When working with power tools, especially nail guns, it’s essential to have a clear understanding of how each element contributes to the overall functionality. Every piece, no matter how small, plays a crucial role in ensuring smooth operation and long-lasting performance. By examining each section of the tool, users can gain insights into its mechanics and identify potential areas for maintenance.

Detailed breakdowns of each component allow for a deeper understanding of their individual functions. With proper knowledge of the internal mechanisms, it becomes easier to troubleshoot any issues that may arise during usage. This can significantly extend the life of the equipment and improve overall safety.

Regular maintenance and replacement of worn-out elements are key to keeping tools in optimal condition. Identifying and understanding these parts ensures that the tool operates efficiently and without unnecessary interruptions.

Understanding the Dewalt DCN692 Diagram

Interpreting the layout of this tool’s internal structure is essential for effective maintenance and troubleshooting. By reviewing the visual representation, users can familiarize themselves with how the various elements are organized and interact with each other. This knowledge can significantly assist in understanding the mechanism’s overall functionality.

Focusing on the specific components can help to identify potential problem areas more quickly. Additionally, recognizing the relationships between different parts can improve repair efficiency and ensure that each element is functioning as intended.

Key Components of the DCN692

This section provides an overview of the main elements that ensure the efficient operation and durability of the tool. Understanding these components is essential for maintaining performance and addressing potential issues during use.

Main Mechanical Elements

- Motor Assembly: A powerful motor that drives the mechanism, delivering reliable force for a range of tasks.

- Firing Mechanism: A crucial part responsible for activating the tool’s core function, ensuring smooth and precise performance.

- Magazine: Holds the fasteners in place, allowing for consistent and uninterrupted work flow.

Supportive Features

- Trigger System: Controls the release, offering the user adjustable settings for varied applications.

- Depth Adjustment: A system that allows for precise control over the penetration, adapting to different surfaces and requirements.

- Battery Slot: Ensures the proper connection of the power source, supporting extended periods of operation.

