For any enthusiast or professional in the realm of woodworking and construction, comprehending the intricate elements of a high-performance cutting instrument is essential. Each component plays a pivotal role in ensuring efficiency and precision during operation. A thorough grasp of these elements not only enhances usability but also empowers users to troubleshoot effectively.

Identifying and visualizing the specific parts of such machinery can significantly simplify maintenance and repair processes. Having access to a detailed representation of these components allows users to recognize wear and tear, ensuring that their tools operate at peak performance. This insight fosters a deeper appreciation for the craftsmanship behind the equipment.

Moreover, understanding the arrangement and function of each piece can lead to more informed decisions when it comes to upgrades or replacements. Whether you’re a seasoned professional or a passionate DIYer, familiarizing yourself with the individual elements will ultimately contribute to better results and longer tool life. Embracing this knowledge is an investment in both your skills and your equipment.

Dewalt DWS716 Overview

This versatile tool is designed for precision and efficiency, making it an essential addition to any workshop. It combines robust construction with advanced features, ensuring that users can achieve accurate cuts with ease.

With a powerful motor and a range of cutting capabilities, this equipment excels in handling various materials. Its user-friendly design enhances operational comfort, allowing for extended use without fatigue. Additionally, the inclusion of safety features ensures that users can work confidently.

Portability is another key aspect, enabling easy transportation between job sites. The tool’s compact size does not compromise its performance, making it ideal for both professionals and DIY enthusiasts. Whether tackling framing, trimming, or molding, this instrument proves to be a reliable companion.

Overall, its combination of strength, precision, and convenience sets this tool apart in the market, catering to a wide array of cutting needs.

