In the realm of power tools, having a clear understanding of the components and their arrangements is crucial for effective maintenance and repair. Familiarity with the structure of each tool not only facilitates troubleshooting but also enhances the overall user experience. By exploring the intricacies of various elements, users can ensure optimal performance and longevity.

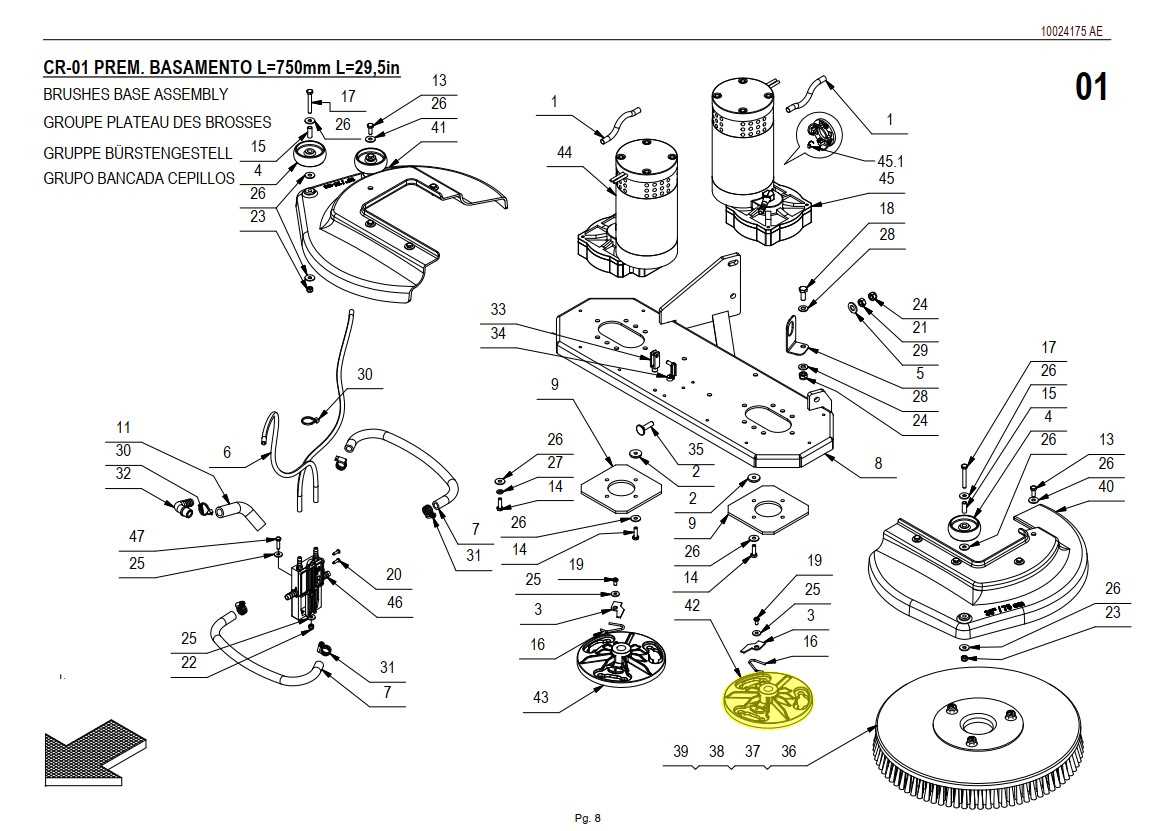

