In any cooling system, efficiency and functionality depend heavily on the proper organization and interaction of various internal elements. These essential components work in harmony to maintain an ideal environment within the system. Knowing the structure and placement of each piece allows for easier maintenance, repairs, and upgrades, ensuring that the device operates at peak performance for years.

By gaining insight into how each element connects and functions, users can quickly identify potential issues and address them before they escalate. A clear understanding of the internal layout not only extends the lifespan of the system but also improves overall user experience, making troubleshooting much more straightforward.

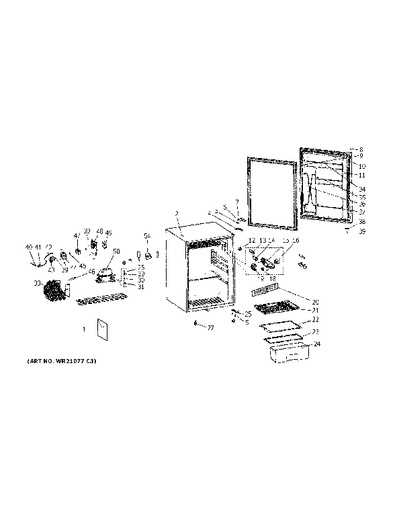

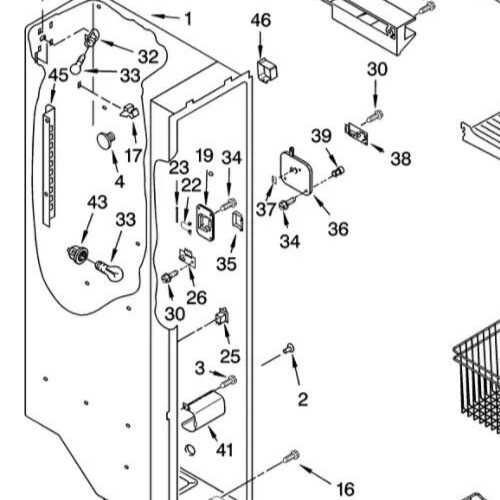

Overview of KitchenAid Fridge Components

Understanding the various elements that make up your cooling appliance is crucial for both maintenance and optimization. The internal structure consists of multiple interconnected systems, each designed to ensure efficient performance. These systems work together to regulate temperature, ensure the circulation of air, and maintain energy efficiency.

Cooling Mechanism: At the heart of the system is the temperature control unit, which monitors and adjusts cooling levels. This section is essential for maintaining optimal conditions for food preservation.

Airflow System: Proper air distribution is key to preventing frost buildup and maintaining consistent temperatures. An intricate ventilation setup ensures even air circulation across compartments.

Storage Zones: Various sections inside provide specific environments for different types of food. These zones allow for organized storage, ensuring that perishables and longer-lasting items are kept at their ideal temperatures.

Electrical Components: The electrical system is responsible for powering the unit’s different functions, including lighting, cooling adjustments, and defrosting cycles. Each component is designed

Understanding the Cooling System

The cooling system is essential for maintaining a consistent low temperature, ensuring that stored items remain fresh. It operates by cycling a refrigerant through various components, absorbing heat from the interior and releasing it outside. This process requires precise control and a coordinated function of different elements, each playing a vital role in achieving optimal efficiency.

Key components work together to remove warm air and maintain the desired environment. The system’s efficiency depends on the balance between these elements, allowing for consistent and reliable performance over time. Understanding how these elements interact helps in diagnosing and addressing potential issues.

Regular maintenance and awareness of the system’s mechanics can prevent malfunctions and ensure smooth operation. Keeping track of its overall condition can extend the life of the cooling unit and improve energy efficiency.

Compressor and Its Role in Refrigeration

The heart of any cooling system is a key mechanical component responsible for managing the circulation of a vital fluid. This element plays a critical role in creating the necessary temperature difference to maintain a cool environment. By transforming the state of the fluid and driving it through the system, it ensures consistent temperature control and efficiency.

The functionality of this unit can be broken down into several key operations:

- Compression: The fluid is pressurized, allowing it to absorb heat more efficiently in later stages.

- Heat release: The pressurized fluid then passes through a heat exchanger, where it releases the absorbed warmth and cools down.

