Understanding the key elements that make up various types of outdoor machinery can be crucial for efficient maintenance and operation. This section aims to offer a detailed look into the essential components, helping you navigate through the intricate structure of your lawn equipment with ease.

By focusing on the assembly and connections within the device, we will guide you through the essential mechanisms that ensure smooth performance. Whether you are performing a routine check or troubleshooting, this information will prove valuable for keeping your machine in top condition.

In the following segments, we will break down the major structural elements and

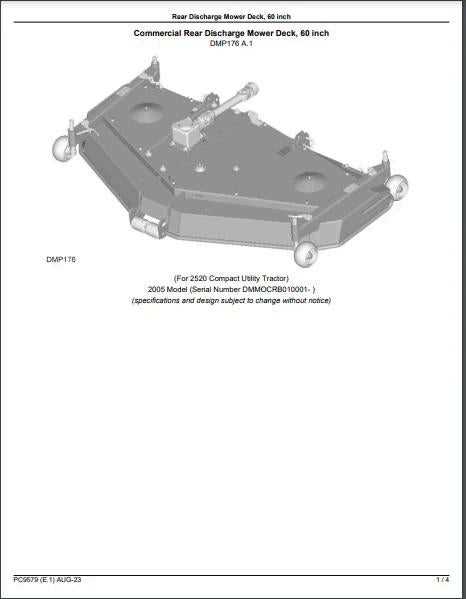

Understanding the John Deere 60 Mower Deck

For efficient lawn care, it’s important to recognize the core elements of a system designed to maintain grassy areas with precision. This specific model offers users a reliable way to handle varying types of terrain while ensuring a consistent cut. By understanding the key structural components and their roles, one can optimize the performance and extend the lifespan of the machinery.

Key Components Overview

The cutting system is built with multiple essential pieces working together. These components ensure that

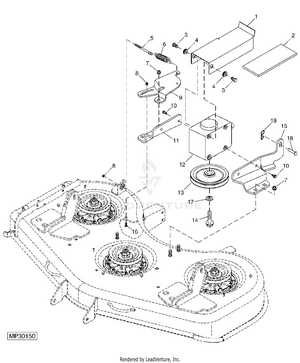

Key Components of the 60 Mower Deck

The system that handles the cutting process of your machine is made up of various essential elements. These parts work together to ensure efficient performance, durability, and precision during operation. Understanding the core components is key to maintaining and enhancing the functionality of your equipment.

Blades and Cutting Mechanism

The sharp, rotating tools are responsible for the primary task of trimming. They are designed to handle different grass types and conditions, ensuring a clean and even finish. The arrangement and sharpness of these cutters directly impact the overall efficiency and quality of the work.

Exploring the Blade System Structure

The design and arrangement of the cutting mechanism play a critical role in the overall efficiency and performance of the equipment. By understanding the composition and function of the blade assembly, one can better maintain and optimize the operation of the entire machine. This section delves into the essential components and their specific roles in the cutting process.

Main Elements of the Blade Assembly

The cutting mechanism is built around a robust system where sharp blades rotate at high speeds to slice through vegetation. These blades are attached to a central hub, which ensures their smooth rotation and balanced operation. The quality of the blades, their alignment, and the maintenance of the hub are key factors in ensuring