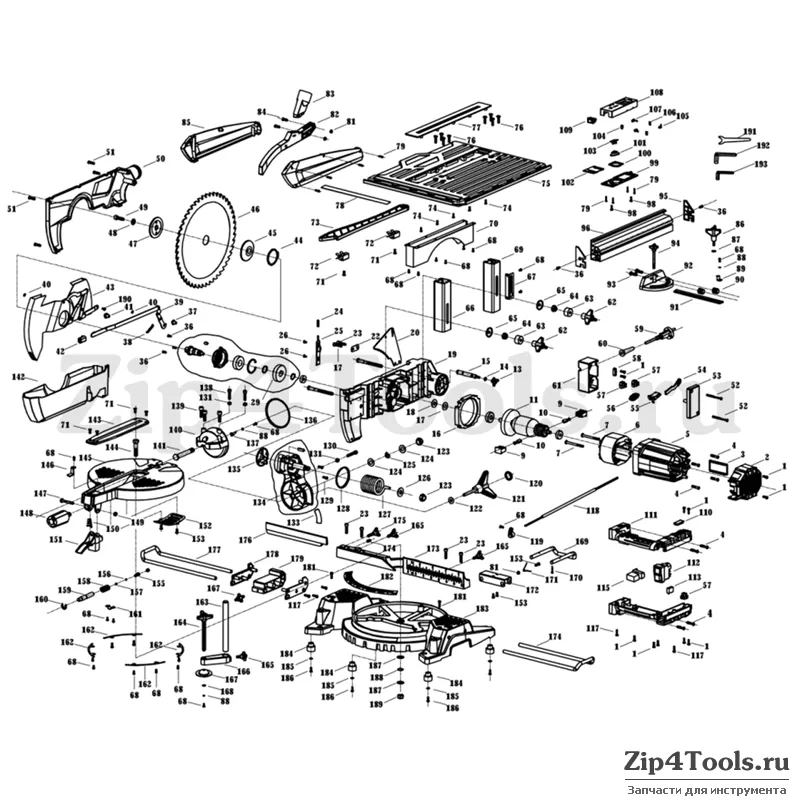

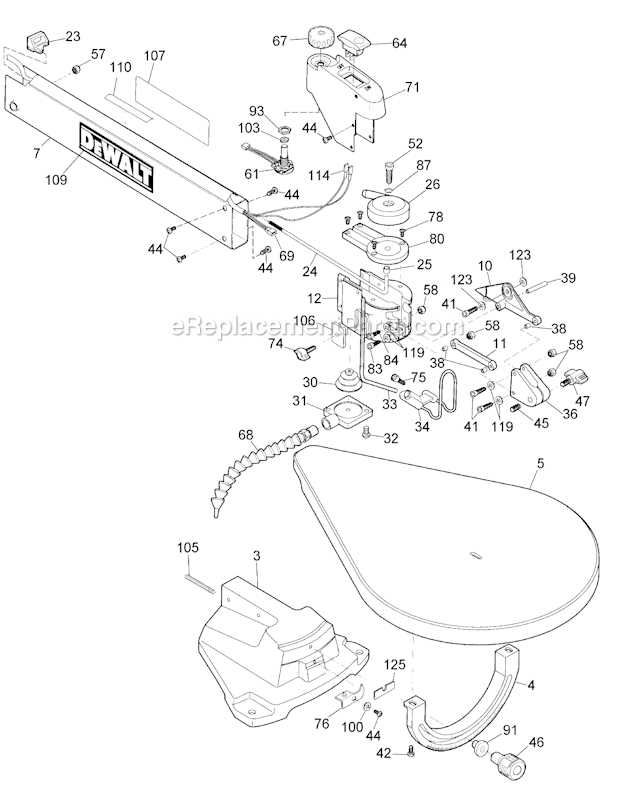

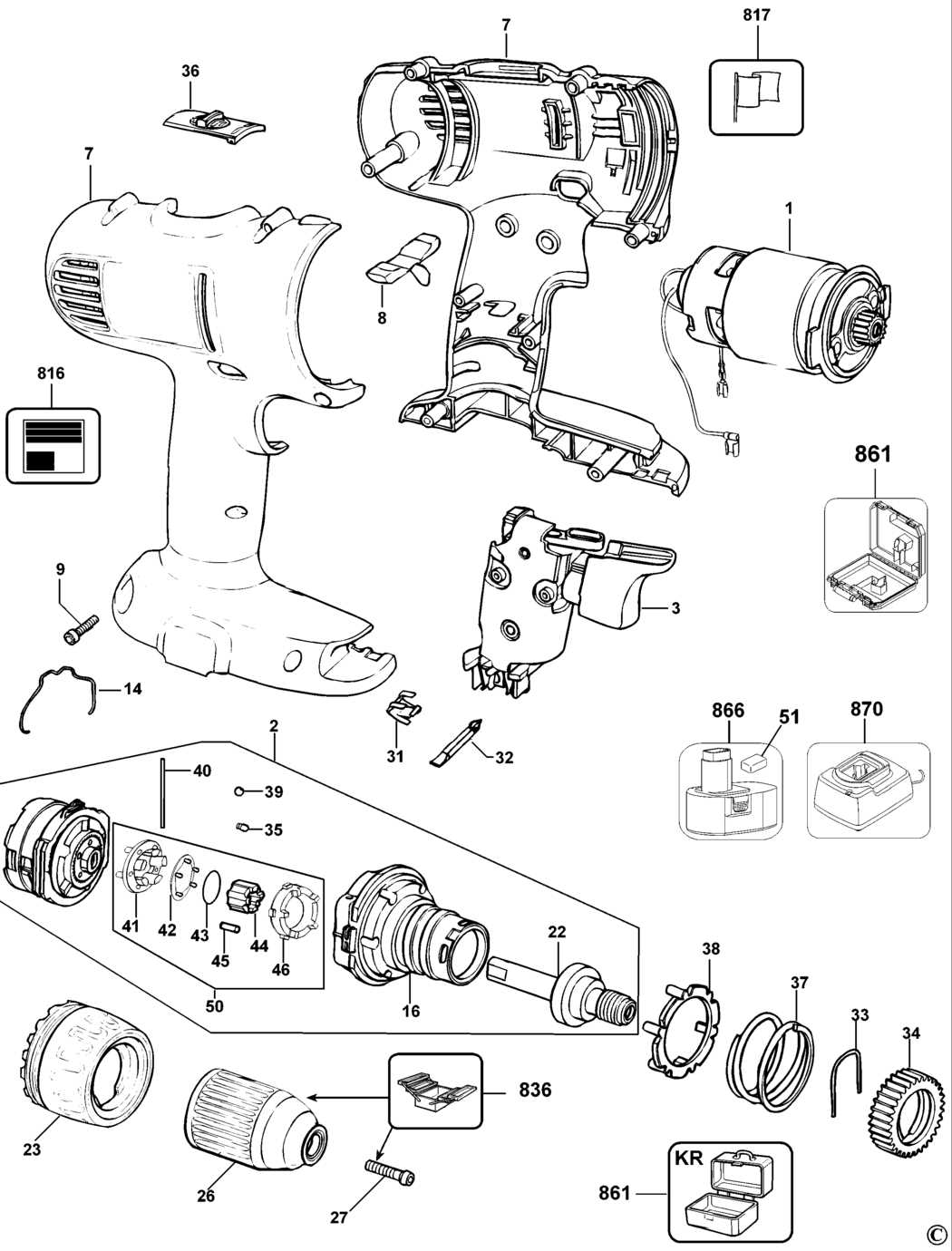

Visual representations play a significant role in comprehending the configuration of tools. These illustrations serve as invaluable resources, helping both novice and experienced users identify specific elements and their functions. With a systematic approach to understanding these layouts, one can effectively navigate the complexities associated with tool upkeep.

Whether you are looking to replace worn-out components or simply seeking to enhance your knowledge, a detailed visual guide can be an indispensable tool in your arsenal. Embracing this knowledge empowers users to make informed decisions, ensuring their equipment remains in peak condition.

