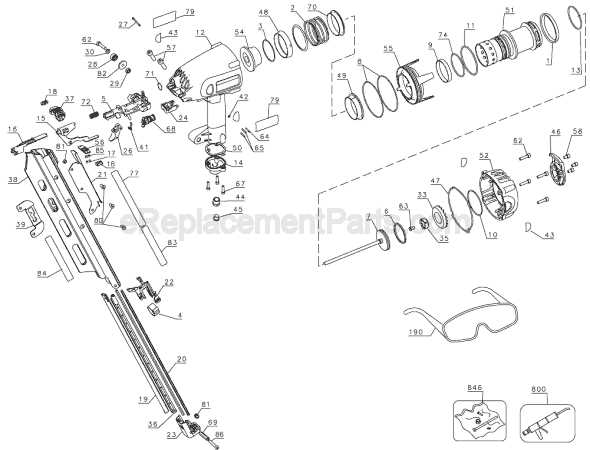

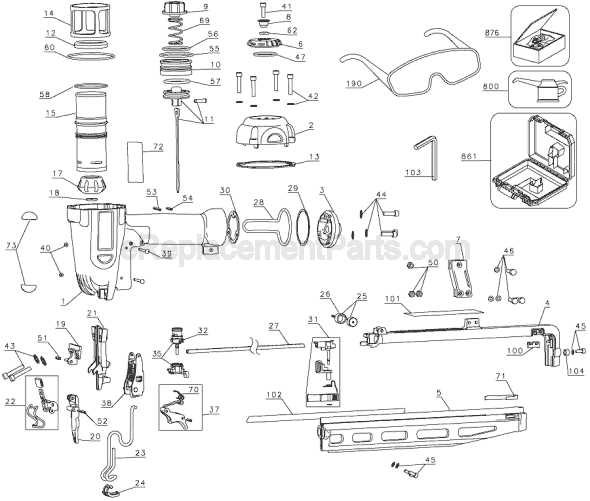

When it comes to maintaining and repairing power equipment, a clear understanding of the internal structures is essential. Each tool consists of various elements, each serving a specific function that contributes to the overall performance. Familiarity with these components allows users to troubleshoot issues effectively and ensure the longevity of their devices.

Visual representations of these elements can significantly aid in identifying parts and their respective roles. Whether you are a seasoned technician or a DIY enthusiast, having access to a well-organized schematic can enhance your ability to navigate the complexities of the machinery. This understanding fosters greater confidence when it comes to disassembly and reassembly, ultimately leading to more successful repairs.

In this section, we will delve into the specifics of component arrangements, offering insights into how each part interacts within the system. By exploring these layouts, readers can gain a comprehensive perspective on their tools, enabling informed decisions regarding maintenance and upgrades. Understanding these intricacies not only improves performance but also empowers users to tackle challenges with ease.

Dewalt D51844 Overview

This section provides a comprehensive insight into a powerful tool designed for efficiency and durability. It highlights the essential features and specifications that make it a reliable choice for professionals and DIY enthusiasts alike.

| Feature | Description |

|---|---|

| Type | Pneumatic Nailer |

| Power Source | Air Compressor |

| Weight | Approximately 6.5 lbs |

| Fastener Range | 18-gauge nails |

| Operating Pressure | 70-120 PSI |

| Magazine Capacity | 100 nails |

Importance of Parts Diagrams

Understanding the layout of components is crucial for effective maintenance and repair of machinery. These visual representations serve as essential tools for both professionals and hobbyists, facilitating a clearer comprehension of how individual elements interact within a system.

Efficiency in repairs significantly increases when one can easily reference these illustrations. They provide clarity, allowing users to quickly identify what is needed and where it fits, ultimately reducing downtime.

Moreover, having a visual guide aids in troubleshooting issues, as it helps users pinpoint malfunctioning elements. This proactive approach not only saves time but also enhances the overall reliability of the equipment.

In conclusion, these resources are invaluable for anyone seeking to delve deeper into machinery maintenance, providing a roadmap for successful repairs and ensuring optimal performance.

Identifying Essential Components

Understanding the critical elements of a tool is vital for effective maintenance and operation. By recognizing these key parts, users can enhance their experience and ensure longevity in performance.

