Maintaining optimal performance in your lawn care machinery requires a thorough grasp of its components. Each element plays a vital role in ensuring efficiency and longevity, making familiarity with the layout and function of these mechanisms essential for any operator.

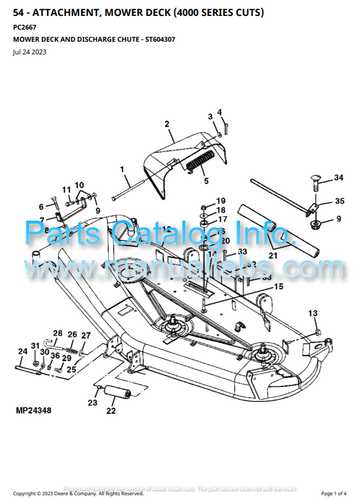

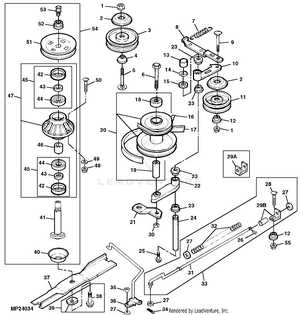

In this section, we will explore a detailed visual representation of essential components associated with a specific cutting system. This knowledge empowers users to identify potential issues and facilitates informed decisions during maintenance and repairs.

By examining the intricate assembly of these parts, you can enhance your understanding and ultimately improve the functionality of your equipment. Gaining insights into the arrangement and interaction of these elements will not only save time but also contribute to a more efficient gardening experience.

Understanding the 54C Mower Deck

This section aims to provide a comprehensive overview of a specific cutting apparatus used in lawn care. By exploring its components and functionality, users can gain valuable insights into maintenance and performance enhancement.

Key Features

The cutting unit in question is designed for efficiency and precision. Its robust construction ensures durability while providing a clean cut. Here are some essential attributes:

| Feature | Description |

|---|---|

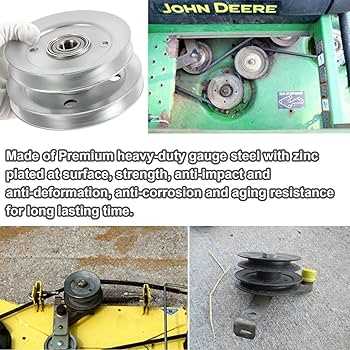

| Material Quality | Made from high-grade steel for longevity. |

| Cutting Width | Generous width allowing for quick mowing sessions. |

| Adjustment Options | Multiple height settings to suit various grass types. |

Maintenance Tips

- Inspect blades for sharpness and replace as necessary.

- Clean the underside to prevent grass buildup.

- Check belts for wear and tear regularly.

Essential Components of the Mower Deck

The effectiveness of a cutting apparatus relies heavily on its critical components, each playing a vital role in ensuring optimal performance and durability. Understanding these elements is crucial for maintenance and troubleshooting.

- Blades: The primary cutting instruments that determine the quality of the trim. Sharp and well-balanced blades are essential for achieving a clean cut.

- Spindles: These support the blades and enable their rotation. Proper functioning is key to maintaining blade speed and efficiency.

- Housing: The outer shell that encases the internal mechanisms. It protects against debris and contributes to the overall stability of the assembly.

- Idler Pulleys: These help maintain tension on the belts, ensuring that power is efficiently transmitted from the engine to the cutting components.

- Belt: A crucial link that transfers power from the motor to the rotating elements, requiring regular checks for wear and tear.

Regular inspection and maintenance of these components can significantly enhance the lifespan and effectiveness of the cutting system, leading to a better overall performance in yard care tasks.

How to Read the Parts Diagram

Understanding an assembly illustration can significantly enhance your ability to maintain and repair your equipment. These visuals provide a comprehensive view of all components involved, allowing you to identify what you need for any service or replacement task.

To effectively interpret the illustration, follow these key steps:

- Familiarize Yourself with Symbols:

- Look for legends that explain various symbols and notations.

- Note any specific markings indicating size, shape, or function.

- Identify Components:

- Scan the illustration to recognize different elements.

- Cross-reference with the provided list of items to understand their roles.

- Understand Assembly Order:

- Pay attention to the sequence of assembly indicated.

- Note any directional arrows that suggest how parts fit together.

- Check for Additional Notes:

- Look for any remarks that may highlight common issues or tips.

- Make use of any troubleshooting advice related to specific components.