This section provides a comprehensive overview of a popular tool model, focusing on its essential components and functionality. Understanding the structure and design of this equipment is crucial for users seeking to optimize their experience and maintain their devices effectively.

| Component | Description |

|---|---|

| Motor | Drives the main function of the tool, providing the necessary power for operation. |

| Base | Stabilizes the tool during use, ensuring accuracy and control. |

| Blade | The cutting element, crucial for achieving desired results on various materials. |

| Handle | Provides user grip and control, enhancing comfort during operation. |

| Switch | Allows the user to turn the tool on and off, ensuring safety and convenience. |

Key Features of Dewalt 788

This section highlights the essential characteristics of a popular tool model, emphasizing its functionality and design that cater to various user needs. Understanding these features can aid in maximizing the tool’s potential in different applications.

Performance and Efficiency

- High power output for demanding tasks.

- Optimized design for prolonged use without overheating.

- Quick adjustments for different materials and projects.

User-Friendly Design

- Ergonomic handle for improved comfort and grip.

- Lightweight construction for enhanced portability.

- Clear visibility of the working area for precise cuts.

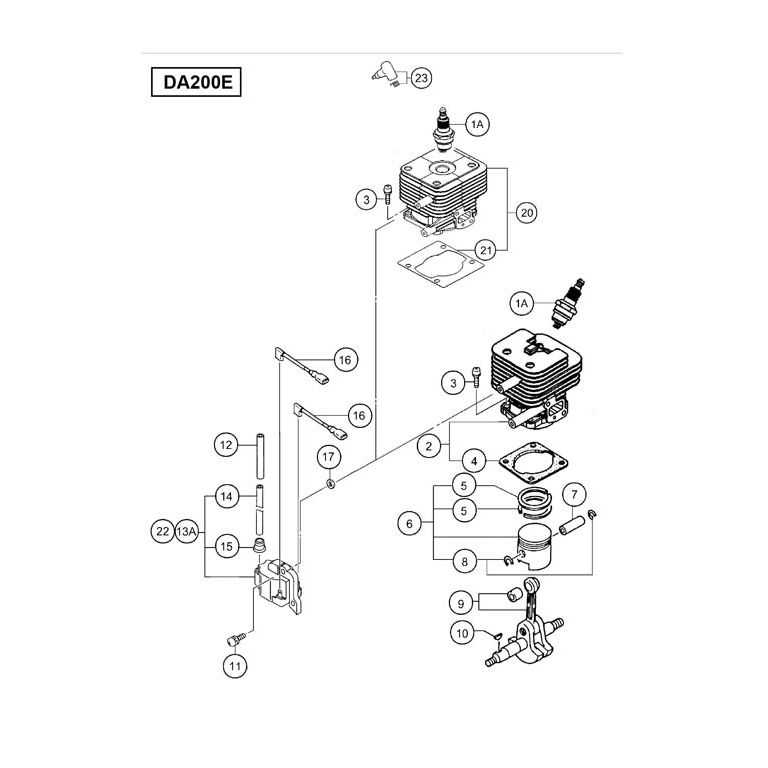

