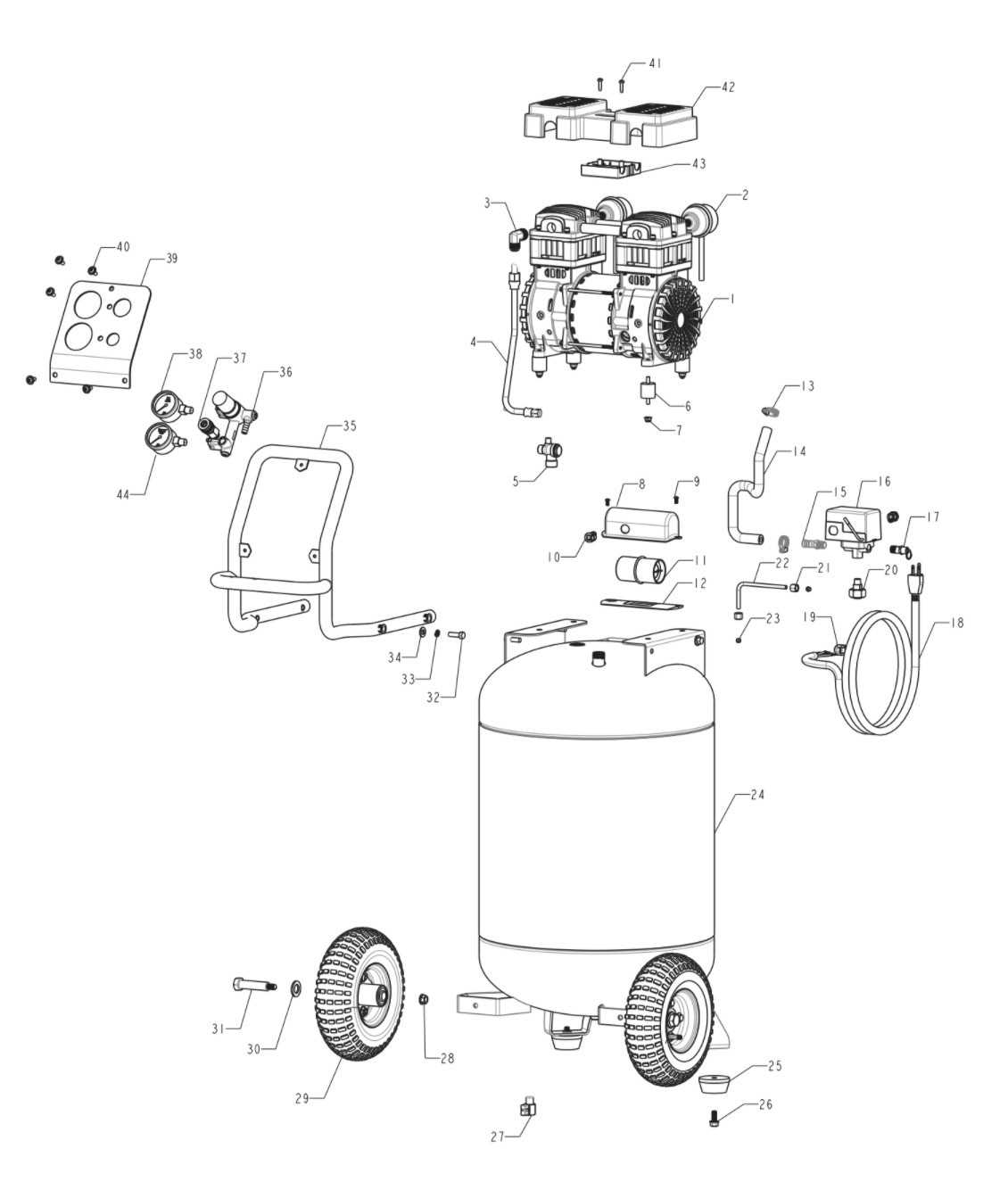

When it comes to maintaining and troubleshooting your machinery, having a clear understanding of its components is essential. This knowledge enables users to identify and resolve issues effectively, ensuring smooth operation and longevity. A comprehensive visual representation can be an invaluable tool in grasping the layout and function of each element.

