Exploring the intricate details of agricultural machinery is essential for anyone involved in maintenance or repair. A clear visual representation of individual elements can significantly enhance understanding, making it easier to identify each component’s function and importance.

Such illustrations not only serve as a reference for technicians but also empower operators to engage more confidently with their equipment. By delving into the specifics of assembly and individual mechanisms, users can gain valuable insights into optimizing performance and ensuring longevity.

Whether you are troubleshooting an issue or simply aiming to familiarize yourself with the machinery, having access to a comprehensive visual guide can streamline the process. This knowledge is crucial for effective upkeep, allowing for timely interventions and informed decisions when it comes to repairs and replacements.

Understanding John Deere 2155 Model

This section aims to provide insight into a particular agricultural machine, focusing on its features, functionalities, and applications. By exploring the essential components and their roles, one can appreciate the significance of this model in modern farming practices.

The machine is designed to enhance efficiency and productivity in various tasks, from tilling to transporting materials. Its robust construction ensures durability, while advanced engineering optimizes performance across diverse terrains. Users can benefit from understanding how each element contributes to the overall operation.

Moreover, familiarizing oneself with the various functions and mechanisms can lead to improved maintenance practices, ultimately extending the lifespan of the equipment. Knowledge of the inner workings enables operators to troubleshoot issues more effectively, ensuring seamless agricultural operations.

In conclusion, delving into the specifics of this model reveals its ultimate value in enhancing agricultural productivity, making it an essential asset for farmers and landowners alike.

Key Features of the 2155 Tractor

This agricultural machine stands out due to its combination of robust performance and user-friendly design. With a focus on efficiency and reliability, it caters to the diverse needs of modern farming.

Engine and Performance

The tractor is equipped with a powerful engine that delivers exceptional torque and horsepower, enabling it to handle various tasks with ease. Its efficient fuel consumption ensures that operators can work longer without frequent refueling.

Comfort and Usability

Designed with the operator in mind, the vehicle features an ergonomic cab layout, providing comfort during extended hours of operation. The intuitive controls and excellent visibility contribute to a seamless user experience.

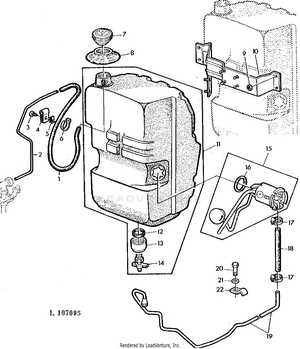

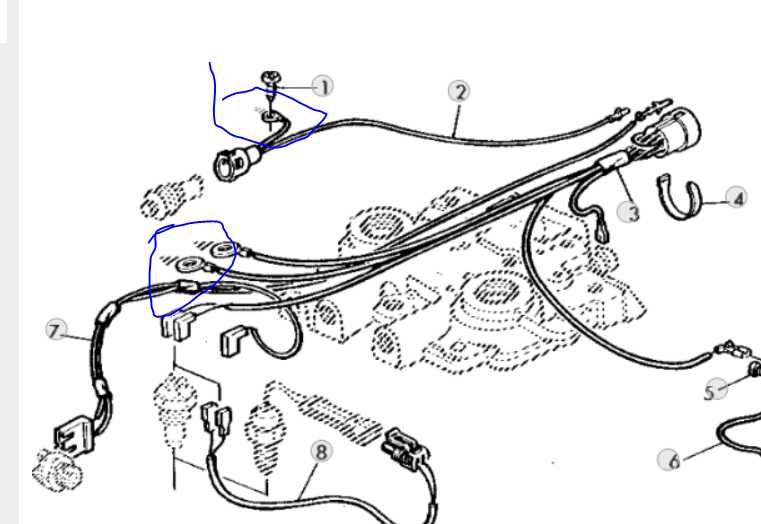

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repairs. Visual representations enhance comprehension, allowing users to identify elements swiftly and accurately. Such illustrations serve as vital tools for both professionals and enthusiasts, streamlining the process of upkeep.

