When it comes to maintaining an efficient lawn care system, having a clear grasp of the various components is essential. This segment delves into the intricate assembly of a specific type of gardening equipment, focusing on how each individual element contributes to the overall functionality. By familiarizing oneself with these components, operators can enhance their understanding and improve their maintenance practices.

The intricate network of elements within this machinery plays a pivotal role in ensuring optimal performance. Each segment, whether it be for propulsion or cutting, is designed to work harmoniously with others. Analyzing the layout and relationships between these sections can provide valuable insights into troubleshooting and repairs.

Furthermore, comprehending the arrangement of these components aids in identifying potential wear points and planning for replacements. Such knowledge not only extends the lifespan of the equipment but also maximizes efficiency during use. In this exploration, we will unravel the complexities of the system, empowering users with the information necessary for informed decisions regarding maintenance and upgrades.

Overview of John Deere LA115

This section provides a comprehensive look at a popular lawn maintenance machine known for its reliability and efficiency. This model is designed for residential use, offering features that enhance performance and ease of operation, making it a favorite among homeowners.

Key Features

Equipped with a powerful engine and user-friendly controls, this machine allows for smooth handling and effective cutting. Its compact design ensures maneuverability in tight spaces, while its robust construction guarantees durability over time.

Specifications

| Feature | Specification |

|---|---|

| Engine Type | Single-cylinder, air-cooled |

| Cutting Width | 42 inches |

| Transmission | Automatic |

| Weight | Approx. 400 lbs |

| Fuel Capacity | 1.5 gallons |

Mower Deck Functionality Explained

The mechanism responsible for cutting grass efficiently plays a crucial role in maintaining a neat lawn. Understanding how this system operates can enhance the user’s experience and extend the lifespan of the equipment. This section delves into the components and their interrelations, shedding light on how they contribute to overall performance.

Key Components and Their Roles

At the heart of this cutting mechanism lies a series of blades, which are powered by an engine. These blades rotate at high speeds, effectively slicing through grass and creating an even finish. Additionally, various pulleys and belts work together to transmit power from the engine, ensuring that the blades operate smoothly. Regular maintenance of these elements is essential to prevent wear and tear, which can lead to inefficient operation.

Operational Efficiency

Another vital aspect is the height adjustment feature, which allows users to control the cutting length. This adaptability ensures that the grass is trimmed to the desired length, promoting healthy growth and an appealing appearance. Moreover, a well-designed housing protects the blades while directing clippings away, preventing blockages and maintaining an unobstructed cutting path. Proper care of this entire mechanism not only enhances performance but also contributes to the longevity of the equipment.

Common Issues with Mower Decks

Maintaining a healthy cutting mechanism is crucial for achieving an immaculate lawn. Various complications can arise during operation, impacting performance and efficiency. Understanding these common challenges can assist users in addressing issues proactively, ensuring a smooth mowing experience.

Uneven Cutting Performance

One frequent problem is uneven cutting. This issue can stem from several factors, including incorrect blade height adjustments or dull blades. When the cutting implements are not level or are worn down, they can leave grass at varying lengths, resulting in an unkempt appearance. Regularly checking and adjusting blade height, as well as sharpening or replacing blades as necessary, can help maintain a consistent cut.

Clogging and Debris Buildup

Another common complication is the accumulation of grass clippings and other debris. When this material builds up, it can hinder the performance of the cutting mechanism, leading to inefficient operation and potential damage. Regular cleaning after use is essential to prevent clogging. Additionally, ensuring that the airflow is unobstructed can contribute to better functionality.

Identifying Replacement Parts Easily

Finding the right components for your equipment can often be a challenging task, especially when dealing with various models and specifications. By understanding the key features and utilizing resources effectively, you can streamline the process of identifying and obtaining the necessary elements to keep your machinery in top condition.