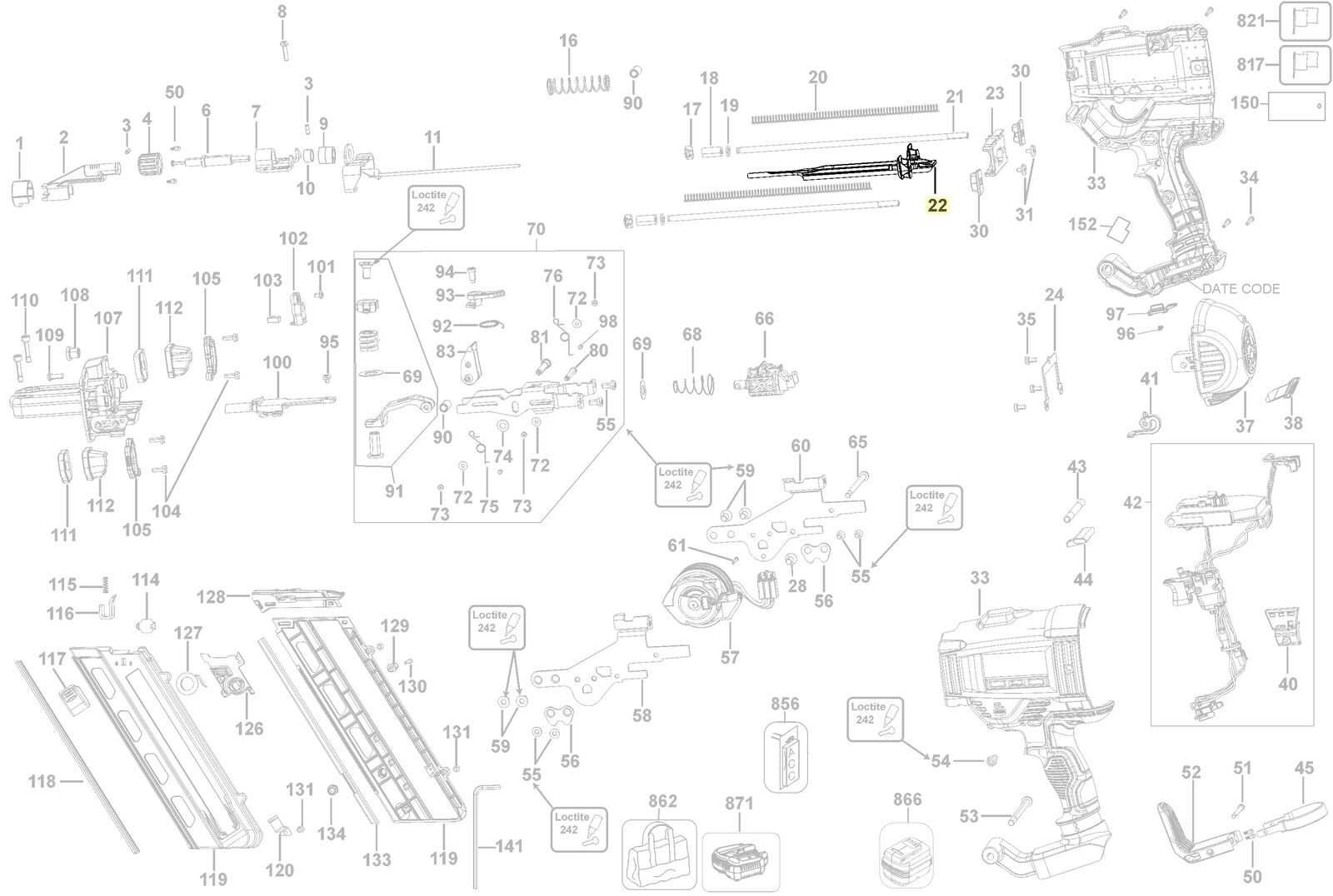

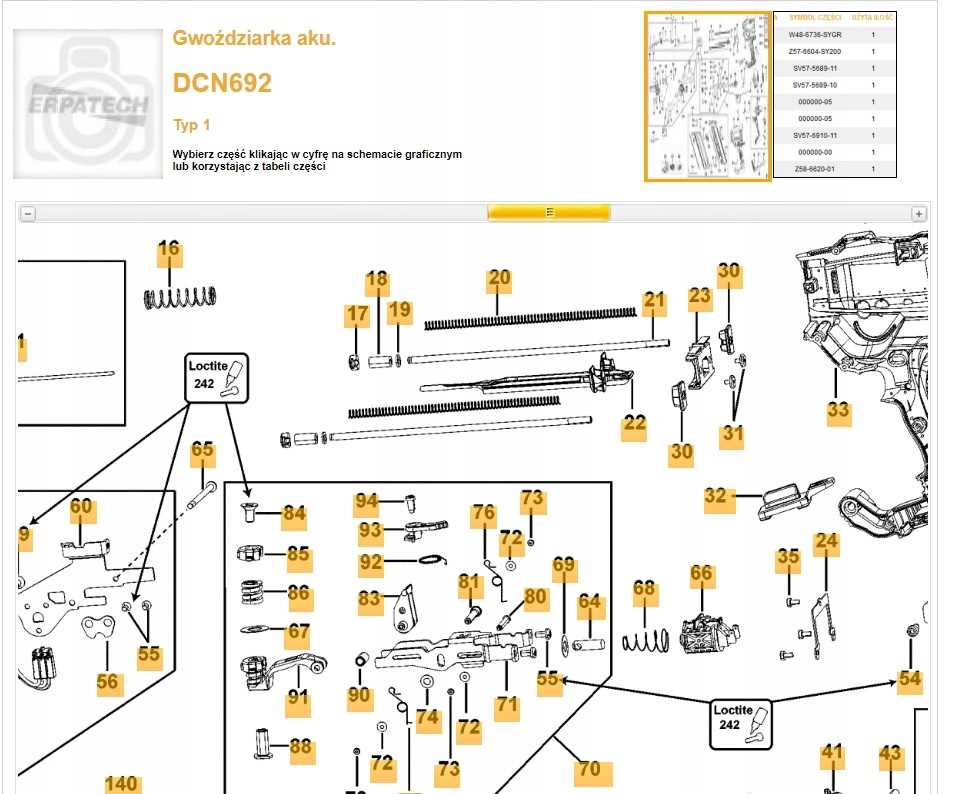

Exploded View for Quick Repairs

Understanding the layout of a tool’s components is essential for efficient maintenance and swift troubleshooting. An exploded view provides a detailed representation of individual elements, enabling users to identify and address issues with ease. This visualization not only simplifies repairs but also enhances the user’s familiarity with the equipment, promoting a more confident approach to upkeep.

