In the realm of outdoor machinery, comprehending the intricate arrangement of components is essential for efficient maintenance and operation. Each element plays a crucial role in ensuring optimal performance, enhancing longevity, and facilitating ease of use.

Knowledge of the individual sections and their interactions allows users to troubleshoot issues effectively. By dissecting the assembly, one can grasp the ultimate functionality and significance of each segment.

Exploring the various parts not only empowers operators but also encourages a deeper appreciation for the engineering behind these powerful tools. Diving into the specifics reveals how careful design contributes to the overall effectiveness of lawn care machinery.

Kubota Z421 Overview

This section provides a comprehensive overview of a popular model known for its efficiency and reliability in various tasks. Designed for both residential and commercial use, this machine excels in delivering performance across different terrains.

The equipment is engineered with advanced technology, ensuring smooth operation and ease of use. With a focus on durability, it features high-quality materials that withstand rigorous conditions, making it a favorite among professionals and homeowners alike.

In addition to its robust design, the model boasts user-friendly controls that enhance the overall experience. Its compact size allows for easy maneuverability, enabling users to navigate tight spaces without hassle.

Maintenance is straightforward, with accessible components that facilitate regular checks and repairs. This not only extends the lifespan of the machine but also ensures optimal performance throughout its service life.

Overall, this model stands out in the market, combining power, efficiency, and convenience, making it a top choice for those seeking reliable machinery for lawn care and landscaping tasks.

Importance of Deck Parts

Understanding the components that contribute to the efficiency of lawn care equipment is essential for optimal performance. Each element plays a crucial role in ensuring the machine operates smoothly and effectively, leading to better results in grass management.

Regular maintenance and timely replacement of these components not only enhance functionality but also prolong the lifespan of the equipment. When every segment is in top condition, the overall operation becomes seamless, minimizing downtime and maximizing productivity.

Moreover, knowledge of these essential components aids users in troubleshooting issues and identifying potential problems before they escalate. This proactive approach ultimately leads to a more enjoyable and efficient mowing experience.