Enhanced Efficiency

Utilizing visual guides significantly boosts efficiency. Technicians can quickly locate necessary components, reducing downtime during repairs. This organized approach minimizes frustration and enhances workflow, ensuring that tasks are completed promptly.

Improved Communication

Visual aids foster better communication among team members. When discussing repairs or modifications, referencing clear illustrations eliminates ambiguity. This shared understanding leads to more cohesive teamwork and effective problem-solving.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components can be essential for maintenance and repair tasks. These visual guides assist users in identifying specific elements, ensuring that repairs are accurate and efficient. Numerous resources are available to help enthusiasts and professionals alike in their search for these invaluable references.

Online Resources: The internet offers a plethora of websites dedicated to agricultural machinery. Manufacturer websites often provide comprehensive libraries where users can access schematics for various models. Additionally, third-party sites may host a wide array of visual aids contributed by other users, making it easier to find what you need.

Forums and Community Groups: Engaging with online communities can also yield fruitful results. Many enthusiasts share their expertise and resources in forums dedicated to machinery repair. Posting a specific inquiry can connect you with experienced individuals who may have the exact schematic you’re searching for.

Manuals and Guides: Printed manuals remain a reliable source for detailed illustrations. Many manufacturers publish extensive guides that include not just schematics but also tips for repairs and maintenance. These can often be purchased or found in libraries and second-hand bookstores.

Local Dealerships: Reaching out to local dealers can provide access to original materials. They often have access to extensive databases of schematics and can offer assistance in locating the right documents for your needs.

Utilizing these resources can significantly enhance your ability to find the necessary visual aids for effective maintenance and repair of your equipment.

