdowns. Users should prioritize understanding the specific needs of their equipment to achieve the ultimate in care and reliability.

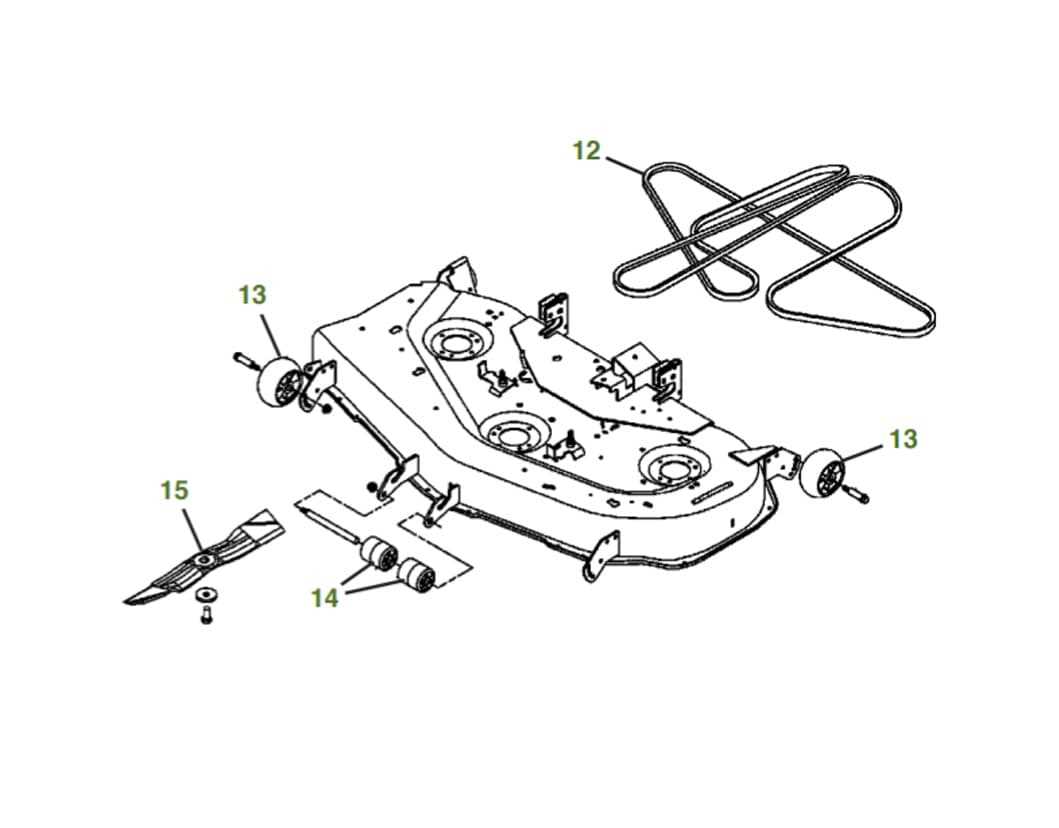

Overview of Mower Deck Components

The efficiency and performance of a cutting apparatus depend on its various elements working harmoniously. Understanding these individual components helps users maintain and troubleshoot effectively, ensuring optimal operation over time.

Key Elements and Their Functions

Each component plays a vital role in the overall functionality. The cutting mechanism is designed to deliver a clean and precise cut, while the housing protects internal parts from debris and damage. Additionally, the drive system facilitates movement, ensuring seamless operation across different terrains.

Maintenance and Care

Regular upkeep of these components is essential for longevity and performance. Cleaning, lubrication, and timely replacement of worn parts can significantly enhance the effectiveness of the entire assembly. Users should familiarize themselves with each element’s role to address any issues that may arise promptly.

Benefits of a 48-Inch Deck

A 48-inch cutting platform offers numerous advantages for maintaining a pristine lawn. Its size strikes a perfect balance, allowing for efficient coverage while still being manageable in tighter spaces. This makes it an ideal choice for both residential and semi-commercial properties.

