In the realm of construction and woodworking, having a reliable fastening tool can significantly enhance efficiency and precision. This guide delves into the various elements that make up such a device, enabling users to better understand its functionality and maintenance. A comprehensive grasp of each component not only aids in effective operation but also fosters a deeper appreciation for the craftsmanship involved.

From the mechanism that drives the fasteners to the housing that encases the internal workings, each piece plays a critical role in the overall performance. Knowledge of these elements empowers users to troubleshoot issues, perform necessary repairs, and ensure longevity. Whether you are a seasoned professional or a DIY enthusiast, familiarizing yourself with these components can elevate your projects to new heights.

Moreover, recognizing how each part interacts within the system provides insights into optimizing usage and achieving superior results. As you explore the intricate details, you will uncover tips for efficient handling and safety precautions, making your experience with the tool not only productive but also enjoyable.

Dewalt 18 Gauge Brad Nailer Overview

This section provides an insight into a versatile tool designed for precision fastening in various woodworking projects. It excels in delivering reliable performance, making it a favorite among both professionals and DIY enthusiasts.

- Lightweight and easy to handle

- Designed for various applications, from trim work to cabinetry

- Features quick jam release for effortless maintenance

- Adjustable depth control for customized results

The tool is equipped with an efficient motor, ensuring consistent firing with minimal effort. Users appreciate its ergonomic design, allowing for extended use without fatigue.

- Enhanced safety features

- Compatible with multiple fastener lengths

- Low nail indicator for timely reloading

Overall, this tool embodies reliability and efficiency, making it an ultimate choice for those seeking quality in their fastening tasks.

Key Features of Dewalt Nailers

When it comes to fastening tools, certain characteristics set these high-performance devices apart from the competition. Designed for efficiency and precision, they offer a range of functionalities that cater to both professionals and DIY enthusiasts. From robust construction to user-friendly features, these tools ensure reliable results for various projects.

Durability and Build Quality

These fastening instruments are engineered with premium materials, making them resistant to wear and tear. Their robust construction not only enhances longevity but also ensures consistent performance, even under demanding conditions. This reliability is essential for those tackling heavy-duty tasks.

Ease of Use

Intuitive designs make these tools accessible for users of all skill levels. Features such as adjustable depth settings and tool-free jam release mechanisms streamline the workflow, allowing for quick adjustments and minimal downtime. Ergonomic handles and lightweight designs further enhance comfort during extended use, making them ideal for prolonged projects.

