Understanding the intricate details of agricultural machinery is vital for efficient operation and maintenance. Each machine consists of numerous elements, each playing a specific role in its overall functionality. A clear visual representation of these components can greatly aid in the identification and troubleshooting of issues that may arise during use.

In this section, we will delve into a detailed illustration showcasing the various segments of a specific piece of farming equipment. This visual guide serves as a valuable resource for operators and technicians alike, enabling them to navigate through the essential parts and their respective functions with ease. Familiarity with these components is crucial for ensuring optimal performance and longevity of the machinery.

Whether you are a seasoned farmer or new to the field, having a comprehensive understanding of your equipment’s layout can enhance your ability to address potential challenges swiftly. This guide will empower you with the knowledge needed to effectively manage and maintain your machinery, ensuring that your agricultural tasks are performed smoothly and efficiently.

Comprehensive Guide to John Deere 1219 Haybine

This section offers an in-depth look at a specific type of agricultural machinery designed for cutting and conditioning forage. Understanding the components and functionality of this equipment is essential for optimizing its performance and ensuring longevity. Knowledge about various elements involved can aid in efficient maintenance and operation.

Key features of this equipment include:

- Efficient cutting system

- Durable build for various terrains

- Adjustable settings for different crop types

To maintain optimal functionality, it is crucial to be familiar with the various components, including:

- Cutter bar assembly

- Conditioner rolls

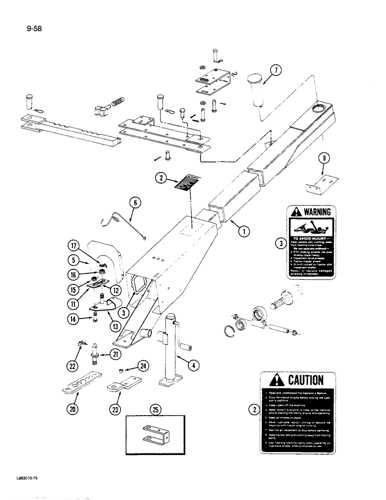

- Drive system

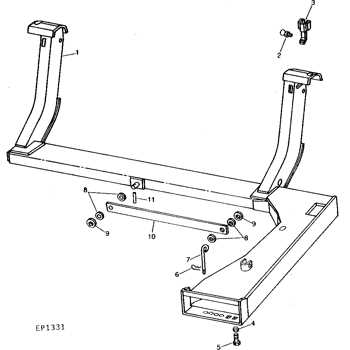

- Frame and hitch

- Safety mechanisms

Regular inspections and timely replacements of worn parts can prevent unexpected breakdowns. Users are encouraged to keep a close eye on:

- Blade sharpness

- Wear on conditioner rolls

- Fluid levels and leaks in the drive system

Consulting the manufacturer’s guidelines and utilizing available resources can significantly enhance the efficiency and reliability of this vital equipment.

Understanding the Haybine Mechanism

The mechanism of a specialized cutting implement is vital for efficient crop management. This system combines various components that work together to enhance the harvesting process. Understanding how these parts interact allows for better maintenance and optimization of performance, ultimately improving productivity in agricultural operations.