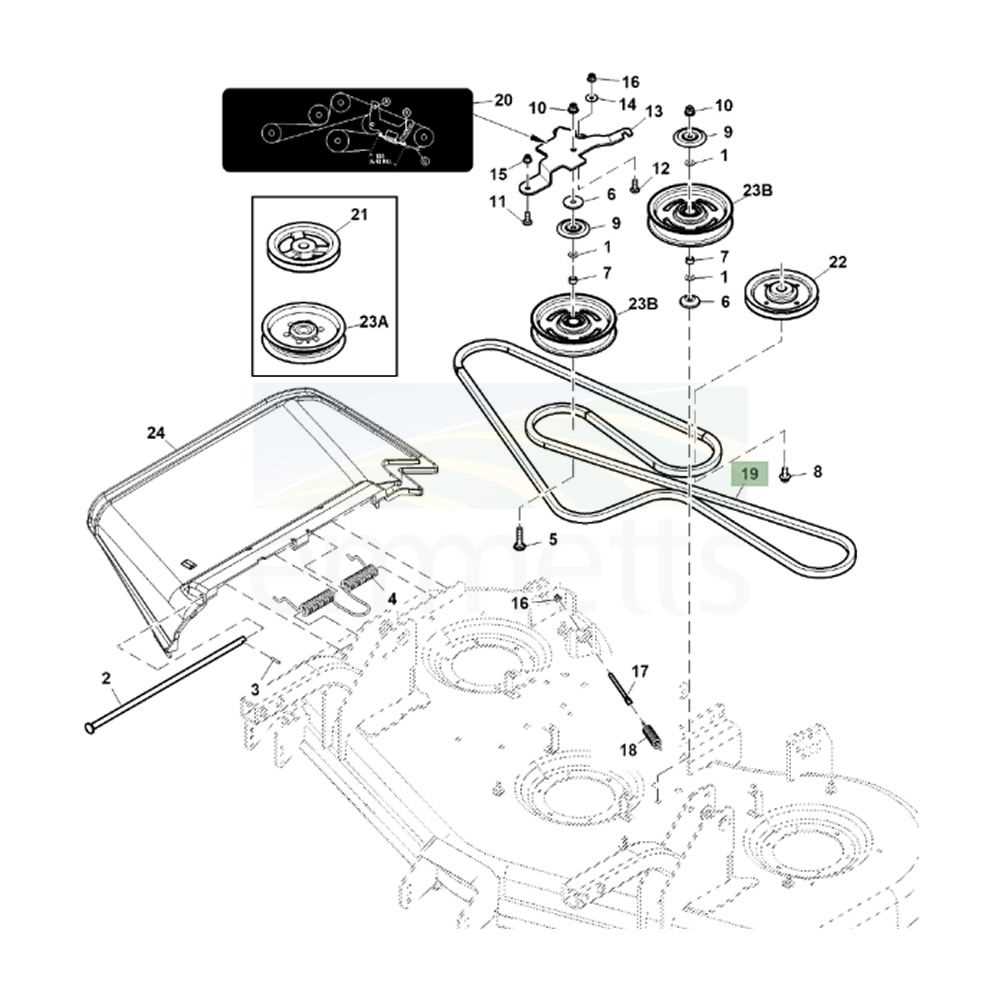

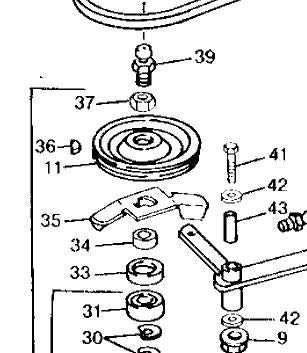

Belt and Pulley Mechanism Overview

The belt and pulley system plays a crucial role in transferring power efficiently between components. This arrangement ensures smooth operation by connecting various rotating parts, allowing them to work together in sync. Understanding how these elements function together helps maintain optimal performance and prolongs the lifespan of the machine.

Belt Structure and Functionality

The belt is designed to handle significant tension while remaining flexible. Its primary function is to connect two or more rotating shafts, ensuring energy transmission from one component to another. Typically made of durable materials, the belt resists wear and provides consistent tension, ensuring continuous operation without slipping.

Pulley Configuration and Purpose

Pulleys are grooved wheels that guide the belt, ensuring it stays aligned and operates smoothly. Different pulley sizes can adjust speed and