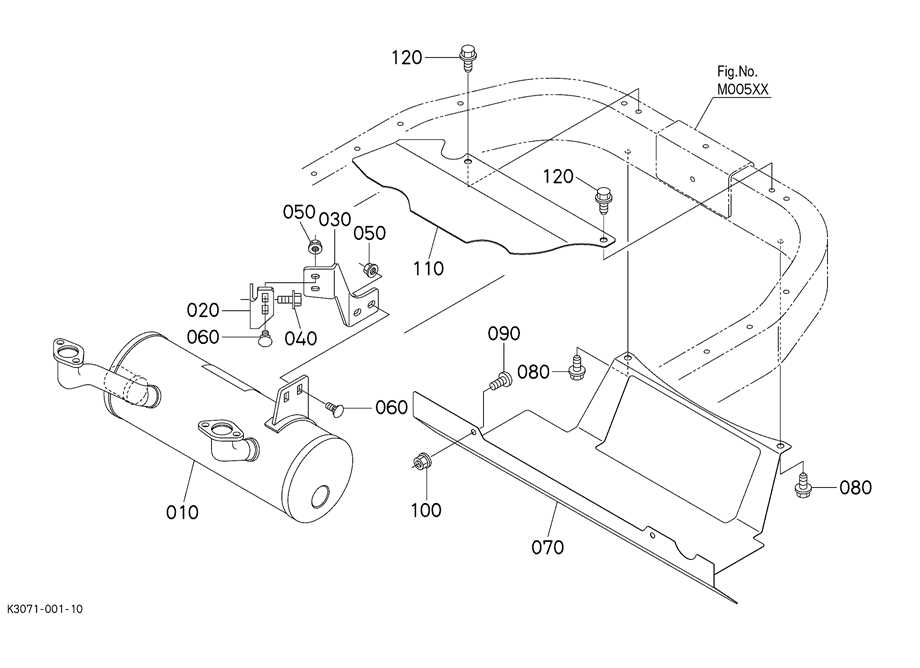

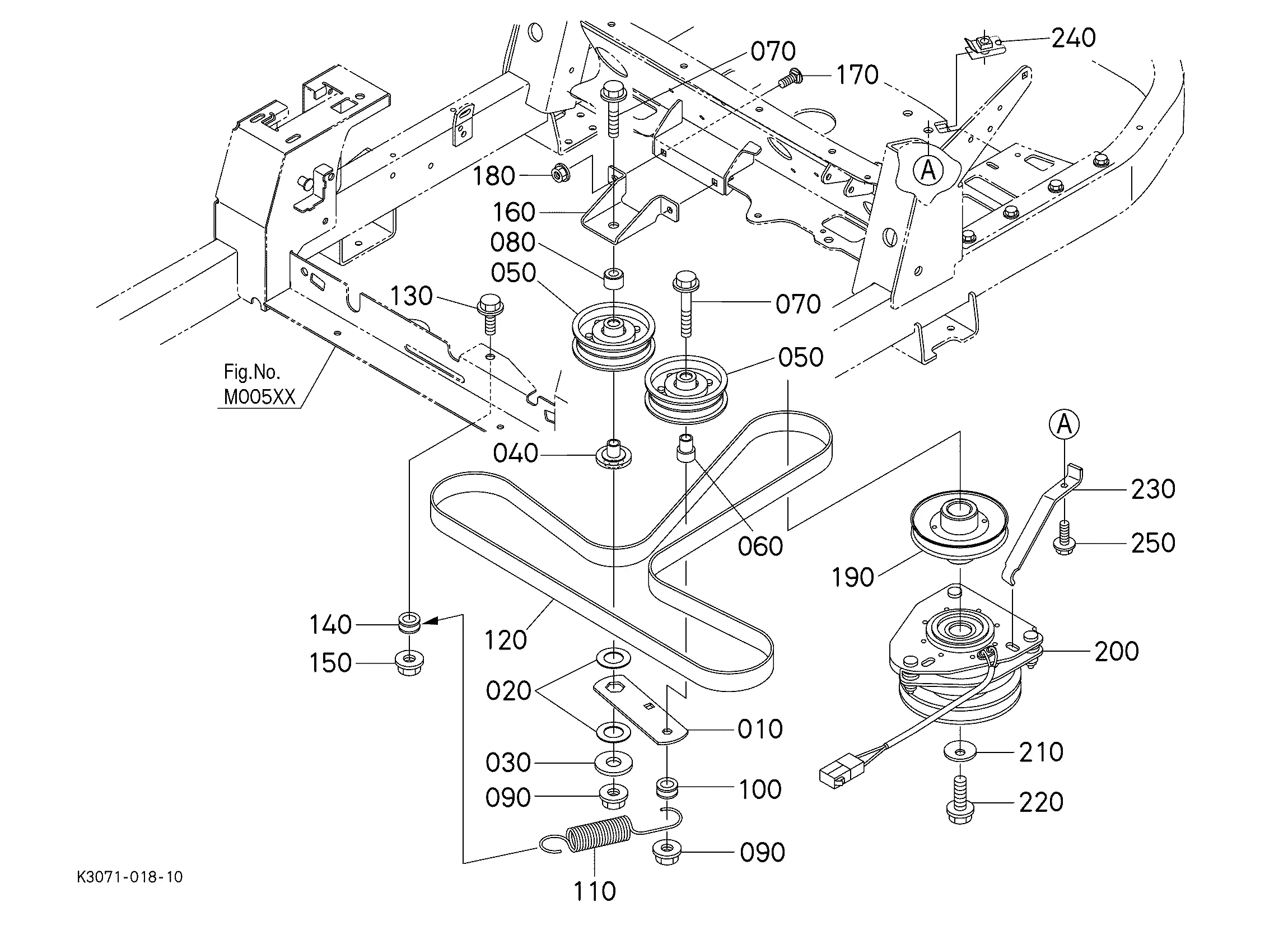

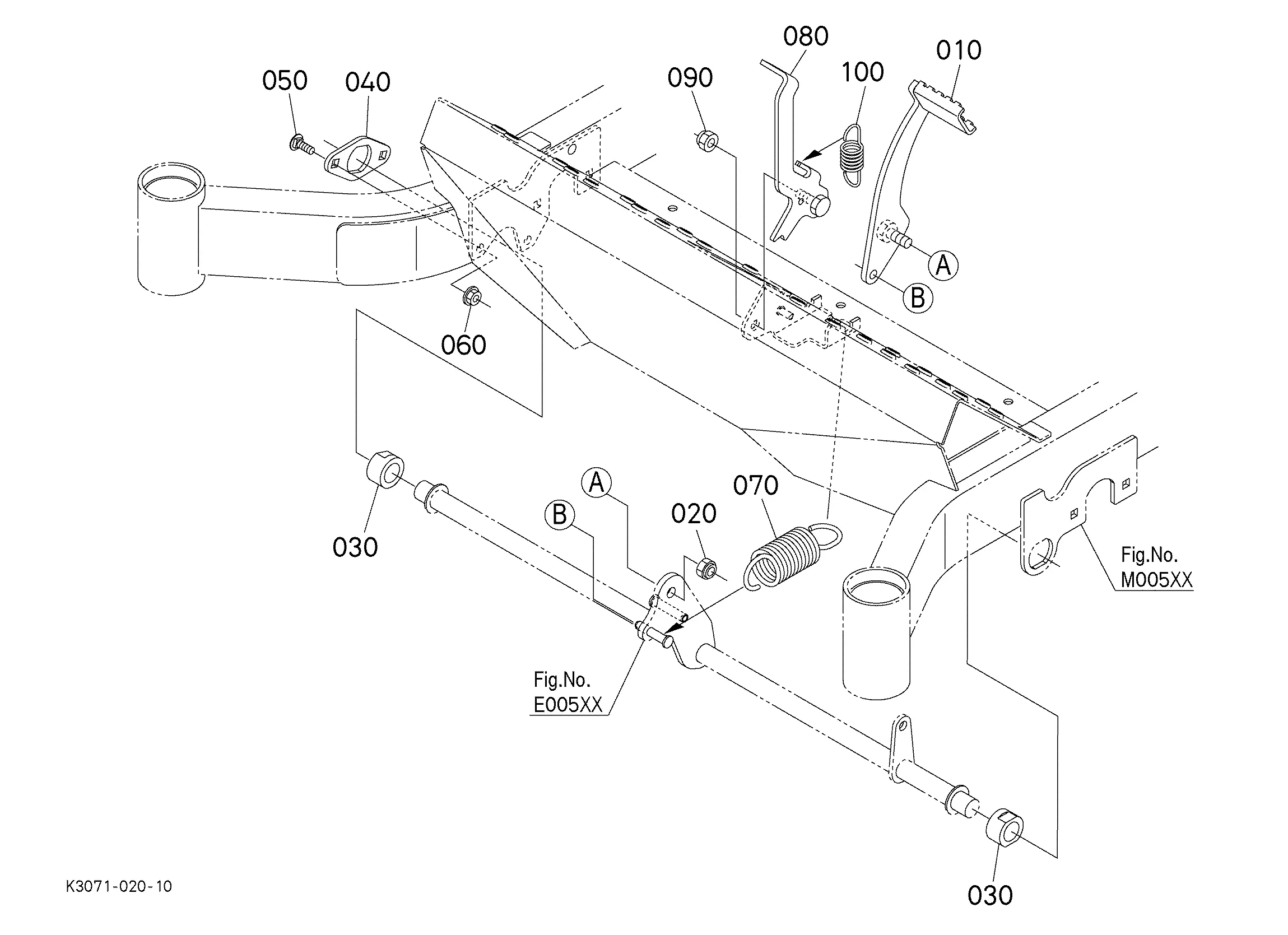

Understanding the Parts Diagram

Grasping the visual representation of machinery components is essential for effective maintenance and repairs. These illustrations provide a clear layout, showcasing the relationship between various elements and their functions. By familiarizing yourself with these graphics, you can enhance your ability to troubleshoot issues and streamline replacement processes.

