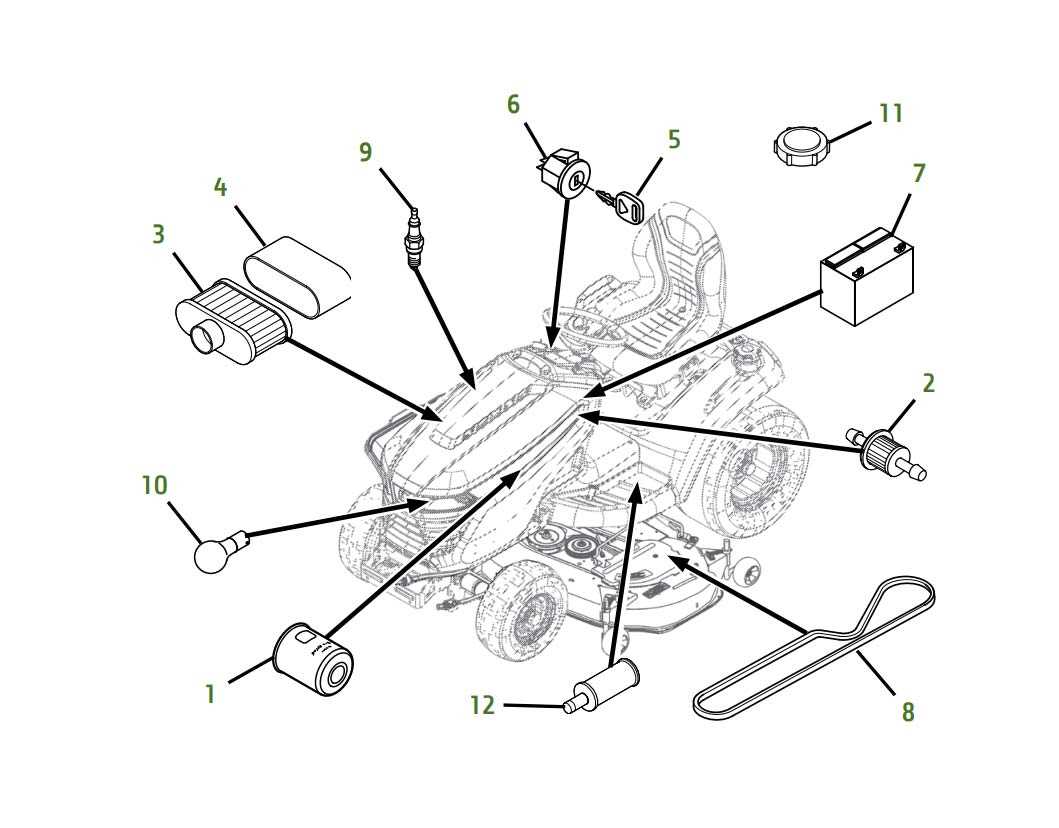

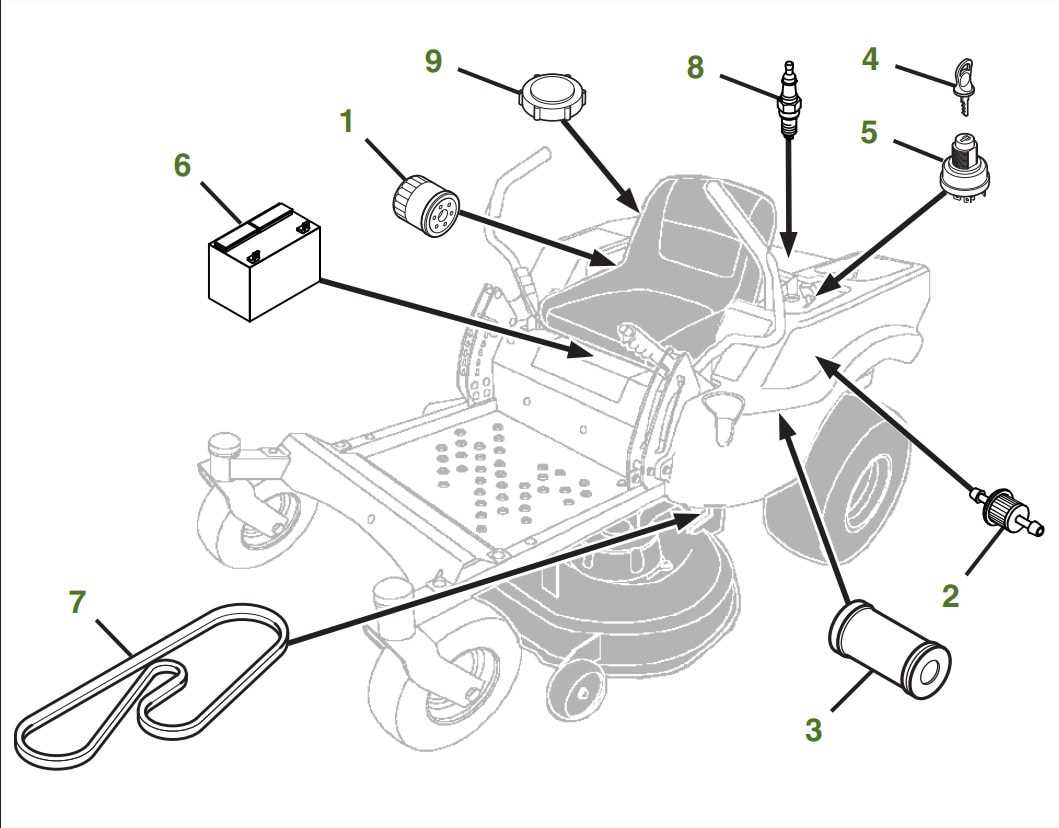

When maintaining a high-performance lawn care machine, it’s essential to have a clear understanding of its intricate mechanical structure. This knowledge helps ensure optimal functionality and longevity. A well-maintained system not only improves cutting efficiency but also reduces the likelihood of breakdowns, keeping operations running smoothly.

One of the key aspects of upkeep is familiarizing yourself with the essential elements and how they work together. By understanding the layout and connections of these elements, it becomes easier to identify any areas that require attention or replacement. Ensuring each component is in proper condition guarantees that the machine performs at its best.

In this guide, we will explore the individual components, their roles, and how they contribute to the overall functionality of the system. Through this, you’ll be better equipped to maintain and repair your equipment, ensuring its longevity and reliability.

