In the realm of mechanical assemblies, a comprehensive visual representation of individual elements is crucial for both maintenance and enhancement. Such illustrations serve as essential guides, enabling users to navigate the intricate interplay between various components. This exploration focuses on the interconnectedness of each piece, providing clarity on their roles and functions.

By examining these vital structures, one can delve into the underlying mechanics that drive performance and reliability. The ultimate goal is to empower users with the knowledge needed to troubleshoot and optimize their systems effectively. A clear understanding of how each element interacts can lead to improved efficiency and longevity.

Through detailed visual aids, enthusiasts and professionals alike can gain insights into assembly and disassembly processes. This foundational knowledge not only aids in repairs but also enhances the overall experience with the machinery, fostering a deeper appreciation for its design and functionality.

Understanding RCK60-29B Components

When working with complex machinery, comprehending the individual elements is essential for efficient operation and maintenance. Each component plays a critical role in the overall functionality, contributing to both performance and reliability. This section delves into the specifics of these elements, offering insights into their functions and interactions.

Key Elements and Their Functions

Every assembly consists of various parts that work together to achieve desired outcomes. Here are some of the primary components and their roles:

| Component Name | Function |

|---|---|

| Motor | Powers the entire system, converting electrical energy into mechanical motion. |

| Gearbox | Regulates speed and torque, ensuring optimal performance under varying loads. |

| Control Unit | Manages operations and adjustments, providing feedback for enhanced efficiency. |

| Chassis | Houses all components, providing structural integrity and support. |

Interconnectivity and Importance

Understanding how these elements interconnect is vital for troubleshooting and optimizing performance. Each part not only fulfills its specific task but also influences the effectiveness of others. Regular maintenance and awareness of potential wear can prevent costly breakdowns and extend the lifespan of the machinery.

