When it comes to woodworking, having a clear grasp of the essential elements of your equipment is crucial for optimal performance and longevity. A well-maintained machine not only enhances productivity but also ensures safety in the workspace. Familiarizing oneself with the various components and their functions lays the groundwork for effective repairs and upgrades.

This section delves into the intricate details of a specific machine model, offering insights into its structure and assembly. By exploring the various segments and their roles, users can better appreciate how each piece contributes to the overall functionality. Understanding these elements can significantly impact maintenance routines and troubleshooting processes.

Moreover, having access to a comprehensive overview of these components provides users with the ultimate advantage in both everyday use and specialized tasks. Armed with this knowledge, enthusiasts and professionals alike can make informed decisions regarding repairs, replacements, and modifications.

Dewalt 734 Planer Overview

This section provides an in-depth look at a highly regarded woodworking tool known for its efficiency and reliability. Ideal for professionals and hobbyists alike, this machine offers features that enhance performance and precision, making it a valuable addition to any workshop.

| Feature | Description |

|---|---|

| Power | Equipped with a robust motor for effortless operation. |

| Portability | Compact design allows for easy transport and storage. |

| Adjustability | Multiple settings provide versatility for different projects. |

| Durability | Constructed with high-quality materials for long-lasting use. |

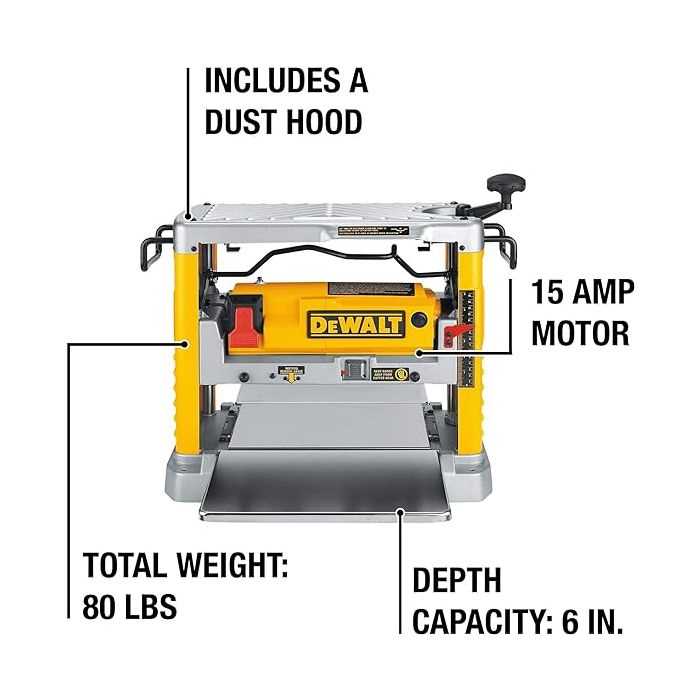

Key Features of the Dewalt 734

This high-performance tool is designed for precision and efficiency in woodworking tasks. Its robust construction ensures durability, making it a reliable choice for both professionals and enthusiasts alike.

| Feature | Description |

|---|---|

| Powerful Motor | Equipped with a strong motor for handling various materials effortlessly. |

| Compact Design | Lightweight and portable, ideal for job sites and workshops. |

| Adjustable Depth | Allows for precise depth settings to achieve the desired finish. |

| High Cutting Speed | Fast feed rate enhances productivity without compromising quality. |

| Durable Blades | Long-lasting blades ensure consistent performance and less frequent replacements. |