Efficiency and Maneuverability

The moderate width of this platform enhances maneuverability around obstacles, such as flower beds and trees. This capability ensures that even the most intricate landscapes can be tended to effectively, saving time and effort.

Quality of Cut

The design promotes an even and precise cut, resulting in a healthier lawn. With optimized airflow and blade positioning, the outcome is a consistently well-maintained appearance that enhances curb appeal.

Common Parts for John Deere Decks

When it comes to maintaining lawn care equipment, understanding the various components that contribute to its functionality is essential. Each element plays a vital role in ensuring efficient operation and longevity. Recognizing these key components allows users to perform effective maintenance and replacements when necessary.

Blades are one of the most critical components, responsible for cutting grass efficiently. Keeping them sharp is crucial for achieving a clean cut and promoting healthy lawn growth.

Spindles support the blades and enable their rotation. Regular inspection is necessary to prevent wear and tear that could lead to operational failures.

Belts transmit power from the engine to the rotating components. Ensuring they are in good condition helps maintain optimal performance and prevents breakdowns.

Housing protects the inner mechanisms while providing structural integrity. It is important to check for any damage that could affect the overall performance of the equipment.

Wheels facilitate movement and stability. Proper alignment and condition are vital for maneuverability across various terrains.

By familiarizing oneself with these essential components, users can better care for their equipment, ensuring it remains reliable and effective for years to come.