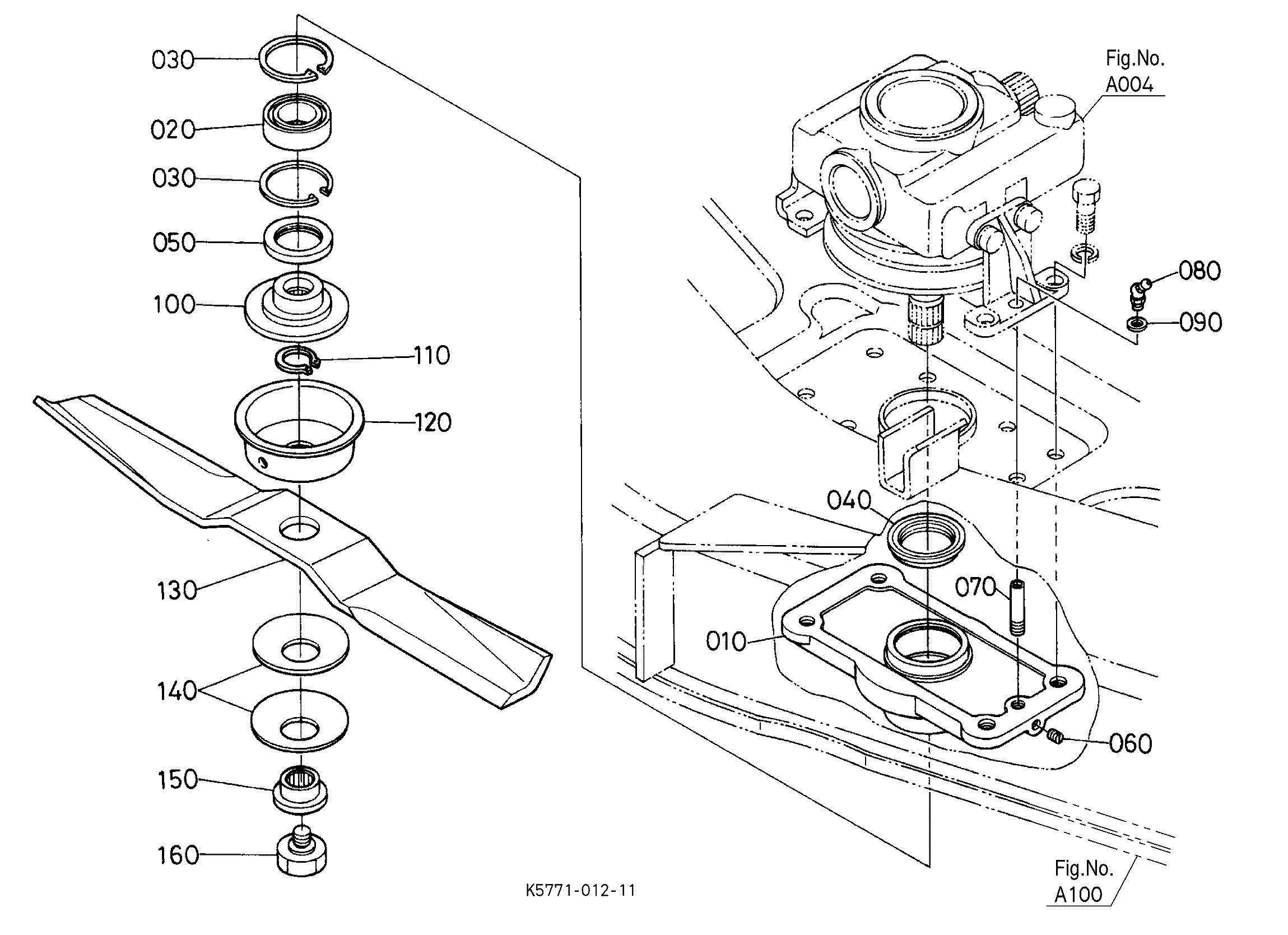

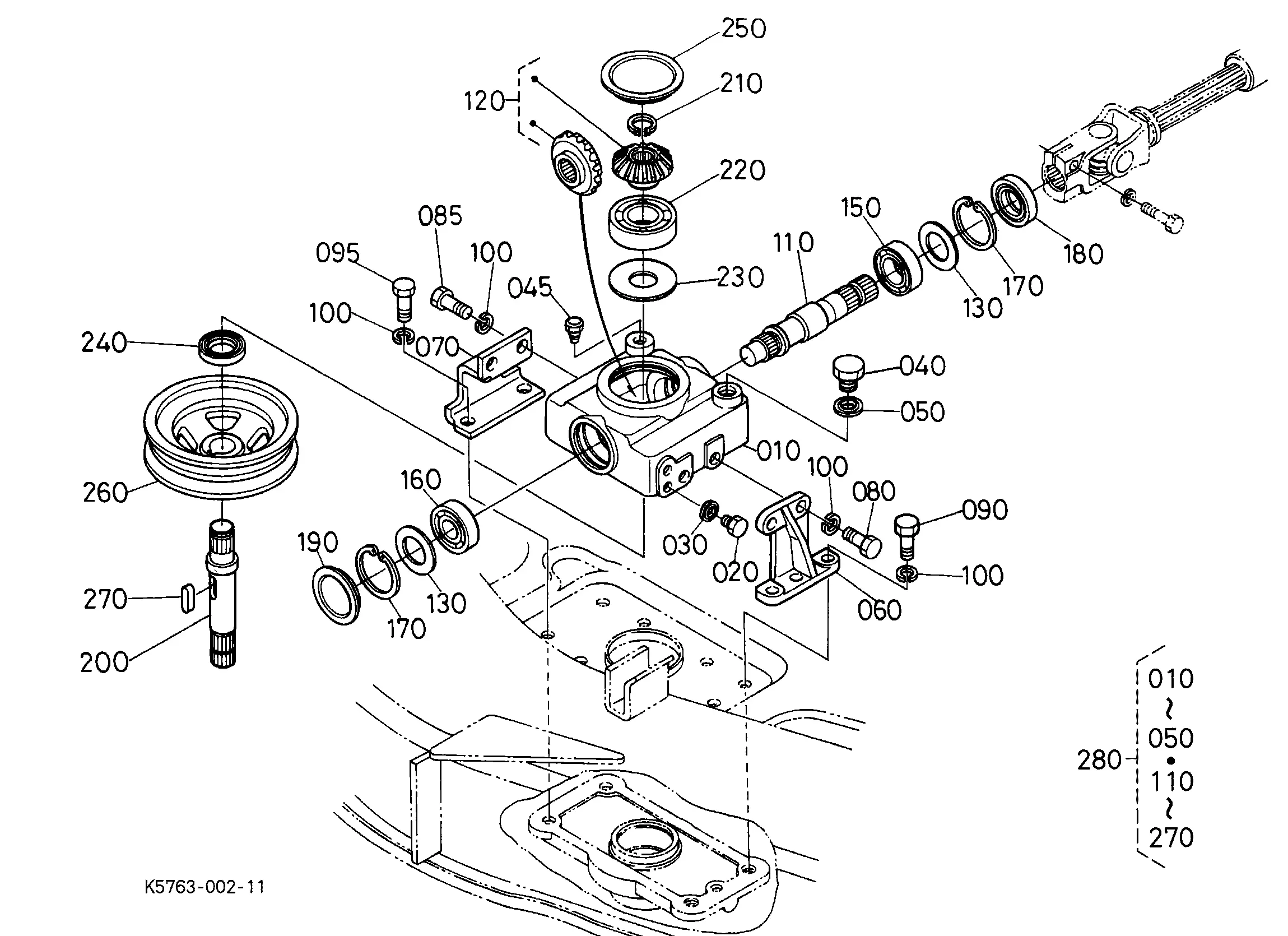

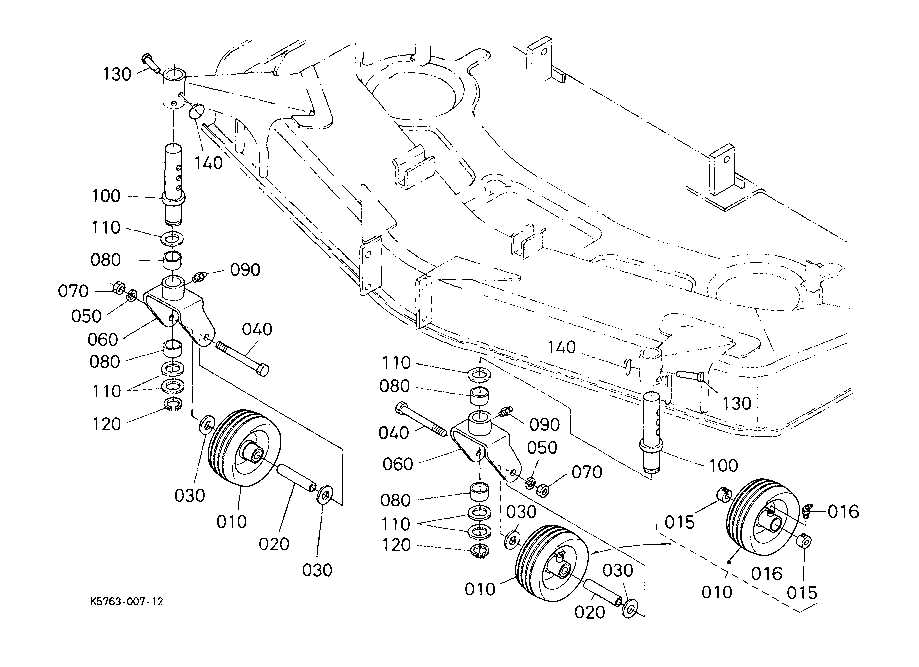

Importance of Parts Diagrams

Understanding the intricate components of a machine is essential for effective maintenance and repair. Visual representations provide a clear overview, enabling users to identify and locate specific elements efficiently. This clarity enhances the troubleshooting process and ensures accurate reassembly.

Facilitating Repairs

When a malfunction occurs, having a visual guide simplifies the diagnosis. Technicians can quickly pinpoint the faulty sections, saving time and minimizing frustration. A well-organized illustration not only aids in finding the right components but also improves overall workflow during repairs.

Enhancing Learning

For individuals learning about machinery, visual aids serve as powerful tools. They facilitate comprehension of complex systems, allowing learners to grasp how different parts interact. This foundational knowledge is crucial for developing expertise in maintenance and operation.

RCK60-29B Overview and Features

This section provides a comprehensive look at a specific model designed for enhanced performance and versatility in various applications. The unit is engineered to meet the demands of users seeking reliability and efficiency.

Key attributes of this model include:

- Robust Construction: Built with high-quality materials for longevity and durability.

- User-Friendly Design: Features intuitive controls that simplify operation.

- Versatile Compatibility: Designed to work seamlessly with various attachments and accessories.