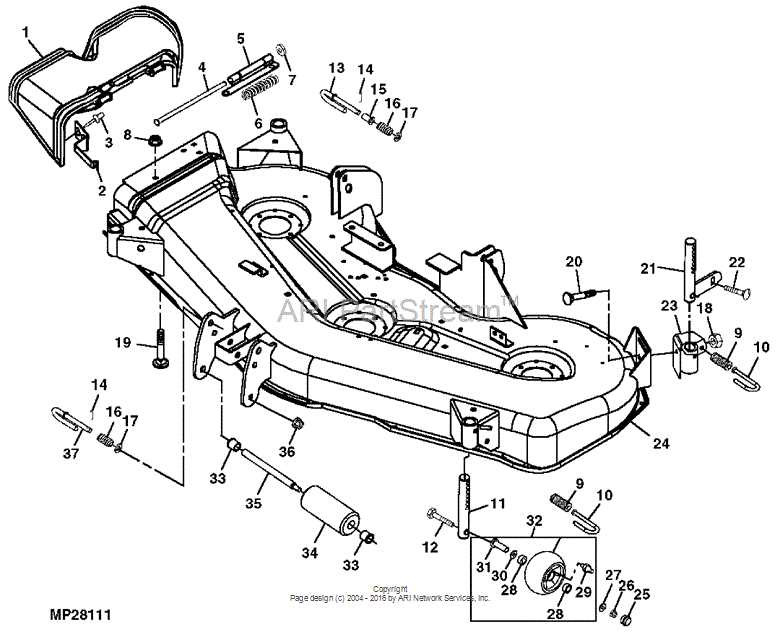

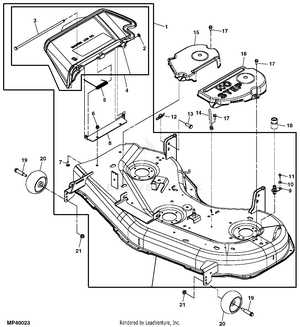

Understanding the 48C Mower Deck Components

Examining the components of a mid-sized lawn cutting system is crucial for ensuring efficient operation and maintenance. Each element plays a specific role, from the mechanism responsible for trimming the grass to the pieces that control movement and distribution. Understanding these parts will help you make informed decisions when it comes to repairs, replacements, or enhancements.

Whether it’s the cutting mechanism, the belt system, or the framework that holds everything together, recognizing how these elements work together ensures a smooth mowing experience. Maintaining awareness of these interconnected systems is essential for proper upkeep and longevity.