- Cycle continuity: After releasing heat, the fluid returns to its low-pressure state and repeats the process, ensuring a continuous cooling cycle.

This mechanical unit must be in optimal condition to guarantee smooth operation and energy efficiency. Any issues with this part can lead to temperature instability and increased

Exploring the Defrost Mechanism

The defrost mechanism plays a crucial role in ensuring optimal performance by preventing frost accumulation. This system helps maintain efficient operation, reducing energy consumption and ensuring a balanced internal environment. Understanding how it functions can provide insights into the maintenance and longevity of cooling systems.

There are various components involved in this process, each working together to regulate temperature and remove excess ice. Let’s take a closer look at how these elements interact.

- Timer: This device initiates regular defrost cycles, ensuring that the cooling unit stays frost-free over time.

- Heater: During the defrost cycle, the heater activates to melt any accumulated ice, converting it into water that can be drained away.

- Thermostat: Once the ice has been melted, the thermostat monitors the temperature, ensuring that the heater is turned off when no longer needed.

- Drain System: Melted ice is directed to a drain, preventing water buildup and

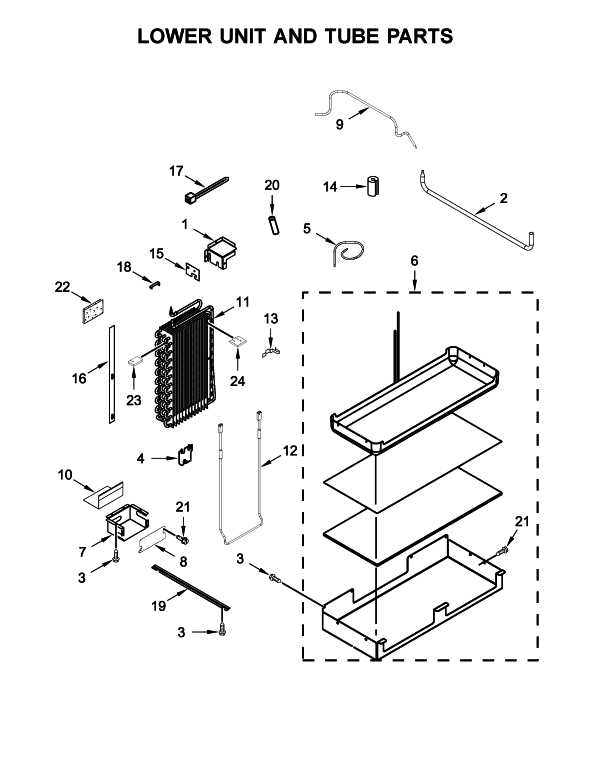

Importance of the Evaporator Fan

The cooling process relies heavily on the efficient circulation of air. One of the key components responsible for this airflow is a specialized device designed to distribute cold air throughout the system. Without this essential part, the internal environment would not be able to maintain the low temperatures required for optimal performance.

This device helps regulate the internal climate by evenly spreading the cold air to every compartment, ensuring that the cooling remains consistent and effective. Proper functionality of this component is crucial for avoiding temperature fluctuations and maintaining efficiency, which ultimately contributes to the system’s longevity.

Water Filter Maintenance and Replacement

Proper upkeep and timely substitution of the filtration system in your appliance are crucial for ensuring the quality of drinking water and ice. Regular attention to this component can enhance its efficiency, prolong its lifespan, and contribute to the overall functionality of the unit.

Importance of Regular Maintenance

Maintaining the filtration system not only improves water taste but also eliminates impurities and contaminants that can affect health. Frequent checks for clogs or leaks can prevent more significant issues and reduce the risk of system failure.

Steps for Replacement

To successfully change the filter, start by locating the filtration system, usually found inside the compartment. Follow the manufacturer’s guidelines for removing the old filter and installing a new one. Ensure that the new component is securely fitted to avoid leaks. After replacement, run water through the new filter for a few minutes to clear any residue.

By adhering to these maintenance practices, you can ensure clean, safe water and improve the efficiency of your appliance.

Ice Maker Assembly and Function

The ice-producing mechanism is a crucial component in any chilling appliance, designed to create and dispense frozen water efficiently. Understanding its assembly and operational principles can enhance the user experience and facilitate maintenance. This section provides insights into the structure and functionality of this essential unit.

