The intricate systems that power high-performance automobiles are essential to their functionality and efficiency. A comprehensive grasp of these crucial elements enables enthusiasts and professionals alike to appreciate the engineering marvels that drive modern vehicles. From the heart of the machine to the auxiliary systems, each component plays a pivotal role in overall performance.

When delving into the various mechanisms that contribute to a vehicle’s operation, one can discover a network of interdependent pieces. Each segment is meticulously designed, showcasing the synergy between engineering innovation and mechanical precision. This understanding not only enhances one’s knowledge but also informs better maintenance and tuning practices.

By exploring these foundational elements, we can unlock the secrets behind enhanced performance and reliability. Whether you’re a seasoned mechanic or an avid car lover, familiarizing yourself with these systems can lead to a deeper appreciation of the artistry involved in automotive design. This exploration serves as a guide to navigating the complexities of vehicle dynamics, empowering you to engage with the machinery on a whole new level.

Understanding BMW Engine Components

Exploring the intricate machinery of a high-performance vehicle reveals a world of essential elements that work in harmony to deliver power and efficiency. Each component plays a crucial role, contributing to the overall functionality and performance of the automobile. By delving into these elements, enthusiasts and owners can gain a deeper appreciation for the technology that drives their vehicles.

Key Components and Their Functions

At the heart of any modern vehicle lies a sophisticated assembly of various units. These components include the pistons, which facilitate combustion; the crankshaft, converting linear motion into rotational force; and the camshaft, managing the timing of valve openings and closings. Understanding how these units interact is vital for maintaining optimal performance.

Maintenance and Upgrades

Regular upkeep of these integral units ensures longevity and reliability. Furthermore, enthusiasts often seek to enhance their vehicle’s capabilities through upgrades. Modifications to elements such as intake systems or exhaust configurations can lead to significant improvements in performance. Knowledge of these components is essential for making informed decisions about maintenance and enhancements.

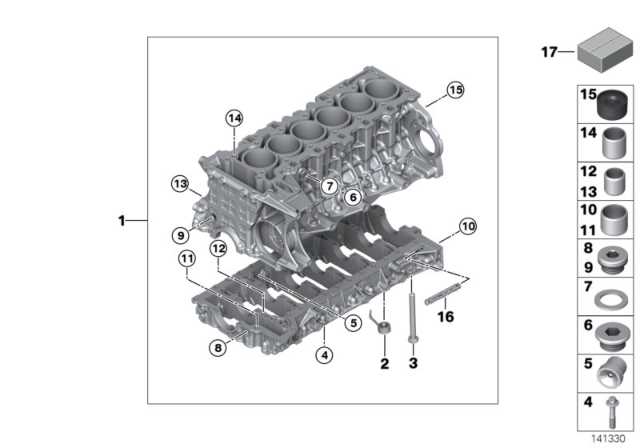

Overview of Engine Parts Diagram

This section provides a comprehensive look at the components that make up the internal workings of a motor, illustrating how they interact to ensure optimal performance. Understanding the layout and function of each element is essential for diagnosing issues and performing maintenance effectively.

Each component plays a vital role, contributing to the overall efficiency and reliability of the vehicle. Below is a table summarizing the key elements involved in this complex system.

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, converting fuel into energy. |

| Piston | Moves within the cylinder to compress the fuel-air mixture. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Camshaft | Controls the timing of the valve openings and closings. |

| Valves | Regulate the intake of air-fuel mixture and the exhaust of gases. |

| Timing Belt | Ensures synchronized movement of the crankshaft and camshaft. |

| Oil Pan | Holds lubrication fluid necessary for smooth operation of moving parts. |

By familiarizing oneself with these crucial elements, one can gain a clearer understanding of how they contribute to the overall functionality and efficiency of the vehicle’s propulsion system.

Types of BMW Engines Explained

Understanding the various powertrains offered by this renowned manufacturer provides insight into the engineering excellence behind their vehicles. Each type is designed to deliver a unique driving experience, catering to different preferences and performance requirements.