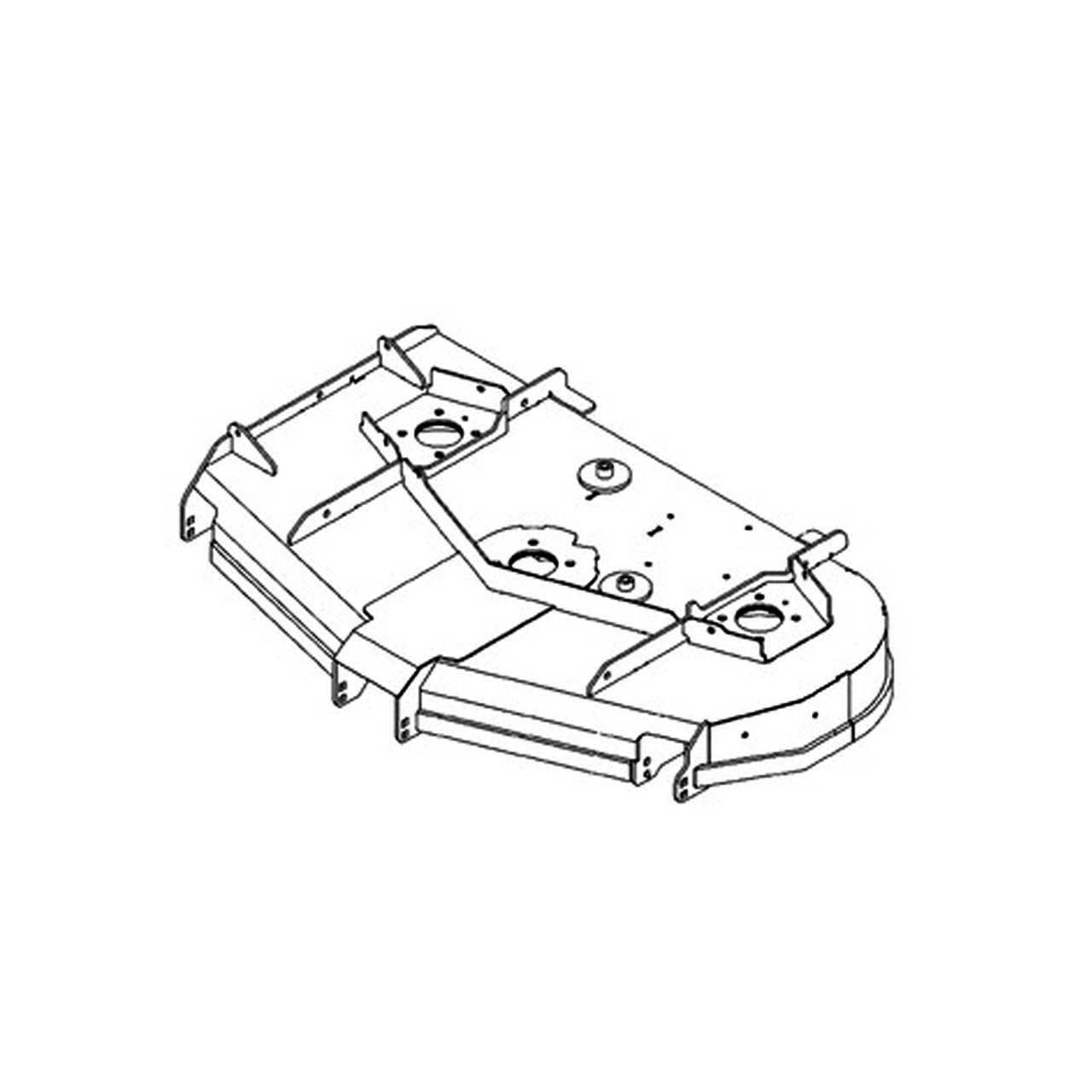

Key Features of the 48C Deck

This component is designed to provide efficiency and durability in demanding environments. It enhances the performance of equipment used for heavy tasks, ensuring reliable operation in various conditions. The structure and design of this system aim to deliver consistent and high-quality results, offering a robust solution for users who need precision and stability during operation.

Durable Construction

The unit is built with sturdy materials, ensuring it withstands frequent use and tough conditions. Its reinforced frame provides added strength, reducing wear and tear over time. This ensures that the equipment remains functional and efficient, even after extended use in challenging environments.

Efficient Cutting Mechanism

Equipped with a cutting system that ensures clean and even results, the design minimizes effort while maximizing output. The integration of multiple cutting blades allows for a smooth and consistent finish, reducing the need for repeated passes over the same area.

| Feature | Benefit |

|---|---|

| Reinforced Frame | Increased durability and longevity |

| Multiple Blades | Enhanced cutting precision and efficiency |

| Optimized Design | Reduced maintenance and smoother operation |

Blade Configuration and Types

The arrangement and variety of cutting blades play a crucial role in achieving optimal performance for lawn care equipment. Understanding the differences between blade configurations allows users to select the most effective type based on the specific conditions of the terrain and the desired results. This section will explore the common setups and blade types to ensure efficient and precise operation.

Blade Configurations