- Enhanced Performance: Engineered to deliver superior results across a range of tasks.

Additional benefits encompass:

- Maintenance-friendly components that facilitate easy upkeep.

- Compact design for convenient storage and transportation.

- Energy-efficient operation, contributing to cost savings.

In summary, this model stands out for its combination of strength, usability, and adaptability, making it an ideal choice for both professional and recreational use.

Identifying Key Parts in Diagrams

Understanding complex visuals is crucial for effective communication and analysis in various fields. Recognizing essential components within these illustrations can significantly enhance comprehension and streamline the troubleshooting process. This involves not only a clear interpretation of the images but also a familiarity with the terminology and the relationships between different elements.

First, it is important to familiarize oneself with the overall layout. Grasping the general structure allows for easier navigation through intricate details. Look for distinct shapes or symbols that indicate specific functions or categories. These identifiers often serve as guides to understanding the entire system.

Second, pay attention to labels and annotations. These descriptors provide vital information that clarifies the role of each part within the larger context. Recognizing common terms can facilitate quicker analysis and aid in pinpointing areas that may require further investigation.

Lastly, practice is essential. Regularly engaging with similar visuals will sharpen your skills in identifying key elements, making the process more intuitive over time. Developing a systematic approach to breaking down these illustrations can significantly improve both efficiency and accuracy in your assessments.

Common Issues with RCK60-29B

Various challenges can arise with the equipment, impacting its overall functionality and performance. Identifying and addressing these problems is essential for maintaining efficiency and ensuring longevity.

Frequent Problems

- Inconsistent cutting height

- Difficulty in maneuvering

- Wear and tear of components

Troubleshooting Tips

- Regularly check for loose connections.

- Inspect and clean the blades frequently.

- Ensure proper lubrication of moving parts.

Maintenance Tips for Longevity

Proper care and routine checks are essential for ensuring the durability and efficiency of your equipment. By adopting effective maintenance practices, you can significantly extend its lifespan and enhance performance, ultimately saving time and costs in the long run.

Regular Inspections

Conduct frequent assessments to identify wear and tear. Pay attention to critical components, checking for any signs of damage or malfunction. Addressing minor issues promptly can prevent major failures and prolong the life of your machinery.

Proper Cleaning

Maintaining cleanliness is vital. Remove debris and buildup regularly to avoid obstructions that can hinder operation. A clean environment helps in reducing the risk of corrosion and enhances overall efficiency, contributing to longevity.

Where to Find Quality Diagrams

Accessing reliable visual aids is crucial for anyone seeking to understand complex machinery or components. Quality representations can significantly enhance comprehension, making it easier to identify parts and their functions effectively. Fortunately, several resources are available to help you locate these invaluable tools.

Online Resources

Many websites specialize in providing detailed visuals and guides. Platforms dedicated to technical manuals often offer comprehensive collections that cater to various models. Additionally, community forums and dedicated online groups can serve as excellent sources for sharing and discussing these illustrations.

Local Libraries and Workshops

Local libraries frequently house technical books and manuals that include high-quality visuals. Moreover, workshops and technical schools may provide access to resources or even allow for hands-on experience with the materials, ensuring a deeper understanding of the subject matter.

Using Diagrams for Troubleshooting

Visual representations are invaluable tools in the problem-solving process, offering clarity and direction when diagnosing issues. They help to simplify complex systems by breaking them down into manageable parts, enabling technicians and users to identify potential faults more efficiently.

Enhancing Understanding

By providing a clear overview of components and their relationships, these illustrations facilitate a deeper comprehension of the entire system. This knowledge is crucial when attempting to pinpoint the source of a malfunction, as it allows one to trace connections and interactions.

Streamlining Repairs

When faced with a malfunction, consulting a visual guide can expedite the repair process. The ability to quickly locate and understand each section enables more effective troubleshooting, leading to faster resolutions and ultimately minimizing downtime.

Parts Replacement Guidelines

When it comes to maintaining machinery, ensuring that each component is functioning optimally is essential for overall performance and longevity. Replacing worn or damaged elements not only improves efficiency but also enhances safety. This section outlines best practices for replacing individual components, ensuring a seamless transition and minimizing downtime.

1. Identify the Component: Before proceeding with any replacement, accurately identify the component that requires attention. This may involve consulting technical documentation or utilizing diagnostic tools to ensure that the right part is targeted.