Inline Engines: These configurations feature cylinders arranged in a straight line. They are known for their balance and smooth operation, making them a popular choice in many models. Their compact design contributes to efficient space utilization and lower center of gravity.

V Engines: This design positions the cylinders in a V shape, allowing for a more powerful output while maintaining a compact size. V engines are often found in high-performance models, delivering impressive torque and acceleration capabilities.

Flat Engines: Also known as horizontally opposed engines, this type features cylinders arranged on either side of a central crankshaft. This layout enhances stability and lowers the center of gravity, contributing to improved handling characteristics in sportier vehicles.

Hybrid Systems: These combine traditional combustion technology with electric power, aiming to enhance fuel efficiency and reduce emissions. They represent a shift towards more sustainable driving without compromising performance.ABCExplore specific engine modelsDiscuss performance metricsLearn about maintenance tips

Key Functions of Engine Components

The intricate assembly of machinery relies on various essential elements that each serve distinct roles to ensure optimal performance. Understanding these functions is crucial for comprehending how the system operates seamlessly as a whole.

- Power Generation: One of the primary responsibilities involves transforming fuel into energy. This process is fundamental for driving the vehicle and maintaining its momentum.

- Air Intake: The introduction of fresh air into the system is vital. This component ensures that the necessary amount of oxygen is available for combustion, influencing efficiency and power output.

- Fuel Delivery: An integral function is to provide the right quantity of fuel to the combustion area. This precision affects performance and emissions, making it crucial for smooth operation.

- Combustion Control: Maintaining optimal conditions for combustion is essential. This involves regulating temperature and pressure, which enhances performance and reduces waste.

- Exhaust Management: The effective expulsion of byproducts from combustion is necessary. Proper management helps in reducing harmful emissions and maintaining air quality.

- Cooling System: Preventing overheating is critical for longevity. This system regulates temperatures to ensure safe operating conditions for all components.

- Lubrication: Ensuring that all moving elements are well-lubricated minimizes friction and wear, contributing to durability and efficient operation.

Each of these functions plays a pivotal role in the overall efficiency and effectiveness of the machinery, highlighting the importance of understanding how they work in concert to achieve peak performance.

Common Issues with Engine Parts

When it comes to the mechanical heart of a vehicle, certain complications often arise, impacting performance and reliability. Understanding these frequent challenges can help owners maintain their machines more effectively and avoid costly repairs.

One prevalent issue is wear and tear. Over time, components can degrade due to friction and heat, leading to decreased efficiency. Regular inspections can identify these worn elements before they cause significant problems.

Another common concern involves leaks. Fluids, whether oil or coolant, may seep from seals or gaskets that have lost their integrity. Addressing leaks promptly not only prevents environmental harm but also safeguards the overall system.

Clogging is yet another challenge that can hinder performance. Accumulation of debris in crucial passages can restrict flow and impact functionality. Routine cleaning and maintenance are essential to keep these pathways clear.

Lastly, improper alignment can lead to uneven wear and potential failure of various elements. Ensuring that all components are correctly positioned can enhance longevity and reliability. Regular alignment checks should be part of any maintenance routine.