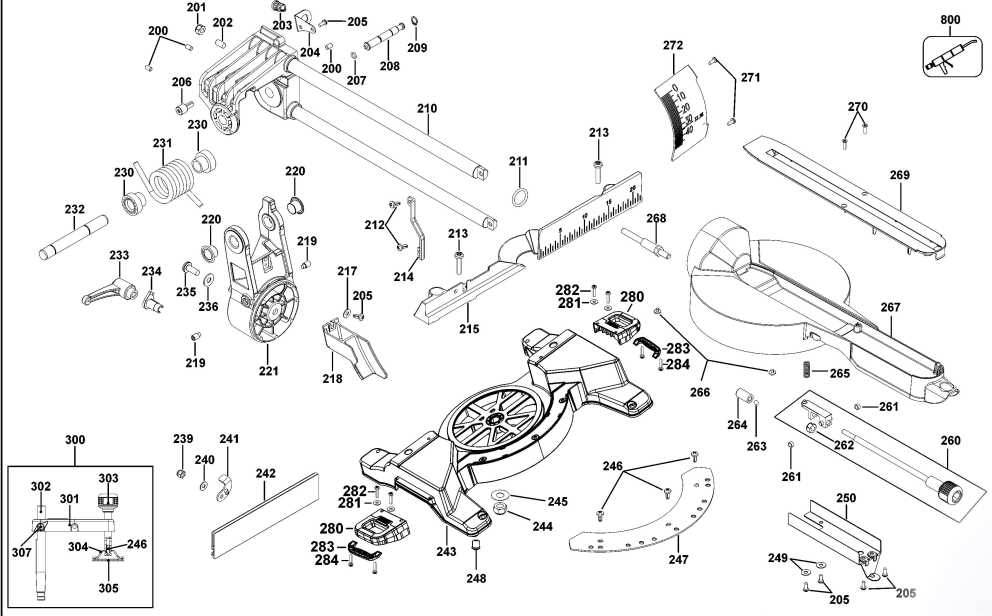

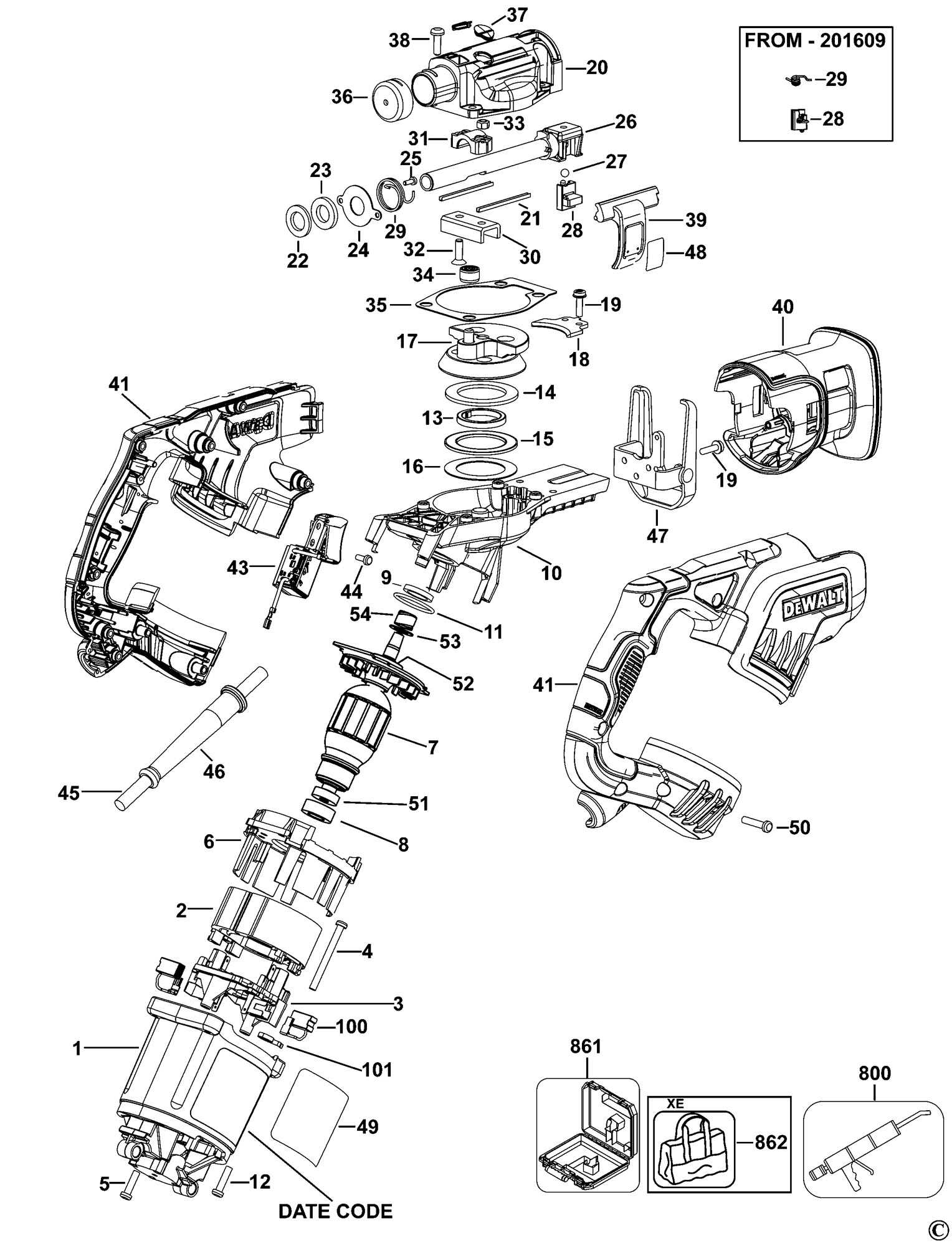

Understanding the Parts Diagram

Comprehending the layout of components within a tool is essential for effective maintenance and troubleshooting. This visual representation serves as a guide, illustrating how various pieces fit together and function in unison. By familiarizing yourself with this schematic, you can enhance your ability to identify specific elements and their roles.

One of the key advantages of such a representation is that it provides clarity regarding assembly and disassembly processes. Each part is labeled, allowing users to pinpoint where issues may arise. This knowledge not only aids in repairs but also fosters a deeper appreciation for the tool’s design and engineering.