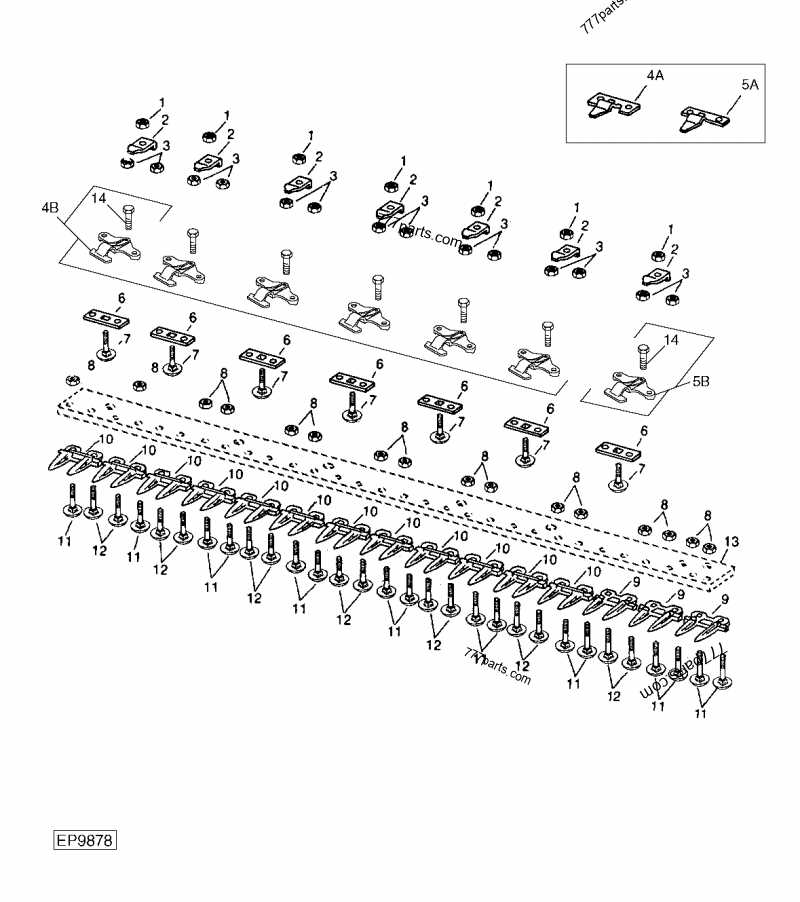

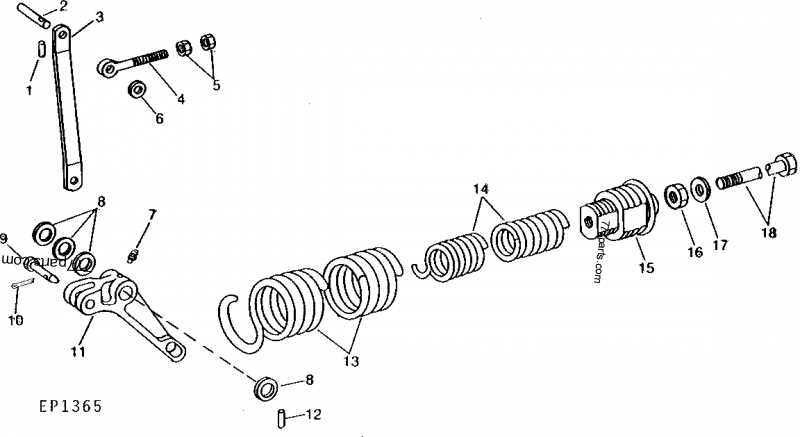

Components of the Cutting System

Each segment of the cutting system plays a crucial role in ensuring smooth operation. Key elements include the cutter bar, which serves as the primary cutting surface, and the drive system that powers the implement. Other components, such as the conditioning units, facilitate the drying process of the harvested material.

Maintenance and Optimization

Regular upkeep of the cutting mechanism is essential for sustaining efficiency. Proper lubrication, timely replacement of worn components, and adjustments to alignment can prevent breakdowns and enhance performance. Familiarity with the individual elements allows operators to diagnose issues swiftly and implement effective solutions.

| Component | Description | Function |

|---|---|---|

| Cutter Bar | Main cutting edge | Performs the cutting of crops |

| Drive System | Mechanical transmission | Powers the cutter and conditioning units |

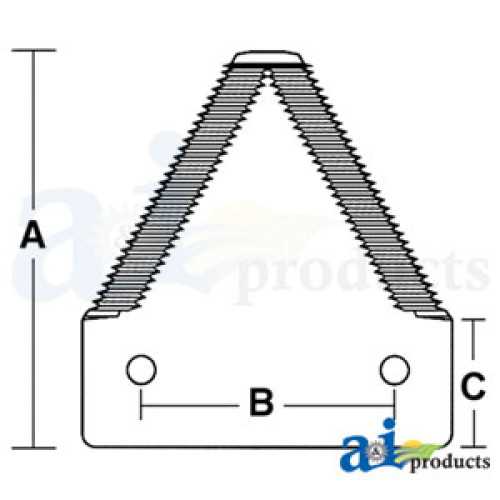

| Conditioning Rollers | Textured rollers | Crushes stems to promote drying |

Essential Components of the 1219 Model

The functionality of this agricultural machine is significantly influenced by its key elements, which work together to enhance performance and efficiency. Understanding these crucial components allows operators to maintain the equipment effectively and ensure optimal operation in various agricultural tasks.

Main Assembly Features

The principal assembly includes several integral parts that contribute to the overall efficiency of the machinery. These components work in harmony to facilitate smooth operation during various processes, ensuring that the equipment performs reliably under different conditions. Regular inspection and maintenance of these parts are essential for prolonging the lifespan of the machine.