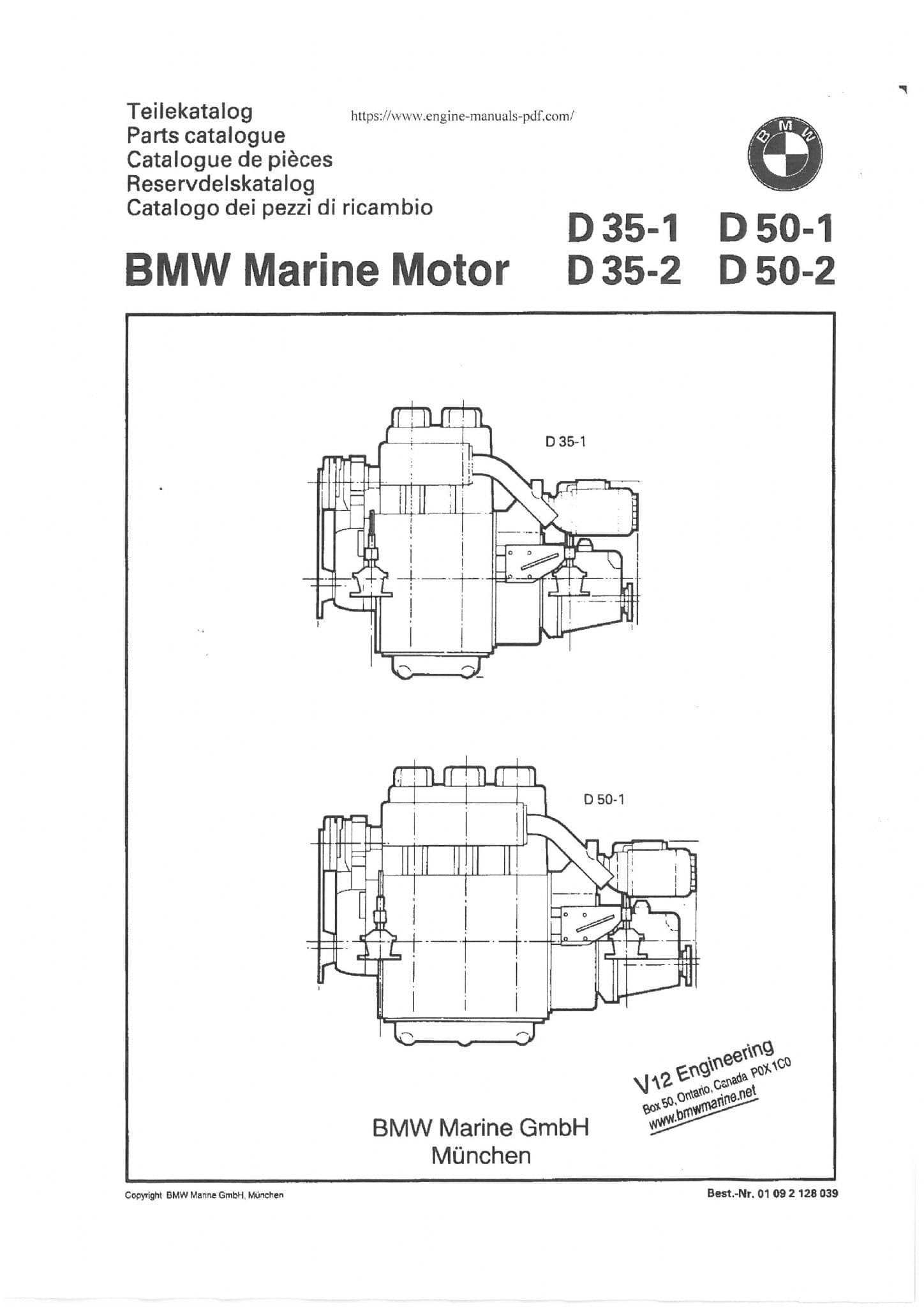

How to Read an Engine Diagram

Understanding a technical illustration is crucial for anyone looking to delve into the mechanics of a vehicle. These visual representations provide insight into the various components and their relationships, enabling a clearer grasp of how everything works together. Learning to interpret these illustrations can significantly enhance your ability to troubleshoot and maintain your machinery.

Here are some key aspects to consider when examining such a visual guide:

| Element | Description |

|---|---|

| Symbols | Various icons represent specific components. Familiarizing yourself with these is essential for proper understanding. |

| Lines | Different types of lines indicate various connections and relationships, such as power flow or mechanical linkage. |

| Labels | Each part is typically labeled, often with a reference number. These correspond to a list that provides further details. |

| Scale | Pay attention to the scale used in the illustration, as it impacts the size relationships between components. |

By familiarizing yourself with these elements, you can enhance your comprehension of the intricate systems at play within the machinery. This knowledge will not only aid in repairs but also improve overall understanding of automotive technology.