Moreover, understanding this visual layout can prevent common mistakes during maintenance. Users can refer to the diagram to ensure they have all necessary components and tools before starting work, streamlining the entire process. In summary, becoming adept at reading these schematics can significantly improve the overall experience of owning and using the equipment.

Common Components of DWS716

Understanding the key elements of this powerful cutting tool is essential for effective use and maintenance. Each component plays a vital role in ensuring optimal performance and longevity. Below is a breakdown of the most common parts found in this model.

- Main Base: Provides stability and support during operation.

- Motor: Drives the cutting mechanism, offering reliable power.

- Blade: The cutting element, available in various sizes and materials.

- Fence System: Helps in accurately guiding the material being cut.

- Mitre Gauge: Assists in making angled cuts with precision.

- Table Extension: Increases workspace for larger materials.

- Dust Collection Port: Facilitates cleanup by minimizing debris during use.

Each of these components contributes to the overall functionality and effectiveness of the tool, making it essential for users to be familiar with them.

How to Identify Each Part

Understanding the components of your tool is essential for maintenance and effective usage. Each element plays a crucial role in the overall functionality, and recognizing them can enhance your ability to troubleshoot and replace parts when necessary.

Visual Recognition

Start by examining the exterior of the device. Familiarize yourself with the major sections, such as the base, motor housing, and cutting mechanism. Observing the shape, size, and arrangement of these sections will help you identify them more easily. Use a reference guide or manual that outlines these features for a clearer understanding.

Functionality Awareness

Each segment serves a distinct purpose. The power source provides energy, while the cutting assembly performs the actual work. Understanding the function of each component not only aids in identification but also assists in troubleshooting issues. For instance, if the cutting mechanism is malfunctioning, knowing its location and role can streamline the repair process.

Utilize labeled illustrations or reference materials to reinforce your knowledge. This can be particularly useful when you need to order replacements or carry out maintenance tasks.

Replacement Parts for DWS716

Ensuring optimal performance of your equipment often requires the timely replacement of worn or damaged components. Understanding the essential elements and their functions can greatly enhance the longevity and efficiency of your tool. This section will guide you through the crucial components that may need attention and how to find suitable replacements.

Common Components to Replace

Regular maintenance involves monitoring several key parts that can affect the overall functionality of your equipment. Identifying which components are most likely to wear out can help in planning for timely replacements.

| Component | Description | Signs of Wear |

|---|---|---|

| Blade | Essential for cutting; must be sharp and intact. | Dullness, chipping, or cracks. |

| Motor | Powers the tool; crucial for performance. | Overheating, unusual noises, or failure to start. |

| Table | Provides stability and support during use. | Warping or damage affecting alignment. |

| Guard | Enhances safety by covering the blade. | Cracks, misalignment, or failure to engage. |

Finding Suitable Replacements

When looking for new components, it is important to source high-quality replacements that match the specifications of your tool. Always consult the manufacturer’s recommendations or trusted suppliers to ensure compatibility and performance.

Maintaining Your DWS716 Tools

Proper upkeep of your cutting equipment ensures its longevity and optimal performance. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By adhering to a consistent care routine, you can keep your tools operating smoothly for years to come.

Regular Cleaning

One of the simplest yet most effective ways to maintain your cutting tools is through regular cleaning. Dust, debris, and residue can accumulate, affecting performance and precision. Use a soft brush and cloth to wipe down surfaces after each use. Additionally, pay special attention to the blades and any moving parts to prevent any obstructions.

Periodic Inspection

Frequent inspections can help identify wear and tear before it becomes a serious issue. Check all components for any signs of damage, such as cracks or excessive wear. Ensure that all screws and fasteners are tightened and that electrical connections are secure. Keeping an eye on these details will aid in prolonging the life of your equipment.

| Maintenance Task | Frequency |

|---|---|

| Clean components | After each use |

| Inspect for wear | Monthly |

| Sharpen blades | As needed |

| Check electrical connections | Quarterly |

Where to Buy Spare Parts

Finding components for your equipment can significantly enhance its longevity and performance. Knowing the right places to look is essential for ensuring you acquire genuine and reliable items that meet your needs.