Components of the Ice-Making Unit

The ice-making unit consists of several key elements that work in harmony to produce ice. Each component plays a specific role in the process, contributing to the overall efficiency of ice production.

Component Function Ice Mold Forms ice cubes by freezing water in specific shapes. Water Inlet Valve Controls water flow into the ice mold based on the system’s requirements. Heating Element Melts a thin layer of ice to facilitate easy removal from the mold. Auger Moves ice cubes from the mold to the dispensing area. Control Module Regulates the entire ice-making process, ensuring optimal performance. Operational Process

The ice-producing assembly follows a systematic process to create ice. Initially, water is supplied to the mold through the inlet valve. Once the water freezes, the heating element activates briefly to loosen the ice cubes. Subsequently, the auger transfers the ice to the dispensing section, making it available for use. This cycle repeats automatically, ensuring a consistent supply of ice as needed.

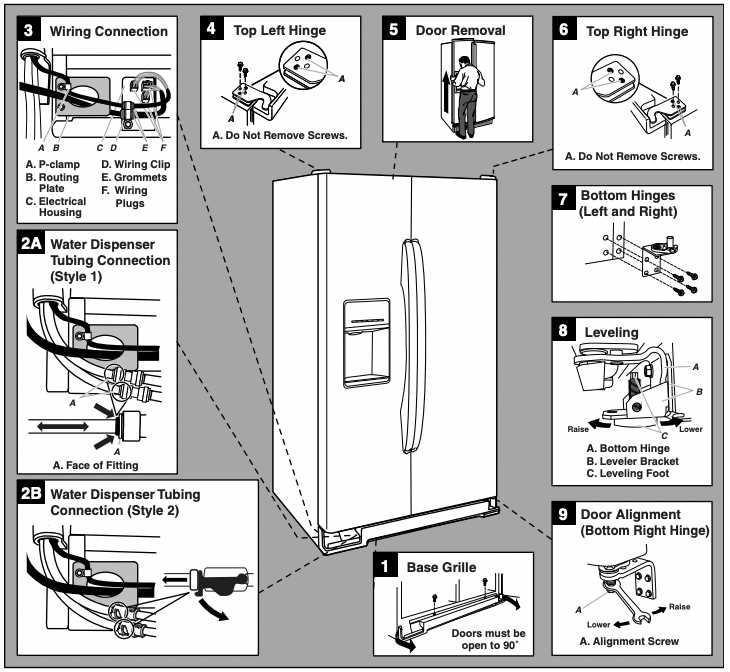

Door Seals and Their Significance

The integrity of a cooling appliance largely depends on its sealing mechanisms. These components are crucial for maintaining optimal temperature and energy efficiency. By ensuring a tight closure, they prevent unwanted air exchange, which can lead to increased energy consumption and fluctuating internal conditions.

Proper sealing plays a vital role in the overall functionality of any cooling unit. When seals are compromised, they can result in condensation and frost build-up, affecting the performance and longevity of the device. Regular inspection and maintenance of these elements are essential to avoid costly repairs and ensure effective operation.

Moreover, the material quality of these seals impacts their durability. Over time, exposure to various temperatures and substances can cause wear and tear, making it necessary to replace them periodically. Investing in high-quality sealing solutions not only enhances efficiency but also contributes to a more sustainable energy footprint.

Shelves and Storage Options

Effective organization is essential in any cooling appliance, allowing for optimal use of space and easy access to food items. Various configurations of shelving and storage compartments can significantly enhance the user experience by accommodating different sizes and types of products. This section explores the diverse shelving solutions and storage possibilities available, emphasizing their functionality and convenience.

Adjustable Shelves

Versatile shelving systems provide flexibility, allowing users to modify the height and arrangement according to their needs. This adaptability is crucial for storing tall bottles or larger containers, ensuring that every inch of space is utilized efficiently. The ability to rearrange shelves also facilitates easier cleaning and maintenance.

Storage Bins and Drawers

Incorporating bins and drawers offers a practical solution for organizing smaller items, such as fruits, vegetables, and dairy products. These compartments can help prevent clutter and keep items visible and accessible. Some designs feature transparent fronts, allowing users to quickly identify contents without opening each compartment.