Maintenance Tips for BMW Engines

Regular upkeep is crucial for enhancing the longevity and performance of any automotive machinery. By following a structured maintenance routine, you can ensure optimal functionality and reduce the likelihood of unexpected issues. Here are some key practices to keep in mind.

Essential Maintenance Practices

- Regular Oil Changes: Ensure that the lubricant is replaced at intervals recommended by the manufacturer to maintain smooth operation.

- Air Filter Replacement: A clean air filter promotes efficient airflow and improves overall performance.

- Check Fluid Levels: Regularly inspect coolant, brake fluid, and transmission fluid to avoid any potential damage.

- Tire Pressure Monitoring: Keeping tires inflated to the correct pressure aids in handling and fuel efficiency.

- Belt Inspections: Inspect and replace belts as necessary to prevent mechanical failures.

Advanced Care Tips

- Consider using high-quality fuel to enhance performance and reduce deposits.

- Schedule periodic inspections with a qualified technician for comprehensive assessments.

- Keep an eye on warning lights and address issues promptly to prevent escalation.

- Maintain cleanliness by washing and detailing the exterior and interior regularly.

By implementing these strategies, you can significantly improve the reliability and efficiency of your vehicle, ensuring it remains a pleasure to drive for years to come.

Identifying Engine Parts by Type

Understanding the components of a power unit is crucial for both maintenance and performance optimization. Each element serves a specific function, contributing to the overall efficiency and effectiveness of the mechanism. By recognizing the various classifications, enthusiasts and professionals alike can better navigate repairs and upgrades.

Here are some primary classifications of these components:

- Mechanical Elements:

- Crankshaft

- Pistons

- Connecting rods

- Auxiliary Systems:

- Fuel delivery systems

- Ignition systems

- Cooling systems

- Support Structures:

- Mounting brackets

- Covers and seals

- Oil pans

Each category contains components that play a pivotal role in the functionality of the entire assembly. Familiarity with these classifications aids in troubleshooting and enhancing performance.

For effective identification, consider the following steps:

- Review the unit’s specifications to understand the general layout.

- Utilize visual aids to match components with their respective functions.

- Consult repair manuals for detailed descriptions of each element.

By systematically categorizing and identifying these elements, one can ensure better upkeep and improved performance of the entire system.

Role of Each Component in Performance

Understanding the significance of various elements in a mechanical system is crucial for optimizing its efficiency and power delivery. Each component plays a distinct role, contributing to the overall functionality and effectiveness of the assembly. This section explores how these individual pieces interact to enhance performance, ensuring a seamless experience on the road.

Key Elements and Their Functions

- Crankshaft: Converts linear motion into rotational energy, facilitating power transfer.

- Pistons: Generate pressure by moving within cylinders, enabling combustion.

- Camshaft: Regulates valve timing, ensuring optimal airflow and fuel delivery.

- Fuel Injectors: Deliver precise amounts of fuel to the combustion chamber, enhancing efficiency.

- Ignition System: Initiates combustion at the right moment, crucial for performance and fuel economy.

Impact on Overall Performance

The interaction among these components influences several aspects, including:

- Power Output: Well-coordinated parts lead to increased horsepower and torque.

- Fuel Efficiency: Enhanced design minimizes waste, maximizing mileage.

- Emissions Control: Effective operation reduces harmful emissions, supporting environmental standards.

By appreciating the role of each element, one can better understand the intricate balance necessary for achieving superior performance in mechanical systems.

Tools for Engine Disassembly and Repair

When it comes to dismantling and repairing mechanical assemblies, having the right tools is essential for achieving efficiency and precision. Proper instruments not only streamline the process but also ensure that each component is handled with care, minimizing the risk of damage.

Essential Tools

- Socket Set: A comprehensive socket set is crucial for loosening and tightening bolts of various sizes.

- Torque Wrench: This tool ensures that fasteners are tightened to the correct specifications, preventing future issues.

- Ratchet and Extension Bars: These facilitate access to hard-to-reach areas, making disassembly easier.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, is needed for various fasteners.

- Pry Bars: Useful for separating components that may be stuck together.

Additional Instruments

- Digital Caliper: For precise measurements of components.