Operational Accessories

In addition to the main assembly, a range of operational accessories plays a vital role in enhancing the functionality of the machine. These accessories provide additional capabilities, allowing the equipment to adapt to various agricultural tasks. Keeping these accessories in good condition is crucial for achieving optimal performance and productivity.

Exploring the Parts Diagram Features

Understanding the various components of agricultural machinery is crucial for effective maintenance and operation. The visual representation of these elements allows users to identify, locate, and comprehend the functionality of each part within the system. This section delves into the key attributes of these visual guides, providing insights into their significance in enhancing efficiency and prolonging the lifespan of equipment.

Key Attributes of the Visual Representation

These visual aids typically possess several noteworthy features:

- Clarity: The images are designed to be clear and easy to interpret, allowing users to quickly grasp the arrangement and connection of components.

- Labeling: Each element is usually labeled, providing essential information regarding specifications, part numbers, and alternative names.

- Color Coding: Different colors may be utilized to signify various systems or functions, helping to differentiate parts at a glance.

- Interactive Elements: Some modern representations offer interactive features, enabling users to click on specific parts for additional details or links to purchase replacements.

Benefits of Utilizing Visual Guides

Employing these graphical representations provides multiple advantages:

- Enhanced Understanding: Users can visualize the relationship between components, aiding in troubleshooting and repairs.

- Time Efficiency: Quick identification of necessary parts reduces downtime during maintenance activities.

- Improved Accuracy: Accurate recognition of components ensures that replacements are suitable, minimizing the risk of operational issues.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of agricultural machinery requires regular upkeep and attention. By implementing effective maintenance strategies, operators can significantly extend the lifespan of their equipment, reduce the risk of breakdowns, and enhance operational efficiency.

Routine Inspections

Conducting frequent inspections is vital to identify any potential issues before they escalate. Examine key components for wear and tear, checking belts, bearings, and hydraulic systems. Promptly addressing minor concerns can prevent costly repairs and downtime.

Proper Cleaning and Lubrication

Maintaining cleanliness is essential for smooth operation. After each use, clean the machinery to remove dirt and debris that could hinder performance. Additionally, regular lubrication of moving parts minimizes friction, reducing wear and prolonging the life of the equipment.