There are several ways blades can be set up on mowing equipment. The configuration often depends on the number of blades and their positioning. Here are the most common configurations:

- Single-blade setup: Typically used for smaller areas and simple cutting tasks, this configuration features one central blade.

- Double-blade setup: More common in larger equipment, two blades work in tandem to cover a wider area and improve cutting efficiency.

- Triple-blade setup: Often found in heavy-duty equipment, three blades offer maximum coverage and precision, especially in uneven terrain.

Blade Types

Blades differ in design based on the type of cut required. The following are some of the most common blade types used in lawn equipment:

- Standard blades: These are general-purpose blades designed for regular trimming and mowing. They provide a clean cut and are suitable for various types of grass.

- Mulching blades: Designed with additional curves, these blades finely chop grass clippings, allowing them to decompose and fertilize the lawn.

- High-lift blades:

Proper Maintenance of Mower Deck

Regular care and attention to your cutting system are essential for ensuring optimal performance and extending its lifespan. By keeping the equipment clean and performing routine checks, you can prevent unnecessary wear and tear, ultimately enhancing the machine’s efficiency and reducing the need for repairs.

Cleaning After Each Use

One of the most important steps in maintaining your cutting equipment is to clean it after every use. Grass clippings and debris tend to accumulate underneath, which can lead to corrosion and reduced cutting effectiveness. A quick rinse or using a scraping tool can help keep the surface clear of blockages.

- Remove accumulated grass and dirt from the underside regularly.

- Ensure proper airflow by keeping vents clear of blockages.

- Dry thoroughly after cleaning to prevent rust.

