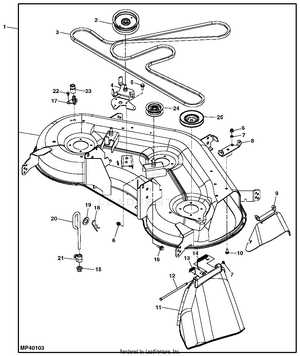

The maintenance and repair of outdoor machinery are essential for ensuring optimal performance and longevity. A clear understanding of various components and their arrangements is crucial for both enthusiasts and professionals alike. This section delves into the intricate layout of essential elements, providing insights that facilitate effective upkeep and troubleshooting.

With a focus on a popular model, this guide aims to present a detailed overview of its structural components. By breaking down the assembly into manageable segments, users can easily identify parts, understand their functions, and address any potential issues that may arise during operation.

Whether you are a seasoned expert or a novice, grasping the configuration of these elements enhances your ability to maintain your machinery efficiently. This exploration not only aids in repairs but also promotes a deeper appreciation for the engineering behind these powerful tools.

Understanding John Deere L130 Components

This section explores the essential elements that contribute to the functionality and efficiency of a specific lawn care machine. Each component plays a vital role, ensuring optimal performance and durability while navigating various terrains.

Key Elements

The machine comprises several critical parts, including the cutting mechanism, which ensures a precise and clean finish. Additionally, the propulsion system is designed for smooth operation, allowing users to maneuver effortlessly across different landscapes.

Maintenance and Care

Regular upkeep of these components is crucial for maintaining performance. Understanding the specific functions and interrelationships of each element can significantly enhance the machine’s longevity and efficiency.