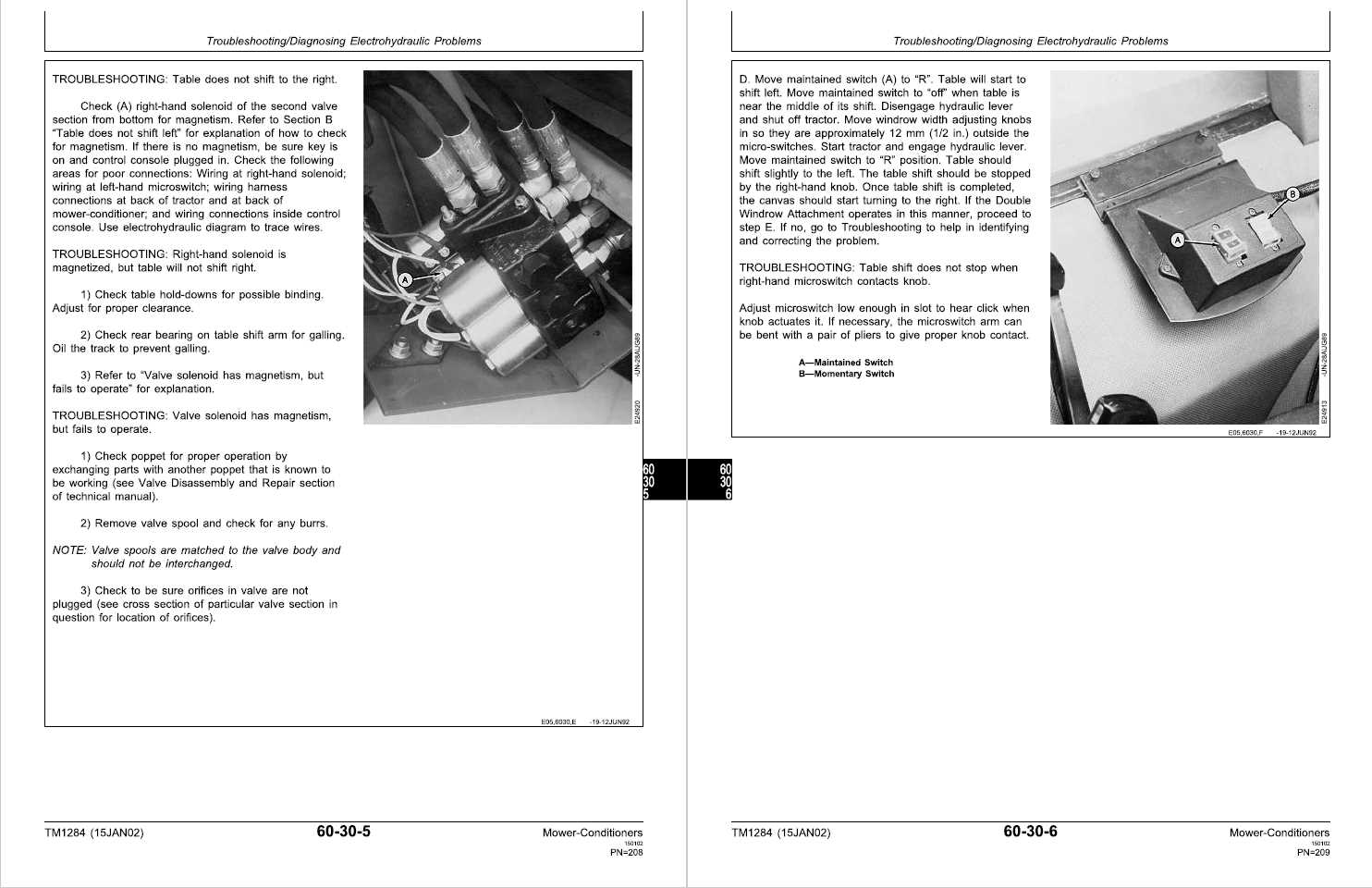

Common Issues and Solutions

In the world of agricultural machinery, challenges are an inevitable part of maintaining operational efficiency. Understanding frequent problems can help users quickly identify and address them, ensuring smooth performance and prolonging the lifespan of equipment. Below are some typical issues encountered with such machinery, along with effective solutions to mitigate them.

-

Unresponsive Mechanism:

If the machine fails to respond to controls, it may indicate electrical issues or a dead battery. Check connections and ensure the battery is fully charged. Replacing faulty wires may also be necessary.

-

Uneven Cutting:

When the cutting action is inconsistent, it could be due to dull blades or incorrect height settings. Sharpening or replacing blades and adjusting the cutting height can resolve this issue.

-

Excessive Vibration:

Vibration may result from unbalanced components or wear in moving parts. Inspect the equipment for loose bolts and tighten them, and check for any signs of damage to belts or bearings.

-

Material Jamming:

When materials become stuck in the machinery, it can disrupt operation. Clear any debris and ensure that feeding mechanisms are functioning correctly. Regular maintenance can prevent this problem.

-

Fluid Leaks:

Leaks in hydraulic systems can lead to severe performance issues. Inspect hoses and connections for signs of wear, and replace any damaged components promptly.

By recognizing and addressing these common challenges, operators can maintain their equipment in optimal condition, ensuring reliability during crucial operational periods.