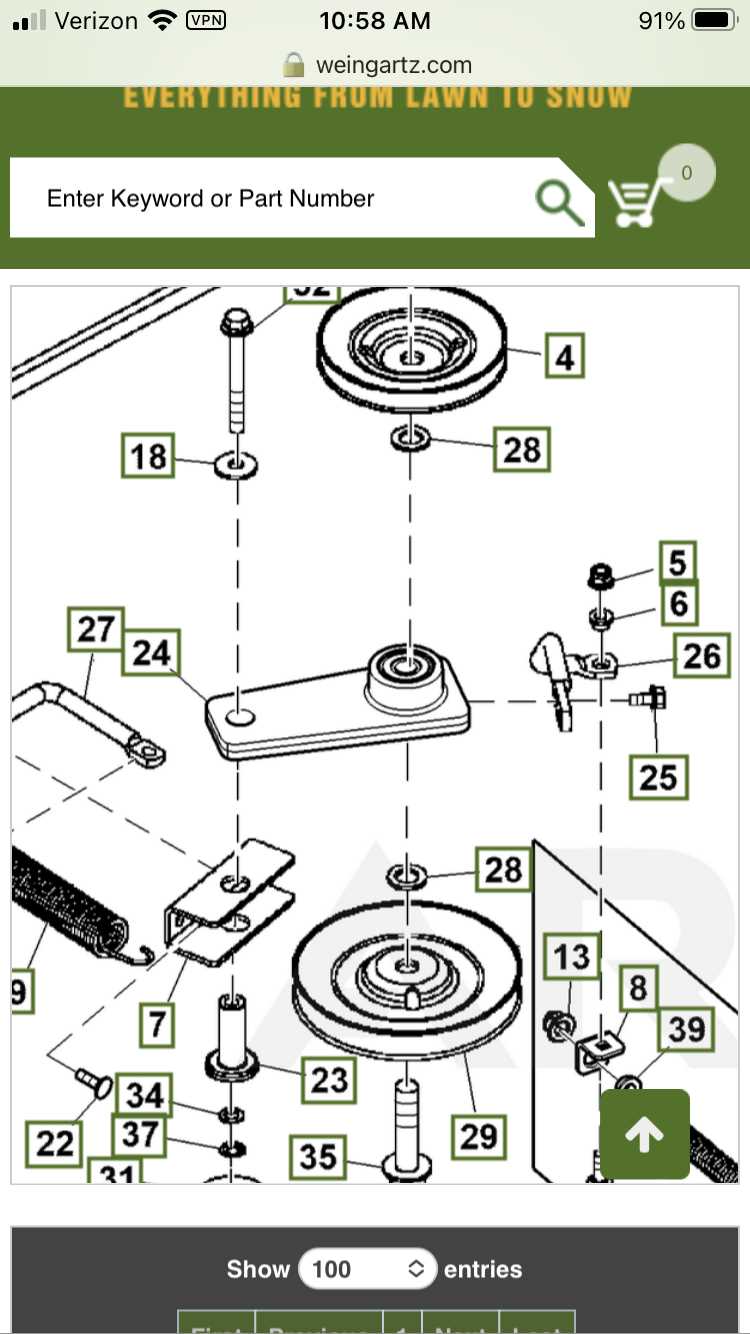

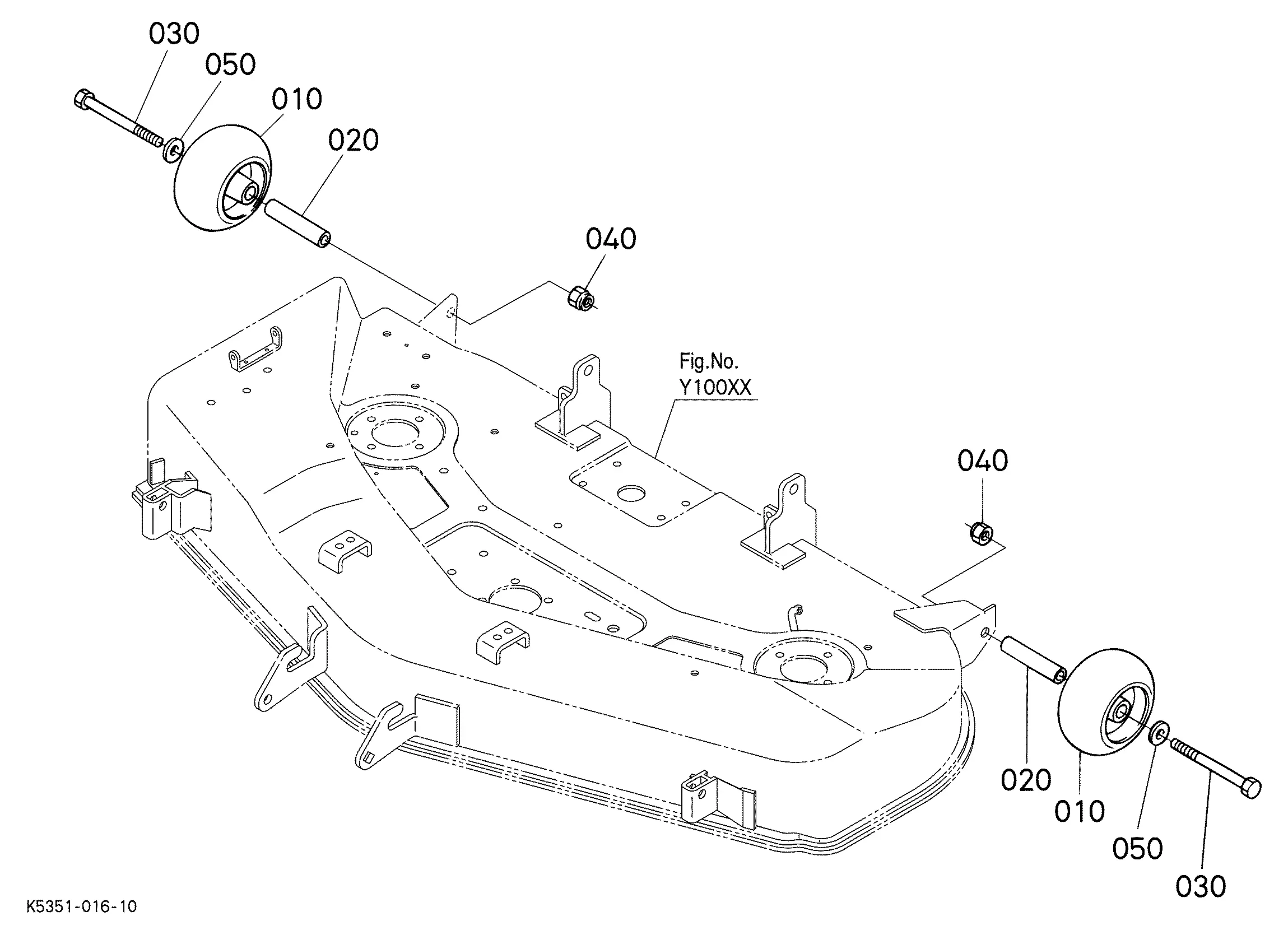

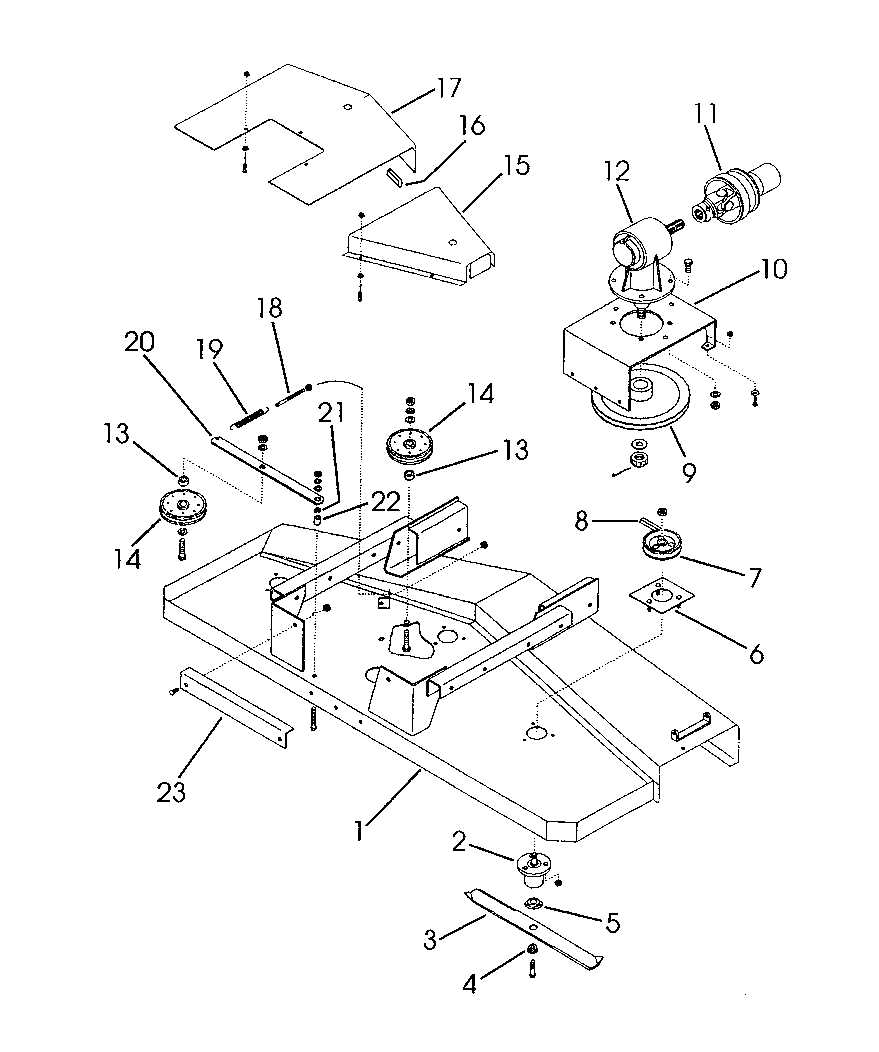

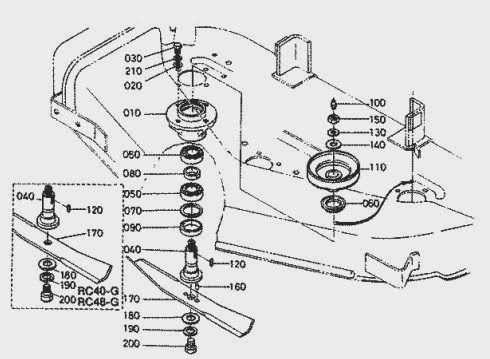

How to Read Parts Diagrams

Understanding mechanical blueprints can significantly simplify the process of maintenance and repairs. These visual guides break down complex assemblies into individual elements, offering a clear perspective on how each component fits and functions within the larger system. By learning to interpret these illustrations, you can efficiently identify necessary replacements and ensure accurate reassembly.

Key Symbols and Layouts

- Exploded views: These show how all components are arranged in relation to one another, often displayed in a spread-out format for clarity.

- Reference numbers: Each element is assigned a unique number corresponding to a list, making identification straightforward.

- Orientation indicators: Diagrams often include arrows or labels that point to critical directions or positions for proper installation.

Best Practices for Interpretation

- Start by familiarizing yourself with the legend or key to understand what each symbol or notation means.

- Follow the flow from the main assembly down to individual pieces, ensuring

Identifying Replacement Parts Easily

To ensure your equipment functions smoothly, it’s crucial to quickly locate and recognize the necessary components for repairs or maintenance. Familiarity with the structure and key elements of your machine helps in identifying potential issues and sourcing the correct pieces for replacement.