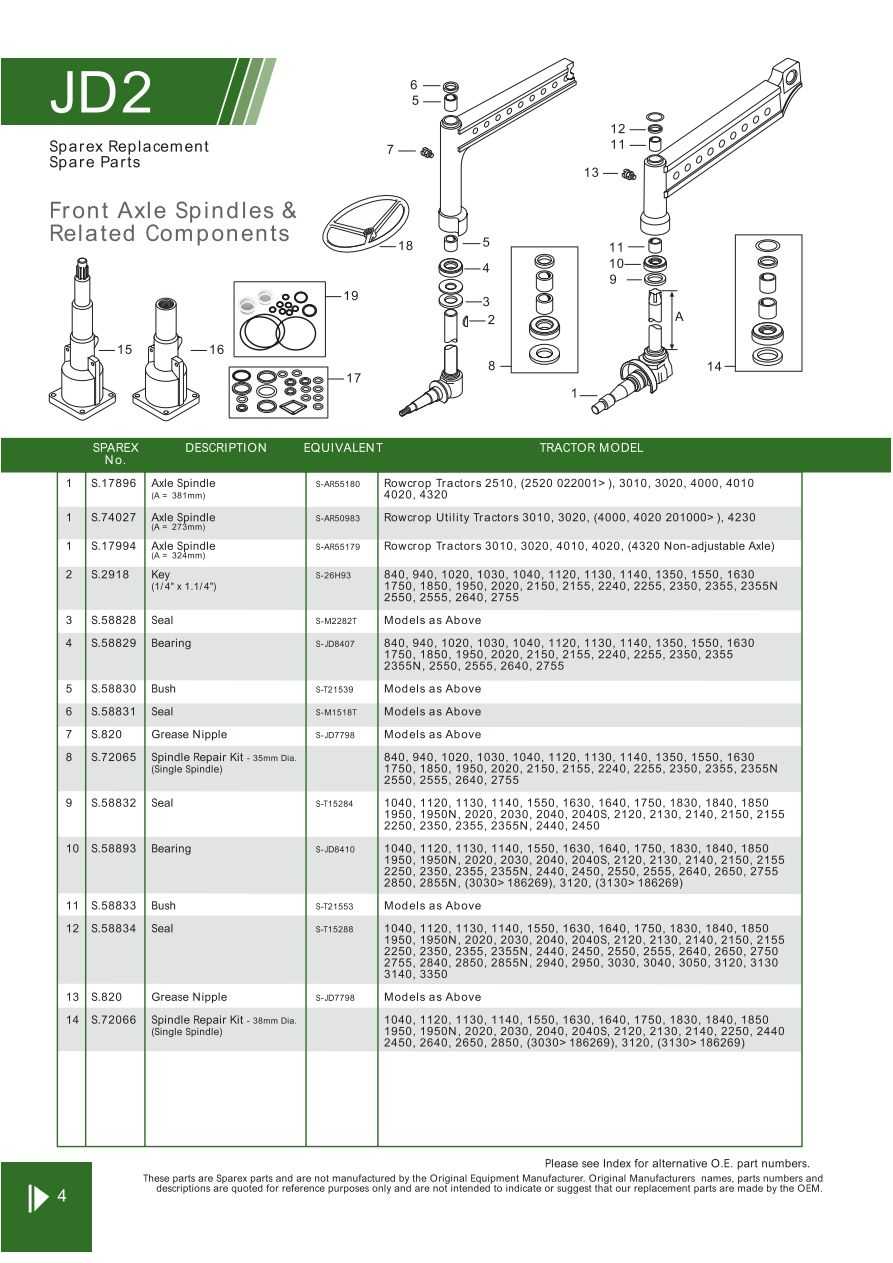

Common Replacement Parts for 2155

Maintaining optimal performance in agricultural machinery often requires replacing certain components over time. Understanding which elements commonly wear out can help in planning maintenance effectively.

- Fuel filters

- Air filters

- Hydraulic oil seals

- Belts and hoses

- Battery terminals

Regular inspection and timely replacement of these items can significantly enhance longevity and functionality. Investing in quality substitutes ensures that machinery operates smoothly and efficiently.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of machinery requires regular attention and care. By implementing a series of maintenance practices, operators can significantly extend the lifespan of their equipment while optimizing performance. Understanding the critical components and their upkeep is essential for any user aiming for reliability and productivity.

Regular Inspections

Frequent evaluations of key elements can prevent minor issues from escalating into major repairs. Pay close attention to fluid levels, filters, and belts. Addressing wear and tear promptly ensures that machinery runs smoothly and avoids unexpected breakdowns. Implement a checklist for each inspection to maintain consistency.

Lubrication and Cleaning

Keeping parts well-lubricated reduces friction and wear. Use high-quality lubricants tailored for specific components, and follow the manufacturer’s recommendations for intervals. Additionally, regular cleaning removes debris and contaminants that can hinder performance. Consider using non-corrosive cleaning agents to protect surfaces.