Exploring the various sections of the assembly allows for a deeper insight into how each piece interacts with others. By familiarizing yourself with these elements, you can streamline maintenance procedures and address potential problems before they escalate. Moreover, this understanding can lead to improved performance and efficiency in your daily tasks.

Whether you are a seasoned professional or a novice, recognizing the significance of each component enhances your capability to perform repairs and upgrades. With the right resources at hand, you can confidently tackle any challenges that arise, ensuring your equipment remains in optimal condition for years to come.

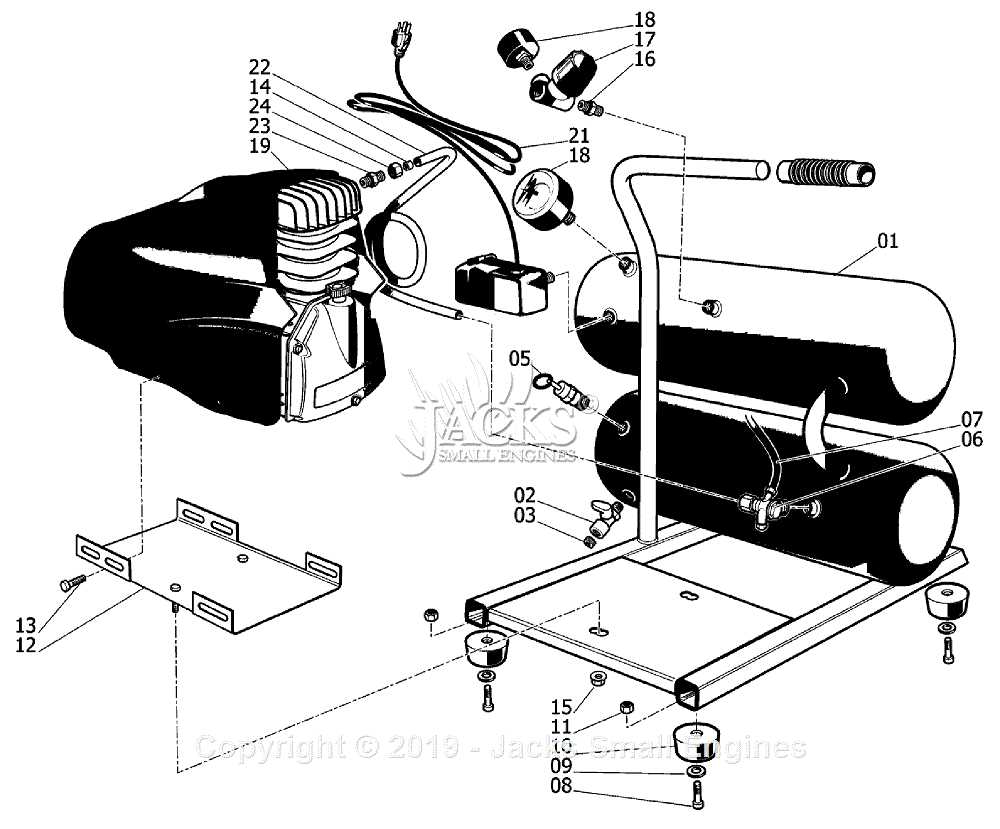

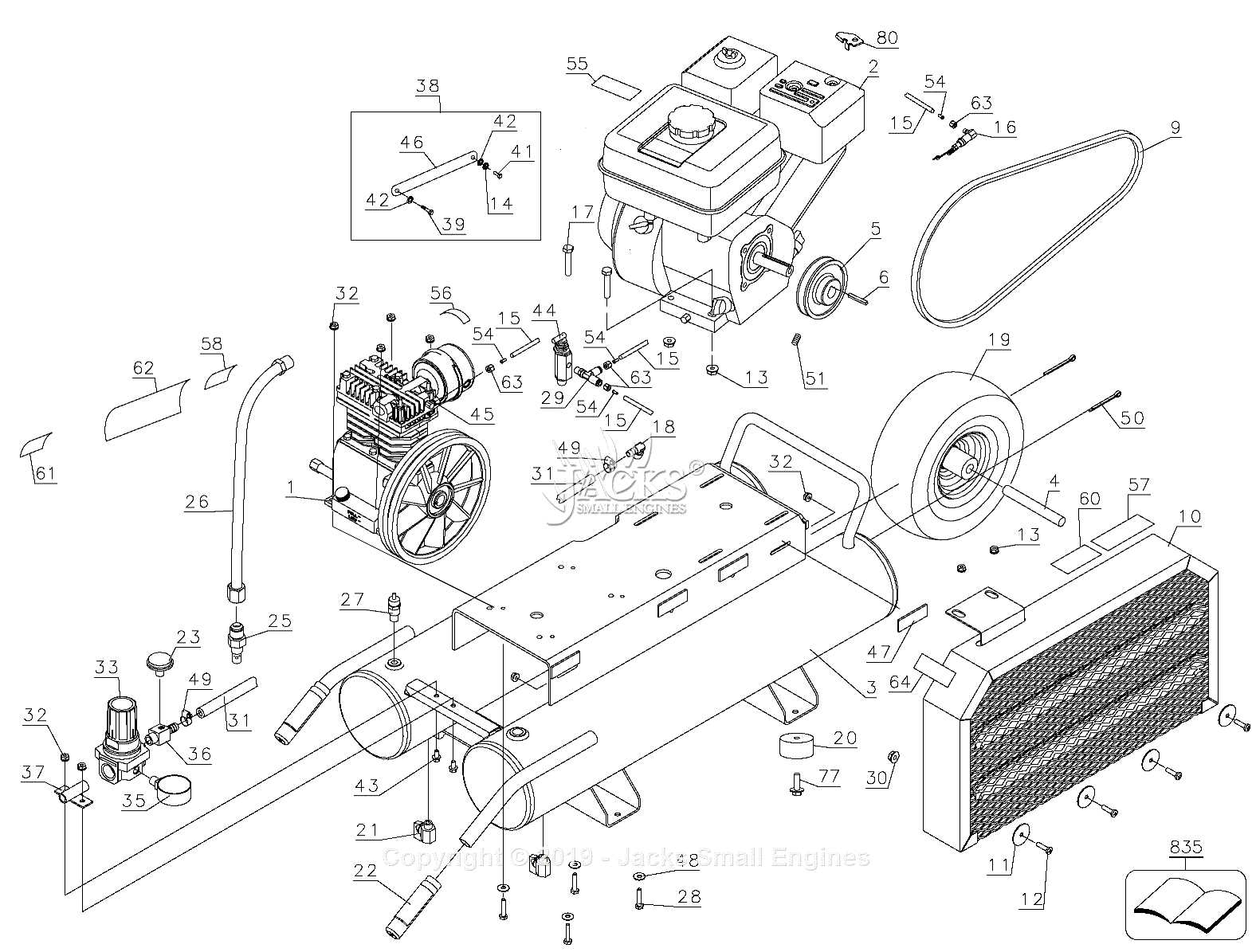

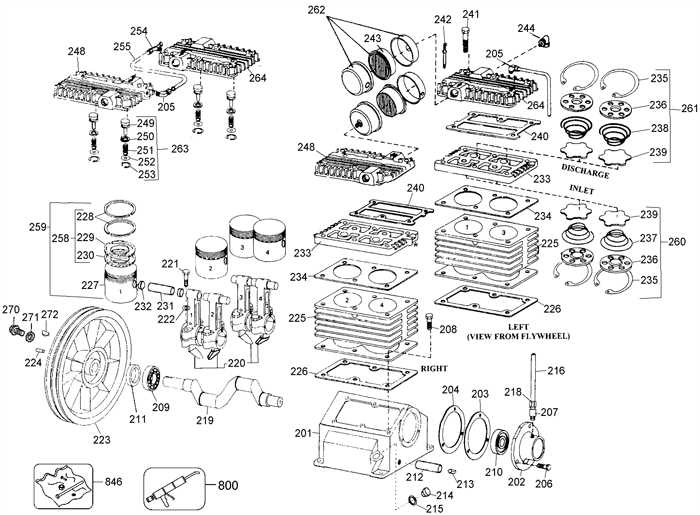

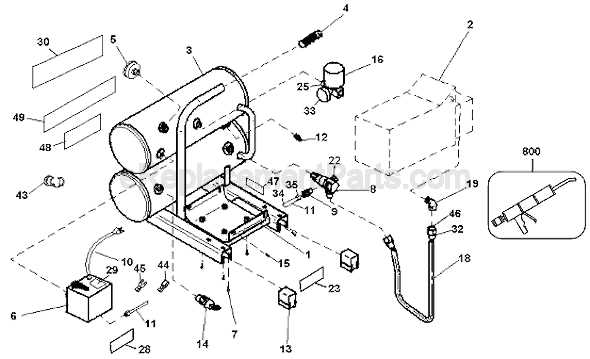

This section provides a general overview of a popular device used for generating high-pressure air. Understanding the various components of this machinery can greatly enhance its usage and maintenance. Each element plays a crucial role in ensuring optimal functionality and efficiency.

| Component | Description |

|---|---|

| Pump | Responsible for compressing the air, converting mechanical energy into pressurized air. |

| Motor | Powers the pump and is essential for driving the compression process. |

| Tank | Stores the compressed air and maintains the pressure for consistent output. |

| Regulator | Controls the pressure of the air being released, ensuring it meets the needs of the connected tools. |

| Hoses | Facilitate the transfer of compressed air from the tank to the tools. |

| Safety Valve | Prevents excessive pressure buildup by releasing air if necessary. |

Importance of Understanding Components

Grasping the intricacies of the various elements that make up a device is crucial for effective operation and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency. Recognizing how these pieces interact can lead to better troubleshooting and informed decision-making when issues arise.

Moreover, familiarity with the individual elements enhances the ability to perform repairs or upgrades. Understanding the specifications and functions of each section empowers users to optimize performance and extend the lifespan of the machinery. This knowledge is invaluable, particularly for those who rely on such equipment for their tasks.

In addition, being well-versed in the components aids in ensuring safety during usage. Awareness of how parts operate together allows for the identification of potential hazards, promoting a safer working environment. Ultimately, a comprehensive understanding of these elements is essential for anyone looking to maintain high operational standards.