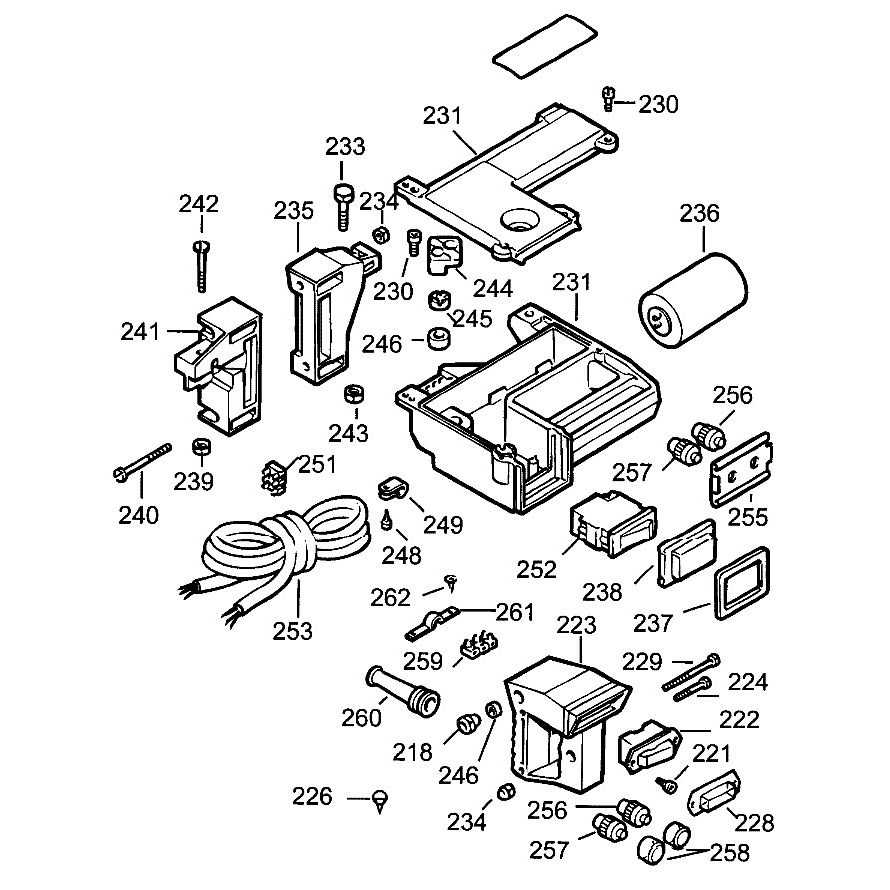

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and repair of machinery. A well-organized visual representation helps users identify individual elements and their relationships within the entire system. This knowledge not only aids in troubleshooting but also facilitates informed decisions regarding replacements and upgrades.

Key Components and Their Functions

Each section of the illustration highlights specific features that play crucial roles in the operation of the device. Recognizing the purpose of each part allows for a more profound understanding of how they interact. Whether it’s the motor, blades, or adjustment mechanisms, knowing their functions is vital for achieving optimal performance.

Maintenance and Repair Insights

Utilizing a detailed illustration serves as a roadmap for effective upkeep. By pinpointing where issues may arise, users can address potential problems before they escalate. This proactive approach not only prolongs the life of the equipment but also enhances overall efficiency, ensuring that tasks are completed with precision.

Main Components Explained

Understanding the primary elements of a woodworking tool is crucial for efficient operation and maintenance. Each part plays a significant role in achieving precise and smooth finishes.

- Cutter Head: This rotating component houses the blades and is responsible for removing material from the workpiece.

- Feed Rollers: These elements grip the wood and feed it through the machine at a consistent speed.

- Table: The flat surface on which the material rests, providing stability during the planing process.

- Depth Adjustment Mechanism: This allows users to set the thickness of the cut, ensuring versatility for various projects.

- Chip Ejector: Designed to clear away shavings and debris, keeping the workspace clean and enhancing visibility.

By familiarizing yourself with these components, you can delve into their functions and ultimately enhance your woodworking experience.

Common Issues with the Dewalt 734

When working with woodworking equipment, users may encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems can aid in timely maintenance and repairs, ensuring optimal functionality.

Frequent Problems

- Unusual Noise: Excessive sound may indicate worn bearings or loose components.

- Inconsistent Cuts: This can result from dull blades or misalignment of the cutting mechanism.

- Overheating: Often caused by prolonged use or inadequate cooling.

Prevention Tips

- Regularly inspect and replace blades to maintain cutting quality.

- Keep all parts clean and lubricated to reduce friction.

- Check alignment periodically to ensure accurate performance.