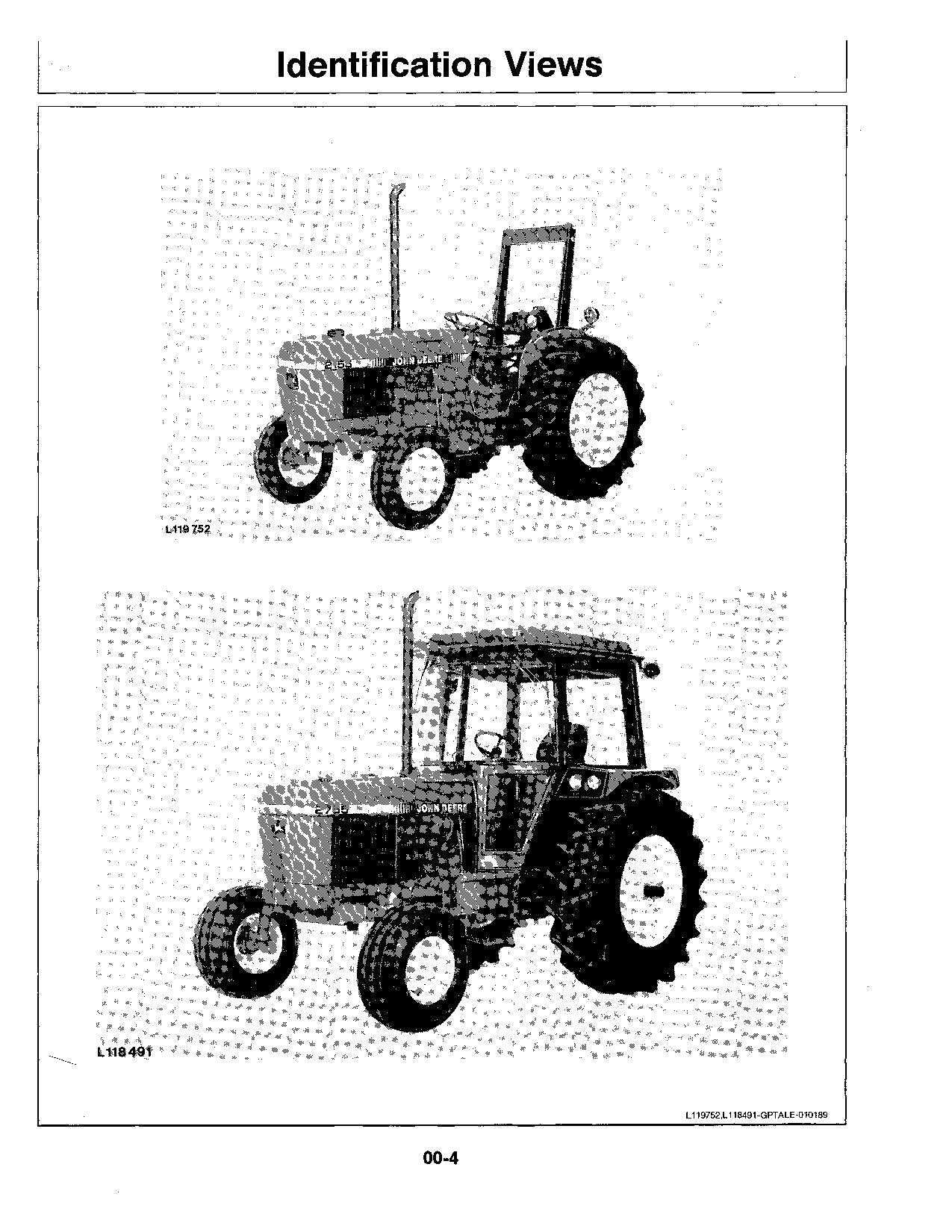

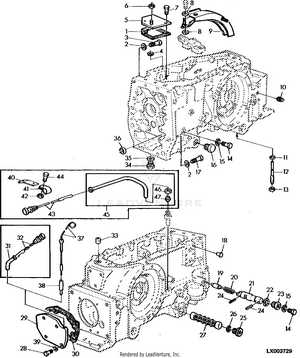

Identifying Parts by Diagram

Understanding the layout of components within machinery is essential for efficient maintenance and repair. Visual representations allow operators to quickly locate and identify each element, ensuring a smoother workflow and minimizing downtime.

Benefits of Visual Guides

Utilizing illustrations enhances the troubleshooting process. These visuals simplify complex information, making it easier to recognize specific elements and their functions, which is crucial for effective repairs.

Tips for Effective Identification

When examining visual references, pay close attention to labels and numbering systems. Familiarizing yourself with these features can significantly improve your ability to pinpoint parts and understand their relationships within the overall structure.