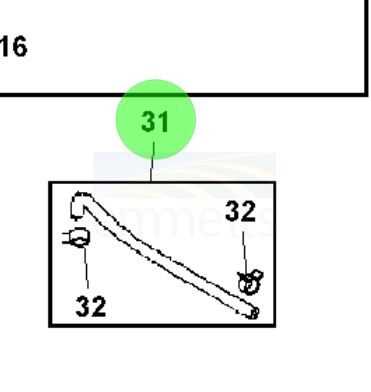

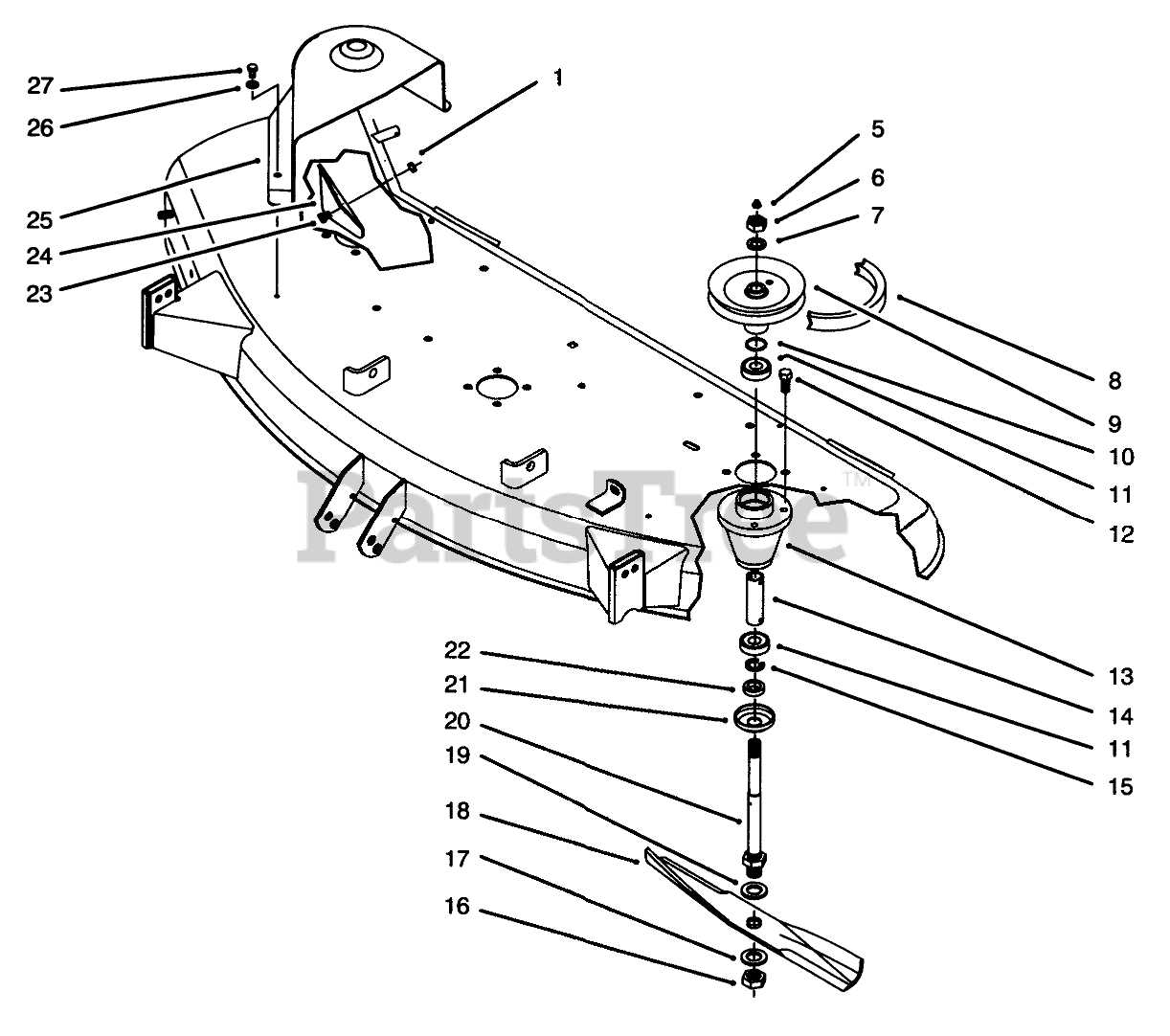

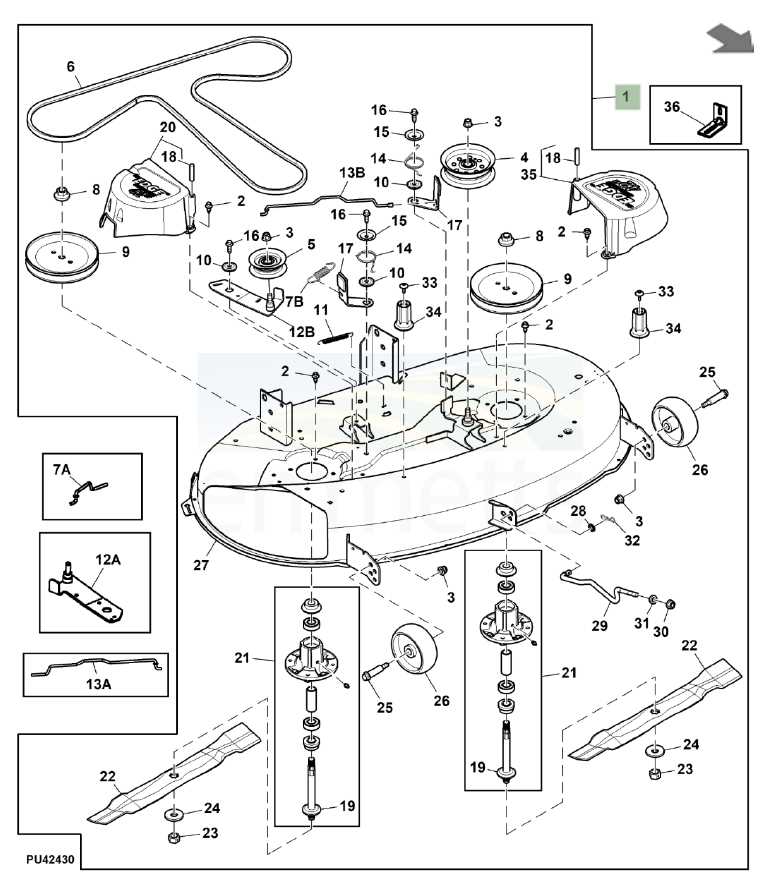

Utilizing Visual Aids

One of the most effective methods for locating specific components is through visual aids. Detailed illustrations can provide clarity on where each component is situated, making it simpler to pinpoint what you need. Additionally, these visuals often include labels that can assist in recognizing the correct names and functions of each item.

Consulting Manufacturer Resources

Another crucial step in identifying the right elements is to consult official resources from the manufacturer. These platforms typically offer comprehensive guides, including specifications and compatibility information, ensuring that you select the appropriate items for your equipment. By leveraging these resources, you can enhance your understanding and ensure a more accurate selection.

Step-by-Step Assembly Instructions

This section provides a comprehensive guide for the assembly process of the cutting unit, ensuring that all components are correctly fitted for optimal performance. Following these steps will help you achieve a seamless installation, contributing to the overall efficiency of your equipment.

Required Tools

Before beginning the assembly, gather the necessary tools to streamline the process. Ensure you have the following items ready:

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening bolts and nuts. |

| Screwdriver | For securing screws. |

| Socket Set | For easier access to hard-to-reach areas. |

| Torque Wrench | To ensure proper fastening torque. |

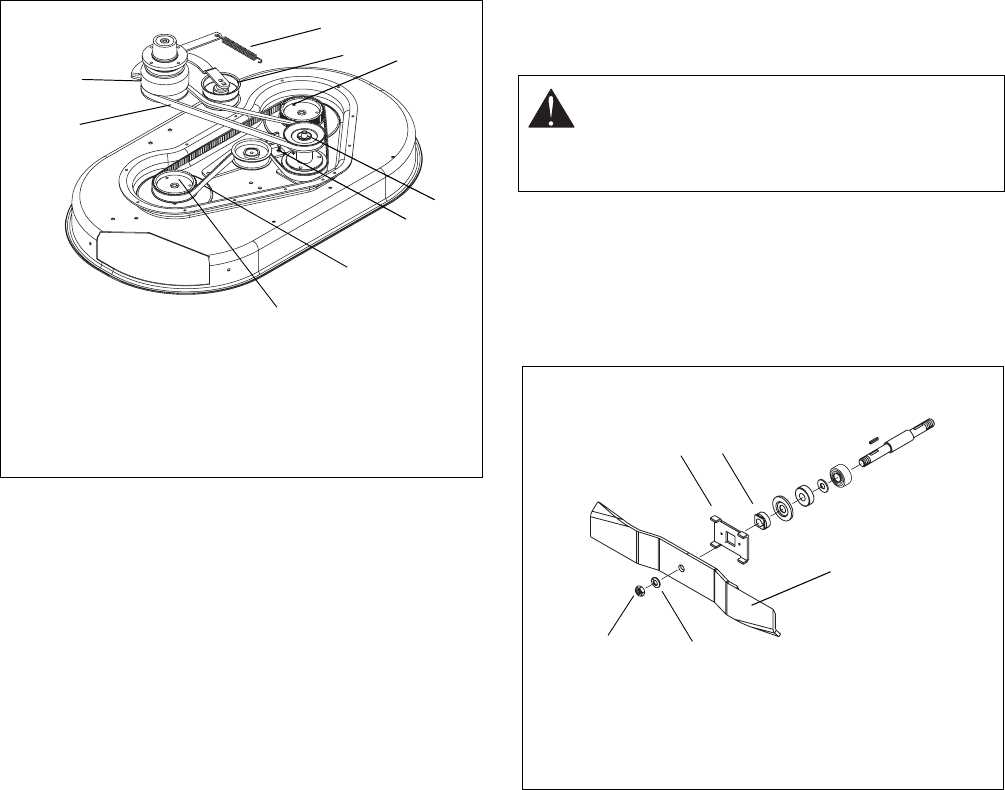

Assembly Steps

Follow these detailed steps to assemble the cutting unit effectively:

- Begin by laying out all components on a flat surface for easy access.

- Attach the main housing to the support frame, ensuring alignment with the pre-drilled holes.

- Secure the housing using the appropriate bolts, checking for snug fit without over-tightening.

- Install the cutting blades onto the spindle assembly, ensuring they are oriented correctly for rotation.

- Connect the spindle assembly to the main housing, aligning the drive shaft accordingly.

- Install any necessary belts, making sure they are properly tensioned.

- Finally, inspect all connections and fasteners for security before proceeding to the operation.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of your equipment. By following a consistent maintenance routine, you can prevent potential issues and enhance the efficiency of your machinery. Below are some effective strategies to help you achieve lasting results.

Routine Inspections

Conducting frequent inspections allows you to identify wear and tear before they escalate into major problems. Consider these key areas:

- Check for any signs of damage on components.

- Examine belts and pulleys for proper tension.

- Inspect the cutting mechanism for sharpness and alignment.

- Look for leaks or signs of wear in hoses and fittings.

Regular Cleaning

Keeping your equipment clean is vital to prevent debris buildup that can hinder performance. Implement these cleaning practices:

- Remove grass clippings and dirt after each use.

- Clean filters to ensure proper airflow and function.

- Use a gentle cleaner to remove any stubborn residue.

- Store your equipment in a dry, covered area to protect it from the elements.

Tools Required for Repairs

Effective maintenance and repair of equipment involve a variety of tools that ensure precision and efficiency. Whether addressing minor adjustments or more extensive fixes, having the right instruments at hand is crucial for successful outcomes.

Essential Tools

- Wrenches: These are necessary for loosening and tightening bolts and nuts, providing the leverage needed for secure fittings.

- Screwdrivers: A selection of flathead and Phillips screwdrivers is vital for removing and installing screws in various components.

- Socket Set: This allows for quick adjustments in tight spaces, enabling access to different sizes of fasteners.

- Pliers: Ideal for gripping, twisting, and cutting wires or other materials.

- Jack Stands: Ensuring safety when working underneath, these provide stability and support.

Additional Supplies

- Lubricants: Necessary for reducing friction and ensuring smooth operation of moving parts.

- Cleaning Supplies: Brushes and cloths for keeping surfaces free from debris and buildup.

- Safety Gear: Gloves, goggles, and ear protection to ensure personal safety during repairs.

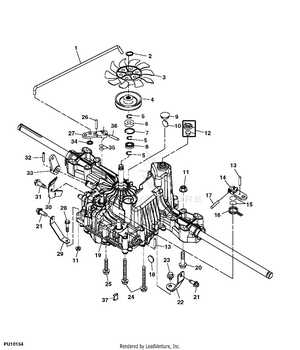

Understanding the Parts Diagram

The schematic representation of a machine’s components serves as a valuable tool for users to comprehend the individual elements that make up the overall assembly. By examining this visual guide, one can identify various segments and their interrelations, which are essential for effective maintenance and repairs.