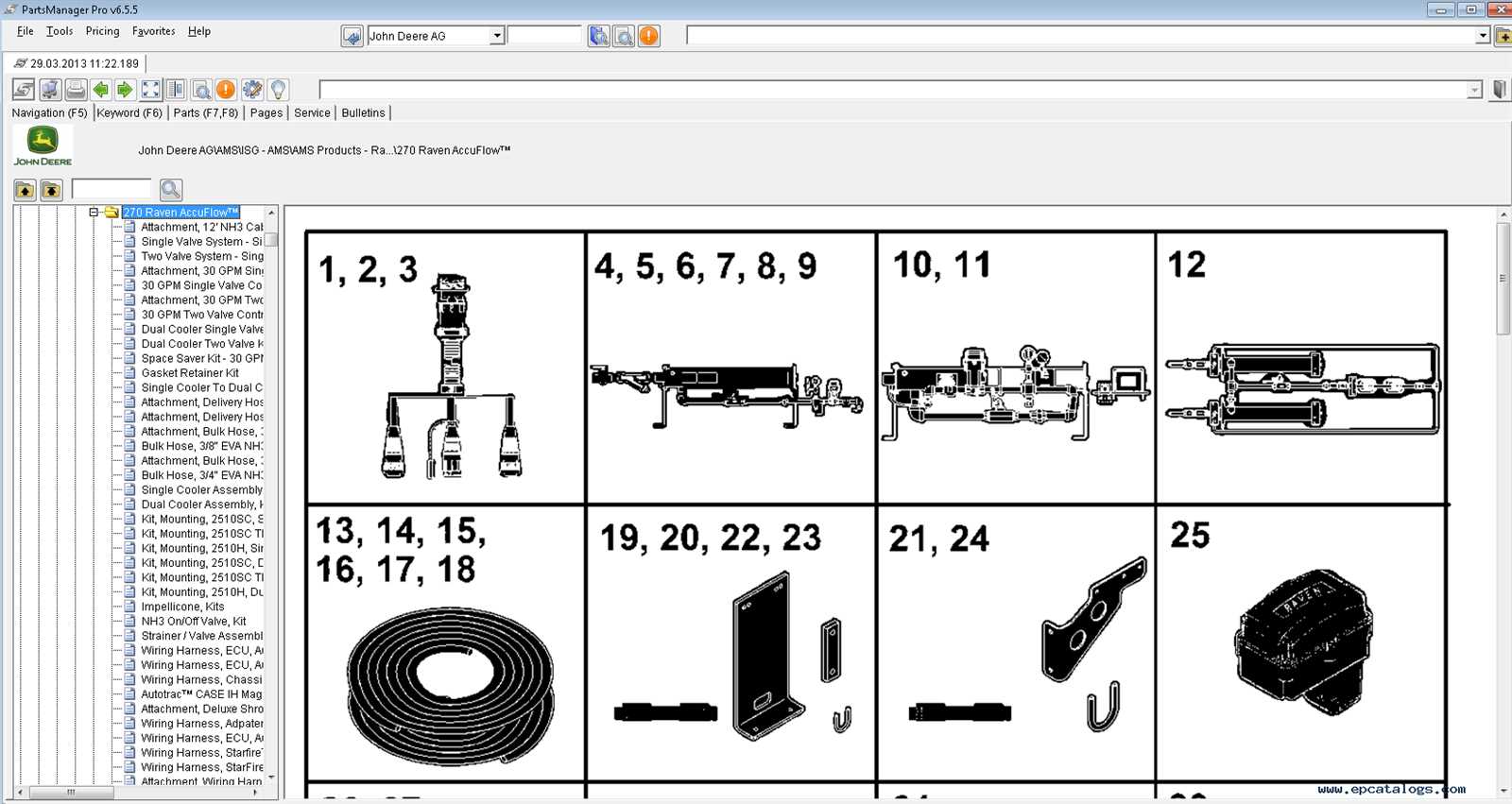

Ordering Replacement Parts Easily

Acquiring necessary components for your agricultural machinery can be a straightforward task with the right approach. Understanding where to look and how to navigate the process will help ensure that you obtain the items needed for optimal performance and maintenance. This section provides guidance on simplifying the ordering process for replacements.

Steps to Follow for Seamless Ordering

- Identify the specific component you require based on your equipment’s needs.

- Consult the machinery’s manual or technical documentation for details about the item.

- Utilize reputable online retailers or authorized dealers to ensure product quality.

- Keep track of any part numbers or identification codes to streamline your search.

- Compare prices and availability from multiple sources before making a purchase.

Tips for Efficient Ordering

- Sign up for newsletters or alerts from suppliers to receive updates on promotions and discounts.

- Consider purchasing in bulk for common items to save on shipping and costs.

- Verify return policies in case the components do not meet your expectations.

- Engage with customer service representatives if you have questions regarding compatibility or specifications.

By following these steps and tips, you can make the process of acquiring essential items for your agricultural equipment not only efficient but also cost-effective. This proactive approach ensures that your machinery remains in excellent working condition for many seasons to come.

Importance of Regular Inspections

Conducting frequent evaluations of agricultural machinery is essential for maintaining optimal performance and extending the lifespan of equipment. These assessments help identify potential issues before they escalate into significant problems, ultimately saving time and resources.

Benefits of Routine Evaluations

Regular assessments contribute to enhanced safety for operators and those working nearby. By ensuring that all components are functioning correctly, the risk of malfunctions is minimized. Additionally, timely inspections can lead to improved efficiency, as machinery operates at peak capacity when all parts are in good condition.