By mastering these aspects, you’ll gain the confidence needed to tackle maintenance tasks efficiently and ensure your equipment operates smoothly.

Common Issues with Mower Deck Parts

Understanding the typical challenges faced with cutting equipment components is essential for effective maintenance. These complications can impact performance and longevity, leading to unsatisfactory results and increased repair costs.

Here are some frequent problems encountered:

- Worn Blades: Dull or damaged blades can result in uneven cuts, requiring more frequent replacements.

- Improper Alignment: Misalignment of the cutting assembly can lead to uneven grass trimming and excessive wear.

- Corrosion: Exposure to moisture can cause rust, which compromises the integrity of the metal components.

- Loose Fasteners: Vibration during operation can lead to loose bolts and screws, affecting stability and performance.

- Clogged Chassis: Grass and debris buildup can obstruct flow, reducing efficiency and causing strain on the motor.

Addressing these issues promptly can enhance the functionality and lifespan of the equipment, ensuring a smoother operation and better results.

Replacement Parts Availability and Sources

Access to essential components for maintenance and repairs is crucial for ensuring optimal performance. Various options are available to procure these necessary items, ranging from official manufacturers to third-party suppliers. Understanding where to find quality replacements can significantly enhance the longevity of your equipment.

Official Manufacturers

Purchasing directly from the manufacturer guarantees authenticity and compatibility. They often provide a comprehensive catalog, making it easier to locate specific components needed for repairs. This option may come with a premium price but assures reliability.

Aftermarket Suppliers

Many aftermarket vendors offer a range of compatible alternatives at competitive prices. These suppliers can be a valuable resource for those looking to save on expenses without sacrificing quality. It’s advisable to read reviews and verify the reputation of these sources before making a purchase.

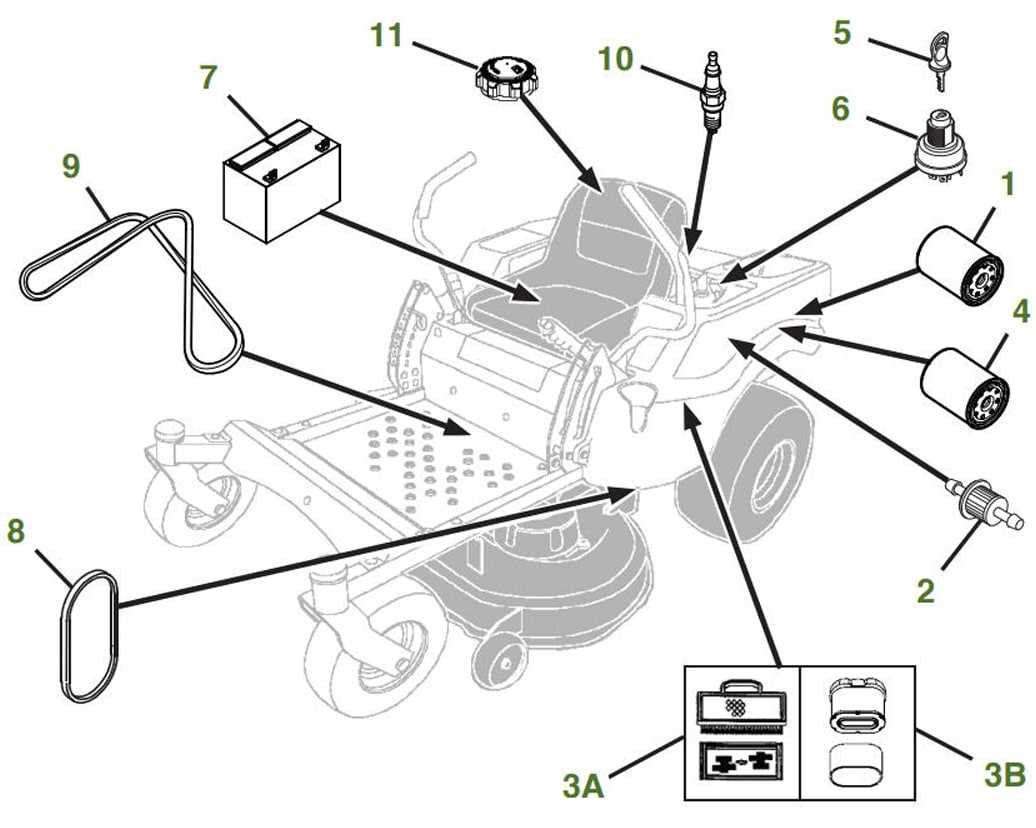

Maintenance Tips for Mower Deck Longevity

Ensuring the durability of your cutting equipment involves consistent care and attention. Regular upkeep not only enhances performance but also extends the lifespan of your machinery, allowing for efficient operation throughout the seasons.