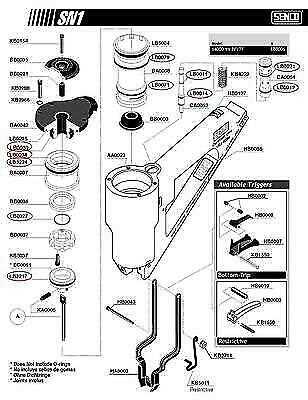

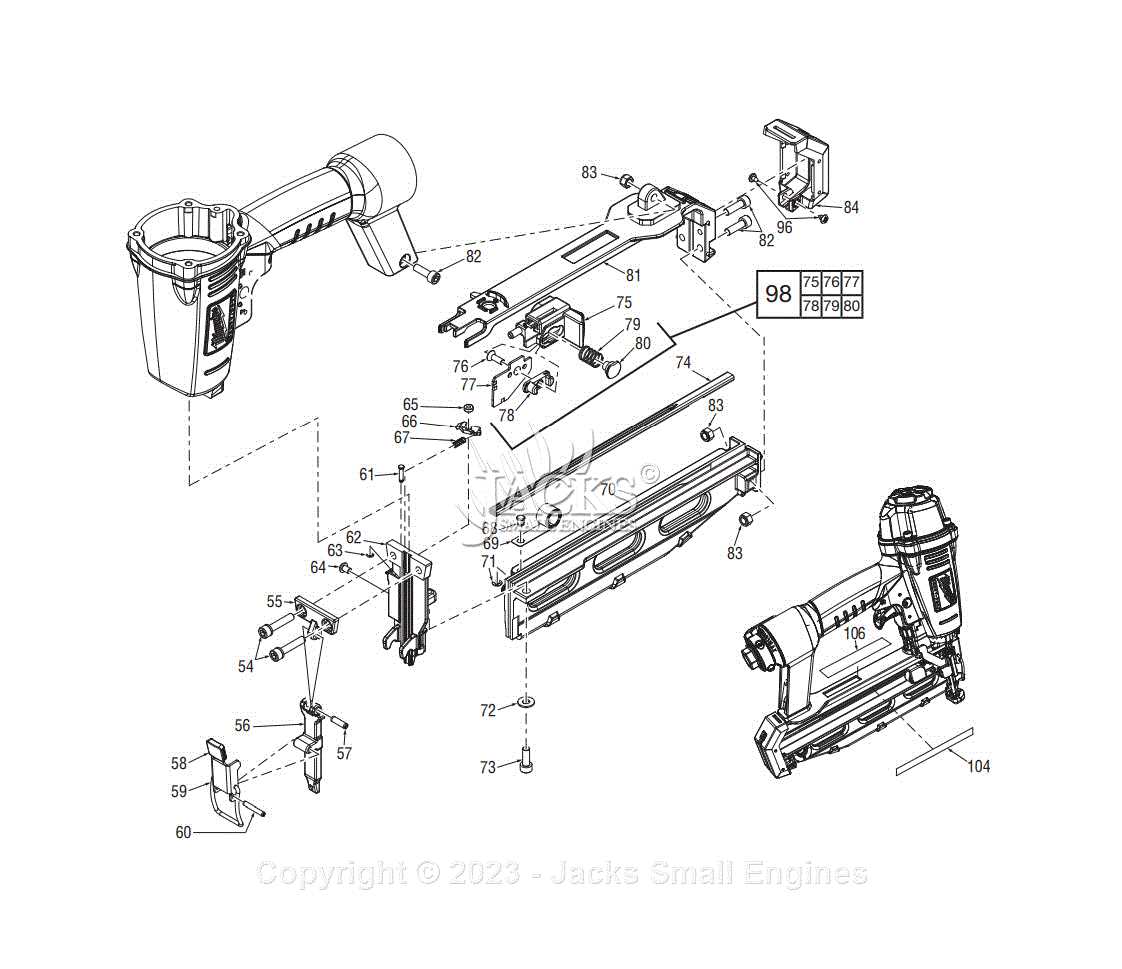

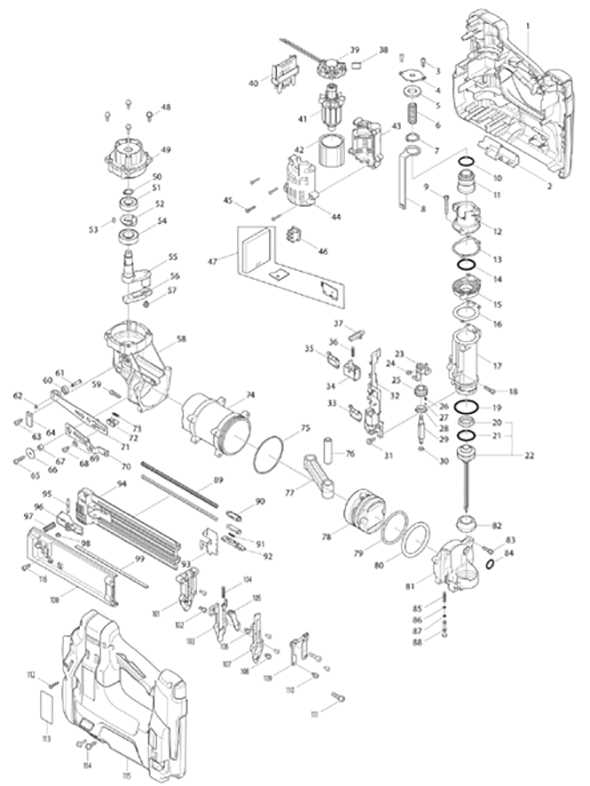

Understanding the Parts Diagram

Grasping the layout of an assembly is essential for effective maintenance and troubleshooting. A well-structured visual representation serves as a guide, highlighting each component and its function within the overall mechanism. By familiarizing yourself with these elements, you can enhance your understanding and improve the efficiency of your tasks.

The schematic illustrates various components, allowing users to identify how they interact and contribute to the tool’s operation. From the trigger to the drive mechanism, each piece plays a pivotal role. Recognizing these parts not only aids in assembly but also in diagnosing potential issues that may arise during usage.

Understanding the configuration empowers users to execute repairs or replacements with confidence. Familiarity with the arrangement facilitates quicker resolutions to problems, ultimately extending the life of the tool and ensuring optimal performance. Engaging with the visual guide is a crucial step toward becoming proficient in handling the device effectively.

Common Issues and Solutions

When working with fastening tools, users often encounter a range of challenges that can hinder efficiency and performance. Understanding these common problems and their respective solutions can greatly enhance your experience and ensure smooth operation.

-

Jams:

One of the most frequent issues is the occurrence of jams. These can happen due to misalignment or improper loading of fasteners.

- Ensure that the fasteners are loaded correctly according to the manufacturer’s guidelines.

- Regularly clean the loading chamber to prevent debris buildup.

- Check for any bent or damaged components that may cause misalignment.

-

Inconsistent Fastening:

Another common concern is inconsistent fastening, which may result in incomplete or improperly set fasteners.

- Verify that the pressure settings are appropriate for the type of material being used.

- Inspect the tool for any wear and tear that may affect performance.

- Ensure a firm grip and steady motion during operation for consistent results.

-

Leakage:

Air leaks can lead to diminished power and performance, making it crucial to address this issue promptly.