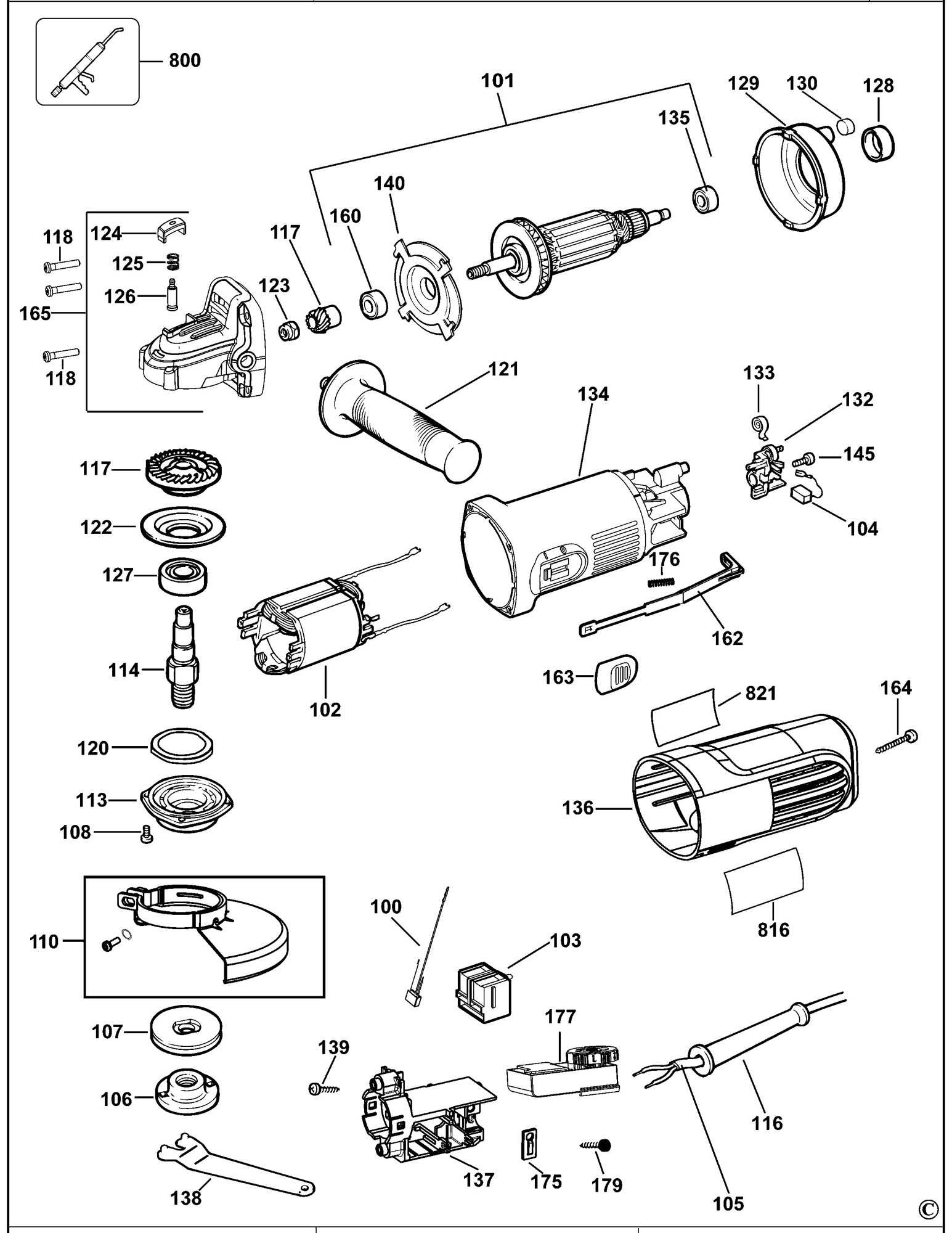

Understanding the Parts Diagram

Analyzing a component layout can significantly enhance your comprehension of machinery. It serves as a visual representation that details the various elements of a device, showcasing their arrangement and how they interact with each other. This knowledge is crucial for troubleshooting, repairs, and maintenance tasks, ensuring efficient operation and longevity.

The Importance of Component Recognition

Familiarizing yourself with individual elements is essential for effective handling. By identifying each piece, you can better understand its function within the entire assembly. This recognition aids in diagnosing issues and selecting the correct replacement items when needed.

Utilizing the Layout for Maintenance

A comprehensive understanding of the layout facilitates proactive upkeep. Knowing where specific components are located allows for efficient inspections and timely interventions. This foresight can prevent minor problems from escalating into significant repairs, ultimately saving time and resources.

Common Components of Dewalt 788

This section explores the various essential elements that contribute to the functionality and efficiency of this power tool. Understanding these components can enhance user experience and ensure effective operation.

- Motor: The heart of the machine, responsible for providing the necessary power for various tasks.