Preventative Maintenance

Implementing a systematic approach to evaluations not only addresses existing concerns but also aids in preventing future complications. Establishing a maintenance schedule encourages a proactive mindset, fostering an environment where potential issues are addressed before they impact productivity.

Upgrades for Enhanced Performance

When it comes to improving the overall efficiency and reliability of agricultural equipment, implementing specific enhancements can greatly contribute to better results. By upgrading essential components and systems, the machine can operate more smoothly and handle tasks with increased precision and speed. Modern updates allow users to achieve higher productivity while also minimizing wear and tear.

Improved Cutting Mechanism

One of the most critical areas for upgrade is the cutting mechanism. Enhancing the sharpness and durability of the blades ensures cleaner cuts and less clogging during operation. New blade materials and designs can also help extend the lifespan of the equipment, making maintenance less frequent.

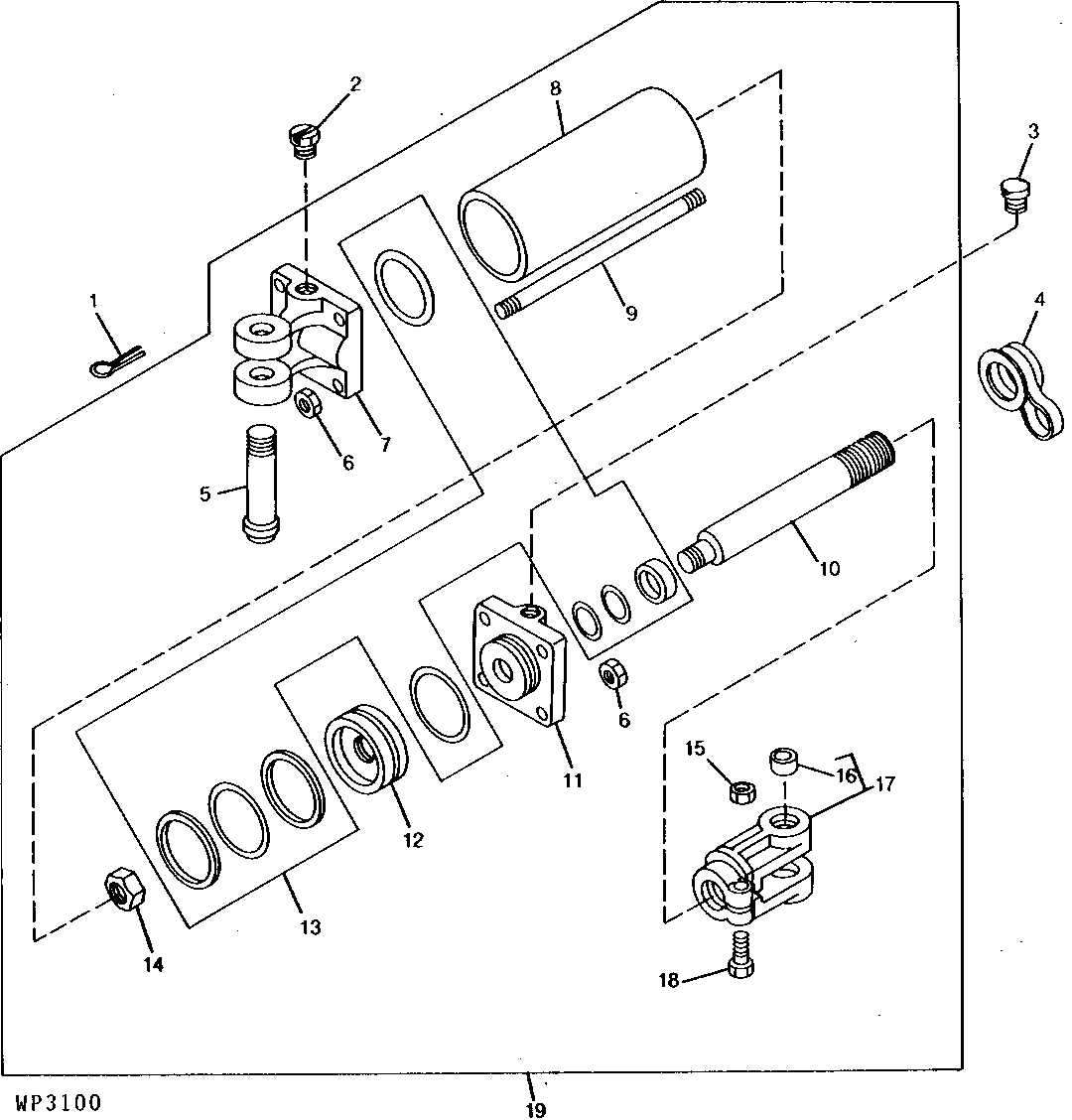

Hydraulic System Optimization

Optimizing the hydraulic system is another significant upgrade that can lead to smoother control and faster response times. This allows the machine to handle more demanding workloads with less strain, improving both performance and operational lifespan. Adding more efficient hydraulic components can also reduce energy consumption, leading to cost savings over time.

Safety Precautions When Operating

Ensuring safety during the operation of machinery is critical to preventing accidents and injuries. Before starting any equipment, it is essential to follow a set of safety guidelines to protect both the operator and those nearby. Careful attention to the working environment and machinery condition can significantly reduce risks.

Wear proper protective gear: Always use appropriate clothing, gloves, and eyewear to shield yourself from debris and potential hazards. Loose clothing should be avoided as it may get caught in moving parts.

Inspect equipment before use: Before operating, perform a thorough check of all components to ensure everything is in working order. Look for signs of wear, damage, or malfunction and address any issues before proceeding.

Maintain a clear working area: Keep the surroundings free of obstructions that could cause accidents or hinder safe operation. Ensure bystanders are at a safe distance while the machinery is in use.

Follow operational instructions: Always adhere to the specific instructions for operating the machine. This includes understanding the controls, proper speed, and safe maneuvering techniques.

Emergency protocols: Be familiar with the emergency shut-off procedures and ensure quick access to emergency equipment, such as fire extinguishers or first aid kits, in case of an incident.

How to Identify Worn Parts

Over time, equipment in agricultural machinery may experience wear and tear due to constant use. Recognizing when components have become less effective is crucial for maintaining smooth operation and avoiding larger breakdowns. Regular inspections can help detect potential issues early, ensuring timely replacements and repairs.