When faced with a malfunction, consulting this visual guide can quickly pinpoint the source of the problem. Each part is clearly delineated, allowing for straightforward replacement or adjustment without unnecessary disassembly. This resource is invaluable for both seasoned professionals and novices alike, ensuring that repairs can be conducted efficiently and accurately.

Identifying Crucial Internal Parts

Understanding the key components within a tool is essential for effective maintenance and optimal performance. Each element plays a vital role in the overall functionality, and recognizing their importance can help in troubleshooting and repairs.

Key elements include the motor, which drives the device’s operation, and the trigger mechanism, responsible for activation. Additionally, the housing protects internal systems, while the battery compartment ensures power supply. Familiarity with these parts enhances one’s ability to perform diagnostics and improvements.

Moreover, elements like the piston and feed mechanism are critical for efficient operation, impacting the tool’s speed and precision. Knowing how these components interact provides insight into the device’s overall efficiency and durability.

Replacing Worn Out Mechanisms

Over time, certain components of your equipment may experience wear and tear, affecting overall performance and efficiency. Addressing these issues promptly is crucial to maintaining optimal functionality. This section will explore the importance of identifying and substituting aged mechanisms to ensure reliability.

Recognizing Signs of Wear is the first step in this process. Look for symptoms such as unusual noises, reduced power, or inconsistent operation. These indicators suggest that internal parts may be nearing the end of their lifespan.

Once you’ve pinpointed the affected components, it’s essential to source high-quality replacements. Choosing reputable suppliers guarantees that you receive durable and reliable pieces, which ultimately enhances the longevity of your tool.

Lastly, installation should be performed carefully, following the manufacturer’s guidelines. This ensures that everything functions correctly and safely, allowing you to return to your tasks with confidence.

How to Read the Parts Layout

Understanding the layout of components in a technical manual is crucial for efficient maintenance and repairs. This knowledge enables users to identify specific elements and their functions, ensuring that any work carried out is both effective and safe.

To begin, familiarize yourself with the overall structure of the illustration. Typically, it will feature a grid or organized layout that categorizes various elements by function or location within the device. Each section usually corresponds to a particular area of the tool.

| Section | Description | Common Issues |

|---|---|---|

| Power System | Includes the battery and electrical components. | Power failure, charging problems. |

| Fastening Mechanism | Contains parts responsible for securing materials. | Jamming, misalignment. |

| Safety Features | Components that ensure user protection during operation. | Failure to engage, wear and tear. |

Each component is often labeled with a unique identifier, making it easier to locate replacement items or refer to them in discussions with technical support. Pay attention to the accompanying legend or key, which will provide additional context on the symbols and numbers used in the layout.

Regularly consulting this reference when conducting repairs or replacements will enhance your understanding and efficiency, ultimately leading to improved performance of the tool.

Common Issues with Specific Parts

When working with power tools, certain components may encounter problems that can hinder performance or lead to malfunctions. Identifying these common issues is crucial for effective maintenance and repair. This section highlights frequent concerns associated with various elements of these devices.

- Battery Performance:

- Short runtime due to age or improper charging.

- Overheating during extended use, which may lead to swelling.

- Trigger Mechanism:

- Inconsistent response, causing the tool to misfire.

- Sticking or jamming due to debris accumulation.

- Motor Issues:

- Unusual noises indicating wear or damage.

- Overheating, often a sign of strain or electrical failure.

- Fastening Components:

- Jams or misfeeds due to incompatible or worn materials.

- Loss of precision in fastening caused by wear over time.

- Housing and Grip:

- Cracks or breaks that compromise structural integrity.

- Slipping grips from wear, reducing user control.

Addressing these common issues promptly can enhance the longevity and efficiency of your tool, ensuring it performs at its best when needed most.

Finding Compatible Replacement Parts

When it comes to maintaining your equipment, locating suitable components is essential for optimal performance. Ensuring that you have the right substitutions can significantly extend the lifespan of your tools and enhance their functionality.