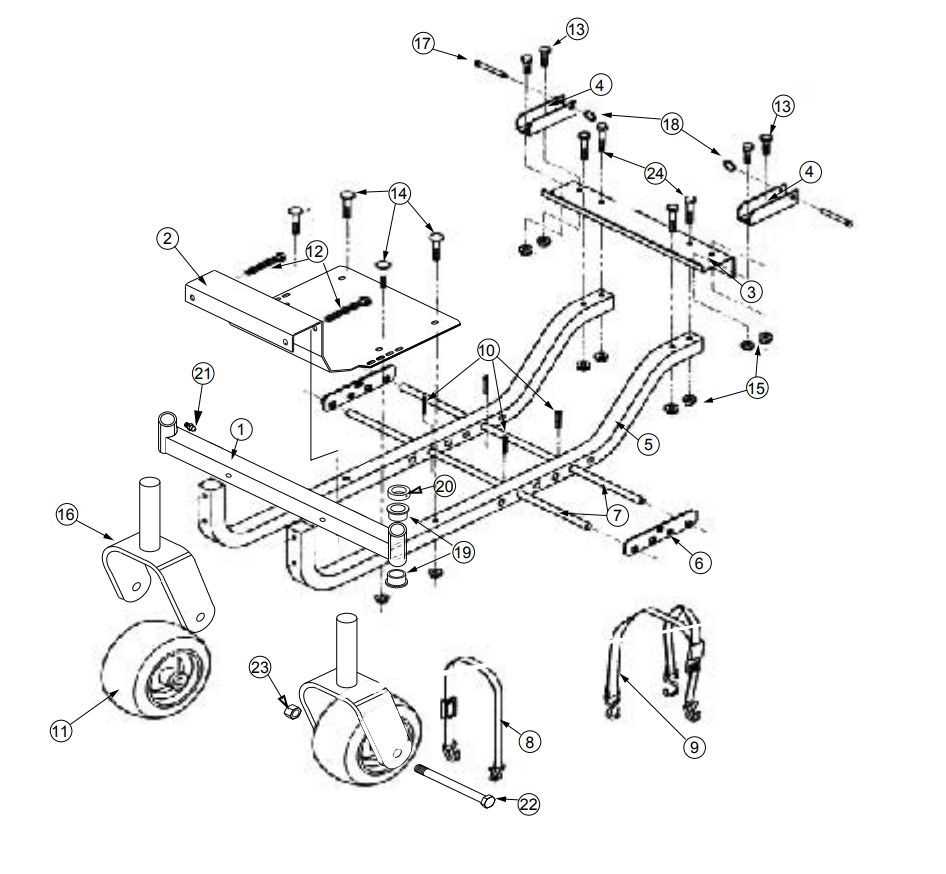

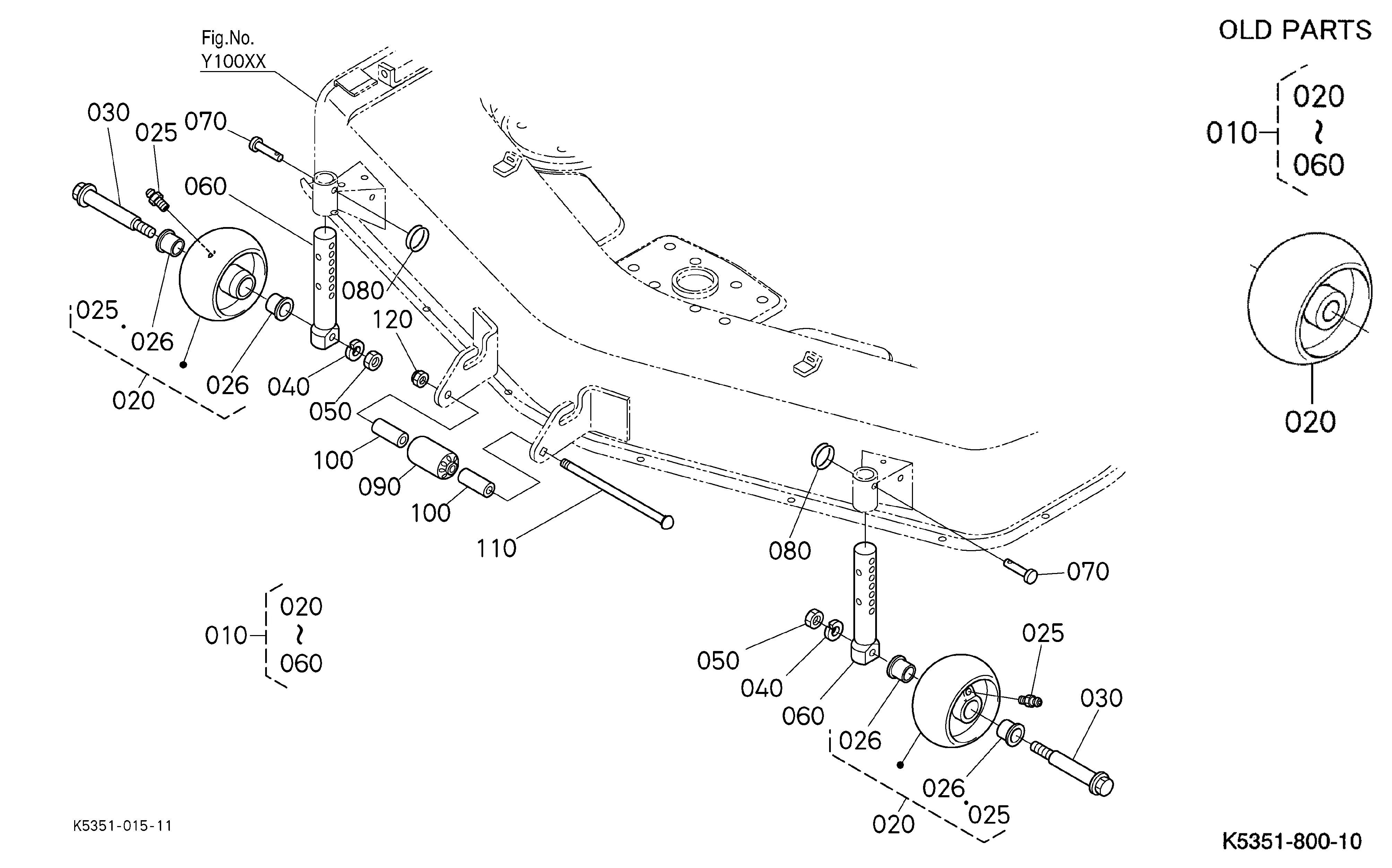

Examining the Spindle Assembly

The spindle assembly plays a crucial role in ensuring smooth and efficient operation of the cutting mechanism. It is responsible for supporting the rotating blades, transferring power from the engine to the cutting edge. By maintaining this essential component, you can achieve precise cuts and extend the overall lifespan of the machinery.

Key Components of the Spindle Assembly

The spindle assembly consists of several interconnected elements that work in harmony to ensure optimal performance. These include the central shaft, bearings, housing, and fasteners. Each part contributes to the structural stability and functionality, with the bearings enabling smooth rotation and reducing friction during use.

Maintaining Optimal Performance

Proper care and timely maintenance of the spindle assembly are necessary to prevent wear and damage. Regular inspection of the bearings, lubrication of moving parts, and

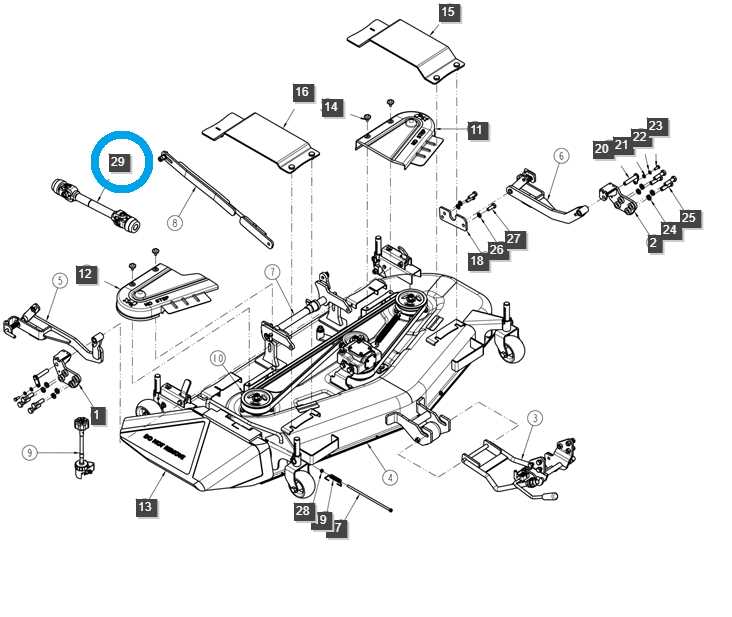

Deck Shell and Frame Construction

The design and assembly of the outer shell and structural framework play a crucial role in the functionality and durability of cutting equipment. These components are engineered to provide stability, reduce vibration, and ensure efficient operation while maintaining a lightweight profile. The materials used in their construction significantly influence the overall performance and longevity of the machinery.