Components and Their Functions

Each segment within the illustration is carefully labeled to indicate its specific role in the overall system. Recognizing these roles helps users understand how each part interacts with others, contributing to the machine’s efficiency. Familiarity with these components not only aids in identifying problems but also facilitates proper reassembly.

Visual Guidance for Maintenance

Utilizing these visuals can significantly simplify the maintenance process. When performing repairs, having a reference that outlines where each component fits and how they connect can save time and reduce frustration. Ultimately, a thorough understanding of these representations empowers users to take better care of their machinery, ensuring optimal performance over time.

Common Components of Z421 Deck

The structure of a lawn care machine is made up of various essential elements that contribute to its functionality and efficiency. Understanding these components can enhance maintenance practices and improve performance over time.

| Component | Description |

|---|---|

| Blades | These are crucial for cutting grass evenly and effectively, designed to withstand wear and tear. |

| Spindles | These support the rotation of the cutting blades, ensuring smooth operation and stability. |

| Mounting Brackets | These hold various elements in place, providing stability and alignment during operation. |

| Belts | These transfer power from the engine to the blades, playing a vital role in the machine’s performance. |

| Wheels | These allow for mobility and maneuverability, making it easier to navigate different terrains. |

| Chassis | The main frame that houses all components, providing structure and support for the entire system. |

Identifying Wear and Tear Signs

Recognizing the signs of deterioration in machinery is crucial for maintaining optimal performance and extending lifespan. Regular inspection helps in detecting issues early, preventing more extensive damage and costly repairs.

Common Indicators

Look for unusual noises, which may indicate friction or misalignment. Vibrations during operation can also suggest wear in components. Additionally, check for any signs of leaks or fluid accumulation around parts, as this can be a red flag for potential failure.

Surface and Structural Damage

Inspect surfaces for cracks or corrosion, as these imperfections can compromise functionality. Pay attention to any abnormal wear patterns, as they can signal that adjustments are necessary to ensure even operation.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Regular maintenance not only enhances performance but also extends the lifespan of various components. By adhering to a structured care routine, you can prevent costly repairs and enjoy optimal functionality.

Start with routine inspections to identify wear and tear early. Keeping the machine clean helps prevent debris buildup that can cause damage. Additionally, always check fluid levels and replace them as needed to ensure smooth operation. Using high-quality lubricants can also significantly reduce friction and wear.

Replace any worn or damaged components promptly. Utilizing original or compatible replacements ensures that your machinery operates at peak performance. Finally, consider storing the equipment in a sheltered area to protect it from harsh weather conditions, which can lead to premature deterioration.

How to Replace Deck Parts

Maintaining your equipment is essential for optimal performance. When components wear out, it’s crucial to replace them promptly to ensure longevity and efficiency. This guide will help you navigate the replacement process effectively, providing steps to keep your machinery in top shape.

Preparation Steps

Before starting, gather all necessary tools and replacement components. Ensure the machine is turned off and properly secured. Familiarize yourself with the specific areas that require attention, as this will streamline the replacement process.

Replacement Process

Begin by removing the old components carefully. Use appropriate tools to avoid damaging surrounding parts. Once removed, compare the old and new pieces to confirm compatibility. Install the new components securely, making sure everything is aligned correctly. After installation, check for any loose fittings and test the machinery to ensure proper function.

Tools Required for Repairs

Proper maintenance and repair require specific instruments to ensure efficiency and safety during the process. Having the right tools on hand can significantly simplify the tasks involved, allowing for a smoother workflow and better results.

Essential Tools

- Wrenches: For loosening and tightening various components.

- Screwdrivers: Needed for handling different types of screws.

- Pliers: Useful for gripping and bending materials.

- Socket Set: Provides a range of sizes for better accessibility.

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

Additional Supplies

- Safety Gear: Gloves and goggles to protect against injuries.

- Lubricants: To ensure smooth operation of moving parts.

