The maintenance and repair of outdoor machinery can often feel overwhelming, especially when it comes to understanding the various elements involved. Having a clear visual representation of these components is essential for both enthusiasts and professionals alike. This guide aims to shed light on the intricate details of a specific lawn maintenance machine, focusing on its essential elements and how they work together.

For those involved in the upkeep of their gardens, knowing the layout and function of each section can significantly streamline the repair process. By familiarizing yourself with the components, you can enhance your machine’s performance and prolong its lifespan. This resource will provide a detailed breakdown, helping you navigate the complexities of machinery maintenance with ease.

Equipped with the right knowledge, users can confidently approach repairs, ensuring that their equipment remains in optimal working condition. Whether you’re tackling a minor fix or preparing for a more extensive service, understanding the layout of these essential parts is the first step toward effective lawn care.

Understanding the F525 Model

This section explores the intricacies of a specific lawn care machine designed for efficiency and performance. It highlights its features, components, and overall functionality, providing valuable insights for users and enthusiasts alike.

| Feature | Description |

|---|---|

| Engine | Powerful and reliable motor for optimal performance. |

| Cutting Width | Designed to provide a broad cutting area for quick mowing. |

| Control System | User-friendly interface for easy operation. |

| Durability | Constructed with high-quality materials for long-lasting use. |

Key Features of John Deere F525

This model stands out for its innovative design and exceptional functionality, making it a popular choice among outdoor equipment enthusiasts. With a blend of power and precision, it caters to a variety of landscaping tasks, ensuring efficiency and ease of use.

Robust Performance

Equipped with a strong engine, this machine delivers reliable performance even in challenging conditions. The powerful motor enhances its ability to tackle tough terrains, making yard maintenance a breeze.

User-Friendly Design

The intuitive controls and ergonomic layout enhance the overall user experience. Operators appreciate the thoughtful design elements that facilitate ease of operation, reducing fatigue during extended use. Additionally, maintenance is simplified, allowing for straightforward upkeep and servicing.

Durability is a hallmark of this equipment, ensuring longevity and dependable service over time. Users can expect a reliable companion for their landscaping needs, combining functionality with a robust construction.

In summary, this model is designed to provide a seamless experience with its powerful capabilities and user-centric features, making it a valuable addition to any outdoor toolkit.