Understanding Key Components

One of the best approaches is learning the specific design and arrangement of the core elements. Knowing how different sections are connected and interact can make it easier to spot the right components that need attention or swapping.

Effective Reference Sources

Utilizing manuals and detailed guides, especially those that include diagrams and lists, is essential for identifying what’s needed. These tools provide a clear visual breakdown, helping to ensure you select the correct item for seamless integration into the machine.

Maintenance Tips for Mower Decks

Proper upkeep of your equipment is essential for ensuring smooth performance and extending its lifespan. By following a few key practices, you can avoid common issues and keep your machine running efficiently throughout the season.

Regular Cleaning: One of the most important steps is keeping the underside free from debris. Grass and dirt buildup can affect performance and cause corrosion, so it’s crucial to clean it after each use.

Blade Inspection and Sharpening: Dull blades reduce cutting efficiency and strain the system. Regularly check the condition of the cutting edges and sharpen them when necessary for a cleaner, more precise cut.

Belt and Pulley Maintenance: Check belts for wear and proper tension. If belts or pulleys are loose or damaged, it may result in uneven operation. Replacing worn-out parts promptly will prevent further damage.

Lubrication: Applying lubrication to key areas helps reduce friction and wear on the components, allowing them to move more freely and prolonging their durability.

Finding Genuine John Deere Parts

When it comes to maintaining agricultural equipment, using authentic replacement components is essential for long-term reliability and performance. Identifying the correct items ensures the machinery functions smoothly, avoiding unnecessary wear and breakdowns.

Original components are specifically designed for each machine, ensuring that all moving parts fit perfectly and work together as intended. These items not only maintain the equipment’s efficiency but also extend its lifespan, reducing overall maintenance costs.

To secure the right components, always refer to authorized suppliers and official sources. This guarantees the quality and durability of the replacement items, helping you keep your equipment in peak condition for many years.

Tools Required for Repairs

When conducting maintenance or repairs, having the correct set of instruments is crucial for efficiency and success. Below is a list of essential tools that will ensure a smooth and effective process.

- Wrenches: A variety of wrench sizes will be needed to tackle different bolts and fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers are essential for handling various screws.