How to Identify Worn Parts

Recognizing when components have reached the end of their lifespan is crucial for maintaining optimal performance in any machinery. Understanding the signs of wear and tear can help you avoid more significant issues down the line. Here are key indicators to watch for.

- Visual Inspection: Regularly check for cracks, chips, or discoloration on surfaces.

- Listen for Unusual Sounds: Grinding, rattling, or squeaking noises can signal that something is not functioning properly.

- Performance Issues: Noticeable changes in efficiency or output can indicate that components are wearing out.

To further assist in the identification process, consider the following methods:

- Measure Tolerance Levels: Use calipers to measure critical dimensions and compare them to manufacturer specifications.

- Check for Excessive Vibration: If the equipment vibrates more than usual, it may point to failing parts.

- Evaluate Lubrication Needs: Increased friction often results from worn elements requiring more frequent lubrication.

By staying vigilant and employing these strategies, you can effectively identify components that need attention, ensuring longevity and reliability in your equipment.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your woodworking equipment requires regular care and attention. By implementing a few simple practices, you can extend the life of your tools and enhance their efficiency, ultimately saving time and resources in your projects.

Regular Cleaning

- After each use, wipe down surfaces to remove sawdust and debris.

- Use a soft brush or compressed air to clean hard-to-reach areas.

- Inspect and clean any filters or vents to prevent overheating.

Routine Inspections

- Check for any signs of wear on blades and replace them as needed.

- Examine belts and pulleys for fraying or damage.

- Ensure all screws and bolts are tightly secured to avoid vibrations during operation.

By prioritizing these maintenance practices, you can enjoy enhanced reliability and performance from your tools, allowing for more productive and enjoyable woodworking experiences.

Replacement Parts Availability

Access to essential components is crucial for maintaining the performance and longevity of any power tool. Availability of these items can significantly influence repair times and overall user satisfaction. Understanding where and how to source these materials is key to efficient maintenance and operation.

Where to Find Components

Users can locate necessary items through various channels, including authorized retailers, online marketplaces, and specialized repair shops. Each source may offer different options, including original equipment and aftermarket alternatives.

Considerations for Sourcing

When selecting components, it’s important to consider factors such as compatibility, warranty, and price. High-quality replacements can enhance tool efficiency, while inferior options may lead to further issues.

| Source | Type of Components | Price Range |

|---|---|---|

| Authorized Retailers | OEM Parts | $$$ |

| Online Marketplaces | OEM & Aftermarket | $$ |

| Repair Shops | OEM Parts | $$$ |

Installation Guide for New Parts

Proper installation of replacement components is crucial for optimal machine performance and longevity. This guide provides essential steps to ensure a seamless integration of new elements into your equipment.

Preparation Steps

Before beginning the installation, gather all necessary tools and new components. Make sure to review the manufacturer’s instructions for any specific requirements. Clearing your workspace will enhance efficiency and safety.

Installation Procedure

Follow these steps for a successful installation:

| Step | Description |

|---|---|

| 1 | Disconnect power supply to avoid accidents. |

| 2 | Remove old components carefully, taking note of their arrangement. |

| 3 | Install the new components, ensuring they fit snugly in place. |

| 4 | Reassemble any covers or housing removed during the process. |

| 5 | Reconnect power supply and test the equipment. |

Upgrading Your Planer Performance

Enhancing the efficiency and functionality of your woodworking machine can significantly improve your projects. By focusing on specific components and making strategic upgrades, you can achieve smoother finishes and greater precision in your work.

Consider the following areas for improvement:

- Blade Quality: Upgrading to high-quality, carbide-tipped blades can provide sharper edges and longer-lasting performance.

- Feed Rate: Adjusting the feed speed can help achieve better results on various materials, allowing for a smoother cut.

- Dust Collection: Installing a more efficient dust extraction system will keep your workspace cleaner and improve visibility while working.

- Power Supply: Ensuring your machine is connected to a reliable power source can prevent interruptions and maintain consistent performance.

- Alignment and Calibration: Regularly checking and calibrating the machine ensures accurate results and reduces wear on components.

By making these enhancements, you can transform your equipment into a more effective tool, allowing you to tackle a wider range of projects with ease and precision.