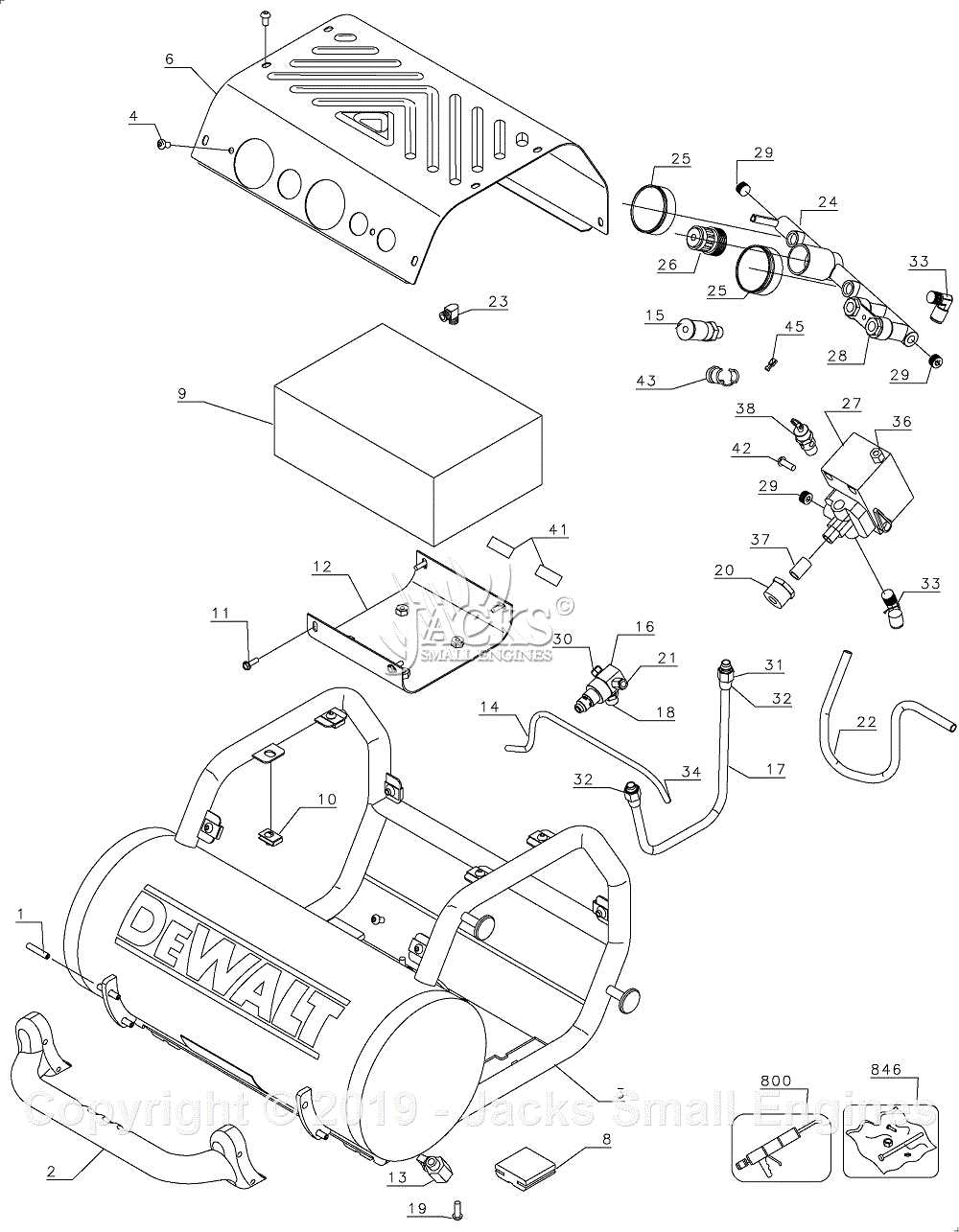

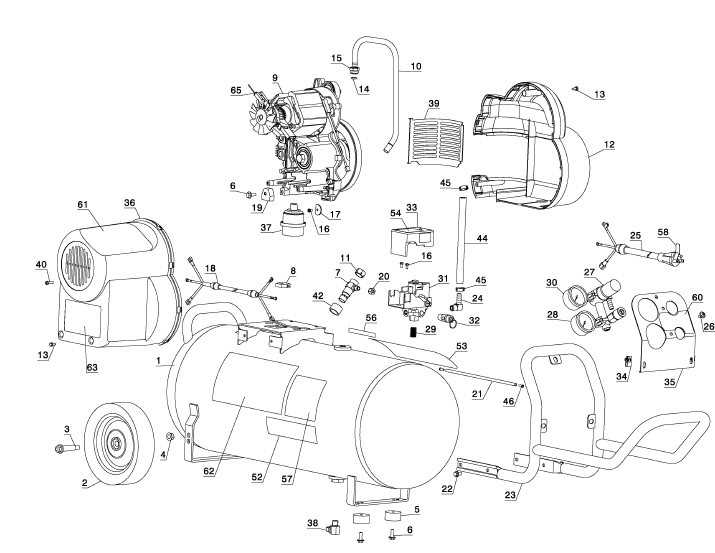

Main Parts of Dewalt Compressors

The functionality of these devices relies on several key components that work together to ensure optimal performance. Understanding the essential elements can help users maintain efficiency and troubleshoot any issues that may arise during operation.

One crucial element is the motor, which powers the entire system, providing the necessary energy to compress the air. Additionally, the tank serves as a reservoir, storing compressed air until it is needed. The pressure switch plays a vital role in regulating the system’s pressure levels, activating and deactivating the motor as required.