- Blade: A crucial part that determines the quality and precision of cuts. Different types of blades can be used for various materials.

- Base: The foundation that provides stability and support during operation, ensuring accurate results.

- Table: A flat surface that assists in holding the material in place while cutting, often adjustable for convenience.

- Guard: A safety feature that helps protect the user from debris and injury while the tool is in use.

- Switch: The control mechanism that allows the user to start and stop the operation smoothly.

- Footplate: Enhances stability and can be adjusted to accommodate different cutting angles.

Familiarity with these fundamental components will aid users in troubleshooting and maintenance, ultimately prolonging the lifespan of the tool.

How to Interpret the Diagram

Understanding an illustration of components can significantly enhance your ability to work with tools effectively. This guide will help you navigate the visual representation, allowing you to identify and comprehend the various elements and their functions within the assembly.

Begin by familiarizing yourself with the overall layout. Pay attention to any labels or numbers that correspond to specific pieces. This can provide valuable insights into how the individual components interact with each other. Look for groupings of similar items, as these often indicate parts that work together or are related in function.

Next, observe the lines and arrows that connect different sections. These indicators are crucial for understanding how each element fits into the larger system. They can show relationships and help you visualize the assembly process. Be sure to note any special instructions or cautions that may be included, as they can provide essential information for proper handling and installation.

Finally, take time to compare the illustration with the actual items. This hands-on approach reinforces your understanding and helps you recognize any variations that may occur between different models or versions. By applying these strategies, you will gain confidence in interpreting visual aids and enhance your practical skills.

Identifying Replacement Parts

When it comes to maintaining your tools, recognizing the necessary components for replacement is crucial. This section will guide you through the process of pinpointing which elements require attention, ensuring your equipment continues to function optimally.

Here are some steps to assist you in identifying the components you may need to replace:

- Examine the tool closely for any visible signs of wear or damage.

- Consult the user manual for a list of essential components and their functions.

- Utilize online resources or forums for guidance on common issues and replacement needs.

- Take note of specific part numbers or descriptions to aid in your search for replacements.

Additionally, understanding the following can be beneficial:

- Familiarize yourself with the various categories of components, such as electrical, mechanical, or structural.

- Look for resources that provide exploded views or schematics, allowing for a clearer understanding of how components fit together.

- Join community discussions where you can learn from others’ experiences regarding repairs and replacements.

By following these steps, you can confidently identify the necessary components to ensure your tool remains reliable and effective.

Maintenance Tips for Dewalt 788

Regular upkeep of your equipment is crucial for ensuring optimal performance and longevity. Proper maintenance not only enhances the efficiency of the tool but also minimizes the risk of potential issues arising during use. Here are some practical recommendations to help you maintain your device effectively.

- Keep it clean: Regularly remove dust and debris from the surface and moving parts. A clean tool operates more efficiently and reduces wear.

- Check for wear: Inspect components for signs of damage or excessive wear. Replace any parts that show signs of deterioration to prevent further issues.

- Lubricate moving parts: Apply appropriate lubricant to moving mechanisms as specified in the user manual. This reduces friction and prolongs the life of the tool.

- Ensure proper storage: Store the equipment in a dry place away from extreme temperatures. Proper storage prevents damage and preserves functionality.

- Follow usage guidelines: Always adhere to the manufacturer’s recommendations regarding usage and maintenance procedures. This ensures safe and effective operation.

By following these maintenance tips, you can extend the life of your tool and enhance its performance for years to come.

Frequently Asked Questions

This section addresses common inquiries regarding a particular tool model, providing clarity on its components and functionalities. Below are some typical questions users may have.

Common Queries

- What are the main features of this tool?

- How can I identify specific components for replacement?

- Where can I find troubleshooting advice?

- Are there any maintenance tips for optimal performance?

Understanding Components

- What is the purpose of the primary parts?

- How do I know if a part needs to be replaced?