Regular Inspection and Adjustments

Performing periodic inspections allows you to catch any potential issues before they become bigger problems. Checking for loose components, worn-out blades, and proper belt tension is crucial for smooth operation.

- Inspect the blades for signs of wear and sharpen them as needed.

- Check the belt for signs of fraying or slackness.

- Tighten any loose nuts or bolts to ensure stability.

By adhering to these maintenance practices, you ensure a longer service life and more efficient performance from your equipment.

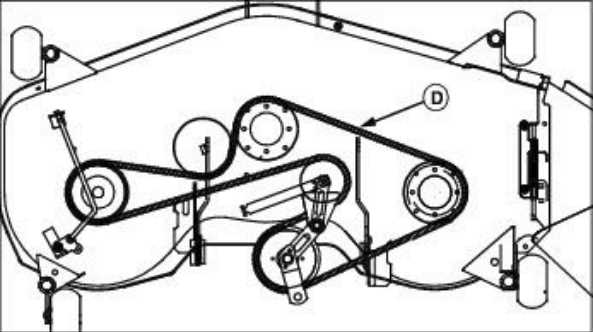

Belt and Pulley Assembly Overview

The belt and pulley system plays a crucial role in ensuring smooth operation and efficient power transmission. This assembly consists of several interconnected components that work together to transfer energy from one part of the machine to another. Understanding how these elements interact can help maintain performance and prolong the life of the equipment.

- Drive Belt: The belt is responsible for transmitting motion between pulleys. It must be properly tensioned to ensure smooth operation.

- Pulleys: These are grooved wheels that guide the belt and provide the rotational force necessary to drive various mechanical parts.

- Tensioner: The tensioner maintains the proper amount of tension on the belt to prevent slippage and ensure consistent performance.

- Idler Pulley: This component helps guide the belt and reduce excess slack, ensuring the belt moves efficiently through the system.

Regular maintenance of the belt and pulley assembly is essential. Keeping the system clean and ensuring that all parts are properly aligned can prevent wear and tear, reducing the need for costly repairs in the future.

Spindle and Hub Components

The spindle and hub assembly plays a crucial role in the functionality of various machinery, contributing to the smooth operation and stability of the equipment. These components are essential for supporting the rotating elements and ensuring proper alignment during use.

Component Description Spindle The central shaft that connects to the rotating parts, allowing for movement and flexibility. Hub The outer component that houses the spindle, providing support and stability. Bearings Facilitate smooth rotation by reducing friction between the spindle and the hub. Seals Prevent dirt and moisture from entering the assembly, ensuring longevity and performance. Deck Cleaning and Upkeep Tips

Maintaining the surface of your outdoor equipment is essential for optimal performance and longevity. Regular cleaning and upkeep not only enhance its appearance but also prevent wear and tear caused by debris buildup. Here are some effective strategies to keep your machinery in top condition.

Regular Inspection

Frequent examinations help identify issues before they escalate. Check for any accumulation of grass, dirt, or other materials that can hinder functionality. Early detection allows for timely cleaning and repairs, ensuring the equipment operates efficiently.

Effective Cleaning Techniques

Utilize appropriate tools and methods for a thorough clean. A gentle wash with a soft brush and mild detergent can effectively remove grime without damaging surfaces. Avoid using high-pressure washers, as they may cause harm to sensitive components. Ensuring the area is dry before storage can prevent rust and other corrosion-related issues.

Common Wear Points on the 48C

The longevity and efficiency of lawn equipment largely depend on the condition of its components. Certain areas tend to experience more wear due to regular use and environmental factors. Recognizing these high-wear zones is crucial for maintenance and ensuring optimal performance.

Frequent Contact Areas

Components that frequently make contact with the ground or grass can show signs of wear over time. These areas often require regular inspection and possible replacement to maintain effectiveness. Blades are a prime example; they can become dull or damaged, impacting cutting performance.