- Cleaning Supplies: Rags and solvents for maintenance.

Where to Find Genuine Parts

When it comes to maintaining your outdoor machinery, sourcing authentic components is crucial for optimal performance and longevity. Utilizing original elements ensures compatibility and reliability, safeguarding your investment. Various options are available for acquiring these essential materials, making the process easier for owners.

Authorized Dealers: One of the most reliable avenues for obtaining authentic components is through authorized retailers. These establishments specialize in specific brands and offer a wide range of original items. Their knowledgeable staff can assist in identifying the correct components needed for your machine.

Online Marketplaces: Numerous online platforms provide access to genuine elements. Ensure that the sellers are reputable and have positive reviews. Look for listings that specifically mention authenticity to avoid counterfeit options.

Manufacturer’s Website: Visiting the official website of the manufacturer can also be beneficial. Many companies have dedicated sections for ordering original components directly. This option often guarantees the latest versions and updates, enhancing your equipment’s efficiency.

Local Repair Shops: Another practical choice is local repair facilities. Many of these shops maintain connections with suppliers and can help you find the necessary components while offering installation services if needed.

Choosing the right source for genuine components not only ensures quality but also provides peace of mind, allowing you to focus on the task at hand without worrying about the integrity of your equipment.

DIY vs. Professional Repair Options

When it comes to maintenance and repairs for outdoor machinery, individuals often face a choice between tackling the task themselves or enlisting the help of experts. Each approach has its own set of advantages and challenges, which can significantly impact the overall effectiveness and cost of the repair process.

Advantages of DIY Repairs

Taking the DIY route can provide a sense of accomplishment and often saves money on labor costs. Additionally, it allows individuals to develop their skills and gain a deeper understanding of their equipment. However, this approach requires access to proper tools, time, and a willingness to learn about the intricacies of the machinery.

Benefits of Professional Services

Hiring a professional can save time and provide peace of mind, as experienced technicians typically have the knowledge and tools necessary to diagnose and fix issues effectively. This can lead to a higher quality of work, reducing the risk of future problems. However, professional repairs can come at a premium cost, which might not be feasible for everyone.

| Criteria | DIY | Professional |

|---|---|---|

| Cost | Lower (No labor fees) | Higher (Labor costs included) |

| Time Investment | Variable (Dependent on skill level) | Usually faster (Experienced technicians) |

| Skill Development | High (Learning opportunities) | Low (Less hands-on experience) |

| Quality of Work | Variable (Depends on expertise) | High (Professional experience) |

Upgrades for Enhanced Performance

Improving machinery efficiency can significantly enhance operational outcomes. By implementing strategic enhancements, users can experience superior functionality and reliability. These upgrades focus on optimizing components, ensuring smoother performance and prolonged durability.

Engine modifications can lead to improved power output and fuel efficiency. Incorporating high-quality air filters and performance exhaust systems helps in maximizing airflow, which is crucial for achieving optimal performance.

Cutting blades play a vital role in achieving precise results. Upgrading to advanced blade materials or designs can reduce wear and improve cutting efficiency, allowing for cleaner finishes and less downtime.

Lastly, tire upgrades can enhance traction and stability, especially on uneven terrain. Choosing tires with better grip can improve maneuverability and overall handling, ensuring effective operation in diverse conditions.

Customer Reviews and Feedback

This section highlights the experiences and insights shared by users regarding their equipment maintenance and performance. Feedback is essential for understanding the overall quality and reliability of components, allowing potential buyers to make informed decisions.

Overall Satisfaction

Customers frequently express their satisfaction with the durability and efficiency of the machinery. Many reviews note the ease of installation and compatibility with existing systems, enhancing user confidence.

Common Issues

While most feedback is positive, some users report occasional challenges. Common issues include minor adjustments needed for optimal performance. Here’s a summary of key points raised:

| Issue | Frequency |

|---|---|

| Installation challenges | 15% |

| Durability concerns | 5% |

| Performance inconsistencies | 10% |

| No issues reported | 70% |