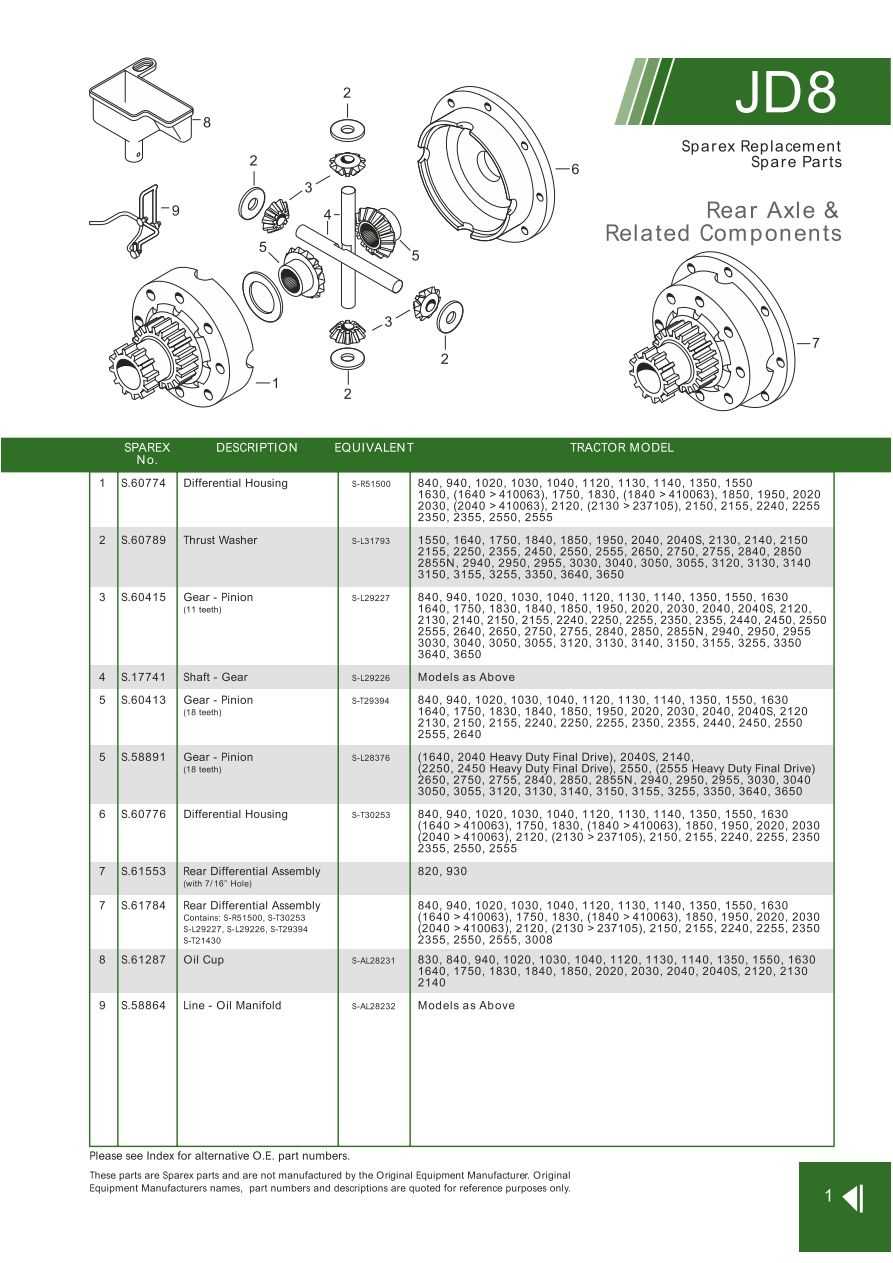

Parts Compatibility with Other Models

Understanding the interchangeability of components among various machinery models can significantly enhance maintenance efficiency and reduce costs. Many equipment users benefit from recognizing which elements can be shared across different variants, allowing for easier sourcing and replacement.

Cross-Model Sharing

Several models within the same brand family share similar configurations and component designs. This similarity facilitates the use of certain components from one model in another, providing flexibility in repairs and upgrades. It is crucial to refer to the compatibility charts or consult with experts to ensure that the elements meet the required specifications.

Identifying Compatible Components

To identify suitable alternatives, users should consider factors such as size, fit, and function. Consulting official manuals or reputable resources can guide users in making informed choices. Investing time in research can lead to successful replacements that not only save money but also extend the longevity of the equipment.

Top Suppliers for 2155 Parts

Finding reliable vendors for agricultural machinery components is essential for maintaining efficiency and performance. Various suppliers offer a wide range of options, ensuring that operators can access high-quality replacements and upgrades. This section highlights some of the leading providers in the market, renowned for their expertise and service.

Leading Vendors

- AgriSupply: Known for its extensive inventory, this supplier offers both original and aftermarket components, catering to diverse needs.