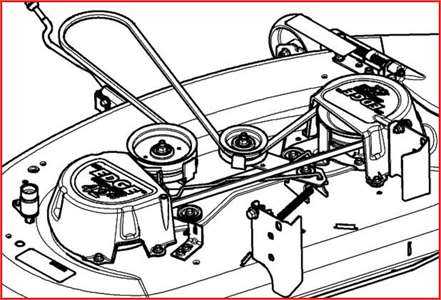

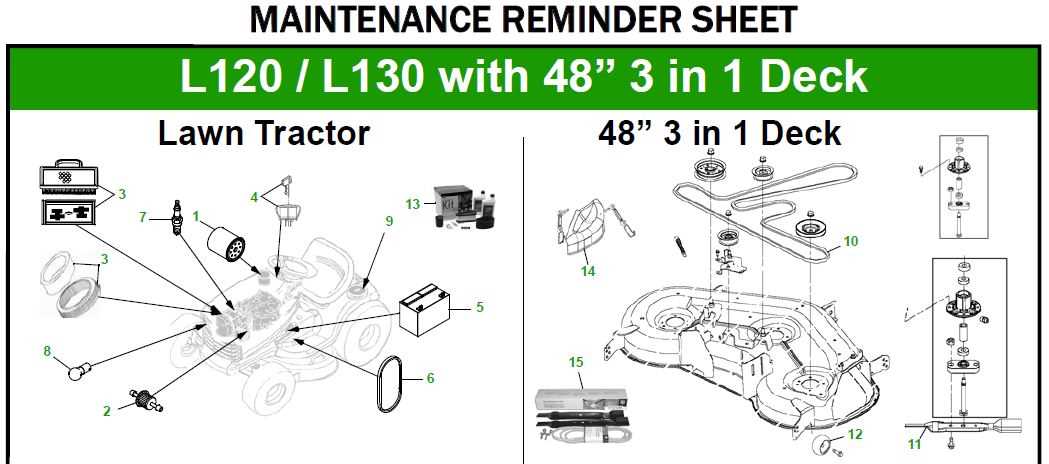

Parts Overview for 48-Inch Deck

This section provides a comprehensive look at the essential components for the 48-inch cutting platform. Understanding these elements is crucial for effective maintenance and optimal performance.

Cutting Blades: The sharpness and quality of the cutting edges are vital for achieving a clean cut. Regular inspections and timely replacements ensure efficiency and longevity.

Spindle Assemblies: These units are responsible for supporting the blades. They must be checked for wear and lubrication to maintain smooth operation.

Belts: These components transfer power to the blades. Over time, they can wear down, leading to decreased performance. Regular checks and replacements are necessary to avoid breakdowns.

Mounting Brackets: These brackets secure the cutting unit to the chassis. Proper alignment and tightness are essential to prevent vibrations and ensure stability during use.

Deck Shell: The outer casing protects internal mechanisms while providing structural support. Inspecting for rust or damage is important for maintaining overall integrity.

Wheels: These facilitate movement and maneuverability. Ensuring they are properly inflated and in good condition contributes to a smoother operation.

By familiarizing oneself with these components, operators can enhance the longevity and functionality of their equipment.

Identifying Essential Components

Understanding the key elements of a lawn care machine is crucial for effective maintenance and operation. Recognizing these components allows users to troubleshoot issues and perform necessary repairs efficiently.

Here are some primary components to focus on:

- Cutting Blade: Vital for achieving a clean cut, this element directly impacts the quality of the lawn.

- Drive Belt: Transfers power from the engine to the cutting mechanism, essential for functionality.

- Spindle Assembly: Supports the blade and allows for smooth rotation, crucial for performance.

- Deck Housing: Protects the internal components and aids in directing grass clippings.

- Height Adjustment System: Enables users to modify the cutting height for varying grass conditions.

Familiarizing yourself with these parts will enhance your ability to maintain the equipment and ensure optimal performance during use.

Maintenance Tips for F525 Deck

Regular upkeep is essential for ensuring optimal performance and longevity of your mowing equipment. By adhering to a few straightforward practices, you can enhance efficiency and avoid costly repairs.

1. Clean After Use: Always remove grass clippings and debris from the underside after each use. This prevents buildup that can affect performance.

2. Check Blade Condition: Inspect the cutting edges frequently. Sharpen or replace them as necessary to maintain a clean cut.

3. Lubricate Moving Parts: Apply lubricant to all moving components to reduce friction and wear. This helps to keep everything running smoothly.

4. Inspect Belts and Cables: Regularly examine belts and cables for signs of wear or damage. Replace any that show significant signs of deterioration.

5. Store Properly: When not in use, store the equipment in a dry place. This helps prevent rust and other weather-related issues.

6. Schedule Professional Servicing: Consider having a professional service the machine periodically to address any underlying issues you might miss.

Implementing these practices will ultimately lead to better performance and a longer lifespan for your mowing equipment.

Common Issues with Deck Parts

Understanding the frequent challenges that can arise with mower components is essential for effective maintenance and operation. Many users encounter similar problems that can hinder performance and efficiency, leading to frustration and costly repairs.

Wear and Tear: One of the most prevalent issues is the gradual deterioration of various components. Over time, exposure to harsh conditions can lead to cracks, rust, and overall degradation, impacting functionality.

Alignment Problems: Improper alignment can cause uneven cutting and increased strain on the machine. Regular checks are necessary to ensure that all components are correctly positioned to avoid excessive wear.