To begin your search, consult manufacturer specifications or reliable online resources that provide detailed information about compatible items. Utilizing forums and user reviews can also guide you in identifying alternatives that meet your needs.

Additionally, checking with authorized dealers can offer peace of mind, as they typically stock verified replacements that ensure a proper fit. Comparing various sources will help you make informed decisions and avoid potential pitfalls associated with mismatched components.

Upgrading the DCN692 for Longevity

Enhancing the durability and efficiency of your cordless tool can significantly extend its lifespan and improve performance. By making targeted upgrades, users can ensure that their equipment remains reliable and effective over time, avoiding frequent replacements and costly repairs.

Key Areas for Improvement

- Batteries: Invest in high-capacity or advanced lithium-ion batteries to increase runtime and reduce downtime.

- Maintenance: Regularly clean and lubricate moving parts to prevent wear and tear.

- Upgraded Accessories: Consider using specialized attachments designed for specific tasks to enhance versatility.

- Protective Cases: Utilize robust storage solutions to safeguard against physical damage during transport.

Best Practices for Longevity

- Store the tool in a dry, cool place to prevent moisture damage.

- Avoid overloading the device; follow recommended usage guidelines.

- Periodically inspect for any signs of wear or malfunction.

- Calibrate and update any software or firmware as needed to maintain optimal performance.

Proper Maintenance Using the Diagram

Effective upkeep of power tools is essential for ensuring longevity and optimal performance. By following a detailed visual reference that outlines individual components, users can easily identify areas that require attention or replacement. This proactive approach not only enhances the tool’s functionality but also minimizes the risk of unexpected breakdowns.

Understanding Component Functions

Each element of the tool plays a crucial role in its overall operation. Familiarizing oneself with the specific functions of each part enables users to perform targeted maintenance. Regular inspections allow for the early detection of wear and tear, which can be promptly addressed to prevent further damage.

Steps for Effective Maintenance

To maintain peak efficiency, follow these guidelines:

- Regular Cleaning: Keep all surfaces free from debris to avoid interference with moving parts.

- Inspection Schedule: Establish a routine for examining key components for signs of wear.

- Replacement Parts: Utilize the visual reference to identify and procure necessary replacements when needed.

By adhering to these steps, users can ensure their tools remain reliable and efficient throughout their lifespan.

Understanding Fastener and Spring Systems

Fastener and spring mechanisms play a crucial role in ensuring the reliable operation of various tools and equipment. These components provide stability, enhance functionality, and contribute to the overall efficiency of the devices they are part of.

Key Components

- Fasteners: These are essential for securing different parts together, ensuring durability and performance.

- Springs: They provide tension and flexibility, allowing for the smooth operation of moving parts.

Functionality Overview

- Fasteners maintain structural integrity under various conditions.

- Springs absorb shocks and return components to their original positions.

- Both systems work in tandem to enhance the user experience and tool longevity.

Benefits of Using the Parts Diagram

Utilizing an illustrated guide for component identification offers numerous advantages for both professionals and DIY enthusiasts. It enhances understanding of assembly, making maintenance and repairs more efficient. This clarity not only saves time but also reduces the likelihood of errors during service.

Improved Efficiency

With a visual reference, users can quickly locate specific components, streamlining the repair process. This efficiency minimizes downtime, allowing for faster project completion and increased productivity.

Enhanced Knowledge

By engaging with a detailed visual aid, individuals can deepen their comprehension of the machinery’s inner workings. This knowledge equips users with the ability to troubleshoot issues more effectively and make informed decisions regarding repairs.

Where to Source Authentic Components

Finding genuine components for your tools is crucial for maintaining their performance and longevity. It’s essential to identify reliable sources that provide original parts, ensuring that your equipment operates safely and effectively.

Authorized Retailers

One of the best options for acquiring authentic components is through authorized retailers. These outlets are directly connected to manufacturers and offer a guarantee of quality. Always check for certifications and endorsements when selecting a retailer.

Online Marketplaces

Online platforms can also be valuable resources, but caution is necessary. Look for sellers with high ratings and positive feedback. Ensure that they specifically mention the authenticity of the items to avoid counterfeit products.