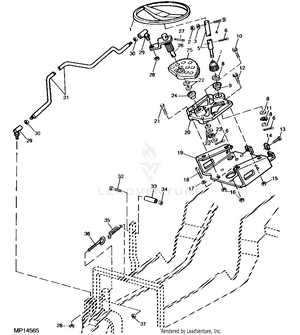

The efficiency of lawn maintenance machinery relies heavily on the intricate network of its various elements. Properly understanding these components can enhance performance and prolong the life of the equipment. This section delves into the essential features and arrangements that make up a specific model of mowing apparatus.

By familiarizing oneself with the layout and functionality of each segment, users can effectively troubleshoot issues and perform necessary maintenance. Moreover, knowledge of these structures assists in making informed decisions regarding upgrades or replacements. Visual aids play a crucial role in simplifying complex configurations, ensuring clarity and ease of reference.

In summary, a comprehensive grasp of these elements not only aids in effective operation but also cultivates a deeper appreciation for the technology behind lawn care solutions. Understanding these connections is key to achieving optimal results.

Understanding John Deere F525 Deck

This section delves into the fundamental components and structure of a specific mowing apparatus, offering insights into its functionality and design. Grasping these elements is essential for effective maintenance and optimal performance.

The essential components can be categorized as follows:

- Cutting Mechanism: The system responsible for grass trimming, often featuring sharp blades for efficient cutting.

- Support Framework: The underlying structure that holds various components in place, ensuring stability and durability.

- Adjustment Features: Mechanisms that allow users to modify the height of the cutting apparatus for varying grass lengths.

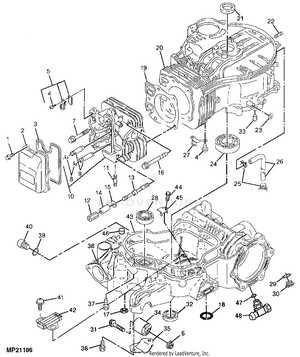

- Drive System: The assembly that transfers power from the engine to the cutting blades, ensuring smooth operation.

Understanding these components not only enhances user experience but also aids in troubleshooting and repairs. Regular maintenance of each element ensures longevity and consistent performance.

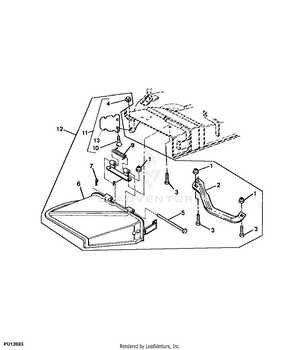

Components of the Mower Deck

The efficiency of a lawn maintenance apparatus relies heavily on its integral components. Understanding these elements allows for improved performance and longevity of the machinery. Each part plays a vital role in ensuring that the unit operates smoothly and effectively, facilitating a well-manicured lawn.

Key Elements of the Mechanism

Among the crucial components are the blades, which are responsible for cutting grass evenly. The housing structure provides stability and protection, while the drive system transfers power from the engine to the blades. Additionally, the attachment mechanism ensures secure connection to the primary machine, allowing for seamless operation.

Maintenance and Upkeep

Regular inspection of these components is essential for optimal functionality. Replacing worn-out blades, checking for debris accumulation, and ensuring all connections are secure contribute to the overall performance. Prioritizing maintenance can extend the life of the equipment and enhance its effectiveness in grass management.

Exploring Replacement Parts Options

When it comes to maintaining and enhancing the functionality of outdoor machinery, understanding the various components available for replacement is crucial. Ensuring that each element is compatible and of high quality can significantly impact performance and longevity.

Types of Components Available

Numerous options exist for replacing worn or damaged components. These include:

- Blades: Essential for effective cutting and should be selected based on durability and sharpness.

- Belts: Vital for power transmission, ensuring smooth operation of moving parts.

- Spindles: Play a critical role in blade rotation, and choosing the right type is necessary for optimal performance.

Finding Quality Alternatives

While original components are often recommended, exploring aftermarket alternatives can also yield satisfactory results. These options may provide similar performance at a lower cost. However, it is essential to verify compatibility and read reviews to ensure reliability.

Maintenance Tips for Lawn Equipment

Proper upkeep of lawn machinery is essential for ensuring longevity and optimal performance. Regular care can prevent breakdowns and enhance efficiency, ultimately saving time and money.

1. Clean After Use: Always remove grass clippings and debris from the machine after each use. This prevents rust and buildup, contributing to smoother operation.

2. Check Fluids: Regularly inspect oil and fuel levels. Keeping these at appropriate levels ensures the engine runs smoothly and prevents damage.

3. Sharpen Blades: Dull blades can cause uneven cuts and stress the engine. Sharpening blades regularly enhances performance and promotes healthy grass growth.

4. Inspect Belts and Cables: Regularly check for wear and tear on belts and cables. Replacing worn components can prevent unexpected failures and ensure reliable operation.