2. Gather Necessary Tools: Having the correct tools on hand is crucial for a smooth replacement process. Ensure that you are equipped with the right equipment, such as wrenches, screwdrivers, and any specialized tools needed for the specific element.

3. Follow Manufacturer Guidelines: Adhering to the manufacturer’s instructions is vital. These guidelines often provide specific steps for disassembly and reassembly, ensuring that the replacement is performed correctly and safely.

4. Inspect Surrounding Components: During the replacement process, take the opportunity to inspect adjacent components for any signs of wear or damage. This proactive approach can prevent future issues and enhance overall system reliability.

5. Test Functionality: Once the replacement is complete, conduct thorough testing to ensure that the new component operates as intended. This final step is essential for confirming that the issue has been resolved and that the machinery is functioning optimally.

By following these guidelines, you can ensure effective replacements that contribute to the reliability and efficiency of your machinery.

Upgrading RCK60-29B Components

Enhancing the functionality and efficiency of your equipment can lead to improved performance and longevity. This process often involves the thoughtful selection and replacement of various elements that contribute to the overall operation. By investing in better materials and components, you can optimize the machinery’s capabilities and tailor it to meet specific needs.

Choosing Quality Components

When considering upgrades, it is essential to select high-quality alternatives that not only fit perfectly but also offer superior durability. Look for trusted brands and reviews to ensure that the new additions will withstand the demands of regular use. Evaluating specifications and compatibility is crucial to prevent any operational issues.

Installation and Maintenance Tips

Proper installation is vital for maximizing the benefits of any new component. Follow manufacturer guidelines carefully, and consider seeking professional assistance if necessary. Regular maintenance checks can help identify any wear or potential issues early, ensuring that your upgraded system remains in optimal condition for years to come.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components used in various machines, helping users better understand their functionality and maintenance needs. Whether you’re looking for specifics on availability or seeking guidance on compatibility, this guide aims to clarify your concerns.

What should I consider when purchasing components?

When acquiring any component, ensure it meets the specifications of your equipment. Check compatibility, quality, and warranty details. Always verify dimensions and material types to avoid potential issues.

How can I ensure proper installation of components?

Proper installation is crucial for optimal performance. Always refer to the manufacturer’s guidelines, and consider consulting a professional if you’re unsure. Utilizing the right tools and following step-by-step instructions can significantly reduce errors and enhance functionality.

Expert Recommendations for Users

When it comes to optimizing the performance and longevity of your equipment, following expert advice can make a significant difference. By adhering to specific guidelines, users can enhance functionality and reduce the likelihood of issues arising during operation.

- Regular Maintenance: Schedule routine inspections to ensure all components are functioning correctly. This proactive approach can prevent unexpected breakdowns.

- Quality Components: Invest in high-quality replacement elements. This choice can lead to improved efficiency and durability over time.

- Consult Documentation: Refer to the manufacturer’s manual for detailed instructions and recommendations. This resource is invaluable for understanding optimal usage practices.

- Seek Professional Assistance: For complex repairs or unfamiliar tasks, consider consulting a trained technician. Their expertise can save time and resources.

By implementing these strategies, users can ensure their equipment operates smoothly, maintaining high levels of productivity and reliability.

Future of RCK60-29B Parts

The evolution of mechanical components is crucial for enhancing performance and reliability in various applications. As technology advances, innovations in design and manufacturing will play a significant role in shaping the landscape of these essential elements. Understanding the trends and potential developments will help users make informed decisions about upgrades and replacements.

Technological Advancements

One of the most promising areas is the integration of smart technology. Incorporating sensors and IoT capabilities into components can provide real-time data on performance, leading to predictive maintenance and increased efficiency. This shift towards connectivity will not only improve usability but also extend the lifespan of these crucial elements.

Sustainability and Material Innovations

As the industry moves towards greener practices, the use of sustainable materials will become increasingly important. Innovations in composites and recycling technologies are expected to reduce environmental impact while maintaining performance standards. This commitment to sustainability will not only benefit manufacturers but also align with consumer preferences for eco-friendly solutions.

In conclusion, the future of these essential components is bright, driven by technological advancements and a focus on sustainability. Staying ahead of these trends will ensure optimal performance and longevity in various applications.