Recognizing each component within the illustration allows for a clearer understanding of how they function collectively. This knowledge is crucial when addressing issues or performing upgrades, as it helps pinpoint specific areas that may require attention.

Furthermore, familiarizing oneself with the layout aids in the accurate reassembly of parts after disassembly. Whether for routine checks or in-depth repairs, having a thorough grasp of the configuration enhances the efficiency and effectiveness of any service task.

Best Practices for Safety

Ensuring a secure working environment is paramount when operating machinery. Adhering to safety protocols not only protects the operator but also safeguards those in the vicinity. Proper precautions can significantly reduce the risk of accidents and injuries.

Before initiating any task, it is essential to don appropriate personal protective equipment (PPE). This may include items such as gloves, goggles, and sturdy footwear to shield against potential hazards. Regularly inspecting the equipment for wear and tear is equally important, as maintaining functionality can prevent malfunctions during operation.

Always familiarize yourself with the user manual and understand the features and controls of the equipment. Taking the time to read the guidelines ensures that operators are aware of safe operating procedures and emergency protocols. Additionally, maintaining a clean workspace free of obstacles can help prevent trips and falls.

It is crucial to keep distractions to a minimum while operating machinery. Focus and awareness are key to avoiding errors that could lead to dangerous situations. Engaging in proper training and refresher courses can further enhance safety knowledge and skills.

Lastly, always adhere to local regulations and industry standards concerning machinery operation. Staying informed about the latest safety practices not only promotes a culture of safety but also contributes to a more efficient working environment.

Comparative Analysis of Deck Models

This section delves into the various configurations of cutting systems available for grass maintenance equipment, highlighting the distinctions in design, functionality, and performance. By examining these configurations, users can make informed decisions regarding which model best suits their specific needs.

| Model Type | Cutting Width | Material | Blade Configuration | Weight |

|---|---|---|---|---|

| Entry Level | 42 inches | Steel | 2 Blades | 120 lbs |

| Mid Range | 48 inches | High-Strength Steel | 3 Blades | 150 lbs |

| Professional | 54 inches | Reinforced Steel | 3 Blades | 180 lbs |

Each configuration is designed with specific applications in mind, catering to different user requirements and environmental conditions. The entry-level variant offers a compact solution for smaller lawns, while the mid-range and professional models provide enhanced durability and cutting efficiency for larger, more demanding tasks.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial to ensure optimal performance and longevity. Authentic components not only guarantee compatibility but also enhance the overall efficiency of your machine. When looking to purchase these essential items, it’s important to consider reliable sources that prioritize quality and authenticity.

Authorized Dealers

One of the best places to find genuine components is through authorized dealers. These retailers are certified to sell original items and often provide expert advice and assistance. By choosing an authorized dealer, you can be confident that you are acquiring top-notch items designed specifically for your machinery.

Online Retailers

In today’s digital age, numerous online platforms offer original components. Websites dedicated to equipment supply typically have a wide selection of items available. Ensure you choose reputable online vendors with positive reviews and customer support to avoid counterfeit products. Always verify the authenticity of the components before making a purchase.

Customer Reviews and Recommendations

This section highlights feedback from users who have experience with the specific components of a well-known landscaping equipment model. These insights can help potential buyers make informed choices regarding their purchases and maintenance needs.

Users consistently emphasize the importance of durability and performance when selecting components for their machines. Many reviews reflect satisfaction with the longevity and reliability of various parts, indicating a positive impact on overall functionality.

| Review Title | Rating | Comment |

|---|---|---|

| Excellent Quality | 5/5 | These components have significantly improved my equipment’s efficiency. Highly recommend! |

| Worth the Investment | 4/5 | Solid build and great performance. A few minor issues, but overall satisfied. |

| Durable and Reliable | 5/5 | I’ve been using these parts for years, and they continue to perform exceptionally well. |

| Good Value for Money | 4/5 | Quality components that are affordable. Would recommend to fellow users. |

| Easy Installation | 5/5 | Installation was straightforward. Great fit and finish! |

Overall, user feedback underscores the significance of selecting high-quality components that ensure optimal performance and longevity. Consider these reviews when making your purchasing decisions to enhance your equipment’s capabilities.