Visual Inspection is one of the easiest ways to identify signs of aging. Look for any unusual wear marks, cracks, or deformations on the components. If you notice any such signs, it might be time to consider a replacement.

Performance Reduction is another key indicator. If the equipment is no longer functioning at full capacity, or if there’s a noticeable decrease in efficiency, this could point to parts that have become worn out. Addressing these issues early can prevent more extensive damage.

Noisy Operation often signals that certain moving parts are wearing down. Pay attention to any unusual sounds, like grinding or squeaking, which could indicate friction or damage.

By staying vigilant and regularly inspecting your equipment, you can easily spot signs of deterioration, ensuring that any necessary adjustments are made before more significant failures occur.

Assembly Instructions for New Owners

When you begin the process of setting up your new equipment, it’s important to follow the steps carefully to ensure optimal performance and longevity. The assembly process may vary depending on the specific model and tools you are using, but the general principles remain consistent. This guide will help you navigate through the essential stages of assembly, from preparing the necessary components to finalizing the setup.

Below is an outline of the main components and their connections that are required during the assembly:

| Step | Description |

|---|---|

| 1 | Unpack and organize all components. Ensure that you have all the necessary bolts, nuts, and other fastening items. |

| 2 | Begin by assembling the frame. Attach the primary structure together using the designated fasteners. Tighten all bolts securely. |

| 3 | Next, install the cutting mechanism. Align it carefully with the main frame, ensuring that the attachment points are secure. |

| 4 | Connect the hydraulic or mechanical components, ensuring that hoses and cables are properly attached and free from obstruction. |

| 5 | Perform a final check to confirm that all parts are correctly aligned and tightened before operating the machine. |

Once the assembly is complete, it’s essential to test the machine in a safe environment before using it fully. This will allow you to identify any potential adjustments or fixes needed. Proper assembly ensures smooth operation and long-term reliability.

Comparing Models: 1219 vs Others

When choosing equipment for field operations, it’s essential to consider various factors that differentiate models. Each model offers distinct advantages, depending on the specific needs of your work, terrain, and productivity goals. In this section, we will compare the model in question to other similar options, focusing on performance, efficiency, and durability.

Performance and Efficiency

Performance varies significantly across different models, with some excelling in speed and cutting precision, while others might offer more versatility in handling different types of crops. Efficiency is another crucial factor, as newer models often come with technological upgrades that reduce operational