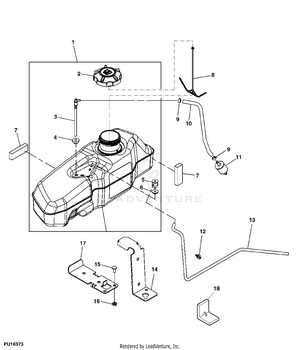

The components of a mowing machine are crucial to ensuring smooth and efficient operation. Each element is designed to work together to provide the necessary power and control for handling various terrains. It’s important to be familiar with the arrangement of these elements to perform regular maintenance and keep the equipment in optimal condition.

Maintenance of such machines can be simplified with a basic understanding of how the individual components connect and function as part of the whole system. Regular inspection of the various sections helps prevent potential issues and prolongs the machine’s life.

In this guide, we will explore the key elements that form the foundation of these machines, focusing on their interconnection and functionality, to give you a comprehensive understanding of the system without diving into overly complex technicalities.

Maintenance Essentials for Lawn Equipment

Regular upkeep is critical to ensure the longevity and efficiency of your lawn care machinery. By focusing on key maintenance tasks, you can prevent issues before they arise and keep the machine running smoothly throughout its lifespan.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 Hours | Use high-quality engine oil to maintain performance. |

| Air Filter Check | Every 25 Hours | Replace the filter if clogged or damaged. |

| Blade Sharpening | Every 10 Hours | Keep blades sharp for clean cuts and efficient mowing. |

| Inspect Belts | Monthly | Check for signs of wear and replace if necessary. |

| Grease Fittings | As Needed | Ensure all moving parts are properly lubricated. |

Components of the 54-Inch Mower Deck

The mowing system is a complex mechanism designed to provide efficient grass cutting performance. It consists of various essential elements that work together to ensure smooth operation and optimal results. Understanding the structure and role of each component can help maintain and improve the machine’s functionality.

Blades and Spindles

Blades are the core cutting tools responsible for trimming grass with precision. They rotate at high speed, driven by spindles, which hold the blades securely in place while allowing them to spin freely. Regular sharpening and inspection are crucial for effective mowing.

Belt and Pulleys

The belt transfers power from the engine to the cutting system. Pulleys guide and support the belt, ensuring that the energy is distributed efficiently to the various components. Proper tension and alignment are important for smooth operation and prolonged lifespan.

How to Replace Deck Blades

Maintaining the sharpness and functionality of your mower’s cutting components is essential for optimal lawn care. Regular blade replacement ensures clean cuts and prevents damage to the machine or the grass. This process can be completed with basic tools and a bit of mechanical knowledge, making it accessible for most users.

| Step | Description |

|---|---|

| 1 | Ensure the mower is on a flat surface and disconnect the spark plug for safety. |

| 2 | Raise the mowing platform to access the blades from underneath. |

| 3 | Use a wrench to loosen the bolts securing the blades to the spindles. |

| 4 | Carefully remove the old blades, noting their position and orientation. |

| 5 | Install the new blades, ensuring they are aligned correctly with the spindle assembly. |

| 6 | Tighten the bolts securely, checking that the blades are properly fastened. |

| 7 | Reconnect the spark plug and lower the mower platform back into position. |

Belt Tension and Adjustment Tips

Proper belt tension is crucial for efficient operation and longevity of your equipment. Ensuring that the belt is neither too tight nor too loose can help prevent issues such as slippage or excessive wear. Regular checks and adjustments can maintain optimal performance.

Signs of Incorrect Belt Tension

- Unusual noise during operation

- Visible belt wear or cracking

- Difficulty engaging or maintaining consistent motion

Steps for Adjusting Belt Tension

- Turn off the equipment and disconnect power to ensure safety.

- Locate the belt and its tensioning mechanism.

- Use the adjustment points to loosen or tighten the belt as needed.

- Check the belt for proper alignment and tension after adjustment.

- Test the equipment to ensure smooth operation before resuming use.