Debris Buildup: Accumulation of grass, leaves, and other debris can obstruct moving parts, leading to overheating and inefficient operation. Routine cleaning is vital to maintain optimal performance.

Fastener Loosening: Vibration during operation can cause bolts and screws to loosen over time. Regular inspections and tightening can prevent potential failures and ensure safety during use.

Inadequate Lubrication: Lack of proper lubrication can lead to friction and premature wear. Using the appropriate oils and greases can significantly extend the lifespan of mechanical components.

By being aware of these common issues, users can take proactive steps to mitigate problems, ensuring smoother operation and longevity of their equipment.

Replacement Parts Availability

When maintaining and repairing outdoor machinery, access to quality components is essential for optimal performance. Ensuring that the necessary items are readily available can significantly impact both the efficiency and longevity of the equipment. Availability can vary based on several factors, including the model and demand in the market.

Sources for obtaining these essential components include authorized dealers, online retailers, and specialized suppliers. Each option presents unique advantages, such as convenience, pricing, and warranty considerations.

Furthermore, understanding the compatibility of components is crucial. Utilizing original or certified replacements can enhance durability and ensure seamless functionality, thereby extending the equipment’s lifespan.

How to Read Parts Diagrams

Understanding component illustrations is essential for effective maintenance and repair tasks. These visual guides provide a detailed overview of individual elements and their relationships, making it easier to identify and source necessary items. By familiarizing yourself with the layout and symbols used in these illustrations, you can streamline your repair processes and ensure optimal performance of your equipment.

Familiarize Yourself with the Layout

Most illustrations follow a standard format that includes a visual representation of the assembly, along with a corresponding list of components. Begin by identifying the main sections of the image. Typically, these are organized in a logical manner, often from top to bottom or left to right. Recognizing the structure allows for quicker navigation through the various elements.

Decode the Symbols and Annotations

Each illustration may feature specific symbols, numbers, or letters that correspond to the item list. Take note of these indicators, as they are crucial for identifying each part accurately. In many cases, additional notes may clarify installation instructions or highlight particular details. Pay close attention to these annotations, as they can prevent costly mistakes during repairs.

Tools Needed for Repairs

When it comes to maintaining outdoor machinery, having the right tools is essential for efficient repairs. Proper equipment not only makes the job easier but also ensures that tasks are completed safely and effectively. Below is a list of essential tools that will assist in carrying out various repair tasks, ensuring that your equipment remains in optimal condition.

Essential Hand Tools

| Tool | Description |

|---|---|

| Socket Set | Used for loosening and tightening bolts, providing versatility in various sizes. |

| Screwdrivers | Essential for handling screws, available in both flathead and Phillips varieties. |

| Wrenches | Available in adjustable and fixed sizes, they are crucial for fastening and loosening nuts. |

| Pliers | Useful for gripping and manipulating components, offering various types for specific tasks. |

Power Tools

| Tool | Description |

|---|---|

| Drill | Facilitates the creation of holes for mounting or assembly purposes. |

| Impact Wrench | Ideal for heavy-duty fastening tasks, delivering high torque with minimal effort. |

| Angle Grinder | Used for cutting, grinding, and polishing various materials, enhancing versatility. |

| Multimeter | Essential for diagnosing electrical issues, measuring voltage, current, and resistance. |

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your equipment can lead to significant benefits in both performance and longevity. By focusing on specific enhancements, users can achieve optimal results and ensure smooth operation during various tasks.

- Engine Tuning: Fine-tuning the engine can improve fuel efficiency and power output.

- Cutting Blades: Upgrading to high-performance blades can enhance cutting quality and reduce wear.

- Transmission Optimization: Modifying the transmission system can increase speed and responsiveness.

- Suspension Enhancements: Improving the suspension system can lead to better stability and comfort during operation.

- Aftermarket Accessories: Investing in specialized accessories can add versatility and functionality to your machine.

By considering these upgrades, users can delve into a world of improved efficiency and ultimately enhance the overall experience of their equipment.