The intake filter is another important component, ensuring that the air entering the system is clean and free of contaminants. Furthermore, the manifold connects various parts of the apparatus, facilitating the flow of compressed air to the desired outlets. Lastly, the pressure gauge allows users to monitor the internal pressure, ensuring safe and effective operation.

How the Air Compressor Works

This section explores the fundamental principles behind the operation of a device that efficiently transforms ambient air into a highly pressurized medium, suitable for various applications. Understanding the mechanics involved can provide valuable insights into its functionality and maintenance.

Basic Principles of Operation

The process relies on several key elements working in harmony. Here are the main components involved:

- Intake System: This is where the surrounding atmosphere enters the system.

- Compression Mechanism: The heart of the unit that reduces the volume of the incoming air, thereby increasing its pressure.

- Storage Tank: A container that holds the compressed medium for later use.

- Regulating System: Ensures that the pressure remains within safe limits, preventing over-pressurization.

Steps of Operation

- The ambient air is drawn into the system through an intake valve.

- Once inside, a piston or rotary element compresses the air, significantly raising its pressure.

- The high-pressure medium is then stored in a tank until it is required for operation.

- A pressure switch monitors the tank’s pressure and activates the motor when it drops below a certain level.

By understanding these mechanisms, users can better appreciate the efficiency and capabilities of such devices in various tasks, from powering tools to inflating equipment.