- Pliers: Useful for gripping, twisting, or removing pins and other small components.

- Socket Set: A complete socket set ensures flexibility when tightening or loosening different-sized nuts.

- Torque Wrench: This tool is vital for ensuring bolts are tightened to the correct specification.

- Hammer: Ideal for loosening stuck parts or gently tapping components into place.

By assembling these tools, you can confidently proceed with any repair or adjustment, ensuring a well-executed task.

Typical Issues with Mower Decks

Equipment used for grass maintenance often faces a variety of common challenges. These problems can affect the quality of cutting, overall efficiency, and longevity of the tool. Addressing them promptly ensures better performance and reduces the need for frequent repairs.

Belt Wear: One frequent issue involves the belt responsible for driving the blades. Over time, it can become worn, loose, or even break, leading to reduced cutting efficiency. Regular inspection and timely replacement are essential.

Uneven Trimming: Another common problem is uneven cutting, which can be caused by misalignment or damage to certain components. This not only affects the visual appearance of the lawn but can also lead to more extensive issues if left unresolved.

Rust and Corrosion: Exposure to moisture and debris can lead to rusting of metal components. This can weaken the structure and cause operational issues. Regular cleaning and proper storage can prevent corrosion and extend the tool’s lifespan.

Upgrades for Enhanced Performance

Improving the efficiency and longevity of your equipment can be achieved through a variety of upgrades. These enhancements focus on optimizing functionality, durability, and ease of operation, allowing for smoother and more consistent use in diverse conditions.

Here are some key modifications that can significantly boost the overall performance:

- Improved Blades: High-quality cutting blades provide a more precise cut, reducing strain on the machine and enhancing overall efficiency.

- Reinforced Bearings: Stronger, more durable bearings can increase lifespan and reduce maintenance needs, ensuring smoother operation.

- Advanced Drive Systems: Upgrading the drive system can improve maneuverability and power distribution, making it easier to handle challenging terrains.

- Enhanced Spindles: Heavier-duty spindles ensure better blade support, leading to more consistent cutting performance over time.

- Protective Coatings: Applying specialized coatings can protect metal components from rust and wear, extending the lifespan of your machine.

These improvements can significantly elevate the functionality and endurance of your equipment, ensuring a more reliable and efficient performance over the long term.

Where to Purchase Parts Online

When it comes to finding replacement components for your equipment, the internet offers a variety of reliable sources. Whether you need new blades, belts, or other mechanical elements, several online stores provide a wide selection tailored to different machinery models. Exploring these platforms can save time and ensure you get the correct fit for your machine.

Trusted Retailers

Many well-known retailers specialize in agricultural and industrial equipment. These sites often have detailed catalogs, allowing you to search by the model or type of machinery. You can compare prices, availability, and shipping options to find the best deal for your needs.

Specialty Stores

In addition to large retailers, there are smaller, niche shops that focus on specific equipment brands. These stores may offer more personalized customer service and often carry hard-to-find items. It’s a good idea to check customer reviews and verify return policies before making a purchase.

FAQs About Mower Decks

There are many questions people commonly ask when it comes to the maintenance and functionality of cutting platforms used in lawn care. Understanding the essential components and their role in providing a smooth trimming experience is crucial for effective upkeep. Below, we address some frequently asked concerns to help you keep your equipment in top shape.

How often should I clean the cutting platform?

Regular cleaning is recommended to avoid buildup of grass clippings and debris. This not only helps in maintaining efficiency but also prolongs the life of the equipment.

What should I do if the platform gets stuck?

If the trimming system becomes jammed, the first step is to turn off the equipment and inspect for any blockages. Removing these obstructions carefully can restore smooth operation.

When should I replace the blades?

Blades should be replaced when they become dull or damaged, as this affects cutting performance. Sharpening or swapping them ensures a clean cut and reduces strain on the motor.

How can I adjust the height for cutting grass?

Height adjustments are typically done using levers or