Authorized Retailers

Start your search at authorized retailers, which often stock original components and accessories. These shops typically offer knowledgeable staff who can assist with selection and compatibility, ensuring you get the right fit for your tools.

Online Marketplaces

Online platforms provide a vast selection of options at competitive prices. Look for reputable websites that specialize in tool components, where you can compare prices, read reviews, and benefit from convenient delivery options.

Assembly and Disassembly Instructions

Understanding how to properly assemble and disassemble tools is crucial for maintenance and efficiency. This section provides essential steps and tips to ensure a seamless process, enhancing both safety and performance during operations.

Assembly Steps:

Begin by gathering all necessary components. Align each part according to the provided guidelines, ensuring that connections are secure. Utilize appropriate tools for tightening screws or bolts, but avoid over-tightening to prevent damage.

Disassembly Steps:

To safely take apart the equipment, first ensure that it is unplugged or powered down. Carefully remove any fasteners, following the reverse order of assembly. Keep track of each component and its respective place to facilitate reassembly later.

Note: Always consult the user manual for specific instructions related to your model for optimal results.

Troubleshooting Common Issues

When working with power tools, encountering difficulties is not uncommon. Understanding how to identify and resolve frequent problems can significantly enhance your experience and efficiency. This section aims to provide insight into typical malfunctions and their potential solutions, ensuring your equipment remains in optimal condition.

Power Failure: If the tool is unresponsive, check the power source and ensure all connections are secure. A blown fuse or tripped breaker might also be the culprit.

Inconsistent Performance: Variations in operation can often stem from dull blades or misalignment. Regularly inspecting and replacing worn components is essential for maintaining consistent functionality.

Excessive Vibration: If vibrations are noticeable during use, it could indicate loose parts or imbalance. Tighten all screws and examine for any damage that may need addressing.

Overheating: Tools can overheat if used continuously without breaks. Allow for cooling periods and ensure ventilation is not obstructed to prevent this issue.

Unusual Noises: Sounds that seem out of the ordinary may point to internal issues. Investigate the source, and if necessary, consult a professional for a thorough examination.

Comparing DWS716 with Other Models

This section explores the features and specifications of a particular miter saw, juxtaposing it against similar tools in the market. Understanding the differences and similarities can aid in making an informed decision for both amateur and professional users.

One of the key aspects to consider is the power output. Many models vary in motor strength, affecting performance in cutting through tough materials. For instance, some alternatives may offer higher RPMs, which can translate to smoother cuts.

Another crucial factor is the cutting capacity. While one model might excel in crosscuts, others may provide superior bevel angles, catering to different project requirements. Evaluating these specifications helps identify which tool aligns best with individual needs.

Portability is also a significant point of comparison. Certain alternatives are lighter and more compact, making them ideal for job sites where space is limited. Users must weigh the importance of portability against other features such as stability and cutting accuracy.

Ultimately, the choice should reflect the user’s specific applications, budget, and preferences. By delving into the characteristics of various models, one can find the most suitable option for achieving desired results.

User Tips for Optimal Performance

Maximizing the efficiency and longevity of your equipment requires attention to detail and best practices. Adhering to certain guidelines can significantly enhance performance and reduce the likelihood of issues arising during operation.

- Regular Maintenance: Schedule routine inspections to identify wear and tear. Clean components regularly to prevent buildup that could hinder functionality.

- Proper Calibration: Ensure your machine is correctly adjusted according to manufacturer specifications. Accurate settings are essential for optimal results.

- Quality Materials: Use high-quality materials suited for your tasks. Subpar supplies can lead to increased strain and premature failure of parts.

- Safe Operation: Follow safety guidelines to protect both yourself and your tools. Proper usage techniques can minimize damage and extend equipment life.

- Storage Practices: Store your equipment in a clean, dry place. Protect it from extreme temperatures and humidity to prevent corrosion and degradation.

By implementing these strategies, users can enjoy improved functionality and durability of their machinery, ensuring reliable performance for years to come.