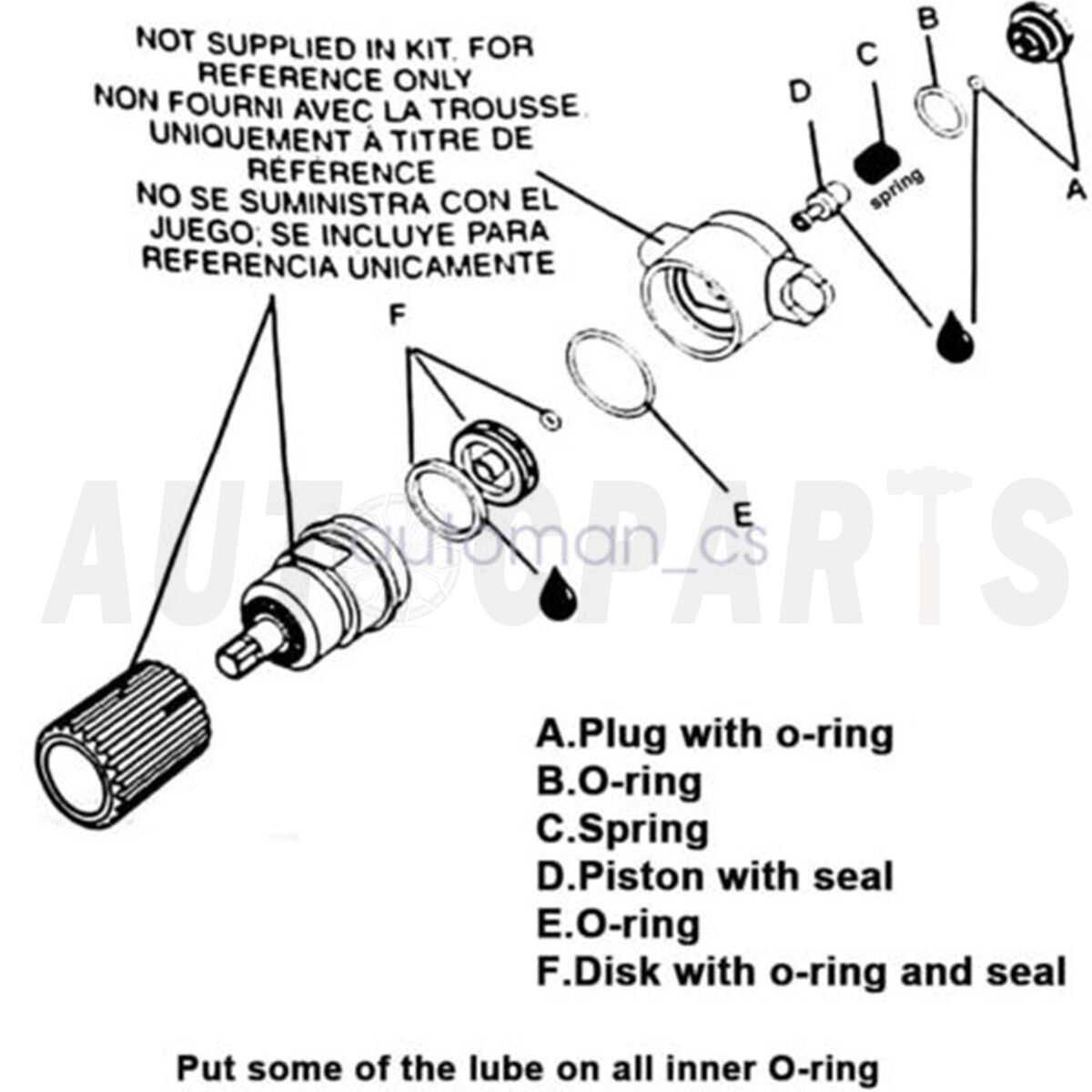

Identifying Key Diagram Elements

Understanding the essential components of a schematic representation is crucial for effective analysis and maintenance. By familiarizing yourself with various symbols and their meanings, you can navigate complex visuals with ease and improve your troubleshooting capabilities.

Common Symbols and Their Functions

- Circuits: Represent electrical pathways, indicating the flow of current.

- Valves: Indicate points of control for fluid movement, often depicted as open or closed states.

- Reservoirs: Show storage units for holding fluids, typically represented by rectangles or squares.

- Pipes: Depict the movement of liquids or gases, illustrated as lines connecting various components.

Reading the Layout Effectively

- Start from the power source to understand the flow of energy.

- Follow the lines to identify connections between different elements.

- Note any annotations or labels that clarify the function of each part.

- Pay attention to the arrangement, as it often reflects the operational sequence.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment requires consistent care and attention. By following a few essential guidelines, you can enhance its durability and efficiency over time.

- Regular Cleaning: Keep the exterior and interior components clean to prevent dust and debris accumulation. This helps maintain optimal functionality.

- Check for Leaks: Inspect for any signs of air or fluid leaks regularly. Addressing leaks promptly can prevent further damage and reduce operational costs.

- Proper Lubrication: Use the recommended lubricants for moving parts to ensure smooth operation. Regularly check and replace oil as needed.

- Monitor Pressure Levels: Keep an eye on the pressure readings. Operating outside the recommended range can lead to premature wear and tear.