Stress Points

Locations where parts are subjected to significant stress or pressure may also deteriorate more quickly. This includes joints and fasteners, which can loosen or corrode. Regularly checking these critical connections ensures stability and prolongs the lifespan of the equipment. Preventive maintenance in these areas can save time and costs in the long run.

Adjusting Mower Deck Height

Achieving the correct cutting height for your lawn care equipment is essential for maintaining a healthy and visually appealing lawn. Proper adjustment ensures even cutting and helps prevent scalping or leaving untrimmed patches. This section outlines the necessary steps to effectively modify the height settings for optimal performance.

Before making any changes, it is important to familiarize yourself with the adjustment mechanism specific to your model. Most equipment features a lever or dial that allows for easy modifications. To begin, ensure that the mower is on a flat and level surface. This helps provide accurate readings when determining the desired cutting height.

Next, locate the adjustment lever or knob and decide on the preferred height based on the type of grass and seasonal conditions. For example, taller grass may require a higher setting to promote healthy growth, while shorter grass might need a lower cut for a clean finish. Once the height is set, double-check the settings on both sides of the equipment to ensure uniformity. After making the adjustments, take a test run to confirm that the desired results are achieved, making further tweaks as necessary.

How to Replace Deck Parts

Changing components of a lawn care machine is essential for maintaining its performance and longevity. Understanding the steps involved in this process can help ensure a smooth replacement experience, enhancing the efficiency of the equipment.

Before starting the replacement, it is crucial to gather the necessary tools and components. Having everything on hand will streamline the process and minimize downtime.

Step Action 1 Turn off the machine and disconnect the power source for safety. 2 Carefully remove the existing components, taking note of their placement for reassembly. 3 Inspect the area for any debris or damage before installing the new components. 4 Install the new components, ensuring they fit securely and align correctly. 5 Reconnect the power source and test the machine to ensure proper functionality. Following these steps will facilitate a successful replacement of components, ensuring that the machine operates efficiently for its intended tasks.

Diagnosing Issues with Cutting Performance

When a mowing device fails to deliver optimal results, it can be frustrating for the operator. Identifying the root causes of poor cutting performance is essential for restoring functionality. Several factors may contribute to this issue, ranging from blade condition to mechanical alignment.

Here are some common reasons for inadequate cutting results:

- Blade Dullness: Over time, blades can become dull, leading to uneven cuts.

- Improper Height Settings: Incorrect height adjustments can prevent the blades from making effective contact with the grass.

- Clogged Chassis: Debris buildup in the mowing mechanism can obstruct airflow and hinder performance.

- Misalignment: Components that are not correctly aligned can cause uneven cutting paths.

- Worn-out Parts: Age and wear can lead to component failure, affecting overall performance.

To effectively troubleshoot these issues, follow these steps:

- Inspect the blades for sharpness and replace if necessary.

- Check the height settings and adjust according to the manufacturer’s recommendations.

- Clean the chassis thoroughly to remove any accumulated debris.

- Examine the alignment of all mechanical components and make adjustments as needed.

- Assess all moving parts for signs of wear and replace any that are compromised.

By systematically evaluating these aspects, operators can enhance the cutting efficiency of their equipment and achieve a well-manicured lawn.

Safety Measures for Deck Repairs

When undertaking repairs on outdoor machinery components, prioritizing safety is essential to prevent accidents and ensure a smooth process. Adhering to proper protocols helps create a secure working environment and minimizes the risk of injuries.

Before starting any maintenance tasks, it is crucial to disconnect the power source to avoid accidental activation. Additionally, wearing appropriate personal protective equipment, such as gloves and goggles, can safeguard against potential hazards. It is advisable to work in a well-ventilated area, particularly when dealing with tools or materials that may emit fumes.

Furthermore, keeping the workspace organized can reduce the likelihood of slips or falls. Always use the correct tools for each task to prevent strain and ensure efficient repairs. By following these safety measures, individuals can carry out maintenance work effectively and with confidence.