- Where can I purchase replacement parts?

- Is there a warranty on the components?

Where to Buy Replacement Parts

Finding the right components for your equipment can be a challenging task, especially when you’re looking for specific replacements. Fortunately, there are several reliable sources available where you can obtain high-quality items that ensure your machinery continues to function effectively.

Authorized Retailers

One of the most dependable options for acquiring replacements is through authorized sellers. These retailers often stock genuine components, ensuring compatibility and longevity. It’s advisable to check their websites or visit their physical stores for the latest offerings.

Online Marketplaces

Online platforms have become increasingly popular for sourcing various components. These websites typically provide a wide range of options and competitive prices. Additionally, customer reviews can guide you in selecting the right item for your needs.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Retailers | Genuine quality, reliable service | Higher prices, limited stock |

| Online Marketplaces | Variety, competitive pricing | Quality can vary, shipping times |

Benefits of Using Original Parts

Utilizing authentic components in equipment maintenance offers several advantages that contribute to overall efficiency and longevity. These high-quality replacements ensure optimal performance and reliability, reducing the likelihood of malfunctions.

Here are some key benefits of choosing original components:

- Quality Assurance: Genuine items are manufactured to meet specific standards, guaranteeing durability and effectiveness.

- Compatibility: Original components are designed to fit perfectly with the equipment, minimizing the risk of issues related to improper fitting.

- Enhanced Performance: Using authentic parts can significantly improve the functionality of the device, ensuring it operates at its best.

- Warranty Protection: Many manufacturers offer warranties on their products when original components are used, providing added peace of mind.

- Resale Value: Equipment maintained with genuine parts often retains higher resale value, appealing to potential buyers.

In conclusion, opting for authentic components is a wise choice for anyone looking to maintain their equipment effectively and ensure long-lasting performance.

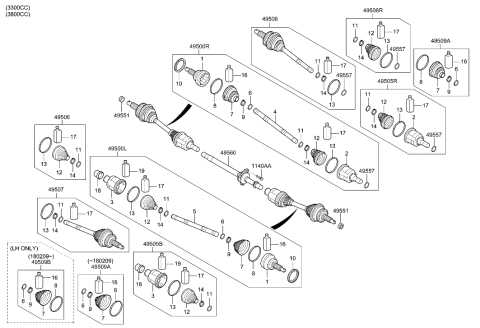

Comparing Parts with Other Models

When examining components from various tools, it is essential to understand how they interact and function within different systems. Each model may present unique attributes, which can affect performance and compatibility. By analyzing these elements, users can make informed decisions about replacements or upgrades.

Key Differences

Different models often feature distinct design choices that influence their efficiency and longevity. For instance, some devices may utilize heavier materials, enhancing durability, while others may prioritize lightweight construction for ease of use. Understanding these disparities is crucial for selecting the right component for your needs.

Compatibility Considerations

It is vital to consider how components from one model can integrate with another. Some parts may fit physically but differ in functionality, potentially leading to suboptimal performance. Evaluating specifications and compatibility ensures that the chosen component aligns perfectly with the intended application.

Resources for Dewalt Users

For enthusiasts and professionals using power tools, having access to reliable information and support is essential. Various resources can enhance the user experience, offering everything from troubleshooting guides to community forums. These tools can significantly improve the functionality and maintenance of your equipment.

Online Support Communities

Engaging with online forums and communities provides a platform for users to share experiences, ask questions, and seek advice. Many of these groups focus on specific tools and their applications, fostering a collaborative environment.

Instructional Materials

Instructional materials such as manuals and video tutorials can offer invaluable insights into the proper use and maintenance of tools. These resources often include step-by-step guides that help users navigate complex tasks efficiently.

| Resource Type | Examples |

|---|---|

| Online Forums | Tool-specific discussion boards, Reddit threads |

| Video Tutorials | YouTube channels, manufacturer websites |

| User Manuals | PDF downloads, printed guides |