- Examine all hoses and connections for cracks or loose fittings.

- Replace any worn seals or gaskets to prevent air loss.

- Regular maintenance can help identify potential leaks before they become a problem.

-

Noise Issues:

Excessive noise can be both a distraction and an indication of potential problems.

- Check for loose screws or components that may cause rattling.

- Consider using lubricants recommended by the manufacturer to reduce friction.

- Ensure the tool is not overworked, as this can lead to increased noise levels.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your tool and ensuring optimal performance. Regular maintenance helps prevent wear and tear, allowing you to work efficiently over time.

- Keep the tool clean: Regularly remove dust and debris from all surfaces.

- Check for wear: Inspect all components for signs of damage or excessive wear.

- Lubricate moving parts: Use appropriate oil to maintain smooth operation.

- Store properly: Keep the tool in a dry, safe place to avoid environmental damage.

- Follow manufacturer guidelines: Adhere to the recommended maintenance schedule.

By following these tips, you can delve into the ultimate care of your equipment, ensuring it remains reliable for years to come.

Choosing the Right Nails

Selecting the appropriate fasteners for your project is crucial for achieving a durable and professional finish. The type of nails you choose can significantly influence both the strength of the connection and the overall appearance of your work. Understanding the different options available will help you make an informed decision tailored to your specific needs.

| Type | Length | Material | Best Use |

|---|---|---|---|

| Finish | 1″ to 2.5″ | Steel | Trim work |

| Common | 2″ to 4″ | Galvanized | Framing |

| Box | 1.25″ to 2.5″ | Stainless | Outdoor projects |

Safety Precautions While Operating

Ensuring safety during the use of any power tool is crucial for preventing accidents and injuries. Following proper guidelines not only protects the operator but also enhances the overall efficiency of the task at hand.

General Safety Guidelines

- Always wear appropriate personal protective equipment, including safety goggles and gloves.

- Keep your work area well-lit and free of clutter to prevent tripping hazards.

- Ensure that the tool is in good condition before use; inspect for any damage.

- Read the manufacturer’s instructions thoroughly before operating the equipment.

Operational Best Practices

- Maintain a firm grip on the tool and always point it away from yourself and others.

- Disconnect the power source when not in use or during adjustments.

- Do not bypass safety features or operate the tool without them in place.

- Be mindful of your surroundings; watch out for bystanders.

Comparing Models in the Series

This section focuses on examining the various models available within the lineup, highlighting their distinct features and functionalities. By analyzing these differences, users can determine which option best suits their specific needs.

Model A offers a lightweight design, making it ideal for extended use without fatigue. Its high-speed performance ensures efficient operation, perfect for quick projects. In contrast, Model B boasts advanced precision technology, enhancing accuracy for intricate tasks.

Additionally, Model C is known for its durability, built to withstand demanding environments, while still providing ease of handling. Each model serves a unique purpose, allowing users to select the ultimate tool for their projects.

Ultimately, understanding the strengths and weaknesses of each model can significantly impact the outcome of your work, ensuring you choose the right tool for your requirements.

Repairing vs. Replacing Components

When it comes to maintaining tools, the decision between fixing an existing element or opting for a new one can significantly impact both functionality and budget. Understanding the nuances of each approach is crucial for achieving optimal performance and longevity of equipment.

Benefits of Repairing

Repairing components often proves to be a cost-effective solution, allowing users to extend the lifespan of their tools without incurring the expense of new purchases. Additionally, repairs can help maintain original specifications, ensuring that the equipment continues to operate as intended. For those who are skilled in hands-on maintenance, the satisfaction of restoring a tool can also be a rewarding experience.

Advantages of Replacement

On the other hand, replacing parts can sometimes be the most practical choice, particularly when damage is extensive or when older components are no longer compatible with modern technology. New components may offer enhanced features, improved efficiency, and reduced risk of future breakdowns. This can lead to better performance overall, making it a viable option for those seeking reliability and innovation in their tools.

Upgrading Your Nailer Effectively

Enhancing your fastening tool can significantly improve its performance and longevity. By focusing on various components and ensuring they are optimized, you can achieve better results in your projects. This section explores effective ways to upgrade your equipment, ensuring you get the most out of your investment.

Key Components to Consider

When upgrading, pay attention to several critical elements that can impact the efficiency and effectiveness of your device:

| Component | Benefits of Upgrading |

|---|---|

| Trigger Mechanism | Improved precision and control for enhanced accuracy. |

| Air Filter | Reduces contaminants, leading to smoother operation and longer lifespan. |

| Depth Adjustment | Allows for customizable fastening depth, ensuring optimal results on various materials. |

| Magazine Capacity | Increases productivity by reducing the frequency of reloads. |

Installation Tips

To ensure a successful upgrade, follow these tips during installation:

- Always consult the user manual for compatibility.

- Use appropriate tools for disassembly and assembly.

- Regularly check and maintain all components to prolong their life.