Main Elements to Consider

- Power Source

- Motor Assembly

- Trigger Mechanism

- Housing

- Attachment Points

Benefits of Familiarity

- Improved Troubleshooting

- Enhanced Safety Measures

- Informed Replacement Choices

- Increased Efficiency

How to Read the Diagram

Understanding an assembly illustration is essential for effective maintenance and repairs. This visual representation breaks down components, helping you identify each part’s function and relation to others. Grasping how to interpret these illustrations can streamline your workflow and enhance your problem-solving skills.

Key Elements to Look For

When examining an assembly illustration, focus on the following elements:

| Element | Description |

|---|---|

| Labels | Each component is typically marked with a unique identifier for easy reference. |

| Lines and Arrows | These indicate the connections and movements between parts, showing how they interact. |

| Legend | A guide often accompanies the illustration, providing details about each symbol used. |

Tips for Effective Interpretation

To maximize your understanding, compare the visual guide with the actual assembly. Take notes on unfamiliar parts, and refer back to the legend for clarification. Regular practice in reading such illustrations will ultimately boost your confidence in handling repairs and modifications.

Common Issues with Dewalt D51844

In the realm of power tools, certain models may encounter frequent complications that can impact performance and reliability. Understanding these common challenges can help users maintain their equipment more effectively and ensure smoother operation.

One prevalent issue involves electrical failures, where the device may experience problems starting or may shut down unexpectedly. This can often be traced back to faulty wiring or a malfunctioning switch, requiring careful inspection and potential replacement.

Mechanical wear and tear is another concern, particularly in components that undergo heavy usage. Components such as bearings and gears may wear down, leading to reduced efficiency and increased noise during operation. Regular maintenance and timely replacements are essential to prolong the lifespan of these parts.

Users may also notice a decrease in power output, which can stem from blockages in airflow or issues with the internal motor. Cleaning air filters and ensuring proper ventilation can mitigate these problems, enhancing overall performance.

Lastly, overheating is a common problem that can arise from prolonged use without adequate cooling. Ensuring proper usage guidelines are followed and allowing the tool to rest can prevent damage from excessive heat.

Finding Replacement Parts

Locating suitable components for your tools can be a straightforward process if you know where to look. Understanding the structure of your equipment and identifying compatible pieces are key steps in ensuring efficient repairs and maintenance. Here are some strategies to help you find what you need.

Researching Online

The internet is a valuable resource for sourcing components. Here are some effective ways to use online platforms:

- Manufacturer Websites: Visit the official site for detailed specifications and available items.

- Online Retailers: Explore e-commerce platforms that specialize in tool supplies.

- Forums and Communities: Join discussions with other users to share experiences and recommendations.

Local Supply Stores

Physical stores can also be a great option for obtaining necessary items. Consider the following:

- Specialty Tool Shops: These stores often carry a wide range of components and can offer expert advice.

- General Hardware Stores: Check if they have a section dedicated to tool repairs and accessories.

- Salvage Yards: For older models, salvage yards might have usable parts at a lower cost.

By utilizing these resources, you can efficiently find the components required to keep your equipment in top shape.

Tools for Maintenance and Repair

Proper upkeep and restoration of equipment require a diverse set of implements designed for efficiency and precision. Utilizing the right tools not only enhances performance but also extends the lifespan of various devices. This section explores essential implements that facilitate effective maintenance and repair tasks.

Essential Hand Tools

Hand tools are fundamental for any maintenance kit, ranging from wrenches to screwdrivers. Each tool serves a specific purpose, allowing for detailed adjustments and repairs. Quality hand tools are indispensable for tackling routine tasks and ensuring that equipment remains in optimal condition.

Power Tools for Efficiency

Power tools dramatically speed up repair processes and provide the ultimate convenience for larger projects. From drills to saws, these machines are engineered to handle demanding tasks with precision. Investing in reliable power tools can significantly reduce effort and time spent on maintenance activities.