Regular maintenance and attention to the belt’s condition can help avoid breakdowns and extend the lifespan of the system.

Spindle Assembly and Its Role

The spindle assembly is a critical component in the overall operation of lawn equipment, ensuring the efficient rotation of the cutting blades. Without this part, maintaining the smooth movement and even cutting performance would be challenging. Its design and function support the transmission of power from the engine to the blades, allowing for effective trimming of grass and vegetation.

The spindle assembly typically includes several integrated elements such as bearings and shafts, which together enable the precise rotation required for optimal cutting action. By managing the balance and speed of the blades, this system contributes significantly to the equipment’s overall performance and longevity.

Steps to Change the Mower Belt

Changing the cutting belt on your lawnmower is a vital maintenance task that ensures optimal performance. This process not only enhances the efficiency of the equipment but also prolongs its lifespan. Below are the essential steps to follow for a successful replacement.

Gather Necessary Tools

Before starting, ensure you have the right tools on hand. Having everything prepared will make the process smoother and more efficient.

| Tool | Purpose |

|---|---|

| Socket Wrench | To remove bolts securing the mower components |

| Screwdriver | To loosen screws on the mower body |

| New Mower Belt | Replacement for the worn-out belt |

| Safety Gloves | To protect hands during maintenance |

Procedure for Replacement

Follow these steps to successfully change the mower belt:

- Turn off the mower and disconnect the spark plug to ensure safety.

- Remove any covers or guards that obstruct access to the belt.

- Carefully detach the old belt, noting its routing for proper installation of the new one.

- Install the new belt according to the previous routing path.

- Reattach any covers or guards removed earlier.

- Reconnect the spark plug and test the mower to ensure the new belt is functioning correctly.

Regular maintenance, including belt replacement, is crucial for the efficient operation of your mower.

Importance of Leveling the Mower Cutting System

Achieving proper leveling of the cutting mechanism is crucial for optimal performance and results. Ensuring that the blades are evenly aligned contributes to a uniform cut, enhancing the appearance of the lawn and promoting healthy grass growth. Neglecting this essential maintenance can lead to uneven mowing, scalp areas of the lawn, and increased wear on equipment.

Benefits of Proper Leveling

- Uniform Cutting: Even alignment of the cutting blades ensures that grass is cut at a consistent height, leading to a more aesthetically pleasing lawn.

- Enhanced Grass Health: Properly leveled cutting systems minimize stress on grass, allowing for better recovery and growth.

- Reduced Equipment Wear: Maintaining correct blade alignment helps in decreasing wear and tear on the mower, extending its lifespan.

Steps to Achieve Leveling

- Start by placing the mower on a flat, level surface to assess the current alignment.

- Adjust the height of the blades according to the manufacturer’s specifications, ensuring both sides are equal.

- Check the angle of the cutting blades and make necessary adjustments for proper leveling.

- Conduct a test run to verify the effectiveness of the adjustments made.

Inspection of Idler Pulley Systems

The examination of the tensioner wheel assemblies is essential for maintaining optimal performance and longevity of the machinery. Regular checks can prevent premature wear and potential failures, ensuring smooth operation.

During the inspection, consider the following key aspects:

- Visual Inspection: Look for signs of wear, cracks, or damage on the pulleys.

- Alignment Check: Ensure that the pulleys are properly aligned with other components to avoid unnecessary strain.

- Noise Assessment: Listen for any unusual sounds during operation, which may indicate issues within the system.

- Rotation Test: Manually rotate the pulleys to check for smooth movement and any obstructions.

By adhering to these practices, users can effectively maintain the functionality of the idler pulley systems, contributing to the overall efficiency of the equipment.

Cleaning the Mower Deck for Efficiency

Maintaining a clean cutting surface is essential for optimal performance and longevity of your lawn equipment. Regular cleaning helps prevent grass buildup, which can lead to clumping and uneven cuts. By keeping this area free of debris, you enhance the efficiency of your machine and ensure a healthier lawn.