- Routine Inspections: Schedule regular check-ups to assess the condition of vital components. Early detection of potential issues can save time and money in the long run.

Implementing these practices will not only extend the lifespan of your device but also enhance its overall performance, ensuring that it serves you effectively for years to come.

Common Issues and Solutions

When operating equipment designed for high pressure, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their solutions can significantly enhance the functionality and longevity of the device.

1. Insufficient Pressure: One of the most frequent issues is inadequate pressure generation. This can be caused by a faulty pressure switch, a leak in the system, or improper settings. To resolve this, check for leaks, ensure the settings are correct, and replace any malfunctioning components.

2. Excessive Noise: Unusual sounds during operation can indicate mechanical problems. This may stem from worn bearings or loose parts. Inspect all moving components and tighten any loose connections, or replace worn-out parts to restore normal operation.

3. Overheating: Overheating can result from continuous use without adequate breaks or blocked airflow. Ensure that the cooling vents are clear and allow the machine to cool down periodically to prevent damage.

4. Failure to Start: If the unit does not start, it may be due to electrical issues or a tripped circuit breaker. Check the power source, inspect the electrical connections, and reset the breaker if necessary.

5. Frequent Cycling: If the device cycles on and off too frequently, it may indicate a malfunctioning pressure switch or an unbalanced load. Check the pressure settings and ensure that the load requirements are met to maintain stable operation.