- Magnetic Tray: Keeps small fasteners organized and prevents loss during the repair process.

- Oil Filter Wrench: Specifically designed for easy removal of oil filters.

- Cleaning Supplies: Brushes and solvents to keep parts free from debris and contaminants.

Equipping yourself with these essential and additional tools will greatly enhance the efficiency and effectiveness of any repair or disassembly task. Proper preparation not only saves time but also ensures a smoother workflow and better results.

Aftermarket Parts vs. OEM Components

The choice between alternative components and original factory-made items can significantly impact performance, longevity, and cost. Understanding the differences between these two categories is essential for making informed decisions when maintaining or upgrading your vehicle.

OEM components are produced by the manufacturer and typically come with specific guarantees regarding quality and compatibility. In contrast, alternative components are often made by third-party manufacturers and can vary widely in quality and price.

- Quality: OEM items are designed to meet stringent specifications, ensuring a perfect fit and reliable performance.

- Price: Alternative components generally offer a more budget-friendly option, but the quality may vary.

- Availability: OEM components might be limited in availability, while alternative options can often be found easily online or in stores.

- Warranty: Many OEM parts come with a warranty, providing peace of mind, while warranties for alternative items can differ significantly.

Ultimately, the decision between these two types of components depends on individual preferences, budget constraints, and performance expectations.

Engine Upgrades for Enhanced Performance

Improving the efficiency and output of your vehicle’s power source can significantly enhance its overall driving experience. By implementing specific modifications, enthusiasts can achieve remarkable gains in horsepower, torque, and responsiveness, ultimately transforming the dynamics of their ride. The following adjustments can elevate performance levels to new heights, allowing for a more thrilling journey on the road.

One effective approach is to enhance airflow through the installation of high-performance intake systems. These modifications facilitate better air delivery to the combustion chambers, resulting in improved combustion efficiency. Coupled with a performance exhaust system, the vehicle can expel gases more effectively, further boosting power output.

Additionally, tuning the vehicle’s software can unlock potential that remains untapped in stock configurations. Optimized settings can adjust fuel delivery and ignition timing, creating a more harmonious balance between power and efficiency. This adjustment not only increases performance but can also lead to improved fuel economy under certain conditions.

Upgrading components such as turbochargers or superchargers can yield substantial increases in power. These forced induction systems compress air entering the engine, allowing for a greater volume of fuel to be burned. The result is a notable surge in power, making the vehicle more exhilarating to drive.

Lastly, investing in high-quality spark plugs and ignition coils can enhance combustion quality, ensuring that every drop of fuel is utilized effectively. These seemingly small components play a crucial role in achieving optimal performance, making them essential for those seeking to maximize their vehicle’s capabilities.

Resources for DIY BMW Repairs

For automotive enthusiasts and owners looking to perform maintenance or repairs on their vehicles, having access to reliable information and resources is essential. Whether you’re tackling minor adjustments or more complex tasks, the right tools and knowledge can make all the difference in ensuring a successful outcome.

Online Forums and Communities: Engaging with dedicated online communities can provide invaluable insights. Platforms such as discussion boards and social media groups offer a wealth of shared experiences, tips, and troubleshooting advice from fellow owners and mechanics.

Instructional Videos: Video tutorials can be a game-changer for visual learners. Websites like YouTube feature countless channels focused on repair techniques, offering step-by-step guidance that simplifies complex procedures.

Repair Manuals: Comprehensive manuals tailored for specific models are excellent resources. These publications often contain detailed procedures, specifications, and diagrams that serve as a reference throughout the repair process.

Toolkits and Equipment: Investing in quality tools is crucial for any repair project. Specialized toolkits designed for your vehicle can enhance efficiency and ensure that you have everything needed to tackle various tasks.

Local Workshops and Classes: Many communities offer workshops or classes focused on automotive repair. Participating in these sessions can provide hands-on experience and valuable knowledge from experienced instructors.

By utilizing these resources, enthusiasts can enhance their skills and confidence, turning automotive challenges into rewarding DIY projects.