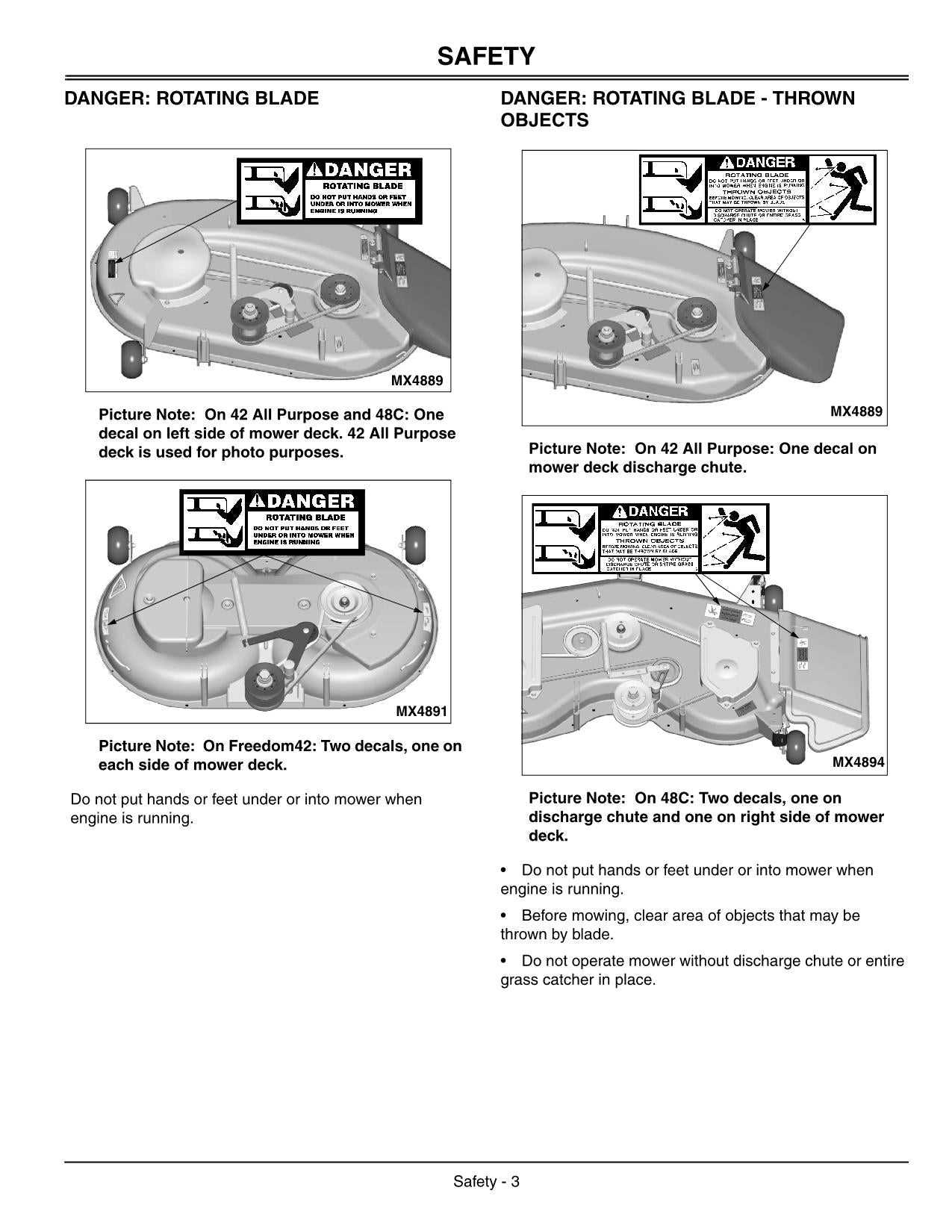

Importance of Deck Parts Diagrams

Visual representations of components are crucial for understanding machinery assembly and maintenance. They offer clarity on how each element interacts, ensuring efficient repairs and optimal functionality. Such illustrations help users identify specific sections, minimizing confusion during work.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Provides a clear view of how parts fit together. |

| Efficient Repairs | Helps locate faulty components quickly. |

| Improved Maintenance | Guides routine checks and servicing. |

| Cost Savings | Reduces chances of errors that lead to expensive fixes. |

Common Issues with L130 Deck Parts

Maintenance of outdoor equipment often reveals various challenges that can affect performance and longevity. Identifying these common problems is essential for ensuring efficient operation. Below are some frequent concerns associated with components used in mowing machines.

| Issue | Description | Solution |

|---|---|---|

| Wear and Tear | Frequent use can lead to deterioration of key elements, impacting functionality. | Regular inspections and timely replacements can mitigate this issue. |

| Alignment Problems | Misalignment can cause uneven cutting and increased strain on the engine. | Adjusting the positioning of the components can resolve this issue. |

| Debris Buildup | Grass and dirt accumulation can obstruct proper operation and cooling. | Routine cleaning after use is necessary to maintain optimal performance. |

| Loose Fasteners | Vibration during operation can loosen bolts and screws, leading to instability. | Checking and tightening all fasteners regularly can prevent this problem. |

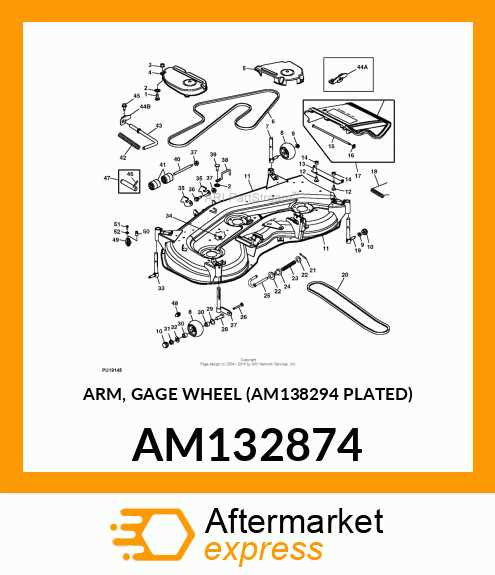

How to Identify Replacement Parts

Identifying suitable components for your machinery can enhance its longevity and performance. Understanding the specific requirements of your equipment is crucial for selecting the right alternatives when maintenance is needed. This section will guide you through the essential steps to ensure you make informed decisions.

1. Refer to the Manual: Always consult the owner’s manual, as it provides valuable information regarding specifications and compatibility. Manuals often include diagrams and lists that can help pinpoint the necessary components.

2. Check Model Numbers: Locate the model number on your machine. This identifier is vital when searching for compatible replacements. It often appears on a label affixed to the chassis or under the hood.