- Tractor Supply Co.: With a reputation for quality, this company provides a variety of products, from essential accessories to specialized equipment.

- Fastenal: This supplier focuses on industrial and agricultural tools, providing a selection of components that enhance machinery performance.

Online Marketplaces

- eBay: A popular platform for both new and used components, where buyers can find competitive prices and various options.

- Amazone: Offers a convenient shopping experience, featuring a range of products from multiple vendors.

- Alibaba: A global marketplace that connects buyers with manufacturers, allowing for bulk purchasing and diverse product availability.

DIY Repair vs. Professional Service

When it comes to maintaining machinery, owners often face the choice between tackling repairs themselves or seeking help from experts. Each option has its own set of advantages and drawbacks, making it essential to consider various factors before making a decision.

Benefits of DIY Repairs

- Cost Savings: Performing repairs on your own can significantly reduce labor costs.

- Learning Experience: Engaging in hands-on repairs can enhance your mechanical skills and knowledge.

- Flexibility: You can work on your own schedule, avoiding the need to book appointments.

Advantages of Professional Services

- Expertise: Professionals bring extensive knowledge and experience, ensuring repairs are done correctly.

- Time Efficiency: Skilled technicians can complete repairs faster, allowing you to get back to work sooner.

- Warranty Protection: Many services offer guarantees on their work, providing peace of mind.

Ultimately, the choice between DIY repairs and professional assistance depends on individual circumstances, including skill level, complexity of the issue, and available resources.

Cost Considerations for Replacement Parts

When maintaining machinery, evaluating expenses for components is crucial for effective budgeting and long-term operational efficiency. Understanding the financial implications of sourcing new elements can significantly impact overall maintenance strategies.

Several factors influence the costs associated with replacements:

- Quality: Higher-quality components often come with a premium price tag, but they may offer improved durability and performance.

- Brand Reputation: Established manufacturers might charge more due to their track record and warranty offerings.

- Availability: Rare or obsolete items can be more expensive due to limited supply, affecting procurement costs.

- Installation Fees: Consider the labor costs involved in replacing components, as professional assistance may be required.

- Shipping Costs: Transport expenses can vary widely depending on the location and supplier’s terms.

Moreover, it’s wise to consider the potential long-term savings associated with investing in more expensive yet reliable options. Cheaper alternatives might lead to frequent replacements, ultimately increasing overall costs.

In summary, a thorough analysis of these considerations will aid in making informed choices that balance quality and expense, ensuring the sustainability of equipment over time.