5. Store Properly: When not in use, store equipment in a dry, sheltered area. This protects against weather damage and prolongs the life of the machinery.

Common Issues with Mower Decks

When it comes to maintaining lawn care equipment, several challenges may arise that can affect performance and efficiency. These problems can stem from a variety of sources, including wear and tear, improper alignment, or inadequate maintenance practices. Addressing these issues promptly can prolong the life of the machinery and ensure a cleaner cut.

Wear and Tear of Components

One of the most frequent concerns involves the deterioration of essential elements over time. Blades may become dull or damaged, leading to uneven cutting and increased strain on the engine. Regular inspections and timely replacements can mitigate this issue and improve overall functionality.

Alignment and Stability Problems

Misalignment can also pose significant challenges for lawn care machines. If the equipment is not properly balanced, it can result in uneven mowing and excessive vibration. Ensuring that all components are correctly positioned and secured can help maintain stability during operation.

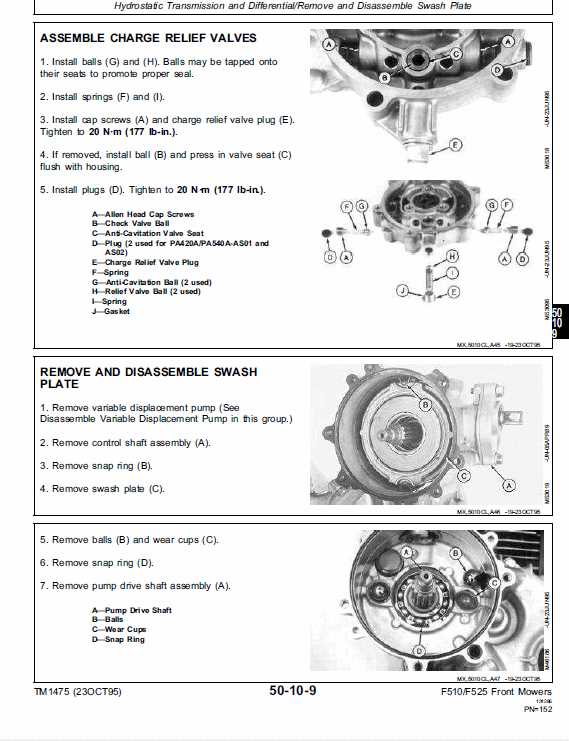

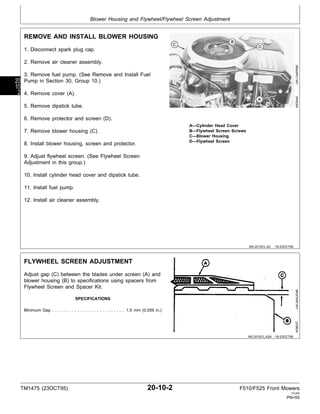

Step-by-Step Assembly Guide

Assembling your equipment can seem daunting, but with a clear plan, the process becomes straightforward. This guide will provide you with an organized approach to ensure each component is correctly fitted for optimal performance.

Essential Components

Before starting, gather all necessary elements. Familiarizing yourself with each item will streamline the assembly process and help prevent any errors.

| Component Name | Quantity |

|---|---|

| Housing | 1 |

| Support Bracket | 2 |

| Blades | 3 |

| Bolts | 6 |

Assembly Steps

Begin by attaching the support brackets to the housing using the provided bolts. Ensure that each bolt is securely fastened. Next, position the blades in their designated slots and confirm they are aligned correctly. Finally, double-check all connections to guarantee stability before operation.

Identifying Worn Out Parts

Recognizing the signs of deterioration in mechanical components is crucial for maintaining optimal performance. Over time, elements within the machinery can exhibit wear that affects functionality. Regular inspection helps in detecting these issues early, preventing further damage and ensuring longevity.

Common Indicators of Wear

Several symptoms can signal that components may be losing their effectiveness. Look for the following:

- Excessive vibration: Unusual movements can indicate imbalance or degradation.

- Unusual noises: Grinding or squeaking sounds often point to problems.

- Physical damage: Cracks or breaks in any element are clear signs of wear.

Importance of Timely Replacement

Addressing worn components promptly can save time and resources in the long run. By replacing ineffective elements, one can restore functionality and enhance the overall efficiency of the machine. Regular maintenance checks are essential for identifying these issues before they escalate.

Tools Needed for Repairs

Proper maintenance and restoration of outdoor machinery require a set of essential tools. Having the right equipment ensures efficiency and effectiveness in addressing various issues that may arise during repairs. Familiarity with these instruments can significantly ease the process and enhance the overall outcome of the maintenance task.

Essential Hand Tools

Among the most important tools are hand-operated instruments that assist in disassembly and reassembly. Commonly utilized tools include wrenches, screwdrivers, and pliers, which are vital for manipulating fasteners and components.