3. Inspect Existing Components: Examine the parts currently in use. Look for identifying marks, numbers, or wear patterns that can guide you in finding exact replacements. Taking measurements can also be beneficial.

4. Use Online Resources: Numerous websites and forums specialize in machinery maintenance. Engaging with these communities can provide insights into common issues and recommendations for replacements.

5. Consult Professionals: If uncertain, don’t hesitate to reach out to a qualified technician. Their expertise can help you navigate the options and ensure the correct components are selected.

By following these steps, you can confidently identify and procure the appropriate replacements for your equipment, ensuring optimal functionality and efficiency.

Maintenance Tips for Lawn Mower Decks

Proper care of mowing equipment is essential for achieving a pristine lawn. Regular maintenance not only prolongs the lifespan of the machinery but also ensures optimal performance. Below are key practices to keep your mowing system in top condition.

Regular Cleaning

- Remove grass clippings and debris after each use.

- Use a scraper or brush to eliminate built-up material.

- Wash the exterior with water and mild soap for a thorough clean.

Inspecting Components

- Check for signs of wear and tear on blades and belts.

- Ensure that all fasteners are tight and in good condition.

- Lubricate moving parts to prevent rust and enhance performance.

Where to Find Original John Deere Parts

Finding authentic components for your equipment is essential for maintaining optimal performance and longevity. Numerous avenues exist for sourcing these crucial items, ensuring you get the best quality for your investment.

Authorized Dealers

One of the most reliable options is visiting an authorized dealer. These locations specialize in genuine merchandise and often provide expert advice, making them a prime choice for acquiring necessary items.

Online Retailers

The internet offers a plethora of online retailers that specialize in high-quality components. Look for websites that are well-reviewed and focus on genuine products to ensure you’re receiving the ultimate in quality and performance.