By addressing these common issues promptly, users can ensure their equipment operates smoothly and effectively for years to come.

Replacement Parts Availability

When it comes to maintaining your equipment, the accessibility of spare components is crucial for ensuring optimal performance and longevity. Fortunately, many manufacturers provide a variety of replacement options to meet the needs of users seeking to repair or upgrade their devices.

Here are some key considerations regarding the availability of these components:

- Authorized Dealers: Check with authorized retailers who specialize in industrial tools. They often stock a wide range of replacement components and can provide guidance on compatible options.

- Online Marketplaces: Numerous online platforms offer a vast selection of replacement options. This can be a convenient way to compare prices and find specific items that may be harder to locate locally.

- Manufacturer’s Website: Visit the official website of the manufacturer for the most accurate information regarding available components. Many brands provide downloadable manuals and lists of available items.

- Local Repair Shops: Consider contacting local repair shops that specialize in tool servicing. They often have access to spare parts and can assist with installation if needed.

Staying informed about the availability of replacement components ensures that you can swiftly address any issues that arise, thereby maintaining the efficiency and functionality of your equipment.

Choosing the Right Model

Selecting the appropriate equipment for your needs involves understanding various factors that can influence performance and efficiency. The right choice will depend on your specific tasks, required output, and the conditions under which you plan to operate the machinery. It is essential to evaluate the features and specifications available to make an informed decision.

When considering different models, it’s helpful to compare key characteristics that impact functionality. Below is a table highlighting some critical aspects to think about:

| Feature | Description |

|---|---|

| Power Source | Choose between electric and gas options based on your accessibility and needs. |

| Tank Size | Larger tanks generally provide more runtime, but may affect portability. |

| PSI Rating | Higher PSI ratings indicate greater pressure capacity for demanding tasks. |

| Portability | Consider weight and wheel design if you need to transport the unit frequently. |

| Noise Level | Check decibel ratings if operating in noise-sensitive environments. |

By analyzing these factors and matching them to your specific requirements, you can confidently select a model that suits your needs best. Prioritizing the features that matter most to your projects will enhance your overall experience and efficiency.

Upgrading Your Compressor Setup

Enhancing your pneumatic system can significantly boost efficiency and performance. Whether you’re looking to increase output, improve reliability, or expand functionality, there are various strategies you can employ. Upgrading certain components or adding new accessories can create a more versatile and powerful setup, tailored to meet your specific needs.

One effective approach is to assess the current configuration and identify areas for improvement. Consider integrating a higher capacity tank for extended operation without interruptions. Additionally, replacing standard hoses with premium options can improve airflow and reduce pressure loss, ensuring that your tools operate at peak performance.

Another valuable upgrade is investing in advanced controls or gauges. These devices provide real-time data on pressure levels and usage, allowing for better monitoring and management of your system. Furthermore, adding filtration systems can help maintain the quality of the output, protecting your tools and enhancing their longevity.

Lastly, don’t overlook the potential benefits of incorporating additional attachments or tools. From specialized nozzles to moisture separators, each accessory can enhance the overall functionality of your pneumatic setup. By carefully selecting upgrades, you can create a powerful and efficient system that meets your demands and exceeds your expectations.

Resources for Further Learning

Exploring various educational materials can significantly enhance your understanding and skills in working with different tools and machinery. By utilizing the right resources, you can gain valuable insights and practical knowledge to improve your maintenance and repair capabilities.

- Online Tutorials: Websites like YouTube offer numerous video guides that demonstrate the operation and maintenance of various equipment.

- User Manuals: Official manuals often contain detailed information about assembly, troubleshooting, and maintenance procedures.

- Forums and Discussion Groups: Participating in online communities can provide support and answers to specific questions from experienced users.

- Workshops and Seminars: Look for local workshops or seminars where experts share hands-on techniques and best practices.

- Books and eBooks: Numerous publications are available that cover fundamental concepts and advanced techniques related to equipment handling.

By utilizing these resources, you can expand your knowledge base and become more proficient in the maintenance and operation of various tools and machines.