To achieve the best results, follow these simple steps for effective cleaning:

| Step | Description |

|---|---|

| 1 | Ensure the equipment is turned off and completely cool before starting the cleaning process. |

| 2 | Use a scraper or a stiff brush to remove any accumulated grass or debris from the surface. |

| 3 | Rinse with water to eliminate any remaining particles, allowing for thorough cleaning. |

| 4 | Dry the area completely to prevent rust and other forms of damage. |

| 5 | Apply a light coat of protective spray to maintain surface integrity. |

By regularly cleaning the cutting surface, you contribute to the overall efficiency and effectiveness of your lawn care equipment.

How to Lubricate Deck Parts

Proper maintenance of your lawn care equipment ensures optimal performance and longevity. One crucial aspect of this maintenance involves the application of lubrication to various components. By ensuring that moving elements are adequately greased, you can prevent wear and tear, reduce friction, and enhance the overall efficiency of your machinery.

| Component | Recommended Lubricant | Frequency of Lubrication |

|---|---|---|

| Spindle Bearings | High-temperature grease | Every 25 operating hours |

| Pivot Points | Multi-purpose lubricant | Every 50 operating hours |

| Wheels | Wheel bearing grease | Every season |

| Linkages | Light oil | Every 100 operating hours |

To ensure the effectiveness of the lubrication process, always clean the areas around the components before applying any lubricant. This practice prevents debris from mixing with the grease and reduces the likelihood of blockages. Following the manufacturer’s recommendations for lubrication types and intervals will help maintain your equipment’s performance and durability.

Common Deck Troubleshooting Issues

When operating lawn maintenance equipment, several frequent challenges may arise that hinder optimal performance. Identifying these problems is essential for effective operation and maintenance.

One common issue is uneven cutting, which can lead to unsightly grass patterns. This often occurs due to improper height adjustments or worn-out components. Regularly checking and calibrating the cutting mechanism can help mitigate this problem.

Another frequent concern is clogging, which can impede the flow of grass clippings. Debris accumulation can cause blockages, reducing efficiency. To prevent this, ensure regular cleaning and maintenance of the equipment.

Additionally, abnormal vibrations may indicate underlying mechanical problems. These vibrations can be caused by unbalanced blades or loose fasteners. Performing routine inspections can help identify and rectify these issues promptly.

Choosing the Right Replacement Parts

Selecting appropriate components for your machinery is crucial to ensure optimal performance and longevity. Whether you are maintaining or repairing your equipment, understanding the various options available can significantly enhance its efficiency. This section will guide you through the essential considerations when seeking replacements, ensuring you make informed decisions.

Understanding Compatibility

One of the primary factors to consider is the compatibility of the components with your specific model. Always refer to the manufacturer’s specifications to confirm that the selected items fit properly. Utilizing parts that are designed for your model will prevent potential issues during installation and operation.

Evaluating Quality

Quality is paramount when choosing replacements. Opt for components that meet industry standards or are OEM-certified to ensure durability and reliability. Investing in high-quality materials can save you from frequent replacements and repairs, ultimately providing better value for your investment.

Signs of Wear in Deck Components

Recognizing the indicators of deterioration in mower components is essential for maintaining optimal performance. Over time, various elements may exhibit signs of damage or inefficiency, which can affect overall functionality. Understanding these signs can help in identifying the need for repairs or replacements.

- Unusual Noises: Listen for any grinding or rattling sounds during operation, which may suggest loose or damaged parts.

- Uneven Cuts: If the grass is not cut evenly, it may indicate worn blades or misaligned components.

- Excessive Vibration: Increased vibrations while mowing can signal issues with the blade assembly or other parts.

- Corrosion: Check for rust or corrosion on metallic components, which can weaken structural integrity.

- Debris Buildup: Accumulation of grass clippings and debris can lead to inefficiency and should be regularly cleared.

By monitoring these signs, owners can ensure that their equipment remains in peak condition and operates smoothly throughout the mowing season.