The outer shell is typically crafted from robust metal alloys that resist wear and corrosion, while the frame is constructed to withstand various stresses during operation. A well-designed structure not only enhances the efficiency of the equipment but also facilitates easier maintenance and repair.

| Component | Material | Function |

|---|---|---|

| Outer Shell | Metal Alloy | Protects internal components and provides a smooth cutting surface |

| Support Frame | Steel | Provides structural integrity and stability during operation |

| Mounting Brackets | Aluminum | Facilitates attachment to the main body of the equipment |

Role of Idler Arms in Operation

Idler arms play a crucial role in the functionality of various machinery, ensuring smooth and efficient operation. These components act as stabilizers, maintaining proper tension and alignment of belts or chains within the system. Their design allows for flexibility and adaptability, which is essential for optimal performance.

One of the primary functions of idler arms is to manage belt tension. By adjusting the tightness of the belt, these arms prevent slippage, thereby enhancing power transmission from the engine to the cutting elements. This mechanism is vital for ensuring that the equipment operates at peak efficiency, providing a consistent cutting action.

Additionally, idler arms contribute to the longevity of the entire system. Proper tension and alignment reduce wear and tear on the components, minimizing the need for frequent replacements or repairs. By facilitating smooth operation, they help maintain the integrity of the machinery over time, ensuring reliable performance in various conditions.