Start with a thorough cleaning after each use to prevent grass build-up and corrosion. Inspect the blades frequently for dullness and damage, sharpening or replacing them as needed. Check all connections and components for wear, ensuring everything is secure and functioning properly.

Lubrication is crucial; apply the appropriate grease to moving parts to minimize friction and wear. Monitor the tension of belts and cables, adjusting them to maintain optimal performance. Lastly, store the equipment in a dry location to protect it from the elements and prolong its usability.

Tools Required for Parts Replacement

When undertaking maintenance or repairs, having the right tools at hand is crucial for efficiency and safety. Each task requires specific instruments that enable precise work, ensuring a seamless process from start to finish.

Essential Instruments

Begin with basic hand tools such as wrenches, screwdrivers, and pliers. These are fundamental for disassembling components and facilitating easy access to the internal mechanisms.

Specialized Equipment

In some cases, more advanced tools may be necessary. Consider acquiring torque wrenches or socket sets for optimal performance. Additionally, protective gear like gloves and goggles is vital to ensure safety while working.

Step-by-Step Assembly Guide

Assembling garden equipment can seem daunting, but with the right approach, it becomes a manageable task. This guide provides clear instructions to help you through each phase of the assembly process, ensuring a smooth and efficient setup.

Step 1: Begin by gathering all necessary components. Verify that you have everything required for assembly, including tools and hardware.

Step 2: Familiarize yourself with the components by referring to the schematic layout. This will help you understand how each piece fits together.

Step 3: Start with the main structure. Align the sections carefully and secure them using the designated fasteners. Ensure everything is tight to maintain stability.

Step 4: Next, attach the auxiliary elements, following the same method. Pay attention to any specific orientation mentioned in the guide.

Step 5: Once all parts are connected, perform a thorough check. Make sure that all connections are secure and that there are no loose pieces.

Step 6: Finally, test the assembled unit to confirm its functionality. Adjust any parts if necessary to achieve optimal performance.

Comparing 54C with Other Models

This section explores the distinctions between the discussed model and its counterparts, highlighting key features, advantages, and suitability for various tasks. By examining these differences, users can make informed decisions on which option best meets their needs.

Key Features

- Blade configuration variations

- Cutting widths and height adjustments

- Weight and stability differences

Suitability for Tasks

- Ideal for residential lawns

- Best for commercial landscaping

- Versatility in varied terrains

Understanding these comparisons allows for a deeper delve into functionality and performance, ensuring optimal selection for specific requirements.

Cost Analysis of Replacement Parts

This section provides an overview of the financial implications involved in acquiring substitute components for garden machinery. Understanding the expenses associated with these elements is crucial for maintaining budgetary control and ensuring optimal functionality.

Factors Influencing Costs

Several variables affect the pricing of replacement items, including brand reputation, material quality, and availability. Premium products often command higher prices due to their durability and performance benefits, while generic options may offer cost savings but could compromise longevity.

Long-term Investment

Investing in quality replacements can lead to significant savings over time. Durable components reduce the frequency of repairs and replacements, ultimately resulting in lower maintenance costs. Evaluating total ownership expenses will help in making informed decisions for future purchases.

Customer Reviews and Recommendations

This section focuses on feedback from users who have experience with the various components related to the equipment in question. Insights from actual customers provide valuable information on performance, durability, and overall satisfaction, helping potential buyers make informed decisions.

Many users highlight the importance of quality and compatibility when selecting components. Reviews often emphasize how well certain pieces function together and the ease of installation. Here’s a summary of key opinions from various customers:

| Feature | Rating | Comments |

|---|---|---|

| Durability | 4.5/5 | Many users report lasting performance even after extensive use. |

| Ease of Installation | 4.7/5 | Most find the setup straightforward with clear instructions. |

| Value for Money | 4.3/5 | Users generally feel satisfied with the cost relative to performance. |

| Customer Support | 4.2/5 | Positive experiences noted with responsive and helpful service teams. |

Overall, recommendations suggest paying attention to detailed specifications and user experiences to ensure optimal performance and satisfaction with purchases.