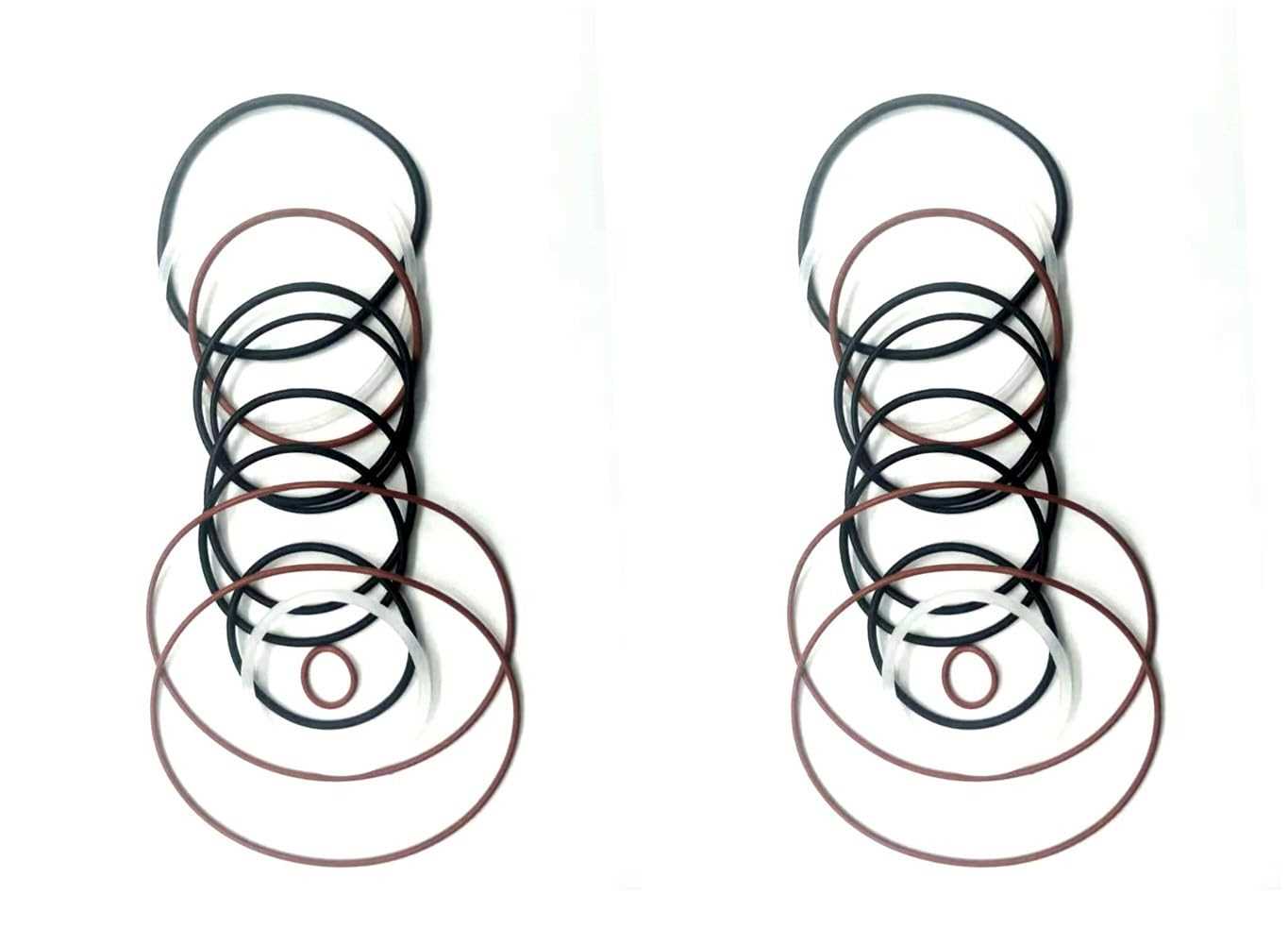

Benefits of Using Genuine Parts

Utilizing authentic components in your equipment ensures optimal performance and longevity. High-quality elements are designed to fit seamlessly and function effectively, reducing the likelihood of malfunctions or breakdowns.

Enhanced Reliability

Authentic components undergo rigorous testing to meet industry standards, guaranteeing that they will perform as intended. This reliability minimizes downtime and maintenance costs over time.