Temperature Control Panel Explained

The temperature control panel serves as the primary interface for managing the cooling environment within your appliance. It plays a crucial role in maintaining the desired temperatures and ensuring optimal performance. This section provides an overview of its components and functions, highlighting how they work together to regulate the internal climate effectively.

Key Components of the Control Interface

The control interface consists of various elements that allow users to set and adjust the temperature settings. Understanding these components can help users operate their appliance more efficiently. The main features typically include:

Component Function Temperature Display Shows the current internal temperature and allows for adjustments. Temperature Adjustment Buttons Used to increase or decrease the desired temperature settings. Power Button Turns the unit on or off, controlling overall operation. Indicator Lights Provide visual feedback on the status of the appliance, such as power or temperature alerts. Understanding Temperature Settings

Setting the appropriate temperature is essential for food preservation. Most models offer a range of settings tailored to different types of food items. Familiarity with these settings can lead to more effective energy use and better food safety. The ideal temperature range generally falls between 35°F and 38°F for optimal freshness.

Lighting System and Bulb Types

The illumination setup within cooling appliances plays a crucial role in enhancing visibility and accessibility. This section explores the various components and bulb types that contribute to an effective lighting solution, ensuring that users can easily see and retrieve items stored within the unit.

Understanding the different types of bulbs used in these systems is essential for maintenance and replacement. Here are the common bulb types:

- Incandescent Bulbs: Traditional bulbs that provide warm light, typically used for general illumination.

- LED Bulbs: Energy-efficient and long-lasting options that emit bright light while consuming less power.

- CFL Bulbs: Compact fluorescent lamps that are more efficient than incandescent bulbs, offering good light output.

- Halogen Bulbs: A type of incandescent bulb that produces a brighter light and has a longer lifespan.

In addition to the bulb types, the configuration of the lighting system is important. Common features include:

- Interior Lighting: Positioned within the main compartment for optimal visibility of stored items.

- Control Mechanism: Often linked to door sensors, activating illumination when the door is opened.

- Energy Efficiency: Modern systems prioritize low-energy bulbs and smart controls to reduce power consumption.

Regular inspection and timely replacement of bulbs are vital for maintaining a well-functioning illumination system. Users should refer to the manufacturer’s guidelines for specific bulb requirements and compatibility.

Common Issues with the Condenser

The condenser is a vital component in many cooling appliances, responsible for dissipating heat and ensuring efficient operation. Understanding common problems associated with this element can help in diagnosing performance issues and maintaining optimal functionality.

Frequent Problems

- Overheating: A common issue arises when the unit becomes excessively hot. This can lead to reduced efficiency and potential failure.

- Blockage: Dust, dirt, and debris can accumulate on the coils, obstructing airflow and hindering heat exchange.

- Faulty Fan: If the fan fails to operate correctly, it can impair the condenser’s ability to cool down, resulting in higher temperatures.

Symptoms to Watch For

- Increased energy consumption due to the unit working harder to maintain cool temperatures.

- Unusual noises coming from the appliance, indicating possible fan or motor issues.

- Frost buildup on the coils, suggesting improper heat dissipation.

Regular maintenance and inspection can help identify these issues early, ensuring longevity and reliable performance of the cooling system.

Finding the Right Spare Parts

Identifying suitable components for your cooling appliance can often seem daunting. However, understanding how to navigate the selection process is essential for effective maintenance and repairs. With a few key strategies, you can simplify the task of sourcing the right replacements to keep your unit running efficiently.

Begin by familiarizing yourself with the various elements that comprise your appliance. Each segment plays a crucial role in the overall functionality, and knowing their specific functions can guide you in identifying what needs to be replaced. Utilize resources such as user manuals or online guides to gain insights into the structure and common issues associated with each component.

When searching for replacements, consider utilizing reputable suppliers or authorized distributors. This ensures that you acquire genuine and compatible elements that meet the manufacturer’s specifications. Additionally, browsing online marketplaces can provide a wider selection, but always verify the reliability of the seller to avoid counterfeit items.

Finally, maintain a record of model numbers and serial codes when seeking replacements. This information can be invaluable in ensuring compatibility and can save you time and frustration. By following these steps, you can effectively locate and procure the necessary components for your appliance, ensuring its continued performance.