Power Tools for Efficiency

For more intensive repairs, power tools can save time and reduce manual effort. Drills, impact drivers, and grinders are examples of equipment that can make challenging tasks more manageable.

| Tool Type | Purpose |

|---|---|

| Wrench | Loosening and tightening nuts and bolts |

| Screwdriver | Fastening screws |

| Pliers | Gripping and bending materials |

| Drill | Creating holes and driving screws |

| Impact Driver | Driving screws with high torque |

| Grinder | Shaping and smoothing surfaces |

Comparing Aftermarket vs. OEM Parts

When it comes to selecting components for machinery, two primary options emerge: original equipment manufacturer (OEM) and aftermarket alternatives. Each choice carries its own set of advantages and disadvantages, impacting performance, durability, and cost.

OEM parts are crafted by the original manufacturer, ensuring a precise fit and adherence to the machine’s specifications. These components typically offer reliability, longevity, and often come with a warranty. However, they may come at a higher price point.

On the other hand, aftermarket alternatives are produced by third-party companies. While they can be more affordable, the quality can vary significantly. Some aftermarket options match or exceed OEM standards, providing excellent value. Yet, buyers must research thoroughly to avoid subpar products. Ultimately, the choice depends on budget, preference for quality, and specific operational needs.

Safety Precautions When Repairing

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Familiarizing yourself with proper practices not only protects the individual working on the machinery but also extends the longevity of the equipment. Adhering to specific guidelines can create a safer working environment.

Wear Appropriate Safety Gear

Always use protective equipment such as gloves, goggles, and steel-toed boots. These items safeguard against potential hazards like sharp edges and flying debris. Proper attire minimizes the risk of injury while performing repairs.

Disconnect Power Sources

Before initiating any maintenance, ensure that all power sources are disconnected. This step prevents accidental starts, which could lead to serious injuries. Taking this precaution is essential for safe handling during repairs.

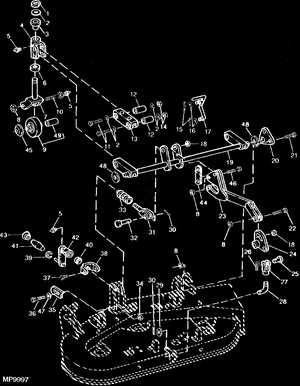

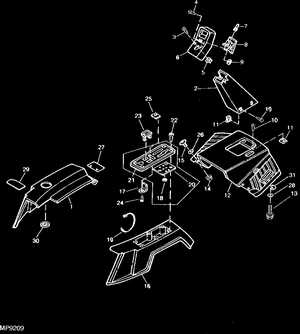

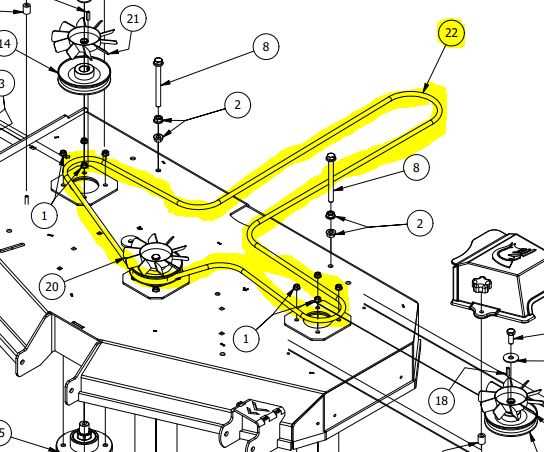

Diagram Overview of Deck Parts

This section presents a comprehensive illustration that highlights the various components essential for efficient operation. Understanding each element’s role can significantly enhance maintenance and repair processes.

| Component | Description |

|---|---|

| Housing | The outer casing that protects internal mechanisms. |

| Blades | Sharp elements responsible for cutting grass and vegetation. |

| Spindle | The rotating shaft that drives the blades. |

| Suspension | The system that supports and stabilizes the assembly. |

Customer Reviews on Deck Components

This section highlights the feedback from users regarding the various elements associated with the mowing apparatus. Insights gathered from consumer experiences can provide valuable information on the functionality and durability of these components.

Overall Satisfaction

Many users express a high level of contentment with the quality of the components, noting their efficiency in maintaining optimal performance. Customers often emphasize how reliable and robust these elements are, making maintenance tasks easier.

Common Concerns

While satisfaction is prevalent, some reviews mention occasional issues with specific components. Users frequently discuss the need for replacements or improvements, particularly in terms of fit and longevity under strenuous conditions.

| Component | Rating | Feedback Summary |

|---|---|---|

| Blade Assembly | 4.5/5 | Sharpness and durability praised; some report wear over time. |

| Spindle Housing | 4.0/5 | Sturdy construction; a few noted issues with installation. |

| Belts | 3.8/5 | Good performance; concerns about lifespan under heavy use. |