Improved Safety

Using original items enhances safety features, protecting users from potential hazards. High-quality materials help prevent accidents caused by faulty or incompatible substitutes, ensuring a secure working environment.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Regular attention to maintenance tasks can significantly extend the lifespan of tools and machinery, reducing the likelihood of unexpected breakdowns and costly repairs. This section provides practical advice to keep your devices in optimal condition.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Cleaning | After each use | Remove debris and dust to prevent buildup. Use a soft brush or cloth. |

| Lubrication | Monthly | Apply appropriate lubricant to moving parts to reduce friction and wear. |

| Inspection | Weekly | Check for wear and tear on components. Replace any damaged parts immediately. |

| Calibration | Every three months | Ensure accuracy by recalibrating settings according to the manufacturer’s guidelines. |

| Storage | Always | Store in a dry, cool place to prevent rust and damage from environmental factors. |

By adhering to these guidelines, you can enhance the performance and reliability of your tools, ultimately leading to a more efficient workflow and fewer interruptions in your projects.

Safety Precautions During Repairs

When undertaking maintenance or repair tasks, ensuring personal safety and the protection of equipment is paramount. Proper precautions can prevent accidents, injuries, and further damage, allowing for a smoother and more effective repair process.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) to shield yourself from potential hazards. This includes safety glasses to protect your eyes from debris, gloves to safeguard your hands from sharp objects, and hearing protection if working with loud tools. Additionally, sturdy footwear can help prevent slips and falls in the workspace.

Workspace Safety

Maintain a clean and organized work area to minimize risks. Ensure that the surface is stable and free of clutter. Proper lighting is essential for visibility, allowing you to see fine details and avoid accidents. Moreover, be mindful of your surroundings and ensure that all tools are stored safely when not in use, reducing the chance of tripping or injury.

Upgrades and Accessories Available

Enhancing the performance and versatility of your tool can significantly improve your work efficiency. A variety of upgrades and add-ons are designed to complement your equipment, providing additional features and capabilities tailored to various tasks. From specialized attachments to advanced safety gear, these options can help you achieve superior results.

Popular Upgrades

Investing in upgrades can elevate the functionality of your tool. Here are some of the most sought-after enhancements:

| Upgrade | Description |

|---|---|

| High-capacity Battery | Provides extended runtime for prolonged tasks. |

| Enhanced Motor | Offers increased power for demanding applications. |

| Ergonomic Handle | Improves comfort and reduces fatigue during use. |

Essential Accessories

In addition to upgrades, a range of accessories can further enhance your tool’s performance. These items are designed to ensure optimal functionality and safety:

| Accessory | Purpose |

|---|---|

| Tool Bag | Facilitates organized storage and transportation. |

| Safety Goggles | Protects eyes from debris and dust. |

| Cutting Blades | Enables precision cutting for various materials. |

Customer Reviews and Feedback

Gathering insights from users is crucial for understanding the quality and performance of any product. Feedback often highlights both strengths and weaknesses, offering potential buyers a clearer picture of what to expect. Customers frequently share their experiences, helping others make informed decisions.

Positive reviews typically emphasize durability, efficiency, and ease of use. Users appreciate tools that not only meet their expectations but also exceed them in functionality. Many highlight how these devices enhance their workflow, making tasks more manageable.

On the other hand, constructive criticism is equally valuable. Some customers mention challenges they faced, whether it be related to assembly or specific features. This feedback is essential as it can drive improvements and innovations in future designs.

Overall, the collective opinions of users serve as a guiding light for both manufacturers and prospective buyers, fostering a community of informed decision-making.

Where to Buy Parts Online

Finding replacement components for your tools can be a straightforward process if you know where to look. Various online platforms offer a wide selection of these items, making it easy to source exactly what you need. Below are some of the most reliable options to consider when searching for your required supplies.

Popular Online Retailers

Several well-known e-commerce sites specialize in tool components, providing users with comprehensive catalogs and user-friendly interfaces. These platforms often feature customer reviews, detailed descriptions, and competitive pricing.

| Website | Special Features |

|---|---|

| Amazon | Wide selection, user reviews, fast shipping |

| eBay | New and used items, bidding options |

| Toolpartsdirect.com | Specialized focus on tool components, detailed search |

Manufacturer Websites

Many manufacturers maintain their own online stores where you can purchase original items directly. This ensures authenticity and compatibility, which can be crucial for optimal performance. Always check the official site first to confirm you’re getting the correct replacements.