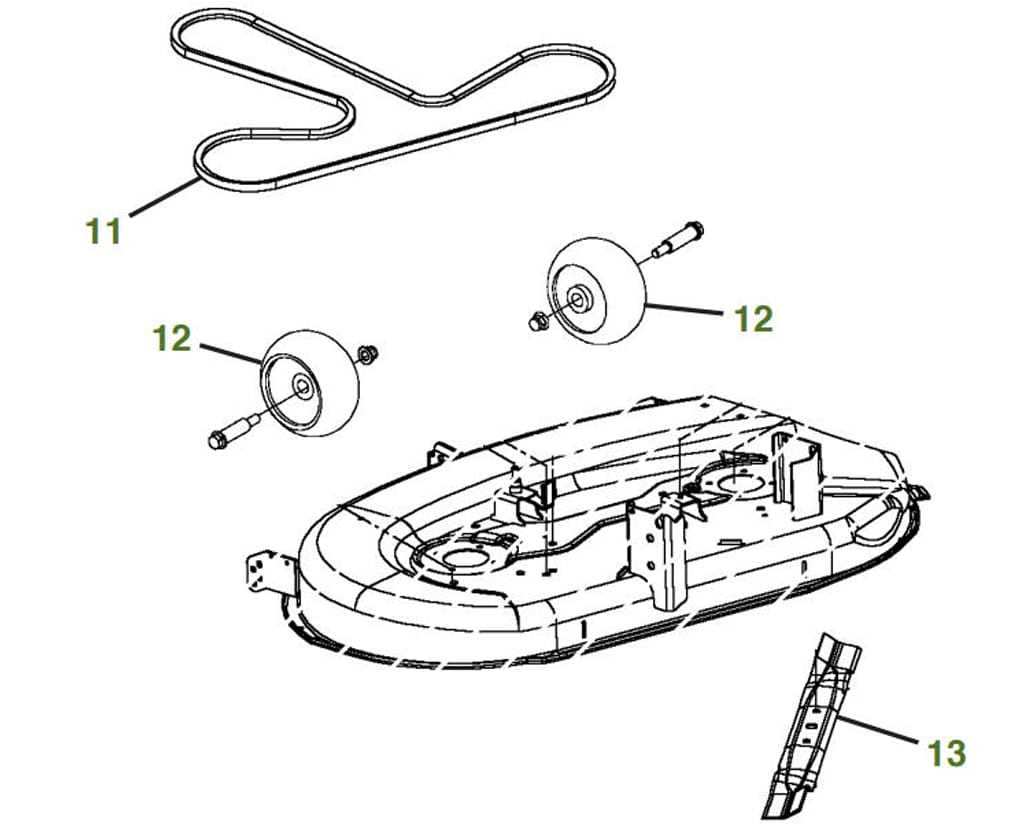

Assembly Instructions for L130 Deck

Proper assembly of the cutting mechanism is crucial for optimal performance and longevity. Following a systematic approach ensures that all components are securely fitted and function as intended. Below are the steps and considerations to effectively assemble this vital system.

Required Tools and Materials

- Socket set

- Wrench set

- Flathead screwdriver

- Phillips screwdriver

- Lubricant

- Replacement components

Step-by-Step Assembly Process

- Begin by laying out all components to ensure everything is present.

- Attach the main housing to the frame, securing it with the appropriate fasteners.

- Install the rotating blades, ensuring they are oriented correctly for effective cutting.

- Connect the drive belts, checking for proper tension and alignment.

- Attach the guards and covers, ensuring they fit snugly to prevent debris escape.

- Lubricate moving parts to ensure smooth operation.

- Conduct a thorough inspection to confirm all connections are tight and secure.

Following these instructions will help maintain efficient performance and extend the lifespan of your cutting apparatus.

Tools Needed for Deck Repair

Repairing your lawn equipment requires specific instruments to ensure efficiency and safety. Having the right tools not only simplifies the process but also enhances the quality of the work performed. Below is a list of essential implements for a successful maintenance task.

- Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening various bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers will help with securing components.

- Pliers: Useful for gripping and twisting wires or small parts.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing damage.

- Safety Gear: Gloves and goggles are necessary to protect yourself during repairs.

- Cleaning Supplies: Brushes and rags for clearing debris and maintaining cleanliness.

- Jack Stands: For elevating the machine safely to access lower components.

Having these tools on hand will make your repair process smoother and more efficient, ultimately extending the life of your equipment.

Comparison of Aftermarket vs. OEM Parts

When considering replacement components for machinery, the choice often boils down to two main categories: original manufacturer offerings and those produced by independent suppliers. Each option presents its own advantages and challenges, impacting performance, longevity, and cost-effectiveness.

Original equipment manufacturer (OEM) offerings are designed to meet the specific standards set by the equipment’s creator. These items typically guarantee compatibility and reliability, as they are crafted with the same specifications as the original components. However, they often come at a higher price point, which can be a significant factor for many users.

On the other hand, aftermarket alternatives provide a more budget-friendly solution. These products can vary widely in quality and compatibility, as they are made by third-party manufacturers. While some aftermarket items perform admirably, others may fall short, potentially leading to issues down the line. Therefore, thorough research and quality assessment are essential when opting for these alternatives.

Ultimately, the decision between OEM and aftermarket options should align with the user’s priorities, whether that be quality assurance or cost savings. Balancing these factors can lead to informed choices that enhance the overall efficiency and performance of the machinery.

Seasonal Maintenance for Lawn Equipment

Proper upkeep of lawn machinery is essential to ensure optimal performance throughout the year. Each season brings unique challenges and tasks that can enhance the longevity and efficiency of your tools.

Here are key maintenance tasks to consider for each season:

- Spring:

- Inspect and clean air filters.

- Sharpen blades for a clean cut.

- Check oil levels and change if necessary.

- Summer:

- Monitor fuel quality and replenish as needed.

- Clean debris from the machine’s body.

- Inspect belts and cables for wear.

- Fall:

- Drain fuel or add a stabilizer for winter storage.

- Thoroughly clean the equipment.

- Check and tighten any loose screws or bolts.

- Winter:

- Store machinery in a dry, sheltered area.

- Cover equipment to prevent dust accumulation.

- Perform an overall inspection and plan for repairs.

By following these seasonal guidelines, you can ensure your lawn tools remain in excellent condition, ready to tackle the tasks ahead.