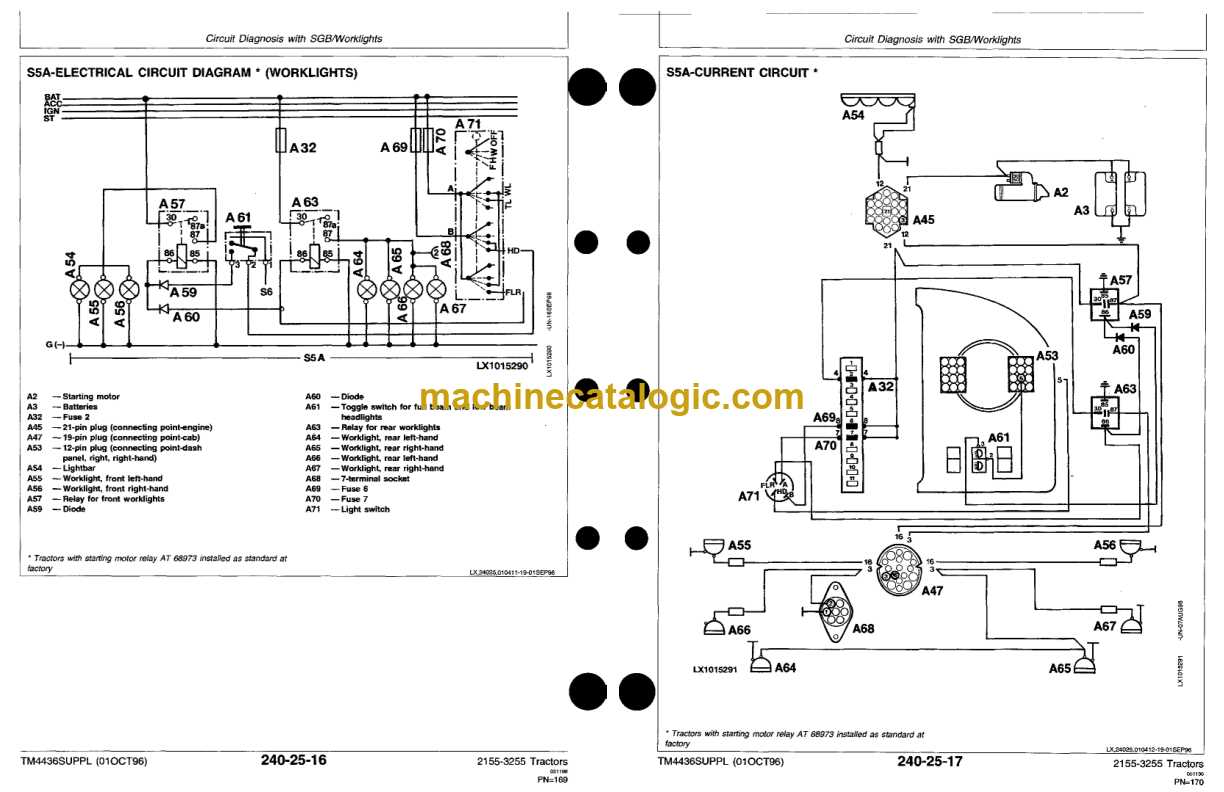

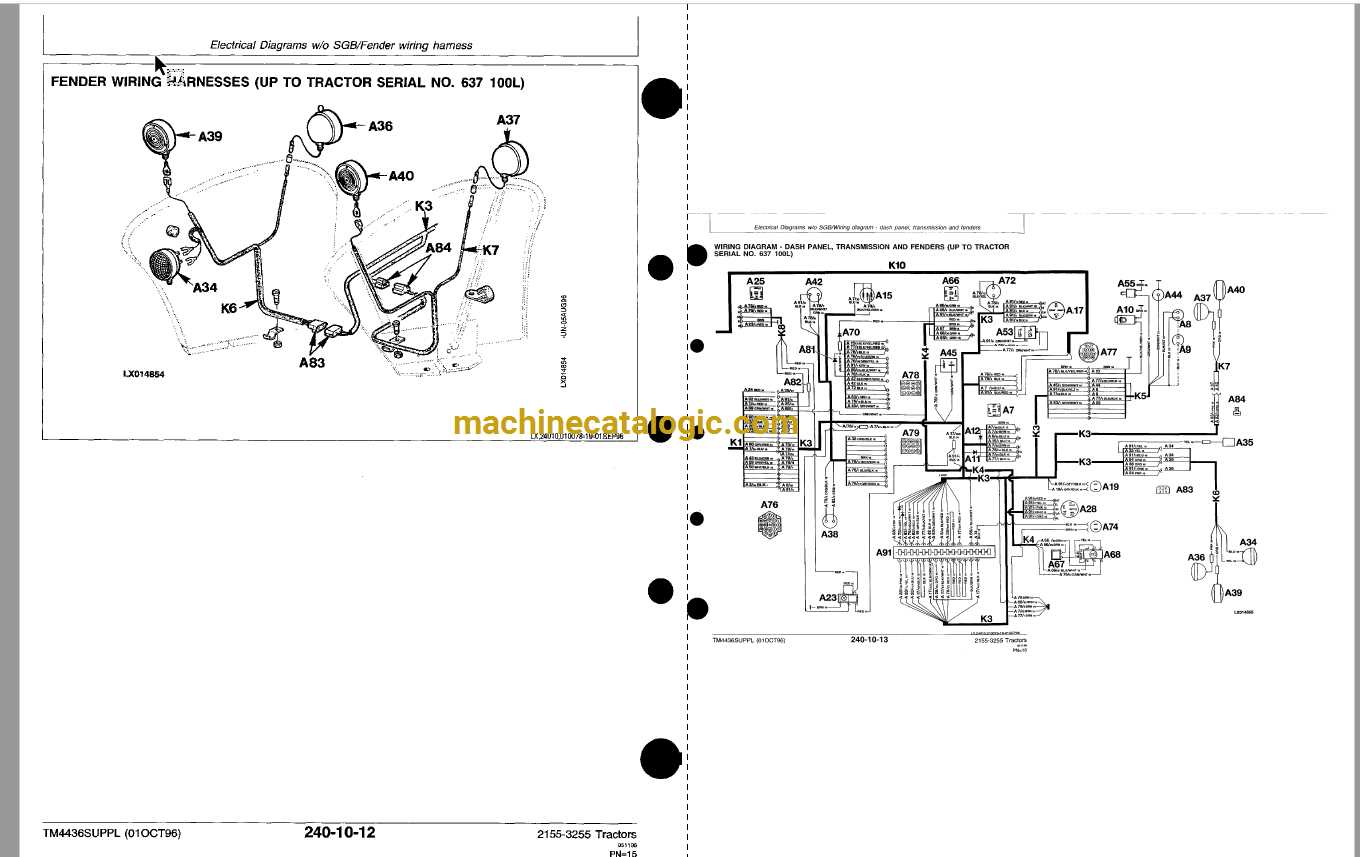

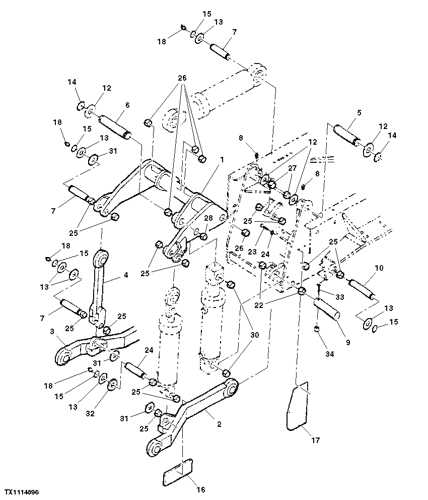

Understanding Tractor Component Functions

Tractors are intricate machines, each component playing a vital role in overall performance. Understanding the functionality of these elements enhances not only maintenance but also the efficiency of agricultural operations. Every part contributes to the seamless operation of the vehicle, allowing it to perform a variety of tasks effectively.

The engine serves as the heart of the machine, providing the necessary power to drive all other systems. It converts fuel into mechanical energy, enabling the tractor to operate under various loads. Transmission systems, on the other hand, facilitate the transfer of this power to the wheels, allowing for smooth acceleration and deceleration based on the operator’s needs.

Another critical aspect is the hydraulic system, which empowers implements and attachments, enabling tasks such as plowing, lifting, and tilling. This system operates through fluid pressure, ensuring precise control and adaptability in different agricultural scenarios. Additionally, the steering mechanism ensures maneuverability, allowing the operator to navigate through fields with ease.

Finally, understanding the electrical system is essential for maintaining modern tractors. This system controls everything from the ignition to the lights, ensuring safety and functionality. By grasping the roles of these key components, operators can optimize their machines, enhancing productivity and extending the lifespan of the equipment.

Frequently Asked Questions about 2155 Parts

This section addresses common inquiries regarding components and accessories for a specific model of agricultural machinery. Understanding these details can significantly enhance maintenance and operational efficiency.

| Question | Answer |

|---|---|

| What are the essential components for maintenance? | Key elements include filters, belts, and fluid systems that require regular inspection and replacement. |

| Where can I find quality replacements? | Authorized dealers and reputable online retailers offer a variety of reliable replacements for optimal performance. |

| How do I identify specific components? | Refer to the user manual or consult a parts catalog that provides detailed illustrations and descriptions. |

| Are aftermarket options viable? | Yes, many aftermarket options are available, but it’s crucial to ensure compatibility and quality standards. |